Beruflich Dokumente

Kultur Dokumente

Sika Waterbar

Hochgeladen von

Nathàn OcàyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sika Waterbar

Hochgeladen von

Nathàn OcàyCopyright:

Verfügbare Formate

Product Data Sheet

Edition No. 01 (June 2014)

®

Sika Waterbar

Sika® Waterbar

Flexible PVC Waterstop

®

Product Description Sika Waterbar are constructed from flexible thermoplastic PVC. They are

designed to stop the migration of water through construction and expansion joints

in concrete structures.

®

Sika Waterbar are available in various sizes and profiles to suit all types of

application.

Construction

Uses For the effective sealing of concrete construction and expansion joints in

structures such as:

Basements.

Water reservoirs.

Sewage treatment plant.

Swimming pools.

Retaining walls.

Lift shafts.

Tunnels, culverts.

Service pits.

Characteristics / Sealing starts as soon as the concrete has hardened.

Advantages

Multi rib profile provides impenetrable barriers to water migration.

Can be easily site welded - (welding knife is available).

Good chemical resistance.

Available various kind of profiles for all type of application.

®

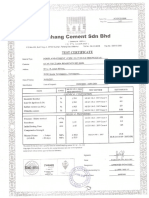

Approvals / Standards Sika Waterbar have been tested in accordance with BS 2571 specification.

Product data

Form / Color Flexible strip / Yellow

Packaging 20 m rolls

Storage Dry shaded place (Protected from sunlight)

Technical data

Base Polyvinyl chloride

Density ~ 1.40 kg/L BS2782:620

Shore A hardness > 70 ISO 868-2003(E)

BS2782:365B

2

Tensile strength 12 N/mm ± 5% BS2782:320A

ASTM D412-98

Elongation at break 300% ± 5% BS2782:320A

ASTM D412-98

0

Water absorption 0.04% (at 23 C) BS EN ISO 62:1999

Sika® Waterbar 1/3

Thermal stability Minimum 70 (Congo Red test at 180 C) BS2782:130A

0

Welding temperature Approx. 180 C

0 0

Service temperature -35 C to +55 C

Chemical resistance Permanent: Seawater, sewage

Temporary: Diluted inorganic alkalis, mineral acids, mineral oils and fuels

Profiles

Important: The indicated maximum waterhead for each waterbar type is related to

the system behavious concrete-PVC normal design and based on practical

experience.

Application

Typical detailing of Sika® Waterbar

Split formwork with Sika® Figure 1: Fixing to formwork:

Waterbar “O” Profile

®

The “O” profile Sika Waterbar may

also be used to in conjunction with split

formwork. However care should be

taken to ensure that that “O” ring is not

squashed flat between two forms. This

method of installation increases the

®

capacity of the Sika Waterbar to

accommodate expansion

Formwork wth Sika® Figure 2: Fixing to formwork:

Waterbars “V” Profile

®

The “V” profile Sika Waterbar is fitted

into the split formwork or shuttering for

casting centrally into the stopends. It is

used for construction joints and

movement joints where nominal

movement is anticipated, such as

basement or retaining walls

Fixing to reinforcement Pre-punched eyelets are located in the outer flanges of the profiles. These

simplify the fixing of waterbars to the steel reinforcement with tie wires to ensure

the waterbars are not displaced during concreting.

Sika® Waterbar 2/3

®

Placing concrete first The Sika Waterbar performs its function only if both sides are well embedded in

stage the concrete. Avoid formation of honey combs by vibrating carefully.

The consistency of the concrete itself should be neither too plastic nor too stiff,

and the aggregate must be well graded.

®

Placing of fresh concrete near the Sika Waterbar requires care, as otherwise it

will be forced from its position by the pressure of the fresh concrete, i.e. the ends

will fold up. To prevent this, the same concrete pressure must be present on both

sides of the Waterbar.

®

Placing concrete second Removal of the formwork in the neighbourhood of Sika Waterbar must be done

stage with care.

