Beruflich Dokumente

Kultur Dokumente

01 - Introduction To Partial Discharge Measurement - Opt

Hochgeladen von

rafael martinezOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

01 - Introduction To Partial Discharge Measurement - Opt

Hochgeladen von

rafael martinezCopyright:

Verfügbare Formate

© OMICRON Academy Page 1 November 2016, Klaus

If we talk about partial discharges, we have to talk about electric fields. Electric fields are also present in nature.

Under normal weather conditions there are electric fields of some hundred volts per meter. Under overhead lines the electric field

strength is about 5 kV per meter.

In an electrical storm the electrical field rises up to 20 000 Volts per meter before the voltage discharges in a lightening flash with

currents up to 200 000 Amps.

© OMICRON Academy Page 2 November 2016, Klaus

What does the standard say?

PD is a localized electrical discharge that only partially bridges the insulation.

This results in a local breakdown in the beginning (not a total breakdown yet).

The third picture shows a partial breakdown, for example in a cavity. This would result in the destruction of the high-voltage

device.

Only few insulation materials are resistant to PD, e.g. mica - a silicate (phyllosilicate) mineral.

Mica insulations are used for example in the end windings in generators.

© OMICRON Academy Page 3 November 2016, Klaus

Outer PD (corona): The UV activity was made visible with a DayCore PD camera, which can be operated under daylight

conditions.

In this case, the surrounding air serves as the insulation. Therefore, the main insulation which is being “destroyed“ by partial

discharges is air.

The air around the high-voltage device will recombine and is getting exchanged by wind. Since there are no additional costs for

“repairing” this insulator, sometimes outer corona is not considered to be dangerous.

Outer corona, however, can harm the solid insulation close to its place of discharge. Furthermore, it can make it hard to measure

inner discharges at the same time.

© OMICRON Academy Page 4 November 2016, Klaus

The change of color proves destructive PD activity, followed by a degradation of the surface material. The black dust and ashes

often lead to an increased surface conductivity, causing parasitic currents and hot spots. These effects will further deteriorate the

insulation – eventually leading to more partial discharges.

© OMICRON Academy Page 5 November 2016, Klaus

This photo shows the cross section of a cable. On the lower right corner, a part of the outer semiconductor screen can be seen.

The inner conductor is in the direction of the left upper corner.

Water breaks through the outer semi conducting layer and creates a „water tree“ in the insulation. This „water tree“ (colorful

structure on the left) grows in the direction of the electrical field – towards the middle of the cable.

Water (at least contaminated water) is a much better conductor than the solid insulation of the cable. Once the water is inside the

insulation, it will influence the electrical field lines. This results in a higher concentration of the electrical field at the tip of the

„water tree“.

Eventually, the electrical field exceeds the limits of the solid insulation and an „electrical tree“ will start.

This „electrical tree“ (fine black lines in the middle of the photo), starts at the tip of the „water tree“ and grows in both directions

towards the electrodes of the cable.

Inside solid insulation material void discharges can grow as „Electrical Trees“ through the insulation, finally forming a breakdown

channel.

© OMICRON Academy Page 6 November 2016, Klaus

Here the insulation of a cable was modified to clear it up.

Therefore light can pass through and allows us to see the results of a discharge.

This discharge bridged the insulation and destroyed it.

If this would have happened in a real-case scenario, the total power (charge) inside the cable would have discharged at this very

spot. This discharge power (in a real-case scenario) would have destroyed a much larger area around the discharge point.

© OMICRON Academy Page 7 November 2016, Klaus

Partial discharges, being present over years or even decades, can cause a massive change of the insulation surface, finally

leading to a break down.

The left photo shows an RBP bushing with massive traces of partial discharge (black lines).

The photo on the right shows the destruction inside a transformer.

© OMICRON Academy Page 8 November 2016, Klaus

In joints, PD activity can often be identified by visible tracking structures or material erosion on the inner surfaces.

© OMICRON Academy Page 9 November 2016, Klaus

Foreign particles will also cause PD, if they are located in areas with high electrical stress. The dark color of this small metal

particle indicates the thermal activity, which indicates the amount of energy that degrades the joint material.

Almost all foreign particles in the solid insulation will have a higher conductivity than the solid insulator. Therefore the electrical

field will be influenced, leading to areas of lower and higher concentration of the electrical field.

