Beruflich Dokumente

Kultur Dokumente

5 Features For Safe Hydraulic Drives

Hochgeladen von

bman0051401Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

5 Features For Safe Hydraulic Drives

Hochgeladen von

bman0051401Copyright:

Verfügbare Formate

Ideas & Applications

ALAN HITCHCOX | Editor

At work in Hyundai Steel’s facility in South Korea, the Kamag’s 3503 ladle transporter relies on a hydrostatic drive for tight control of speed,

torque, and power; articulated steering for high maneuverability; and hydraulic cylinders for precise linear positioning to keep the molten

steel level within the ladle.

GENTLE GIANT

Transports Molten Steel

TRANSPORTING MOLTEN STEEL can be extremely dangerous surfaces. Furthermore, articulated steering allows the opera-

because any sudden movement can cause an accident with seri- tor to maneuver around obstacles throughout the plant. The

ous consequences. So, whenever a ladle of molten steel must be hydrostatic drive can scale gradients up to 8% when fully

transported within a steel plant, it must be done slowly and by loaded and reaches a speed of up to 6 km/h with the dangerous

a vehicle with precise drive, steering, braking, and level con- cargo. The high maneuverability and relatively high speed of

trol. The longer the travel distance, and the slower the vehicle the transporter cuts transportation time, thereby increasing

speed, the more money it costs to transfer a ladle. So if a vehicle productivity over conventional machines.

can transport a ladle faster without sacrificing safety, it would

improve a steel plant’s productivity.

Because they move so slowly, most ladle carriers are used FIVE FEATURES for

only for short distances. Not so with Kamag’s 3503 ladle car-

rier. Manufactured by Kamag Transporttechnik (www.kamag.

Safe Hydraulic Drives

com), Ulm, Germany, the 3503 has a payload of 180 tons and TODAY’S ELECTRONIC CONTROLS advanced hydraulic drives

is nearly 16 meters long. A ladle is placed in the transporter’s allow self-propelled machines to reach high speeds even

payload platform, which can be hydraulically lowered onto when working in the most arduous conditions. But speed isn’t

the ground for crane loading. An extensive range of protec- worth anything unless the vehicle operates safely. That’s where

tive measures ensures that the driver’s cabin and the drive designing the drive layout and specifying the hydraulic motor

components are protected from the heat. can mean the difference between a machine that operates

The transporter can be maneuvered from the driver’s cab safely under all conditions and one that must go back to the

clearly and easily despite the vehicle’s large size. Hydraulic drawing board.

axle compensation corrects irregularities from uneven ground One of the great advantages of hydraulic drives is the

12 AUGUST 2015 HYDRAULICS & PNEUMATICS

Ideas & Applications

absence of axles that would otherwise traverse a vehicle’s wheel engaged with the ground gives the operator greater con-

undercarriage. Hydraulic drives allow designers to place more trol and helps keep loads from shifting.

mass between the wheel centers, rather than above them. The Matteo Michelin, of SAI Hydraulics, Modena, Italy, expands

result is a lower center of gravity, which makes the vehicle on these concepts with five factors that should be considered

more stable on uneven ground. Another big plus for hydrau- when designing a safe, compact, and efficient hydraulic drive:

lics is independent drive control. Speed, torque, or power can Center of gravity — A compact hydraulic motor keeps the

be directed to individual wheels to match the specific ground drive’s center of gravity lower than with purely mechanical

conditions. The result is optimum traction control. Keeping drive trains, resulting in high stability, even when operating on

very steep slopes. The vehicle’s overall

performance is thereby improved, and

the risk of overturning reduced.

Furthermore, a drive layout using

HOW DO I KNOW hydraulic wheel motors allows greater

flexibility of cabin design and engine

placement, resulting in more flexible

IF I’M TALKING TO equipment designs and greater comfort

and safety.

Traction distribution — Distribut-

ing traction means simply transmitting

AN ENGINEER OR the available torque to the ground in the

most efficient way possible. Flow divid-

ers or connecting motors in series are

A SALESMAN? not the most efficient methods for pre-

venting a wheel from spinning, nor do

they give the fastest reaction times.

Ask Smalley. It’s simple to tell The best solution is to balance each

when you work with Smalley. That’s individual wheel torque output to the

because you’ll always collaborate torque transmissible to the ground.

directly with our world-class team SAI’s variable-displacement motors

of engineers—experts whose only adjust their displacement continuously

focus is helping you get the most in full power, thereby limiting torque

performance from your precision to each individual wheel (even down to

wave springs or retaining rings. zero displacement) to prevent spinning.

