Beruflich Dokumente

Kultur Dokumente

Sop For Change Management

Hochgeladen von

Gaurav WadhwaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sop For Change Management

Hochgeladen von

Gaurav WadhwaCopyright:

Verfügbare Formate

Department : CORP QA

Document No : SOP/CQA/01

ADVIK Standard Operating Procedure for Change Point Control Revision No : 00

Revision Date : 17.08.2015

Origin Date: 17.08.2015

ISO /TS -Clause No : 6.3.2 ,7.1.4

PURPOSE :-

This Procedure Provide guidelines to Control all Change Points wrt Part Drawing Specification, Labour, Manufacturing Process, Manufacturing Method or Process Condition etc at

Inhouse as well as Supplier End.

SCOPE:

This Procedure is applicable for Overall Chage Management of Product Eg : Specification Change, 4M Condition Change, Quality Improvement Change, Self Controlled Changes etc.

All changes must be recorded in 4M Change Record Register and Maintain the tracebility of all Change Points.

RESPONSIBILITY :-

HOD ME, HOD QA, HOD PROD ,HOD R&D from Corporate Plant and QA of Respective Plant is responsible for Compliance of the System.

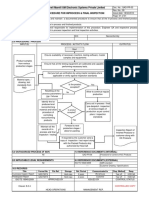

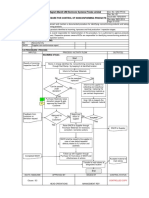

Flowchart:-

4M CONDITION CHANGES ,CHANGES DUE TO QUALITY PROBLEMS(

SPECIFICATION CHANGE FIELD OR WARRANTY COMPLAINTS). SELF CONTROLLED

CHANGES.ETC

Change in 4M Conditions or Quality Improvements or Self

Controlled Changes Such as1) New Supplier or Supplier

Change ,Inhouse Processes Outsourced or Vise Versa.2)

Need for Changes in Design /Drawing

Need for Change in Design /Drawing Process Condition or Method Change (Changes in Process

Specification/Material (Inhouse or Supplier Suggested

Specifications/Material (Customer Trigered Changes ) Parameters)3) Jig/Tool/Fixture Modification or Change.3) Die

Changes) or Mould Modification Or Change 4) Inspection Method

Change 5) Any changes due to Quality Problem 6) Operator

Change 7) Change in Delivery Method or Delivery Packaging.

Generate the Engineering Change Note (ECN) /DCAR and Generate the Change Management Note regarding Changes

Submit the Change approval request or IPP Tag or ECN

Circulate to all Concern Department and Circulate to Concern Dept for Verification and

etc to Customer for approval with Product Samples. (If

RESPONSIBILITY : DESIGN Engineer / Manager Implementation. If required Send to Customer for approval

Customer decide to Evaluate the Samples in one or Two

through IPP tag , Countermeasure request form ,Change

Stages) approval request ,DCAR or any other Valid format.

RESPONSIBILITY : HOD R&D,HOD QA. Responsibility :- HOD QA

Change Proposal needs to discuss in NPD Meeting by all

CFT Members including Design,ME,QA,CD etc.

RESPONSIBILITY : HOD R&D.

Proposed changes is internally approved by Concern

Change Proposal approved by Customer? HOD'S or CFT Members in NPD Review Meeting or

No

approved by Customer ??

Change Proposal approved by

ADVIK CFT Team? No

Yes

Continue with Existing Yes

Yes Process and inform to

Customer Implement the Changes as Per Change Management

Implement the Changes and accordingly revise all

Implement the Changes Note and Record in 4M Change sheet.

Necessary Documents such as Drawing,PFD,Process

Control Plan, PFMEA,DFMEA,Inspection Standard etc.

Responsibility: HOD ME/HOD QA

Revise the all Necessary documents for the Changes such as

Revise the all necessary Documents for the Changes

Drawings ,PFD,Control Plan,PFMEA, Inspection

Such as PFD,Process Control Plan, PFMEA,DFMEA,Process

Standards,Work Instructions etc.