An increased concentration of the electrical field might result in partial discharges at this very point.

© OMICRON Academy Page 10 November 2016, Klaus

This is a video of a needle on the left side and a large electrode on the right.

This needle is pushed into a silicon mass in a glass jar.

High voltage is applied and the treeing process can be witnessed.

The channels/tunnels formed by partial discharges, have the strong tendency to “follow“ the electrical field lines. This takes into

account that every channel/tunnel will change the electrical field on its own.

Since the discharges are within a glass housing, the conductivity on the right side is very limited. Therefore, new

channels/tunnels can be created even though others have already reached the right side. Without the glass bottom of the jar on

the right side, the first channel/tunnel reaching the right side would result in a total breakdown – destroying most of the silicon

around it.

© OMICRON Academy Page 11 November 2016, Klaus

This is a video of a needle on the left side and a large electrode on the right.

This needle is pushed into a silicon mass in a glass jar.

High voltage is applied and the treeing process can be witnessed.

The channels/tunnels formed by partial discharges, have the strong tendency to “follow“ the electrical field lines. This takes into

account that every channel/tunnel will change the electrical field on its own.

Since the discharges are within a glass housing, the conductivity on the right side is very limited. Therefore, new

channels/tunnels can be created even though others have already reached the right side. Without the glass bottom of the jar on

the right side, the first channel/tunnel reaching the right side would result in a total breakdown – destroying most of the silicon

around it.

© OMICRON Academy Page 12 November 2016, Klaus

The growth of an electrical tree is similar to the growing process of total electrical discharges, such as lightning.

The physical processes for total discharges and partial discharges are more or less the same. Electricity is a natural process.

Even though electricity is a natural process, humans are unable to sense electrical fields.

© OMICRON Academy Page 13 November 2016, Klaus

The nerve-cord communication of the human body works with electricity. A current of ions leads to potential differences between

the cells and the intra cellular space.

The human body, consisting of about 65% of water, can influence the electrical field just by its presence.

Every day we are exposed to Electro Static Discharges (ESD) with some thousands of volts, which are of very short duration and

only produce currents on the very outer parts of our bodies.

© OMICRON Academy Page 14 November 2016, Klaus

For DC, charge can be defined as the current, flowing through a conductor, multiplied by the time progressed.

For time dependent currents (AC currents), the simple multiplication has to be replaced by an integral.

© OMICRON Academy Page 15 November 2016, Klaus

Seen from a geometrical point of view, both mathematical expressions on the top of the slide are describing an area below a

current curve.

Since current cannot be measured easily, the voltage drop over a known resistor (shunt) will be used.

This resistor will be R, t1 and t2, which and defined by the user of the measurement system.

Charge Measurement by Frequency Domain Integration will be covered later in detail.

© OMICRON Academy Page 16 November 2016, Klaus

These are SI prefixes mostly used.

Charge is measured in Coulomb [C]. Commonly, discharge values will be displayed in pico Coulombs [pC] or nano Coulombs

[nC].

Only places with almost no interferences from other electrical devices (e.g. shielded rooms), the background noise can be

measured in femto Coulombs (fC).

© OMICRON Academy Page 17 November 2016, Klaus

For PD charge measurement by Frequency Domain Integration, the time-domain signal is transferred to the frequency-domain.

The integration into frequency-domain is done by a frequency filter, typically by a band-pass system.

© OMICRON Academy Page 18 November 2016, Klaus

Analog PD measurement systems consisted of a pre-amplifier, some kind of physical filter and setup of a capacity and a resistor.

The PD pulse is first amplified and then filtered. Afterwards, the capacitance gets charged with the peak value of the PD. The

resistor discharges the capacitance.

Therefore, the first analog meters for partial discharge measurements used to be volt meters. These volt meters displayed the

voltage over the capacitance. The higher the measured partial discharge, the higher the capacitor gets charged.

The first analog systems had a constant and a fixed filter, which would alter over time and temperature. A mechanical display

would indicate mechanical behaviour. A further disadvantage was the slow reaction of the system.

Furthermore, every laboratory cable between the measurement system and the volt meter would have a capacitance, inductance

and resistance of its own. Therefore it would change the behavior of the whole partial discharge measurement system.

© OMICRON Academy Page 19 November 2016, Klaus

The second generation of PD measurement systems was the so called “digital system“:

The first digital systems made it possible to create fingerprint diagrams (PRPD) by recording the PD event and test-voltage by

zero detection.