Traction control — Safety is also a

major benefit of traction control. SAI’s

variable-displacement wheel drive units

allow fine independent output torque

distribution from every individual

motor. By using a continuously variable

wheel motor, the machine makes the

Smalley Coil Spring

Wave Spring most efficient use of the power available

dependent upon specific soil conditions.

Smalley wave springs reduce spring

operating height by 50%, saving space Also, when maneuvering on steep

and weight, fi tting tight radial and axial

spaces. We offer more than 4,000

slopes, increasing the displacement of

stock sizes in carbon and stainless steel. motors driving the more heavily loaded

Visit smalley.com for your

wheels provides safe traction. There-

no-charge test samples. fore, the hydraulic circuit will use the

same power or the same flow setting and

route more flow to the front or rear axle,

as required by the working conditions.

™

Assisted braking torque — The con-

THE ENGINEER’S CHOICE

tinuously variable displacement motors

14 AUGUST 2015 HYDRAULICS & PNEUMATICS

torque on any individ-

ual wheel as needed.

Auxiliary traction

— SAI motors used

for au x i l i ar y t r a c -

tion can work at high

speeds by modulat-

ing the displacement.

Therefore, they can

be used for driving

t o r q u e at l ow a n d

medium speeds but

Low center of gravity and precise traction control under even on set to zero displace-

steep, unstable surfaces are hallmarks of hydraulic drives for off- ment if the is towed

highway machines. towed. Motors without

this capability must be

produc ed by SAI have high mechani- mechanically disengaged from the drive

cal efficiency that supply high braking train to prevent damaging the motor or

torque from the moment the vehicle hydraulic system.

starts to decelerate, thereby guarantee-

ing rapid and controlled stopping. Fur- FOR MORE INFORMATION on SAI’s

thermore, the operator can continuous- fixed-, dual-, and variable-displacement

ly reduce or increase the displacement as motors and other components, call (610)

required, thereby boosting the braking 497-0190, or visit www.saispa.com.

OilN2

Patent & Patent Pending

™ Introducing an alternative

to frequent hydraulic oil and

flter changes that simply

“Eliminates the source of the

problem”. OilN2™ is a self

• Keeps Oil Clean & Dry contained environmental

• Prevents Oil Oxidation apparatus. OilN2™ seals

• Removes Oxygen the system “closed” and

• Removes Water

• Increases Nitrogen % uses thermal conduction

• Stops Ingression rod technology to attract

• Seals System Closed and capture internal

• Simple & Effective

oxygen and moisture into

a replaceable cartridge.

This results in blanketing

DRY NITROGEN

OilN2™ Alters The Interior Environment

the oil in pure clean dry

nitrogen. This helps stop oil

oxidation, emulsifcation,

CLEAN OIL condensation, acid, sludge,

and corrosion. Simply

connect to the vent port

and avoid high O&M costs.

OilN2™ has a fast payback.

Inventive Resources Inc. (IRI) • PO Box 1316 Salida CA 95368 USA

Phone: (888) 285-6158 • www.OilN2.com • Email: info@OilN2.com

GO TO HYDRAULICSPNEUMATICS.COM 15

Das könnte Ihnen auch gefallen

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorVon EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNoch keine Bewertungen

- SY135C4Dokument12 SeitenSY135C4Vieira InvestidorNoch keine Bewertungen

- Advanced Seat Suspension Control System Design for Heavy Duty VehiclesVon EverandAdvanced Seat Suspension Control System Design for Heavy Duty VehiclesNoch keine Bewertungen

- Dl200a enDokument9 SeitenDl200a enMarcus LopesNoch keine Bewertungen

- Dl200a enDokument9 SeitenDl200a enBhagoo HatheyNoch keine Bewertungen

- Dl250a enDokument9 SeitenDl250a enBhagoo HatheyNoch keine Bewertungen

- Doosan DL450Dokument16 SeitenDoosan DL450Foromaquinas100% (3)

- Chain DrivesDokument16 SeitenChain DrivesShashidhara ShamaiahNoch keine Bewertungen

- 950c John Deere.Dokument16 Seiten950c John Deere.Walter LazoNoch keine Bewertungen

