Beruflich Dokumente

Kultur Dokumente

4.7 Gas-Shielded Metal Arc (Mig or Gmaw) : Dip (Or Short Circuiting) Transfer - Low Heat

Hochgeladen von

satnam0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten1 Seitepub139_13

Originaltitel

pub139_13

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenpub139_13

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten1 Seite4.7 Gas-Shielded Metal Arc (Mig or Gmaw) : Dip (Or Short Circuiting) Transfer - Low Heat

Hochgeladen von

satnampub139_13

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

4.

7 Gas-shielded Metal Arc (MIG or GMAW)

The higher capital cost of equipment and

the need to buy complete spools of filler

wire make MIG (GMAW) more appropriate

for extensive welding operations. The

process is less used for copper-nickels than

those discussed earlier.

MIG (GMAW) can be operated over a range

of currents to provide various transfer

modes:

Dip (or short circuiting) transfer - Low heat

input, used for thinner sections. Modern

power sources and electronic systems

permit close control of metal transfer.

Pulsed-arc transfer - A technique which

provides a combination of low overall heat

input and adequate fusion to the base

TIG (GTAW) weld process metal. It is suitable for a range of material

(Courtesy Eucaro Buntmetall GmbH) thicknesses.

Spray transfer - Relatively high heat input

and suitable only for thicker materials -

say, above 6mm thickness - and down-

hand welding.

Because of the range of transfer conditions

which are possible with the gas-shielded

metal arc process, welding parameters can

vary widely. In all cases these should be

set for the equipment, and the position

and thickness of the material, by careful

welding procedure trials directed towards

stable transfer conditions and welds of

good appearance.

• Argon or a mixture with helium is

the preferred shielding gas.

• The spooled filler wire must be

kept dry and not exposed to

contamination.

• Attention should be paid to the

effectiveness of the wire feeding

system when welds have to be made

some distance from the welding

equipment, since filler wire is

relatively soft.

• Low friction liners are essential for

TIG (GTAW) welding 90-10 copper-nickel assembly. Note baffle for backing gas supply at root the feed hose.

run stage (Courtesy Eucaro Buntmetall GmbH)

Copper-Nickel Welding and Fabrication | 11

Das könnte Ihnen auch gefallen

- Ijirt157448 PaperDokument6 SeitenIjirt157448 PaperesteveranchezcabahugjrNoch keine Bewertungen

- Tandem GMAWDokument2 SeitenTandem GMAWNirmal GhoshNoch keine Bewertungen

- Metal Inert Gas Welding (GMAW)Dokument13 SeitenMetal Inert Gas Welding (GMAW)S GoudaNoch keine Bewertungen

- Introduction:-: B.E. MECHANICAL: Shree S'ad Vidya Mandal Institute of TechnologyDokument1 SeiteIntroduction:-: B.E. MECHANICAL: Shree S'ad Vidya Mandal Institute of TechnologyHandri YantoNoch keine Bewertungen

- FCAW Process WeldingDokument130 SeitenFCAW Process WeldingahmetNoch keine Bewertungen

- Murex Mig Poster 2008 PDFDokument1 SeiteMurex Mig Poster 2008 PDFPCNoch keine Bewertungen

- Section Design of Welded ConnectionsDokument5 SeitenSection Design of Welded ConnectionsLương TrườngNoch keine Bewertungen

- Murex Tig Poster 2008 PDFDokument1 SeiteMurex Tig Poster 2008 PDFPCNoch keine Bewertungen

- Gas Metal Arc and Flux Cored Arc Welding Principles: Chapter ObjectivesDokument8 SeitenGas Metal Arc and Flux Cored Arc Welding Principles: Chapter ObjectivesWilly UioNoch keine Bewertungen

- 2015L - Prevendo A Geometria Do Cordão de Solda Do Novo Processo de CW - GmawDokument11 Seiten2015L - Prevendo A Geometria Do Cordão de Solda Do Novo Processo de CW - GmawIgor Alexsander Barbosa MagnoNoch keine Bewertungen

- Gas Tungsten Arc Welding Practice:: Jobs 20-J1-J17 (Pipe)Dokument8 SeitenGas Tungsten Arc Welding Practice:: Jobs 20-J1-J17 (Pipe)Willy UioNoch keine Bewertungen

- Gasless Wire Welding Isa Breeze: by Greg HolsterDokument6 SeitenGasless Wire Welding Isa Breeze: by Greg HolsterAda Dev CsabaNoch keine Bewertungen