®

The end of the Sika Waterbar should be thoroughly checked for honey- combing

on the stop-end and repaired if necessary. It must also be cleaned of all hardened

concrete remnants adhering from the first concrete stage. Further procedure is

similar to the first stage

Welding On site welding can be undertaken using a Sika Electric Welding Knife. Both ends

of the joint are heated simultaneously on the faces of the welding knife until an

Construction

®

even, molten bead of PVC appears. The welding knife is withdrawn and the Sika

Waterbar are immediately pushed together. The joint should be held rigid until the

plastic cools down and solidifies.

Check for any gaps or imperfect joints. Redo the welding if necessary.

Failures can be caused by irregularities of cut edges, insufficient heat, dust etc.

Limits on application / Level differences, bends, junctions, etc. should be carefully considered when

Notes placing.

Health and safety information

Ecology Can be disposed according to local law.

Transportation Non Hazardous.

Toxicity Non-toxic.

Important note Care should be taken to avoid breathing fumes and smoke during the PVC

welding process. Hence, welding should be performed in open, well-ventilated

area.

In case of doubt always follow the directions given on the pack or label.

Legal notes The information, and, in particular, the recommendations relating to the

application and end-use of Sika’s products, are given in good faith based on

Sika’s current knowledge and experience of the products when properly stored,

handled and applied under normal conditions. In practice, the differences in

materials, substrates and actual site conditions are such that no warranty in

respect of merchantability or of fitness for a particular purpose, nor any liability

arising out of any legal relationship whatsoever, can be inferred either from this

information, or from any written recommendations, or from any other advice

offered. The proprietary rights of third parties must be observed. All orders are

accepted subject of our terms and conditions of sale. Users should always refer to

the most recent issue of the Product Data Sheet for the product concerned,

copies of which will be supplied on request.

Sika Philippines, Inc.

Unit A&B

888 M.Alvarez Ave., Talon V, Phone: +63 02 806 2875-76

Las Piñas City 1747, Telefax: +63 02 806 2883

Philippines phl.sika.com

Sika® Waterbar 3/3

Das könnte Ihnen auch gefallen

- Mac GuideDokument16 SeitenMac GuideColin SillmanNoch keine Bewertungen

- DN-STR-03009-01 - BD 47.99Dokument44 SeitenDN-STR-03009-01 - BD 47.99đức anh caoNoch keine Bewertungen

- Superthermolay App PL / MT: DescriptionDokument2 SeitenSuperthermolay App PL / MT: DescriptionTarun80Noch keine Bewertungen

- 62.27 Mastic Asphalt TakingDokument3 Seiten62.27 Mastic Asphalt TakingAaliyan Syed100% (1)

- BPD Master Catalogue-2Dokument18 SeitenBPD Master Catalogue-2Dr. Manamohan R KalgalNoch keine Bewertungen

- TechFab Metal Gabion PVC Galvanized Product DataDokument1 SeiteTechFab Metal Gabion PVC Galvanized Product DataHimanshu KotakNoch keine Bewertungen

- Concrete Canvas GCCM Specification19Dokument6 SeitenConcrete Canvas GCCM Specification19MeowMeowNoch keine Bewertungen

- Sika Admixutures PDFDokument2 SeitenSika Admixutures PDFDaisy PaulNoch keine Bewertungen

- Dinesh Chandran K.P, Head - Technical Services and R&D Ultratech Cement Limited, Building Products Division, MumbaiDokument7 SeitenDinesh Chandran K.P, Head - Technical Services and R&D Ultratech Cement Limited, Building Products Division, MumbaiRabish ANoch keine Bewertungen

- BOQ Water Proofing With BASF RangeDokument1 SeiteBOQ Water Proofing With BASF Rangehemantrulz0% (1)

- Specifications For The Steel Fibers Reinforced ConcreteDokument1 SeiteSpecifications For The Steel Fibers Reinforced ConcretecoolkaisyNoch keine Bewertungen

- Bridge Deck WaterproofingDokument3 SeitenBridge Deck WaterproofingKhin Sandi KoNoch keine Bewertungen

- TDS-US-Gabion, PoliMac-Jan19Dokument2 SeitenTDS-US-Gabion, PoliMac-Jan19johnnee98Noch keine Bewertungen

- Flyer Ostraadt Concrete FleximatDokument2 SeitenFlyer Ostraadt Concrete FleximatChristian BarNoch keine Bewertungen

- Waterproofing Admixture PDFDokument2 SeitenWaterproofing Admixture PDFSegun100% (1)