The first analog/digital-converters had a drift of the voltage, which was influenced by temperature shift, aging process and

warming up. Thus, the behavior would be slightly different every time.

Still, no flexible filters were included. Only one filter frequency and bandwidth were used for the measurement. This was pre-set

by the manufacturer, but as mentioned before, this would change over time.

These changes are almost impossible to monitor, and therefore remain unknown.

© OMICRON Academy Page 20 November 2016, Klaus

The uncertainty of an analog filter has now been solved.

The PD pulse gets pre-amplified and digitized by an analog/digital converter. Real digital filters are used, making it a true digital

system. These filters do not change their behavior over time and temperature.

Furthermore, the user is able to switch the measuring frequency and alter the bandwidth.

The PD impulses are digitized by maintaining their amplitude and point of time when they occurred.

Furthermore, more PD processing functions are included in the hardware, such as thresholds and adjustable preamplifiers.

The voltage signal is digitized as well. All of this information is transmitted via fiber optical cables. These fiber optic cables and

the battery allow the user to use the measurement system on high voltage. The information about PD and voltage is processed

further in the computer. A recording of the entire measurement is possible.

© OMICRON Academy Page 21 November 2016, Klaus

Details of the MPD600:

The voltage input is secured by a protection circuit. The maximal input value is 60 volts RMS and 10 V at the PD input.

Behind the pd input follows an anti-aliasing filter, damping frequencies higher than 16 MHz (20MHz cutoff freq. 3dB).

Then the signal goes into a AD converter and is digitalized with 14 bit and a sampling rate of 64 MSamples.

The intelligence of the measuring system is an FPGA:

At each start of the software the data is loaded into the FPGA, this assures always the newest software on the MPD.

Implemented fast mathematical algorithm saves processing power of the laptop.

By using a fully digital systems the user can change the measuring frequency and bandwidth for flexible measuring adapting to

the appearing circumstances.

The battery power supply can work up to 2 weeks.

Max. detection of pulses: 1.5 Mio pulses per second restricted by the bandwidth of the USB interface

Every 300ms the data is send via the USB interface to the controlling unit.

The double pulse resolution time is smaller than 200ns.

The system noise is below 15 fC.

© OMICRON Academy Page 22 November 2016, Klaus

A big advantage of the MPD600 is its high synchronous measurement within 2-5 ns. That allows to measure at different positions

at the same time, e.g. 3-phase measurement or at a joint or cross-bonding boxes.

The maximum number of units for synchronous measurement is 32 channels.

In London at a 20 km long XLPE cable more than 30 unit were installed in a tunnel system for PD measurements on the joints

and terminations.

The MPD can communicate over an distance up to 2 km. For larger up to 8km distances the optical module in the MPD has to be

changed, e.g. baltic sea cable.

Each unit is an independent one because the processing is done in each MPD unit. Therefore the settings of each unit can be

changed.

© OMICRON Academy Page 23 November 2016, Klaus

The upper part of the diagram shows a digitized voltage signal in (dark) green. Here the Vrms value of the voltage is 23.20kV.

The lower part of the diagram in red shows the applied testing voltage at the test object over time (11m 10s).

The green curve represents the discharge values correlated to the voltage and therefore time.

The voltage was raised to around 245kV; the discharge values was raised to around 1.1nC.

© OMICRON Academy Page 24 November 2016, Klaus

PD generates electro-magnetic fields => that‘s good because we can measure it.

Furthermore, PD produces sound, light and heat, and it will cause chemical reactions.

With the MPD600, only the changes of the electro-magnetic fields can be measured.

Let´s summarize it:

local electrical stress of insulation => will produce PD

PD generates electromagnetic signals => this can be measured

© OMICRON Academy Page 25 November 2016, Klaus

PD can be distinguished into two major groups: internal and external PD.

The group of internal PD is subdivided into void discharges and treeing.

The group of external PD is subdivided into corona discharges and surface discharges.

© OMICRON Academy Page 26 November 2016, Klaus

Surface discharge:

- Occurs at “triple points” – a point where a conductor, a good insulator (e.g. solid insulator) and a bad insulator (e.g. air) meet.