- Svetsaren Vol 58 One + One Is More Than TwoDokument4 SeitenSvetsaren Vol 58 One + One Is More Than TwolvcuichanghuaNoch keine Bewertungen

- Voestalpine - Boehler Cored Wires BrochureDokument6 SeitenVoestalpine - Boehler Cored Wires Brochurerusf123Noch keine Bewertungen

- Welder HandbookDokument7 SeitenWelder Handbooksandeepkumar63Noch keine Bewertungen

- Double-Sided Arc Welding Increases Weld Joint PenetrationDokument9 SeitenDouble-Sided Arc Welding Increases Weld Joint PenetrationberhaneNoch keine Bewertungen

- Dense Phase Transmission of Natural Gas, King and KatzDokument6 SeitenDense Phase Transmission of Natural Gas, King and KatzFredrick MartinNoch keine Bewertungen

- Gas Metal Arc WeldingDokument96 SeitenGas Metal Arc WeldingBinu RajuNoch keine Bewertungen

- Submerged Arc Welding: Training & EducationDokument17 SeitenSubmerged Arc Welding: Training & Educationtanveer ahmedNoch keine Bewertungen

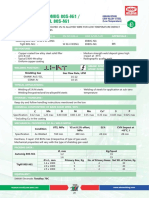

- Voltage & Low Amp) : Note Globular Transfer (Mode Note For Welding Steel Used The Steel LinerDokument3 SeitenVoltage & Low Amp) : Note Globular Transfer (Mode Note For Welding Steel Used The Steel LinerAmnur AkhyanNoch keine Bewertungen

- DKPWDokument5 SeitenDKPWMurad AlamNoch keine Bewertungen

- Effects of Torch Configuration and Welding Current On Weld Bead Formation WeldDokument10 SeitenEffects of Torch Configuration and Welding Current On Weld Bead Formation WeldMenad SalahNoch keine Bewertungen

- Laser Assisted Arc Welding: Shop TalkDokument8 SeitenLaser Assisted Arc Welding: Shop TalkWilly UioNoch keine Bewertungen

- Heat Trace BartecDokument4 SeitenHeat Trace BartecIRAN.HEAT-TRACE GROUPENoch keine Bewertungen

- Module 4 - Welded Connections PDFDokument28 SeitenModule 4 - Welded Connections PDFqazwsxedcrfvtgb plmoknijbNoch keine Bewertungen

- 4.5 Manual Metal Arc (Mma or Smaw) : 10 - Copper-Nickel Welding and FabricationDokument1 Seite4.5 Manual Metal Arc (Mma or Smaw) : 10 - Copper-Nickel Welding and FabricationsatnamNoch keine Bewertungen

- TeroMatec OA 2020Dokument2 SeitenTeroMatec OA 2020EdwinNoch keine Bewertungen

- Unit 2 Vacuum ApplicationsDokument5 SeitenUnit 2 Vacuum ApplicationsRaniya p AGS21MPHY012Noch keine Bewertungen

- Enclosed Arc WeldingDokument7 SeitenEnclosed Arc WeldingMakrand ShindeNoch keine Bewertungen

- LV HRC Fuses: DIN Type Geared up for any situationDokument20 SeitenLV HRC Fuses: DIN Type Geared up for any situationsuresh kanchanaNoch keine Bewertungen

- A 33-Ghz Lna For 5G Wireless Systems in 28-Nm Bulk CmosDokument5 SeitenA 33-Ghz Lna For 5G Wireless Systems in 28-Nm Bulk CmosVarun DevNoch keine Bewertungen

- GAP Type Conductors Provide Double Current Capacity & Lower SaggingDokument6 SeitenGAP Type Conductors Provide Double Current Capacity & Lower Saggingfixer_007722Noch keine Bewertungen

- 2021l - Transição Globular para Spray Na Soldagem A Arco de Metal A Gás de Arame FrioDokument11 Seiten2021l - Transição Globular para Spray Na Soldagem A Arco de Metal A Gás de Arame FrioIgor Alexsander Barbosa MagnoNoch keine Bewertungen

- Thermal Cycle-Dependent Metallurgical Variations and Their Effects On The Through-Thickness Mechanical Properties in Thick Section Narrow-Gap WeldsDokument13 SeitenThermal Cycle-Dependent Metallurgical Variations and Their Effects On The Through-Thickness Mechanical Properties in Thick Section Narrow-Gap Weldsmario alvaradoNoch keine Bewertungen