- Ic 8758Dokument6 SeitenIc 8758Nurali MamenNoch keine Bewertungen

- Sikatherm® Foam 45 IN: Product Data SheetDokument4 SeitenSikatherm® Foam 45 IN: Product Data SheetTarun KumarNoch keine Bewertungen

- Experimental Investigation On Mechanical Properties of Geosynthetic Cementitous Composite Mat (GCCM)Dokument10 SeitenExperimental Investigation On Mechanical Properties of Geosynthetic Cementitous Composite Mat (GCCM)Phan Thanh HiếuNoch keine Bewertungen

- Protect PRODUCTS From NATURE So That, PRODUCT Protects You From NATUREDokument14 SeitenProtect PRODUCTS From NATURE So That, PRODUCT Protects You From NATUREannayya.chandrashekar Civil EngineerNoch keine Bewertungen

- Sika Fibre 2011 - PDSDokument4 SeitenSika Fibre 2011 - PDSIbnu SenaNoch keine Bewertungen

- Stellgrid HR 30 - GeofabricsDokument2 SeitenStellgrid HR 30 - GeofabricsMario CordovaNoch keine Bewertungen

- TDS STEELGRID HR SYSTEM - Rev 08 - Jun 2014Dokument2 SeitenTDS STEELGRID HR SYSTEM - Rev 08 - Jun 2014mandeep571Noch keine Bewertungen

- Sika Carbodur Plate PdsDokument6 SeitenSika Carbodur Plate PdsJesieca SiemaNoch keine Bewertungen

- Pavements Constructed With Clay, Natural Stone or Concrete PaversDokument20 SeitenPavements Constructed With Clay, Natural Stone or Concrete Paversfaizankhan23Noch keine Bewertungen

- Nilex Fabriform BrochureDokument4 SeitenNilex Fabriform BrochureApurba haldarNoch keine Bewertungen

- TriAx 160 MPDSDokument1 SeiteTriAx 160 MPDSsica1234Noch keine Bewertungen

- MS 14 - Internal Waterproofing PDFDokument3 SeitenMS 14 - Internal Waterproofing PDFsullamsNoch keine Bewertungen

- TDS - Flowcable 50Dokument2 SeitenTDS - Flowcable 50Venkata RaoNoch keine Bewertungen

- Saveto Concrete Repair Guide - Concrete Repair Guide 2017 - en - 53 PDFDokument2 SeitenSaveto Concrete Repair Guide - Concrete Repair Guide 2017 - en - 53 PDFBadhur ZamanNoch keine Bewertungen

- Curing In-Place ConcreteDokument2 SeitenCuring In-Place ConcreteaaNoch keine Bewertungen

- BORNEO GEOTECHNICAL TRIAL MIX FOR 300MM DIAMETER MICROPILE GROUTDokument1 SeiteBORNEO GEOTECHNICAL TRIAL MIX FOR 300MM DIAMETER MICROPILE GROUTAlsonChin100% (2)

- Sikagard - 550 W ElasticDokument4 SeitenSikagard - 550 W ElasticAndrei GheoNoch keine Bewertungen

- Steel FiberDokument224 SeitenSteel FiberAttila KovácsNoch keine Bewertungen

- Repair and Refurb BrochureDokument11 SeitenRepair and Refurb BrochurePRERNA SINGHNoch keine Bewertungen

- State of The Art in Grout MixesDokument38 SeitenState of The Art in Grout MixesChristian SchembriNoch keine Bewertungen

- A975-11 (Reapproved 2016)Dokument8 SeitenA975-11 (Reapproved 2016)duongNoch keine Bewertungen

- Use of Geogrid PDFDokument16 SeitenUse of Geogrid PDFatokkuNoch keine Bewertungen

- Ytl Cement - Kursb 1Dokument1 SeiteYtl Cement - Kursb 1الهادي الياس100% (1)

- Guide For The Use of Polymers in Concrete: ACI 548.1R-97Dokument29 SeitenGuide For The Use of Polymers in Concrete: ACI 548.1R-97Control de calidad Antamina100% (1)

- D3406 - 95 (Reapproved 2006) PDFDokument3 SeitenD3406 - 95 (Reapproved 2006) PDFBlack GokuNoch keine Bewertungen