RESPONSIBILITY : HOD ME /HOD QA. Capability Studies, Inspection Standards etc.

Responsibility : HOD ME/HOD QA

If Decision by Customer to Evaluate the Samples in one or two

stages, Submit the Samples with all supporting(PPAP)

Documents Such as PFD,PEMEA,PCP,Inspection

reports,Testing Reports etc to Customer for approval.

RESP : Design Engineer/Manager , QA Engineer/ Manager

Customer approval Transition to Mass Production

Prepared By Checked By Approved By

Name Mr Rajesh Kulkarni Mr S.Udayabhanu Mr Prem Gajpal

Designation Manager CQA Sr VPP COO

Signature

Das könnte Ihnen auch gefallen

- Change Control Management SOP PDFDokument7 SeitenChange Control Management SOP PDFnetelsrt12980% (1)

- Change ControlDokument7 SeitenChange ControlPrince MoniNoch keine Bewertungen

- QSP-10 Change Control Rev 02Dokument4 SeitenQSP-10 Change Control Rev 02ukavathekarNoch keine Bewertungen

- Change Control: DR - K. Venkateswara Raju & Mr. K. T. Sunil KumarDokument27 SeitenChange Control: DR - K. Venkateswara Raju & Mr. K. T. Sunil Kumarmeenu sruthi priyaNoch keine Bewertungen

- Change Control Related PharmaDokument3 SeitenChange Control Related PharmaSaurabh Raja0% (1)

- 4M Changing Point ManagementDokument7 Seiten4M Changing Point ManagementKumaravelNoch keine Bewertungen

- Competence For Internal AuditorsDokument2 SeitenCompetence For Internal AuditorsSachin Ramdurg100% (1)

- Change Management ProcedureDokument4 SeitenChange Management ProcedureQuality Unit 1 Ajay PandeyNoch keine Bewertungen

- Change Control Request FormDokument3 SeitenChange Control Request FormSuleman FaizNoch keine Bewertungen

- Manufacturing Process AuditDokument1 SeiteManufacturing Process AuditSachin Kumbhar100% (1)

- Shriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)Dokument5 SeitenShriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)deepak sharma100% (1)

- Change Control SOPDokument7 SeitenChange Control SOPGhanta Ranjith Kumar100% (1)

- 4M Change Management Rule RevisedDokument2 Seiten4M Change Management Rule RevisedKumaravelNoch keine Bewertungen

- Procedure For NPD HandoverDokument1 SeiteProcedure For NPD HandoverTushar Wagh100% (1)

- KEY-QMS-05 - F-01 Document Change Request FormDokument1 SeiteKEY-QMS-05 - F-01 Document Change Request FormMenuka SiwaNoch keine Bewertungen

- Supplier Quality QuestionnaireDokument4 SeitenSupplier Quality QuestionnairesutharitesshNoch keine Bewertungen

- 5M CHANGE ProcedureDokument8 Seiten5M CHANGE ProcedurePk Nimiwal100% (1)

- Supplier Audit Checklist: Nisan Scientific Process Equipments PVT - LTDDokument6 SeitenSupplier Audit Checklist: Nisan Scientific Process Equipments PVT - LTDPratik KarekarNoch keine Bewertungen

- Change Control ProcedureDokument2 SeitenChange Control ProcedurePavan Kumar0% (1)

- APS-WP-15 Process Validation ProcedureDokument24 SeitenAPS-WP-15 Process Validation Procedureshobha shelarNoch keine Bewertungen

- New Vendor System Audit Check SheetDokument6 SeitenNew Vendor System Audit Check SheetJetesh Devgun83% (6)

- Change Control Management SOPDokument7 SeitenChange Control Management SOPcarbou100% (7)

- Process Audit - Sheet New ......Dokument1 SeiteProcess Audit - Sheet New ......MUKESH KUMARNoch keine Bewertungen