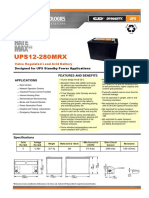

- UPS12-280R MRX Valve Regulated Lead Acid Battery for UPSDokument2 SeitenUPS12-280R MRX Valve Regulated Lead Acid Battery for UPSMuneer AhamedNoch keine Bewertungen

- ULINC Curriculum - Sample Lesson PlanDokument42 SeitenULINC Curriculum - Sample Lesson Plankamal touilebNoch keine Bewertungen

- Materials 14 03617Dokument16 SeitenMaterials 14 03617Tolga YüzüncüyılNoch keine Bewertungen

- Surface Tension Transfer (STT) : ApplicationDokument6 SeitenSurface Tension Transfer (STT) : ApplicationAnonymous dvrhf5Noch keine Bewertungen

- Teromatec Oa 4601: Premium Open Arc Wearfacing Wire For Combating Extreme AbrasionDokument2 SeitenTeromatec Oa 4601: Premium Open Arc Wearfacing Wire For Combating Extreme AbrasionJuan Carlos EspinozaNoch keine Bewertungen

- GTAW TIG Welding GuideDokument15 SeitenGTAW TIG Welding GuideIshan VermaNoch keine Bewertungen

- Weldability of Steel PDFDokument5 SeitenWeldability of Steel PDFVC100% (2)

- Plasma Arc WeldingDokument2 SeitenPlasma Arc WeldingSaiful AmreeNoch keine Bewertungen

- Comparative Study Between Welding of Normal Pipes and Coated Pipes.Dokument1 SeiteComparative Study Between Welding of Normal Pipes and Coated Pipes.srinivas raoNoch keine Bewertungen

- Welding: Engr. Dheylvin Roy P. BuenaventuraDokument8 SeitenWelding: Engr. Dheylvin Roy P. BuenaventuraEarl Justin EnriqueNoch keine Bewertungen

- Progress in MIG/MAG-Welding With The Help of Modern Multi-Process Welding Power SourcesDokument9 SeitenProgress in MIG/MAG-Welding With The Help of Modern Multi-Process Welding Power SourcesbryłaNoch keine Bewertungen

- Orbital Weldingfab-May99Dokument4 SeitenOrbital Weldingfab-May99GagrigoreNoch keine Bewertungen

- Asme Jemt 2008 PandaDokument9 SeitenAsme Jemt 2008 PandaDarshan HanchateNoch keine Bewertungen

- Weld Repair of GTD 111 SuperalloyDokument10 SeitenWeld Repair of GTD 111 SuperalloyJJNoch keine Bewertungen

- Application Note Metallography of WeldsDokument8 SeitenApplication Note Metallography of WeldsLorena Grijalba LeónNoch keine Bewertungen

- The Influence of Various Hybrid Welding Parameters On Bead GeometryDokument7 SeitenThe Influence of Various Hybrid Welding Parameters On Bead GeometrytazzorroNoch keine Bewertungen

- Optimization of Welding Process Bead Geometry in Gas Metal Arc Welding Process Using Response Surface MethodologyDokument7 SeitenOptimization of Welding Process Bead Geometry in Gas Metal Arc Welding Process Using Response Surface MethodologyAdvanced Research PublicationsNoch keine Bewertungen

- Svetsaren Vol 58 Tandem MIG MAG WeldingDokument2 SeitenSvetsaren Vol 58 Tandem MIG MAG WeldinglvcuichanghuaNoch keine Bewertungen

- UPS12-280MRX: Valve Regulated Lead Acid BatteryDokument2 SeitenUPS12-280MRX: Valve Regulated Lead Acid BatteryCristopher JayloNoch keine Bewertungen

- Application Notes Welding (English)Dokument8 SeitenApplication Notes Welding (English)metallurgist100% (6)

- API 577 QuestionsDokument14 SeitenAPI 577 QuestionsabdoNoch keine Bewertungen

- Gallium Nitride-enabled High Frequency and High Efficiency Power ConversionVon EverandGallium Nitride-enabled High Frequency and High Efficiency Power ConversionGaudenzio MeneghessoNoch keine Bewertungen

- Automig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36Dokument1 SeiteAutomig FC 71T-1: AWS A/SFA 5.20 EN ISO 17632 A AWS A/SFA 5.36satnamNoch keine Bewertungen