- 725 Truck ArticulatedDokument20 Seiten725 Truck ArticulatedForomaquinas100% (3)

- Articulated Trucks: Engine Weights Body CapacitiesDokument20 SeitenArticulated Trucks: Engine Weights Body Capacitiesabdallah badrNoch keine Bewertungen

- Articulated Truck: Engine Weights Body CapacitiesDokument20 SeitenArticulated Truck: Engine Weights Body CapacitiesArmando EscobarNoch keine Bewertungen

- Wa380 1 1994 (D1e)Dokument8 SeitenWa380 1 1994 (D1e)Plstina RamsNoch keine Bewertungen

- Hyundai Heavy Industries: Electric Counterbalance TrucksDokument12 SeitenHyundai Heavy Industries: Electric Counterbalance TrucksDragan PilipovićNoch keine Bewertungen

- E Series Wheel LoadersDokument8 SeitenE Series Wheel LoadersЖеня СавченкоNoch keine Bewertungen

- Hydraulic Direct Drives Offer Unbeatable Conveyor ProductivityDokument2 SeitenHydraulic Direct Drives Offer Unbeatable Conveyor ProductivityTamal Tanu RoyNoch keine Bewertungen

- Doosan Co ZaDokument20 SeitenDoosan Co ZaNatanNoch keine Bewertungen

- 44667779Dokument11 Seiten44667779enggtrainee2Noch keine Bewertungen

- Photo May Include Optional EquipmentDokument16 SeitenPhoto May Include Optional EquipmentHussein SayedNoch keine Bewertungen

- Motor Graders C Series Brochure 202106Dokument16 SeitenMotor Graders C Series Brochure 202106Heesler PerezNoch keine Bewertungen

- Downhill Belt Conveyors-The Starting and Speed Control ThereofDokument14 SeitenDownhill Belt Conveyors-The Starting and Speed Control ThereofKorosh ForoghanNoch keine Bewertungen

- CAT D6R2-Brochure PDFDokument24 SeitenCAT D6R2-Brochure PDFalvaro gavrielNoch keine Bewertungen

- LHD R1300G Cargador de Bajo Perfil CaterpillarDokument16 SeitenLHD R1300G Cargador de Bajo Perfil CaterpillarCesar Chu AcevedoNoch keine Bewertungen

- Cat 735Dokument20 SeitenCat 735Tiago AlvesNoch keine Bewertungen

- Underground Mining Loader: Engine Operating SpecificationsDokument20 SeitenUnderground Mining Loader: Engine Operating SpecificationsFabian MorquechoNoch keine Bewertungen

- Tren ScoopDokument16 SeitenTren ScoopHugoRamosMamaniNoch keine Bewertungen

- Ficha Tecnica Erp025-030vcDokument8 SeitenFicha Tecnica Erp025-030vcRAUL HERRERANoch keine Bewertungen

- Wheel Loader: 162 KW / 217 HP at 2.000 RPM (Straight / 37°) 14,5 / 12,3 Ton 3,0 MDokument16 SeitenWheel Loader: 162 KW / 217 HP at 2.000 RPM (Straight / 37°) 14,5 / 12,3 Ton 3,0 MBilal VURALNoch keine Bewertungen

- Mini-Load: Small Loads at Great HeightsDokument6 SeitenMini-Load: Small Loads at Great HeightsBülent KabadayiNoch keine Bewertungen

- pcr200 FurkawaDokument8 Seitenpcr200 FurkawaadheetteeaNoch keine Bewertungen

- Backhoe Loaders: 820 860 SX 860 Elite 970 Elite 880 SX 880 Elite 980 EliteDokument4 SeitenBackhoe Loaders: 820 860 SX 860 Elite 970 Elite 880 SX 880 Elite 980 EliteJuan Carranza LeonNoch keine Bewertungen

- Case 1221Dokument12 SeitenCase 1221Foromaquinas50% (2)

- WL 856H PDFDokument16 SeitenWL 856H PDFrusydi raushan fikriNoch keine Bewertungen

- Engine Power: SAE J1995, Gross 156 KW (212 HP) @ 2,100 RPM Operational Weight: 17,640 KG - STD. Bucket Capacity (SAE) : 2.7 3.3 M (3.3 4.3 Cu - Yd)Dokument9 SeitenEngine Power: SAE J1995, Gross 156 KW (212 HP) @ 2,100 RPM Operational Weight: 17,640 KG - STD. Bucket Capacity (SAE) : 2.7 3.3 M (3.3 4.3 Cu - Yd)Bhagoo HatheyNoch keine Bewertungen