- Procedure: Measurement System Analysis ExecutionDokument1 SeiteProcedure: Measurement System Analysis Executionaslam100% (1)

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Dokument1 SeiteQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- QP Nonconforming Product Sample 2014Dokument2 SeitenQP Nonconforming Product Sample 2014Anna Maree100% (1)

- RU-QSP-MR-04 - Procedure For Problem Solving & Error ProofingDokument4 SeitenRU-QSP-MR-04 - Procedure For Problem Solving & Error ProofingDhananjay Patil100% (2)

- 14-QSP - 59 Procedure For Temporary Change of Process Controls PDFDokument1 Seite14-QSP - 59 Procedure For Temporary Change of Process Controls PDFsahyadri engineersNoch keine Bewertungen

- Procedure Manual - IMS: Locomotive Workshop, Northern RailwayDokument2 SeitenProcedure Manual - IMS: Locomotive Workshop, Northern RailwayMarjorie Dulay Dumol100% (2)

- A Procedure For Change ManagementDokument3 SeitenA Procedure For Change ManagementMarivic MediavilloNoch keine Bewertungen

- Change Control Management SOP PDFDokument7 SeitenChange Control Management SOP PDFcarbou100% (4)

- QAD Procedure - Control of Non-Conforming Products P1Dokument1 SeiteQAD Procedure - Control of Non-Conforming Products P1sumanNoch keine Bewertungen

- Training Program On 4M Change ManagementDokument28 SeitenTraining Program On 4M Change Managementsunil kumar90% (10)

- Basic Principles of GMP: Complaints and RecallsDokument20 SeitenBasic Principles of GMP: Complaints and Recallshardik_20Noch keine Bewertungen

- COMP-OPP-01 Procedure For Control and Validation of ProductionDokument4 SeitenCOMP-OPP-01 Procedure For Control and Validation of ProductionISODCC DSPINoch keine Bewertungen

- Master List of RecordsDokument21 SeitenMaster List of RecordsRaja DuraiNoch keine Bewertungen

- 4M Change Management DefinitionDokument4 Seiten4M Change Management DefinitionManasi shindeNoch keine Bewertungen

- 4M Change FormatDokument1 Seite4M Change FormatOBSC PerfectionNoch keine Bewertungen

- Annex 1 - Prerequisite Program / Preventive Controls MatrixDokument3 SeitenAnnex 1 - Prerequisite Program / Preventive Controls MatrixЕлена Коваленко100% (1)

- APQP With Flow of ProcessDokument8 SeitenAPQP With Flow of ProcessVarun KumarNoch keine Bewertungen

- 4M Change Management For Supplier - TennecoDokument1 Seite4M Change Management For Supplier - TennecoOBSC PerfectionNoch keine Bewertungen

- Procedure For Continuous ImprovementDokument5 SeitenProcedure For Continuous ImprovementJobair AlamNoch keine Bewertungen

- Product Audit FormDokument2 SeitenProduct Audit Formcong da0% (1)

- Ref Flow Charts Layout InspectionDokument1 SeiteRef Flow Charts Layout Inspectionrajesh.bNoch keine Bewertungen

- Sop-Nc-01 - Management of NC, CapaDokument10 SeitenSop-Nc-01 - Management of NC, Capaapi-278193171Noch keine Bewertungen

- Supplier Rating ProcedureDokument4 SeitenSupplier Rating ProcedureAmine Chahi100% (1)

- QMP-01 - Control of DocumentDokument7 SeitenQMP-01 - Control of Documentom cncNoch keine Bewertungen

- 1) Procedure For Product SafetyDokument2 Seiten1) Procedure For Product SafetyGANESH BORUDE100% (2)

- Manufacturing Audit ChecklistDokument8 SeitenManufacturing Audit Checklistgksp100% (1)

- 15 (QSP-QA - 07) Process & Product AuditDokument3 Seiten15 (QSP-QA - 07) Process & Product AuditBASAVA ENGINEERING100% (1)