- CWC-BookletF1 59Dokument1 SeiteCWC-BookletF1 59satnamNoch keine Bewertungen

- GTAW TIGFIL CuNi solid filler rod for welding copper nickel alloysDokument1 SeiteGTAW TIGFIL CuNi solid filler rod for welding copper nickel alloyssatnamNoch keine Bewertungen

- Tiginox 385: Classification: en Iso 14343-ADokument1 SeiteTiginox 385: Classification: en Iso 14343-AJagannath SahuNoch keine Bewertungen

- CWC-BookletF1 36 PDFDokument1 SeiteCWC-BookletF1 36 PDFJagannath SahuNoch keine Bewertungen

- GMAW Solid Wire for Welding Copper AlloysDokument1 SeiteGMAW Solid Wire for Welding Copper AlloyssatnamNoch keine Bewertungen

- AUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalsDokument1 SeiteAUTOMIG 5356 / TIGFIL 5356: Classification: ApprovalssatnamNoch keine Bewertungen

- NiCu-7 solid wire for welding nickel-copper alloysDokument1 SeiteNiCu-7 solid wire for welding nickel-copper alloyssatnamNoch keine Bewertungen

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDokument1 SeiteAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNoch keine Bewertungen

- AUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalsDokument1 SeiteAUTOMIG 4043 / TIGFIL 4043: Classification: ApprovalssatnamNoch keine Bewertungen

- GMAW/GTAW Welding of Aluminium Alloys with ER1100 WireDokument1 SeiteGMAW/GTAW Welding of Aluminium Alloys with ER1100 WiresatnamNoch keine Bewertungen

- GMAW GTAW MIGINOX 347Si STAINLESS STEELDokument1 SeiteGMAW GTAW MIGINOX 347Si STAINLESS STEELJagannath SahuNoch keine Bewertungen

- CWC-BookletF1 15Dokument1 SeiteCWC-BookletF1 15satnamNoch keine Bewertungen

- Automig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28Dokument1 SeiteAutomig 90S-B9 / Tigfil 90S-B9: EN ISO 21952-A AWS A/SFA 5.28satnamNoch keine Bewertungen

- CWC-BookletF1 38 PDFDokument1 SeiteCWC-BookletF1 38 PDFsatnamNoch keine Bewertungen

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADokument1 SeiteTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNoch keine Bewertungen

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADokument1 SeiteAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNoch keine Bewertungen

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDokument1 SeiteAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNoch keine Bewertungen

- CWC-BookletF1 10Dokument1 SeiteCWC-BookletF1 10satnamNoch keine Bewertungen

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Dokument1 SeiteTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNoch keine Bewertungen

- Tigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-ADokument1 SeiteTigfil 80S-B2 SPL: AWS A/SFA 5.28 EN ISO 21952-AsatnamNoch keine Bewertungen

- CWC-BookletF1 17Dokument1 SeiteCWC-BookletF1 17satnamNoch keine Bewertungen

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDokument1 SeiteAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNoch keine Bewertungen

- CWC-BookletF1 9Dokument1 SeiteCWC-BookletF1 9satnamNoch keine Bewertungen

- CWC-BookletF1 12Dokument1 SeiteCWC-BookletF1 12satnamNoch keine Bewertungen

- Tigfil 70S-2: Aws A/sfa 5.18 en Iso 636-ADokument1 SeiteTigfil 70S-2: Aws A/sfa 5.18 en Iso 636-AsatnamNoch keine Bewertungen

- Automig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48Dokument1 SeiteAutomig 70S-6 N: EN ISO 14341-A AWS A/SFA 5.18 Csa W48satnamNoch keine Bewertungen

- TIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48Dokument1 SeiteTIGFIL 70S-6: AWS A/SFA 5.18 EN ISO 636-A Csa W48satnamNoch keine Bewertungen

- CWC-BookletF1 9Dokument1 SeiteCWC-BookletF1 9satnamNoch keine Bewertungen

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Dokument1 SeiteAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNoch keine Bewertungen

- Micro Electronic PillDokument2 SeitenMicro Electronic PillDevendra Singh RajpurohitNoch keine Bewertungen

- GetDoc - PDF MT X 1440AE3 ElectDokument242 SeitenGetDoc - PDF MT X 1440AE3 ElectEdison PondaNoch keine Bewertungen