- As 3583.1-1998 Methods of Test For Supplementary Cementitious Materials For Use With Portland and Blended CemDokument2 SeitenAs 3583.1-1998 Methods of Test For Supplementary Cementitious Materials For Use With Portland and Blended CemSAI Global - APACNoch keine Bewertungen

- Introduction of Cement: When Was Cement Begin?Dokument11 SeitenIntroduction of Cement: When Was Cement Begin?مايف سعدونNoch keine Bewertungen

- Nitoflor SL2050: Constructive SolutionsDokument4 SeitenNitoflor SL2050: Constructive SolutionsNishant VasuNoch keine Bewertungen

- Basal Reinforced Platform for A40 Carmarthen BypassDokument2 SeitenBasal Reinforced Platform for A40 Carmarthen BypasssandycastleNoch keine Bewertungen

- Repair and Strengthening MaterialsDokument10 SeitenRepair and Strengthening MaterialsabdulkaderNoch keine Bewertungen

- Dry Mix Conc ProposalDokument2 SeitenDry Mix Conc Proposalnishat meghnaNoch keine Bewertungen

- Fairfix UnderlaymentDokument4 SeitenFairfix UnderlaymentfairmatechemicalNoch keine Bewertungen

- Effect of Using Ground Waste Tire Rubber As Fine Aggregate On The Behaviour of Concrete MixesDokument9 SeitenEffect of Using Ground Waste Tire Rubber As Fine Aggregate On The Behaviour of Concrete MixesMaridil IsidroNoch keine Bewertungen

- P K Mehta - Advancement in Con. Tech - 090405Dokument8 SeitenP K Mehta - Advancement in Con. Tech - 090405Narayan SinghaniaNoch keine Bewertungen

- Polypropylene Fibre Reinforced ShotcreteDokument11 SeitenPolypropylene Fibre Reinforced Shotcreteabhineet srivastava100% (2)

- Izolacija Tunela Sa Detaljima 05-04-04Dokument29 SeitenIzolacija Tunela Sa Detaljima 05-04-04IzetNoch keine Bewertungen

- Presented by - Aniket Ghosh Dastidar Construction Engg. 4 Year Jadavpur UniversityDokument20 SeitenPresented by - Aniket Ghosh Dastidar Construction Engg. 4 Year Jadavpur UniversitySaurabh AgrawalNoch keine Bewertungen

- CE6503 Highway Materials Lec7Dokument110 SeitenCE6503 Highway Materials Lec7AhmedNoch keine Bewertungen

- Construction Waterproofing MaterialsDokument11 SeitenConstruction Waterproofing MaterialsAyush TiwariNoch keine Bewertungen

- Roller Compacted Concrete (RCC) in PavementsDokument15 SeitenRoller Compacted Concrete (RCC) in PavementsAlhilali ZiyadNoch keine Bewertungen

- Asphalt Pavements A PracticalDokument2 SeitenAsphalt Pavements A PracticalMahmoudRadi0% (1)

- Ucs TestingDokument4 SeitenUcs TestingkmandisodzaNoch keine Bewertungen

- QWA Synthetex BrochureDokument6 SeitenQWA Synthetex BrochurejimboNoch keine Bewertungen

- Sika Waterbar o VNDokument3 SeitenSika Waterbar o VNSlamet Tri UsadhaNoch keine Bewertungen

- sika-waterbar-o-vnDokument3 Seitensika-waterbar-o-vnIpraNoch keine Bewertungen

- Kurzweil MicropianoDokument24 SeitenKurzweil Micropianoestereo8Noch keine Bewertungen

- Tube Upsetting Machines BrochureDokument10 SeitenTube Upsetting Machines BrochuredemirilkNoch keine Bewertungen

- Sop Flower Arrangement in HotelDokument2 SeitenSop Flower Arrangement in HotelwawahalimNoch keine Bewertungen

- TM4320 PDFDokument85 SeitenTM4320 PDFandres cortezNoch keine Bewertungen

- Floor ManualDokument35 SeitenFloor ManualGihan ChathurangaNoch keine Bewertungen