- Process & Product Audit Check SheetDokument6 SeitenProcess & Product Audit Check SheetPrakashRai100% (7)

- Sta-P08-02 Non Conforming ProductDokument6 SeitenSta-P08-02 Non Conforming ProductAnonymous B7pghhNoch keine Bewertungen

- Change Management ProcedureDokument2 SeitenChange Management ProcedureAnkur33% (3)

- SOP QA 010 00 Handling of DeviationDokument17 SeitenSOP QA 010 00 Handling of Deviationnetelsrt129867% (3)

- G Change MGTDokument14 SeitenG Change MGTmrsrinathNoch keine Bewertungen

- Quality & Industrial Performance: Managing ChangeDokument37 SeitenQuality & Industrial Performance: Managing ChangeMojtaba MousaviNoch keine Bewertungen

- Change Control Report: X Pharmaceutical Manufacturing Company Quality Assurance Department Ref. SOP No.: Sop-XxxDokument7 SeitenChange Control Report: X Pharmaceutical Manufacturing Company Quality Assurance Department Ref. SOP No.: Sop-Xxxrouss1906Noch keine Bewertungen

- 10 - Managing ChangexDokument26 Seiten10 - Managing ChangexAdriana HubleaNoch keine Bewertungen

- 0706 Product Change Request FormDokument2 Seiten0706 Product Change Request FormulyssesNoch keine Bewertungen

- Training of Change Management Process Phase II V02Dokument71 SeitenTraining of Change Management Process Phase II V02roshanNoch keine Bewertungen

- Approval Matrix ModuleDokument4 SeitenApproval Matrix ModuleGaurav WadhwaNoch keine Bewertungen

- Delegation of Authority: Duluxgroup LimitedDokument7 SeitenDelegation of Authority: Duluxgroup LimitedGaurav WadhwaNoch keine Bewertungen

- Delegation of Authority: Duluxgroup LimitedDokument7 SeitenDelegation of Authority: Duluxgroup LimitedGaurav WadhwaNoch keine Bewertungen

- Sop For Change ManagementDokument1 SeiteSop For Change ManagementGaurav Wadhwa0% (1)

- 4M Nissan Criteria For The AuditDokument29 Seiten4M Nissan Criteria For The AuditGaurav WadhwaNoch keine Bewertungen

- Bill Overview: Jlb96Kutpxdgxfivcivc Ykpfi9R9Ukywilxmvbj5Wpccvgaqc7FDokument5 SeitenBill Overview: Jlb96Kutpxdgxfivcivc Ykpfi9R9Ukywilxmvbj5Wpccvgaqc7FMani KalpanaNoch keine Bewertungen

- Economy of VeitnamDokument17 SeitenEconomy of VeitnamPriyanshi LohaniNoch keine Bewertungen

- BDA Advises JAFCO On Sale of Isuzu Glass To Basic Capital ManagementDokument3 SeitenBDA Advises JAFCO On Sale of Isuzu Glass To Basic Capital ManagementPR.comNoch keine Bewertungen

- StepanFormulation149 Liquid Soap PDFDokument2 SeitenStepanFormulation149 Liquid Soap PDFeduardoaffreNoch keine Bewertungen

- Dictatorship in Pakistan PDFDokument18 SeitenDictatorship in Pakistan PDFAsad khanNoch keine Bewertungen

- 9/11: Twenty Years Later (2001-2021)Dokument46 Seiten9/11: Twenty Years Later (2001-2021)Timothy80% (5)

- Comparative Financial Statement - Day4Dokument28 SeitenComparative Financial Statement - Day4Rahul BindrooNoch keine Bewertungen

- Covernote of Krishendu RoyDokument1 SeiteCovernote of Krishendu Royanon_3913650Noch keine Bewertungen

- Godines vs. Court of AppealsDokument3 SeitenGodines vs. Court of AppealsTinersNoch keine Bewertungen