- BH Ivony 302 4DDokument16 SeitenBH Ivony 302 4DElma MaranNoch keine Bewertungen

- Montacarga HYUNDAI 50D-9SA PDFDokument8 SeitenMontacarga HYUNDAI 50D-9SA PDFdanielaNoch keine Bewertungen

- Driveline Technologies Dana Technologies and Reduced Noise Vibration andDokument12 SeitenDriveline Technologies Dana Technologies and Reduced Noise Vibration andJitendra ItankarNoch keine Bewertungen

- Three-Wheel Electric Lift Trucks 3,000-4,000 LB CapacityDokument12 SeitenThree-Wheel Electric Lift Trucks 3,000-4,000 LB CapacityMocasa SA DE CVNoch keine Bewertungen

- TCM Fg20t5c-Fg30t5c Brochure 102020final1 EngDokument8 SeitenTCM Fg20t5c-Fg30t5c Brochure 102020final1 EngSamuel AndradeNoch keine Bewertungen

- 793F Specalog AEHQ6038Dokument28 Seiten793F Specalog AEHQ6038Belimar Costa0% (1)

- 740 Ejec - AEHQ5467 01 16pag - EngDokument16 Seiten740 Ejec - AEHQ5467 01 16pag - EngOrrazip OilujNoch keine Bewertungen

- Dl420a enDokument9 SeitenDl420a enBhagoo HatheyNoch keine Bewertungen

- Aehq6166 00Dokument28 SeitenAehq6166 00AlbertoNoch keine Bewertungen

- Cat 793 FDokument28 SeitenCat 793 F_ReVoLvR100% (1)

- Efficient and Economical Gearmotors as an AlternativeDokument4 SeitenEfficient and Economical Gearmotors as an AlternativeFelipeAndrésLondoñoGrandaNoch keine Bewertungen

- Active Brake Torque Vectoring in Differential UnitDokument4 SeitenActive Brake Torque Vectoring in Differential UnitLeo BoyNoch keine Bewertungen

- Design Report Car 30Dokument14 SeitenDesign Report Car 30PRANESH SHANKAR SNoch keine Bewertungen

- Conturbex: The Worm/screen CentrifugeDokument12 SeitenConturbex: The Worm/screen CentrifugeLeonan CaréliNoch keine Bewertungen

- Articulated Truck: Engine Weights Body CapacitiesDokument28 SeitenArticulated Truck: Engine Weights Body Capacitiesozeto03Noch keine Bewertungen

- Wheel Loader: Engine Gross Power Operating Weight Bucket CapacityDokument16 SeitenWheel Loader: Engine Gross Power Operating Weight Bucket CapacityAbo Achraf LaalawiNoch keine Bewertungen

- 785d Mining TrucksDokument24 Seiten785d Mining TrucksWynand Van ZylNoch keine Bewertungen

- Design and Fabrication of Chainless BicycleDokument4 SeitenDesign and Fabrication of Chainless BicycleGarish TerangNoch keine Bewertungen

- Volvo - G930C-G960C Product Brochure - Final1Dokument24 SeitenVolvo - G930C-G960C Product Brochure - Final1Jose MartinezNoch keine Bewertungen

- BAJA Design ReportDokument55 SeitenBAJA Design ReportGauravNoch keine Bewertungen

- CLT V dp100nm dp150nm Brochure EnglishDokument8 SeitenCLT V dp100nm dp150nm Brochure EnglishSreejith SureshNoch keine Bewertungen

- Crane Operation Brochure English - EsDokument24 SeitenCrane Operation Brochure English - EsClaudio RodriguesNoch keine Bewertungen

- Compact Wheeled Excavators: Product RangeDokument16 SeitenCompact Wheeled Excavators: Product RangemajastojkeNoch keine Bewertungen

- Articulated Trucks: 327B-330B-335B-340BDokument20 SeitenArticulated Trucks: 327B-330B-335B-340BRforceIbañezNoch keine Bewertungen

- Elphinstone-3900-Series-SpecalogDokument24 SeitenElphinstone-3900-Series-SpecalogMarkNoch keine Bewertungen

- Tire Survey Results HPDokument2 SeitenTire Survey Results HPbman0051401Noch keine Bewertungen