- Therefore it can be found at boundaries of different insulation materials (e.g. on bushings, end of cables)

Corona discharge:

- Occurs in gaseous dielectrics in the presence of inhomogeneous fields, usually not inside of objects

(One can hear the PD of overhead lines in a substation (transformer / distribution station)

© OMICRON Academy Page 27 November 2016, Klaus

Internal discharges in laminated material:

- Occur when laminated materials delaminate, allowing the formation of gas bubbles or entire areas of gas inside the insulator to

form.

Cavity / void discharges:

- Occur in voids or cavities within solid or liquid dielectrics (voids and cavities are usually filled with some kind of gas).

Treeing:

- Continuous impact of discharges in solid dielectrics forming discharge channels (treeing) in organic materials (e.g. cable

insulation).

PD activity can occur on the surface or/and inside insulations. The cavity discharge and treeing are the most dangerous

processes for assets’ insulation systems being almost impossible to accurately localize them.

© OMICRON Academy Page 28 November 2016, Klaus

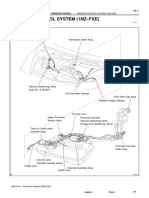

Two different types of faults in a cable are shown; damage of the outer semi conductive screen and a void inside the insulation.

Both faults are causing stress in the insulation. Further details can be seen in the magnifications of these faults.

The first fault (left picture) is a tip or conductive particle concentrating e-field lines.

This erosion phenomenon propagates where the stress is high, i.e. at the sharpest point.

The second fault (right picture) is a void with gas, e.g. air, inside.

The electric field rises inside the tiny void for two reasons:

1. The epsilon (permittivity) of the isolation is different.

2. The electrical conductance kappa is different as well.

© OMICRON Academy Page 29 November 2016, Klaus

© OMICRON Academy Page 30 November 2016, Klaus

Das könnte Ihnen auch gefallen

- © OMICRON Academy 01 - IntroductionDokument29 Seiten© OMICRON Academy 01 - IntroductionJackson Berganza100% (1)

- Partial Discharge Monitoring On Rotating Machines Using A Modular Instrument ApproachDokument26 SeitenPartial Discharge Monitoring On Rotating Machines Using A Modular Instrument Approachreza515heiNoch keine Bewertungen

- A Guide For Partial Discharge Measurements On Medium Voltage (MV) and High Voltage (HV) ApparatusDokument6 SeitenA Guide For Partial Discharge Measurements On Medium Voltage (MV) and High Voltage (HV) ApparatusAmanda MeloNoch keine Bewertungen

- Singapore Seminar 14.05.2020Dokument96 SeitenSingapore Seminar 14.05.2020HafiziAhmadNoch keine Bewertungen

- PD Analysis in MonitoringDokument6 SeitenPD Analysis in MonitoringZakaria BelloulaNoch keine Bewertungen

- UTP MKII Product Training SlidesDokument65 SeitenUTP MKII Product Training Slidesberkahharian100% (1)

- Different Ways To Mount Travel TransducerDokument14 SeitenDifferent Ways To Mount Travel TransducerIsa SolakNoch keine Bewertungen

- Case Study of VLF / Tan Delta & Partial Discharge Acceptance Testing of New 23kV CablesDokument38 SeitenCase Study of VLF / Tan Delta & Partial Discharge Acceptance Testing of New 23kV CablesAshwin SevariaNoch keine Bewertungen

- Vibro-Acoustic Method For OLTC TestingDokument15 SeitenVibro-Acoustic Method For OLTC TestingWisnu DewaNoch keine Bewertungen

- HVPD Longshot PD Mapping System User Manual Sep 2009Dokument37 SeitenHVPD Longshot PD Mapping System User Manual Sep 2009navi_0403100% (1)

- PD 6 Online PD Monitoring Power CablesDokument21 SeitenPD 6 Online PD Monitoring Power CablesAbhishek GuptaNoch keine Bewertungen

- PD Diagnostics On Rotating Machines - Possibilities and Limitations - M. Hoof, S. Lanz - ABB - EIC - 1999Dokument6 SeitenPD Diagnostics On Rotating Machines - Possibilities and Limitations - M. Hoof, S. Lanz - ABB - EIC - 1999tecolanzNoch keine Bewertungen

- Partial Discharge Equipment PDFDokument6 SeitenPartial Discharge Equipment PDFSellappan MuthusamyNoch keine Bewertungen