- Claim Form - Part A' To 'Claim Form For Health Insurance PolicyDokument6 SeitenClaim Form - Part A' To 'Claim Form For Health Insurance Policyanil sangwanNoch keine Bewertungen

- D'Alembert's Solution of The Wave Equation. Characteristics: Advanced Engineering Mathematics, 10/e by Edwin KreyszigDokument43 SeitenD'Alembert's Solution of The Wave Equation. Characteristics: Advanced Engineering Mathematics, 10/e by Edwin KreyszigElias Abou FakhrNoch keine Bewertungen

- Letter of Recommendation SchelieDokument1 SeiteLetter of Recommendation Schelieapi-237542168Noch keine Bewertungen

- BailmentDokument3 SeitenBailmentanoos04Noch keine Bewertungen

- DemocarcyDokument5 SeitenDemocarcyAdil ZiaNoch keine Bewertungen

- Clerkship HandbookDokument183 SeitenClerkship Handbooksanddman76Noch keine Bewertungen

- Fmea Aiag Vda First Edition 2019Dokument254 SeitenFmea Aiag Vda First Edition 2019Sabah LoumitiNoch keine Bewertungen

- 8 Soc - Sec.rep - Ser. 123, Unempl - Ins.rep. CCH 15,667 Alfred Mimms v. Margaret M. Heckler, Secretary of The Department of Health and Human Services, 750 F.2d 180, 2d Cir. (1984)Dokument8 Seiten8 Soc - Sec.rep - Ser. 123, Unempl - Ins.rep. CCH 15,667 Alfred Mimms v. Margaret M. Heckler, Secretary of The Department of Health and Human Services, 750 F.2d 180, 2d Cir. (1984)Scribd Government DocsNoch keine Bewertungen

- Babylone Convent Bye Laws Chapter 1Dokument5 SeitenBabylone Convent Bye Laws Chapter 1Karan RajveerNoch keine Bewertungen

- Criminal LawDokument21 SeitenCriminal LawDee WhyNoch keine Bewertungen

- Elias Casiano Jr. AffidavitDokument3 SeitenElias Casiano Jr. AffidavitEmily BabayNoch keine Bewertungen

- Alliance AirDokument3 SeitenAlliance AirvikasmNoch keine Bewertungen

- Vikrant SinghDokument3 SeitenVikrant SinghUtkarshNoch keine Bewertungen

- Commercial Banking Operations:: Types of Commercial BanksDokument6 SeitenCommercial Banking Operations:: Types of Commercial BanksKhyell PayasNoch keine Bewertungen

- KEPITAL-POM - KEPITAL F20-03 LOF - en - RoHSDokument8 SeitenKEPITAL-POM - KEPITAL F20-03 LOF - en - RoHSEnzo AscañoNoch keine Bewertungen

- Renter Information Rental Information Charge Information: Biswadeep Das Time ChargesDokument1 SeiteRenter Information Rental Information Charge Information: Biswadeep Das Time ChargesBiswadeep DasNoch keine Bewertungen

- Atty. Aileen R. Maglana v. Atty. Jose Vicente R. Opinion, B.B No. 2713Dokument16 SeitenAtty. Aileen R. Maglana v. Atty. Jose Vicente R. Opinion, B.B No. 2713Ramon Carlo GuicoNoch keine Bewertungen

- TYFO SCH-41 Data Sheet PDFDokument2 SeitenTYFO SCH-41 Data Sheet PDFAnastasia SantosoNoch keine Bewertungen

- G.R. No. 160384 - Cesar T. Hilario v. Alan T. SalvadorDokument11 SeitenG.R. No. 160384 - Cesar T. Hilario v. Alan T. SalvadorKIM COLLEEN MIRABUENANoch keine Bewertungen

- PEG SchemeDokument13 SeitenPEG Schemed-fbuser-120619586Noch keine Bewertungen

- Deed of Real Estate MortgageDokument6 SeitenDeed of Real Estate MortgageCristopher ReyesNoch keine Bewertungen