- Tire Survey Results WinterDokument2 SeitenTire Survey Results Winterbman0051401Noch keine Bewertungen

- Flatness Tolerances by Primary Material - Sheet & Plate ChartDokument1 SeiteFlatness Tolerances by Primary Material - Sheet & Plate Chartbman0051401Noch keine Bewertungen

- Directly Proportional and Inversely ProportionalDokument5 SeitenDirectly Proportional and Inversely Proportionalbman0051401Noch keine Bewertungen

- Tire MufflersDokument1 SeiteTire Mufflersbman0051401Noch keine Bewertungen

- Seismic Sway Brace System Data SheetDokument4 SeitenSeismic Sway Brace System Data Sheetbman0051401Noch keine Bewertungen

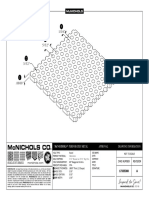

- The Information Provided Below Is Your Guide For Choosing The Right PERFORATED METAL Product For Your Project. Please SpecifyDokument1 SeiteThe Information Provided Below Is Your Guide For Choosing The Right PERFORATED METAL Product For Your Project. Please Specifybman0051401Noch keine Bewertungen

- Tire Survey Results Touring AsDokument2 SeitenTire Survey Results Touring Asbman0051401Noch keine Bewertungen

- Tire Survey Results Passenger AsDokument2 SeitenTire Survey Results Passenger Asbman0051401Noch keine Bewertungen

- Mcnichols Perforated Metal: Drawing Information ApprovalDokument1 SeiteMcnichols Perforated Metal: Drawing Information Approvalbman0051401Noch keine Bewertungen

- Format Text As Superscript or Subscript - Office SupportDokument4 SeitenFormat Text As Superscript or Subscript - Office Supportbman0051401Noch keine Bewertungen

- Replacing With A Subscript (Microsoft Word)Dokument1 SeiteReplacing With A Subscript (Microsoft Word)bman0051401Noch keine Bewertungen

- Wbi & WBD: Mason Industries, IncDokument2 SeitenWbi & WBD: Mason Industries, Incbman0051401Noch keine Bewertungen

- Manufacturers of Vibration Control Products and Pipe Accessories Data SheetDokument2 SeitenManufacturers of Vibration Control Products and Pipe Accessories Data Sheetbman0051401Noch keine Bewertungen

- ss-28-4 WebDokument4 Seitenss-28-4 Webbman0051401Noch keine Bewertungen

- Mason-Mercer: Test Data Stainless Steel & Bronze VeesDokument8 SeitenMason-Mercer: Test Data Stainless Steel & Bronze Veesbman0051401Noch keine Bewertungen

- Mason-Mercer: Stock Ball JointsDokument4 SeitenMason-Mercer: Stock Ball Jointsbman0051401Noch keine Bewertungen

- Hanger Soportes - Mason IndustriesDokument16 SeitenHanger Soportes - Mason IndustriesolivaresjhonNoch keine Bewertungen

- Mason Industries, Inc.: Full Vacuum Rating - 30" HGDokument1 SeiteMason Industries, Inc.: Full Vacuum Rating - 30" HGbman0051401Noch keine Bewertungen

- Ficha Tecnica SW 16 3Dokument2 SeitenFicha Tecnica SW 16 3Mauricio TiusabáNoch keine Bewertungen

- Data MaterialsDokument40 SeitenData Materialsjeff_56Noch keine Bewertungen

- Vibration Pads: Mason Industries, IncDokument2 SeitenVibration Pads: Mason Industries, Incbman0051401Noch keine Bewertungen

- Shear On Urethane RubberDokument4 SeitenShear On Urethane Rubberbman0051401Noch keine Bewertungen

- Supporting Shallow Foundation Systems When Subjected To Lateral LoadsDokument12 SeitenSupporting Shallow Foundation Systems When Subjected To Lateral Loadsbman0051401Noch keine Bewertungen

- Dixie Ratchet Turnbuckles: When You Need The BestDokument6 SeitenDixie Ratchet Turnbuckles: When You Need The Bestbman0051401Noch keine Bewertungen

- Shape Factor & Modulus of Elasticity Urethane RubberDokument6 SeitenShape Factor & Modulus of Elasticity Urethane Rubberbman0051401Noch keine Bewertungen