- TSDOS Adv Diag Testing DW PDFDokument61 SeitenTSDOS Adv Diag Testing DW PDFDhammika Dharmadasa100% (1)

- MPD 600 Self Test: Application NoteDokument7 SeitenMPD 600 Self Test: Application NoteInsan AzizNoch keine Bewertungen

- Instrument Transformer Testing Brochure ENUDokument36 SeitenInstrument Transformer Testing Brochure ENUJayakumar JNoch keine Bewertungen

- MEGGER PD Presentation PDFDokument91 SeitenMEGGER PD Presentation PDFvoruganti harishNoch keine Bewertungen

- 31 - OMICRON PD Seminar - Rotating Machines - IEC 60034-27Dokument102 Seiten31 - OMICRON PD Seminar - Rotating Machines - IEC 60034-27Miguel AngelNoch keine Bewertungen

- Wilsonville SFRA PDFDokument65 SeitenWilsonville SFRA PDFkourapas100% (1)

- Ms - PD Chek and Mpd-s2-17062013Dokument10 SeitenMs - PD Chek and Mpd-s2-17062013Mohammad Asif100% (1)

- DRM of OltcDokument4 SeitenDRM of OltcBestwick Braveen SylvesterNoch keine Bewertungen

- Distance Relay 101Dokument40 SeitenDistance Relay 101Brandon James Summers100% (1)

- Demag Test Card Presentation PDFDokument27 SeitenDemag Test Card Presentation PDFsimitzuNoch keine Bewertungen

- DGA Ebook WebDokument16 SeitenDGA Ebook Webjulio cesar silvaNoch keine Bewertungen

- CB Monitor: On Line Circuit Breaker Monitoring SystemDokument4 SeitenCB Monitor: On Line Circuit Breaker Monitoring Systemashu_2787Noch keine Bewertungen

- Transformer Fuses Mind The Ga IEEE IASDokument8 SeitenTransformer Fuses Mind The Ga IEEE IASkcirrenwodNoch keine Bewertungen

- Online PD Measurement Using Embedded VDS For 22kV GISDokument51 SeitenOnline PD Measurement Using Embedded VDS For 22kV GISzarchiwin05Noch keine Bewertungen

- 13 Ed Gulski PraesentationDokument45 Seiten13 Ed Gulski Praesentationcarlos vidalNoch keine Bewertungen

- Partial Discharge (PD) Test & Measurement For High Voltage Cables SEBA OWTSDokument10 SeitenPartial Discharge (PD) Test & Measurement For High Voltage Cables SEBA OWTShafezasadNoch keine Bewertungen

- 25.insulation Testing M4000Dokument86 Seiten25.insulation Testing M4000rashid rahmanNoch keine Bewertungen

- Comprehensive transformer testing and maintenance guideDokument17 SeitenComprehensive transformer testing and maintenance guidelrpatraNoch keine Bewertungen

- Qualitrol - Low Frequency Vs High Frequency Partial Discharge DetectionDokument20 SeitenQualitrol - Low Frequency Vs High Frequency Partial Discharge DetectionDennis MendozaNoch keine Bewertungen

- SFRA White PaperDokument4 SeitenSFRA White Paperykh92167Noch keine Bewertungen

- Method Statement For Partial Discharge Measurement: Application NoteDokument13 SeitenMethod Statement For Partial Discharge Measurement: Application Notejmrs7322Noch keine Bewertungen

- 1348583100dielectric Diagnosis of EHV Current Transformer Using Frequency Domain Spectroscopy (Recovered)Dokument11 Seiten1348583100dielectric Diagnosis of EHV Current Transformer Using Frequency Domain Spectroscopy (Recovered)samrendraNoch keine Bewertungen

- Megger-Application Guide For Power Factor Testing of Circuit BreakersDokument6 SeitenMegger-Application Guide For Power Factor Testing of Circuit Breakerspemanr1914Noch keine Bewertungen

- A Guide For Partial Discharge Measurements On Medium Voltage (MV) and High Voltage (HV) ApparatusDokument8 SeitenA Guide For Partial Discharge Measurements On Medium Voltage (MV) and High Voltage (HV) ApparatuskashifNoch keine Bewertungen

- On-site Transformer Partial Discharge Diagnosis Using Mobile Test SetsDokument7 SeitenOn-site Transformer Partial Discharge Diagnosis Using Mobile Test Setsanurag_jay12464Noch keine Bewertungen