- Conquer Radio Frequency Page Selection PDFDokument54 SeitenConquer Radio Frequency Page Selection PDFNajafNoch keine Bewertungen

- Growatt Three-Phase Meter TPM Quick Installation GuideDokument2 SeitenGrowatt Three-Phase Meter TPM Quick Installation GuideLady Vanessa VargasNoch keine Bewertungen

- Transmission Line TranspositionsDokument4 SeitenTransmission Line TranspositionsLRHENGNoch keine Bewertungen

- RCF MB15H401Dokument2 SeitenRCF MB15H401Domnu_BibiNoch keine Bewertungen

- Testing of TransformersDokument5 SeitenTesting of Transformersjinojk100% (1)

- UA6176 ManualDokument46 SeitenUA6176 ManualmpewebNoch keine Bewertungen

- Mirra530 ManualDokument16 SeitenMirra530 ManualMark SeredaNoch keine Bewertungen

- PSTX72-600-70 Softstarter Product DetailsDokument4 SeitenPSTX72-600-70 Softstarter Product DetailsRaul EirisNoch keine Bewertungen

- Tpca8057-H Mosfet Ps3 Placa Modelo PQX 001Dokument9 SeitenTpca8057-H Mosfet Ps3 Placa Modelo PQX 001Eisenhower Garcia LealNoch keine Bewertungen

- Use 7% detuned reactor for power factor correctionDokument1 SeiteUse 7% detuned reactor for power factor correctionMartono Abu HanifNoch keine Bewertungen

- Metal JoiningDokument62 SeitenMetal Joiningbhavna agarwalNoch keine Bewertungen

- Jarrett SLA12-120 PDFDokument2 SeitenJarrett SLA12-120 PDFValentin RusuNoch keine Bewertungen

- Control Systems Viva VoiceDokument10 SeitenControl Systems Viva VoiceSunil MotepalliNoch keine Bewertungen

- STCC2540: USB Charging Controller With Integrated Power SwitchDokument32 SeitenSTCC2540: USB Charging Controller With Integrated Power SwitchAndré Andersen PicerniNoch keine Bewertungen

- 2.4 Wheatstone 91-10Dokument8 Seiten2.4 Wheatstone 91-10Murray PhysicsNoch keine Bewertungen

- Iesco 2019Dokument6 SeitenIesco 2019بد تميزNoch keine Bewertungen

- Mitsubishi Electrique SPLIT-TYPE AIR CONDITIONERS Servoce ManualDokument48 SeitenMitsubishi Electrique SPLIT-TYPE AIR CONDITIONERS Servoce ManualEtienne GuinardNoch keine Bewertungen

- Project Report On Room Noise DetectorDokument31 SeitenProject Report On Room Noise DetectorSubhash Verma0% (1)

- Project - Review ThermoelectricDokument30 SeitenProject - Review ThermoelectricAbhishek KumarNoch keine Bewertungen

- Iec 62271 1 Edition 2017Dokument28 SeitenIec 62271 1 Edition 2017Prabhu Govindaswamy50% (2)

- BX SOL DS T800999 enDokument2 SeitenBX SOL DS T800999 enGrace ZuluetaNoch keine Bewertungen

- Alstom ContactorsDokument8 SeitenAlstom Contactorshassan karimiNoch keine Bewertungen

- Cqc1103u Auto RadioDokument30 SeitenCqc1103u Auto RadioMilutinNoch keine Bewertungen

- 01-Jan-2020 Shift B Logbook Operator PakseDokument1 Seite01-Jan-2020 Shift B Logbook Operator PakseLove Buddha's WordsNoch keine Bewertungen

- Advanced Photoelectric Smoke Detectors: FeaturesDokument8 SeitenAdvanced Photoelectric Smoke Detectors: FeaturesoscarninanNoch keine Bewertungen

- How To Setup 5MW and 10MW Solar PV ModulDokument33 SeitenHow To Setup 5MW and 10MW Solar PV ModuljorgeNoch keine Bewertungen

- PNR Porcelain Bushing Brochure 33209 EN A4 202112 R002Dokument9 SeitenPNR Porcelain Bushing Brochure 33209 EN A4 202112 R002setiyawanNoch keine Bewertungen

- Cathodic Protection System For Onshore Buried PipelineDokument1 SeiteCathodic Protection System For Onshore Buried PipelinebyanggoNoch keine Bewertungen