- EPDM Properties Unreinforced General Information Designation Ethylene - Course HeroDokument2 SeitenEPDM Properties Unreinforced General Information Designation Ethylene - Course Herobman0051401Noch keine Bewertungen

- Resilience and Durability - RubberDokument3 SeitenResilience and Durability - Rubberbman0051401Noch keine Bewertungen

- Urethane Compared With Natural & Synthetic RubbersDokument3 SeitenUrethane Compared With Natural & Synthetic Rubbersbman0051401Noch keine Bewertungen

- Wear Resistant and Lubricated Rubber CompoundsDokument3 SeitenWear Resistant and Lubricated Rubber Compoundsbman0051401Noch keine Bewertungen

- Manual R3060 Gii Eng LRDokument20 SeitenManual R3060 Gii Eng LRFabiano100% (1)

- De 6th SemDokument39 SeitenDe 6th SemJay NaikNoch keine Bewertungen

- d13h 440 EngineDokument69 Seitend13h 440 EngineSherzad Chem80% (5)

- Ficha Tecnica de RetroexcavadoraDokument4 SeitenFicha Tecnica de RetroexcavadoraKelly Ruth Blacido FernandezNoch keine Bewertungen

- Kubota Engine SpecsDokument84 SeitenKubota Engine Specsjmbcp96100% (1)

- A Comparative Study of Brand Preference of TVS Motors & Bajaj MotorsDokument75 SeitenA Comparative Study of Brand Preference of TVS Motors & Bajaj MotorsRamesh SunejaNoch keine Bewertungen

- V. Babu (Author) - Fundamentals of Engineering Thermodynamics-CRC Press (2019)Dokument440 SeitenV. Babu (Author) - Fundamentals of Engineering Thermodynamics-CRC Press (2019)Sushanth ShenoyNoch keine Bewertungen

- OTIS Planning Guide 2012 PDF Low PDFDokument50 SeitenOTIS Planning Guide 2012 PDF Low PDFAvinash Pathania100% (2)

- (David Crolla - Behrooz Mashadi) Vehicle Powertrain Systems-Integration and Optimization - Solution ManualDokument256 Seiten(David Crolla - Behrooz Mashadi) Vehicle Powertrain Systems-Integration and Optimization - Solution Manualsadegh_199067% (3)

- Engine Service Training (DP222CA, DP222CB, DP222CC)Dokument70 SeitenEngine Service Training (DP222CA, DP222CB, DP222CC)Quang PhamNoch keine Bewertungen

- Training Book - 950 LoadersDokument248 SeitenTraining Book - 950 LoadersSandeep Nikhil100% (3)

- NH L218 - Maintenance ChartDokument2 SeitenNH L218 - Maintenance ChartKristomiDerMarine-IngenieurNoch keine Bewertungen

- 320 KVA To 625 KVADokument8 Seiten320 KVA To 625 KVAganesh318Noch keine Bewertungen

- Engine and Transaxle Configuration DiagramsDokument24 SeitenEngine and Transaxle Configuration DiagramsSaHdo AbdelHamid100% (1)

- Fusibles Jetta 2001 2.0LDokument21 SeitenFusibles Jetta 2001 2.0LLuis Angel BarajasNoch keine Bewertungen

- 1939-1 - 1472Dokument1 Seite1939-1 - 1472seafire47Noch keine Bewertungen

- Machine For Industrial Applications: Operating Weight: 78,700 - 83,334 LB Engine Output: 204 HP / 150 KWDokument20 SeitenMachine For Industrial Applications: Operating Weight: 78,700 - 83,334 LB Engine Output: 204 HP / 150 KWLiebherr100% (3)

- Airbus A320 Eng OilDokument13 SeitenAirbus A320 Eng OilPanagiotis Diakidis100% (2)

- How VNT turbochargers optimize engine power and efficiencyDokument3 SeitenHow VNT turbochargers optimize engine power and efficiencymebarki aberraoufNoch keine Bewertungen

- Introduction To Urban Water Distribution Nemanja Trifunovic-18-37Dokument20 SeitenIntroduction To Urban Water Distribution Nemanja Trifunovic-18-37Ngurah BuanaNoch keine Bewertungen

- Honda HRA214 User ManualDokument41 SeitenHonda HRA214 User ManualhighlandsguyNoch keine Bewertungen