- Paper - A Measurement Technique To Identify and Locate Partial Discharge in Transformer With AE and HFCTDokument6 SeitenPaper - A Measurement Technique To Identify and Locate Partial Discharge in Transformer With AE and HFCTNguyen Vu Nhat HaNoch keine Bewertungen

- Discover Internal PD in Italy's New 400kV Cable System TerminationsDokument66 SeitenDiscover Internal PD in Italy's New 400kV Cable System TerminationsJuanes CevallosNoch keine Bewertungen

- Partial Discharge PDFDokument11 SeitenPartial Discharge PDFMuhammad KashifNoch keine Bewertungen

- Omicron - Synchronous Multi-Channel PD Measurements and The Benefits For PD AnalysesDokument8 SeitenOmicron - Synchronous Multi-Channel PD Measurements and The Benefits For PD AnalysesNguyen Vu Nhat HaNoch keine Bewertungen

- Bushing Power Factor Training PPTDokument44 SeitenBushing Power Factor Training PPTMiguel Zuñiga100% (1)

- High Voltage Testing Techniques and EquipmentDokument16 SeitenHigh Voltage Testing Techniques and Equipmenthadrien100% (1)

- Votano 100Dokument26 SeitenVotano 100buicongbinhNoch keine Bewertungen

- Modern Techniques for Condition Monitoring of Circuit BreakersDokument33 SeitenModern Techniques for Condition Monitoring of Circuit BreakersRakesh KumarNoch keine Bewertungen

- IEEE Insulation Resistance GetPDFDokument8 SeitenIEEE Insulation Resistance GetPDFMohamed SalahNoch keine Bewertungen

- OMICRON SFRA Measurement Results Predl Paper Omicronized PDFDokument27 SeitenOMICRON SFRA Measurement Results Predl Paper Omicronized PDFbrianNoch keine Bewertungen

- 1-5 Introduction To Ieee c57 - Omicron TDWDokument13 Seiten1-5 Introduction To Ieee c57 - Omicron TDWfernandoquecaNoch keine Bewertungen

- 7kg6000 Transducer SpecificationDokument8 Seiten7kg6000 Transducer SpecificationwiyatnoNoch keine Bewertungen

- Partial Discharge Patterns in High Voltage InsulationDokument7 SeitenPartial Discharge Patterns in High Voltage Insulationfery zenNoch keine Bewertungen

- Ausgrid Utiltiy Cable Test Plan 2017Dokument31 SeitenAusgrid Utiltiy Cable Test Plan 2017Ali NaderianNoch keine Bewertungen

- On-Load Tap-Changers For Power Transformers: MR PublicationDokument24 SeitenOn-Load Tap-Changers For Power Transformers: MR Publicationcarlos alberto100% (1)

- Method Statement For Partial Discharge Measurement: Application NoteDokument11 SeitenMethod Statement For Partial Discharge Measurement: Application NoteInsan AzizNoch keine Bewertungen

- Electrical BreakdownDokument4 SeitenElectrical Breakdowndraganscribd12Noch keine Bewertungen

- 3.5.1 Observation of Electrical Breakdown and FailureDokument4 Seiten3.5.1 Observation of Electrical Breakdown and FailureValeria Orannel Lopez MorilloNoch keine Bewertungen

- An Overview of Electrostatic SpeakersDokument10 SeitenAn Overview of Electrostatic Speakerslavande16Noch keine Bewertungen

- Electrical Breakdown PDFDokument4 SeitenElectrical Breakdown PDFcorneliusflavius7132100% (1)

- E I (EC 323) : Lectrical NstallationsDokument69 SeitenE I (EC 323) : Lectrical NstallationsMalith DeemanthaNoch keine Bewertungen

- Insulator (Electricity) - Wikipedia, The Free EncyclopediaDokument4 SeitenInsulator (Electricity) - Wikipedia, The Free Encyclopediadonodoni0008Noch keine Bewertungen

- Service Manual: Color Television Chassis No. GA-1'Dokument28 SeitenService Manual: Color Television Chassis No. GA-1'tecniconivelNoch keine Bewertungen

- Moving MeterDokument5 SeitenMoving MetertechnoprimeNoch keine Bewertungen

- Electronic Instrumentation & Control SystemsDokument90 SeitenElectronic Instrumentation & Control SystemsshahnawazuddinNoch keine Bewertungen