- Machine TimeDokument11 SeitenMachine TimeFRANCIS THOMASNoch keine Bewertungen

- Model Manajemen Rantai Pasok Industri Perikanan Tangkap Berkelanjutan Di Propinsi MalukuDokument12 SeitenModel Manajemen Rantai Pasok Industri Perikanan Tangkap Berkelanjutan Di Propinsi MalukuEmanuellaNoch keine Bewertungen

- Cisco CCNA SecurityDokument85 SeitenCisco CCNA SecurityPaoPound HomnualNoch keine Bewertungen

- MARSIC300 trainingDokument31 SeitenMARSIC300 trainingDenys Podlevskykh100% (1)

- Learjet 45 Pilot Traning Manual Volumen 2Dokument539 SeitenLearjet 45 Pilot Traning Manual Volumen 2Agustin Bernales88% (8)

- SM-800.11 TypeM Plus ValvesDokument13 SeitenSM-800.11 TypeM Plus ValvesAdel AhmedNoch keine Bewertungen

- PLAXIS Tutorial ManualDokument124 SeitenPLAXIS Tutorial ManualPeteris Skels100% (2)

- Parts Catalog TT75, TT55 NEW HOLLANDDokument360 SeitenParts Catalog TT75, TT55 NEW HOLLANDrogerio97% (35)

- DT Progression Pathways ks3 Textiles Y9Dokument1 SeiteDT Progression Pathways ks3 Textiles Y9api-240012980Noch keine Bewertungen

- Abstract, CRIMINOLOGYDokument2 SeitenAbstract, CRIMINOLOGYvishnu PNoch keine Bewertungen

- Types of Camera AnglesDokument2 SeitenTypes of Camera AnglesMaJudith JavilloNoch keine Bewertungen

- Unit 8 #10 Doppler - Effect - PPTDokument13 SeitenUnit 8 #10 Doppler - Effect - PPTPrasanta NaskarNoch keine Bewertungen

- Huffman & ShannonDokument30 SeitenHuffman & ShannonDhamodharan SrinivasanNoch keine Bewertungen

- Assignment OracleDokument4 SeitenAssignment OracleKyle Austin PabustanNoch keine Bewertungen

- Reaction Paper The Flight From ConversationDokument4 SeitenReaction Paper The Flight From ConversationJoe NasalitaNoch keine Bewertungen

- AcrSavoniacJ ZDokument454 SeitenAcrSavoniacJ ZЕвгенияNoch keine Bewertungen

- John Deere 125 HP PDFDokument2 SeitenJohn Deere 125 HP PDFJulio TovarNoch keine Bewertungen

- Physics Roller Coaster ProjectDokument13 SeitenPhysics Roller Coaster Projectapi-348624957Noch keine Bewertungen

- Aymeric Gogibus - ManagementDokument1 SeiteAymeric Gogibus - ManagementSoufanGroupNoch keine Bewertungen

- BOE-025 Consejo de EstadoDokument1 SeiteBOE-025 Consejo de Estado15mls23Noch keine Bewertungen

- (Urban and Landscape Perspectives 15) Marco Mareggi (Auth.), Dietrich Henckel, Susanne Thomaier, Benjamin Könecke, Roberto Zedda, Stefano Stabilini (Eds.)-Space–Time Design of the Public City-SpringerDokument332 Seiten(Urban and Landscape Perspectives 15) Marco Mareggi (Auth.), Dietrich Henckel, Susanne Thomaier, Benjamin Könecke, Roberto Zedda, Stefano Stabilini (Eds.)-Space–Time Design of the Public City-SpringerFuadAshadLNoch keine Bewertungen

- Ax2012 Enus Sam 04 PDFDokument26 SeitenAx2012 Enus Sam 04 PDFErnesto J DuranNoch keine Bewertungen

- Julian Assange Why The World Needs Wikileaks: General InstructionsDokument1 SeiteJulian Assange Why The World Needs Wikileaks: General InstructionsChris CiervoNoch keine Bewertungen

- Project Report PDFDokument4 SeitenProject Report PDFPradeep VermaNoch keine Bewertungen

- Ln26r71bd Ln-s2652d Ln26r71b Ln32r71bd LN s3252d DiagramaDokument261 SeitenLn26r71bd Ln-s2652d Ln26r71b Ln32r71bd LN s3252d DiagramaVictor Julio AlvarezNoch keine Bewertungen