- AL31-FP Engine & Pneumatic Cylinder Project HAL PDFDokument39 SeitenAL31-FP Engine & Pneumatic Cylinder Project HAL PDFGuddu100% (5)

- Power Plant Familiarisation V III+ AllfreesharezDokument283 SeitenPower Plant Familiarisation V III+ AllfreesharezGanesh Dasara100% (1)

- Instruction ManualDokument56 SeitenInstruction ManualAdi Surya100% (1)

- Volvo Trucks Parts Catalog 2015Dokument412 SeitenVolvo Trucks Parts Catalog 2015HorváthVargaLászlóNoch keine Bewertungen

- Hybrid EvDokument24 SeitenHybrid Ev231 Harshit SainiNoch keine Bewertungen

- Mechanism AtlasDokument14 SeitenMechanism AtlasEdward Calderón100% (2)

- Excavator Inspection ChecklistDokument1 SeiteExcavator Inspection ChecklistArsalan Ahmad100% (2)

- 01 - Utility Consumption PDFDokument6 Seiten01 - Utility Consumption PDFVinod Varadan SNoch keine Bewertungen

- Yanmar ViO57U BrochureDokument12 SeitenYanmar ViO57U BrochureLuka BornaNoch keine Bewertungen

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Guidelines for Implementing Process Safety ManagementVon EverandGuidelines for Implementing Process Safety ManagementNoch keine Bewertungen

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisVon EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsVon EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsBewertung: 4 von 5 Sternen4/5 (11)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeVon EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNoch keine Bewertungen

- A Complete Guide to Safety Officer Interview Questions and AnswersVon EverandA Complete Guide to Safety Officer Interview Questions and AnswersBewertung: 4 von 5 Sternen4/5 (1)

- Guidelines for Auditing Process Safety Management SystemsVon EverandGuidelines for Auditing Process Safety Management SystemsNoch keine Bewertungen

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesVon EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesBewertung: 5 von 5 Sternen5/5 (1)

- Introduction to Petroleum Process SafetyVon EverandIntroduction to Petroleum Process SafetyBewertung: 3 von 5 Sternen3/5 (2)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationVon EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNoch keine Bewertungen

- Inherently Safer Chemical Processes: A Life Cycle ApproachVon EverandInherently Safer Chemical Processes: A Life Cycle ApproachBewertung: 5 von 5 Sternen5/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersVon EverandRules of Thumb for Maintenance and Reliability EngineersBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Incidents That Define Process SafetyVon EverandIncidents That Define Process SafetyNoch keine Bewertungen

- Safety Fundamentals and Best Practices in Construction IndustryVon EverandSafety Fundamentals and Best Practices in Construction IndustryNoch keine Bewertungen

- Radium Girls: Women and Industrial Health Reform, 1910-1935Von EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Bewertung: 4.5 von 5 Sternen4.5/5 (4)

- Chemical Process Safety: Learning from Case HistoriesVon EverandChemical Process Safety: Learning from Case HistoriesBewertung: 4 von 5 Sternen4/5 (14)

- LNG Risk Based Safety: Modeling and Consequence AnalysisVon EverandLNG Risk Based Safety: Modeling and Consequence AnalysisNoch keine Bewertungen

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemVon EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNoch keine Bewertungen

- Nobody Cares: The Story of the World from SafetymanVon EverandNobody Cares: The Story of the World from SafetymanNoch keine Bewertungen

- Exercise, Sport, and Bioanalytical Chemistry: Principles and PracticeVon EverandExercise, Sport, and Bioanalytical Chemistry: Principles and PracticeNoch keine Bewertungen

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionVon Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotNoch keine Bewertungen

- One Health: Integrated Approach to 21st Century Challenges to HealthVon EverandOne Health: Integrated Approach to 21st Century Challenges to HealthJoana C. PrataNoch keine Bewertungen

- Autophagy in Health and DiseaseVon EverandAutophagy in Health and DiseaseBeverly RothermelNoch keine Bewertungen

- The Single Cure: Human Life Extension to 300+ YearsVon EverandThe Single Cure: Human Life Extension to 300+ YearsNoch keine Bewertungen

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceVon EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceBewertung: 5 von 5 Sternen5/5 (1)

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaVon EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNoch keine Bewertungen

- Fire in the Night: The Piper Alpha DisasterVon EverandFire in the Night: The Piper Alpha DisasterBewertung: 4.5 von 5 Sternen4.5/5 (5)