- Engineering Practices Lab Manual for Electrical and ElectronicsDokument72 SeitenEngineering Practices Lab Manual for Electrical and ElectronicsCHARUMATHE NNoch keine Bewertungen

- Analog InstrumentsDokument148 SeitenAnalog InstrumentsPramod PathadeNoch keine Bewertungen

- FT 12 Gr10 P4 Qs (Electricity)Dokument8 SeitenFT 12 Gr10 P4 Qs (Electricity)Kiron SheiqNoch keine Bewertungen

- Experiment No. 1 Resistance Per Unit LengthDokument6 SeitenExperiment No. 1 Resistance Per Unit Lengthpeniwal magicsNoch keine Bewertungen

- Jobsheet 2 Mesin Sinkron 2019Dokument10 SeitenJobsheet 2 Mesin Sinkron 2019Koko AhmadNoch keine Bewertungen

- Experiment 8 Current and Voltage Measurements: StructureDokument8 SeitenExperiment 8 Current and Voltage Measurements: StructureGanesh DhyaniNoch keine Bewertungen

- Online Lab 4 - DC CircuitsDokument8 SeitenOnline Lab 4 - DC CircuitsSardar Rehan AhmedNoch keine Bewertungen

- Switchboard Instruments Data Sheet 4921210012 UKDokument8 SeitenSwitchboard Instruments Data Sheet 4921210012 UKEdi LeeNoch keine Bewertungen

- Sony kdl-22bx325, 32bx325, 32bx326,-32bx425 40bx425 Chassis Az2-TkDokument31 SeitenSony kdl-22bx325, 32bx325, 32bx326,-32bx425 40bx425 Chassis Az2-TkCarlos AcostaNoch keine Bewertungen

- Introduction To Semiconductor DiodesDokument7 SeitenIntroduction To Semiconductor DiodesAndy CentenaNoch keine Bewertungen

- Testing & Maintaining Power TransformersDokument83 SeitenTesting & Maintaining Power Transformerscharleselitb92100% (1)

- NISSAN SENTRA 1993 Power WindowsDokument3 SeitenNISSAN SENTRA 1993 Power WindowsAlessandro BaffaNoch keine Bewertungen

- Practical Electronics 1968 01 PDFDokument84 SeitenPractical Electronics 1968 01 PDFCarlos Soares100% (3)

- EIM ErrorsDokument63 SeitenEIM ErrorsSam KeplerNoch keine Bewertungen

- Aerostar Maintenance Manual ATA-24-Electrical PowerDokument40 SeitenAerostar Maintenance Manual ATA-24-Electrical PowerNsafetyalwaysoffNoch keine Bewertungen

- Diesel Engine Lecture Notes WordDokument37 SeitenDiesel Engine Lecture Notes WordM J Rhoades80% (5)

- EEE Lab - Worksheet 1Dokument2 SeitenEEE Lab - Worksheet 1datUPstudentdoeNoch keine Bewertungen

- KDL-40BX450 Az3fk 9-883-873-01Dokument37 SeitenKDL-40BX450 Az3fk 9-883-873-01Александр АндриановNoch keine Bewertungen

- 3 - High Voltage Testing TechquniesDokument101 Seiten3 - High Voltage Testing TechquniesAnil MarkaleNoch keine Bewertungen

- A2 Relleta JamesDokument9 SeitenA2 Relleta JamesLorenzo AbolarNoch keine Bewertungen

- Analog vs Digital Multimeters GuideDokument32 SeitenAnalog vs Digital Multimeters GuideAgnes S TandipauNoch keine Bewertungen

- 12 - Emission ControlDokument29 Seiten12 - Emission ControlpejopoNoch keine Bewertungen

- Lab ReportDokument2 SeitenLab ReportHannah Lee Cruz DomingoNoch keine Bewertungen

- Class XII Physics Support Material Final-1Dokument399 SeitenClass XII Physics Support Material Final-1Adithyan AjithNoch keine Bewertungen

- Precaution in ExperimentDokument2 SeitenPrecaution in Experimenthusna nabila100% (1)

- Multiple Choice Question (MCQ) of MeasurementsDokument60 SeitenMultiple Choice Question (MCQ) of Measurementskibrom atsbhaNoch keine Bewertungen