Beruflich Dokumente

Kultur Dokumente

Solution of Transient 2D Heat Conduction Problem Using Freefem++

Hochgeladen von

Chicca PantanoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Solution of Transient 2D Heat Conduction Problem Using Freefem++

Hochgeladen von

Chicca PantanoCopyright:

Verfügbare Formate

1

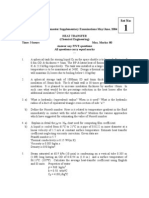

LAB #13

Solution of transient 2D heat conduction problem using FreeFem++

1) Consider a bar (square cross section with edge length L = 1 m, infinite height), initially at

T0 = 100oC. At t > 0 three edges are placed in (perfect) contact with a thermal capacity at

Tc = 200oC, while the remaining edge is adiabatic.

Compute the temperature evolution in the bar cross section (reducing as much as

possible the computational domain taking advantage of the symmetry of the

problem), assuming a thermal diffusivity α = 0.01 m2/s (ρ = 7000 kg/m3, cp (specific

heat capacity) = 1.5 J/kg/K).

Check the grid independence of the solution with time discretization t = 1 s, and

plot the evolution of the temperature in the middle of the insulated edge.

When the new steady state is reached, the insulation is removed from the adiabatic

edge, and it gets cooled by a fluid at a temperature Tf = 100oC with a heat transfer

coefficient h = 10 W/m2/K. Compute the new temperature evolution in the bar cross

section, until a new steady-state is reached.

Save your plots in files to be named ES1_yoursurname_plot#.properextension

2) Consider a metal cube (edge length L = 1 m, ρ = 7800 kg/m3, cp = 1 kJ/kg/K), initially at T0

= 100oC. The cube is removed from an oven and placed in air at Ta = 30oC. The heat transfer

coefficient with the air is h = 10 W/m2/K. Compute the temperature evolution in the center

of the cube and in the corner, 1 cm below the surface (0.49 m, 0.49 m), see Fig. 1, for the

two cases: Bi (Biot number) = 0.005 and Bi = 5.34, assuming the problem is 2D. Stop the

transient when the temperature in the cube center is smaller than 98oC.

Save your plots in files to be named ES2_yoursurname_plot#.properextension.

Figure 1

3) A rod 20 mm in diameter and 40 mm in length is fabricated from alumina (k = 1 W/m/K, ρ

= 1500 kg/m3, cp = 500 J/kg/K) and is initially at a uniform temperature T0 = 850oC. The

rod is suddenly exposed to a fluid at Tf = 350 K with h = 500 W/m2/K. Compute the

centerline temperature evolution of the rod at an exposed end and at an axial distance of 6

mm from the end (reduce as much as possible the computational domain taking advantage

of the symmetry of the problem).

Save your plots in files to be named ES7_yoursurname_plot#.properextension.

4) The cross section of a copper cable for the combined transport of electrical current and

hydrogen is shown in Fig. 2. During normal operation the cable carries a current Iop and in

ICHT – Lab #13

2

the hole gaseous hydrogen flowing at TH cools the copper with a heat transfer coefficient

hin. The conductor (in grey in Fig. 2) is heated by the joule losses that induce volumetric

heat generation. The external surface of the conductor experiences convection with

stagnant ambient air (T=Ta, h=hext).

One of the most dangerous accidents foreseen for this system is the failure of the hydrogen

pumps. In that case, the cooling from the hydrogen flow is lost and the conductor starts to

heat up.

– Write a script that computes the 2D temperature evolution on the cable cross

section during this transient, starting from normal operating conditions and

removing at time t0 = 0 s the cooling from hydrogen flow: consider adiabatic the

wall cooled by hydrogen, while only the air cooling will remain active. Stop the

analysis when the maximum allowed temperature Tmax for the conductor is reached.

Reduce as much as possible the computational domain. Save the script in the file

EX2_yoursurname.properextension.

– Plot the initial and final temperature distributions in the 2D cross section. Save the

plots in two files named EX2_yoursurname_initial.properextension and

EX2_yoursurname_final.properextension.

DATA:

Iop = 20 kA

TH = 273 K

Ta = 300 K

hin = 500 W/m2/K

hext = 25 W/m2/K

Tmax = 1100 K

Cu density = 8900 kg/m3

Cu cp = 350 J/kg/K

Cu thermal conductivity = 150 W/m/K

Cu electrical resistivity = 20 nΩ×m

Figure 2.

5) In ITER, Inconel 718 bolts are used to attach to the Vacuum Vessel the Blanket Modules

directly facing the plasma. A 3D view of one of these bolts is shown in Fig. 3a, while its

cross section is reported in Fig. 3b. During plasma burn, the top (round) surface of the bolt

experiences a surface heat flux qs, while the whole bolt bulky structure experiments a

volumetric heating qv depending on the axial coordinate (y in Fig. 3) according to:

450 y

qv 1

2 0.17

where qv is in kW/m3 and y is in m. The two edges indicated in Fig. 3b (edges AB and CD)

are always kept at T = T0.

During pulsed plasma operation both the surface and volume heat loads on the bolt vary

according to the shape reported in Fig. 4. The pulses are periodic with period = 1800 s.

– Write a script that computes the 2D temperature evolution on the bolt cross section,

reducing as much as possible the computational domain. Discretize the

computational domain using a mesh having an average element size δAave smaller

than 10-7 m2. Save the script in the file ES3_yoursurname.properextension.

– Plot the evolution of the maximum temperature in the 2D cross section during 3

subsequent pulses (initial temperature before the first pulse = T0). Save the plot in a

file named ES3_yoursurname_plot1.properextension.

ICHT – Lab #13

3

– Plot the temperature map in the bolt at t = 400s during the third pulse. Save the plot

in a file named ES3_yoursurname_plot2.properextension.

DATA:

T0 = 343 K

qs = 5 kW/m2

density = 8200 kg/m3

cp = 450 J/kg/K

thermal conductivity = 12 W/m/K

A B C

D

Figure 3. (a) 3D view and (b) cross section of the bolt described in exercise 3. In (b) dimensions and

boundary conditions are also shown.

Figure 4. Time profile of the heat load application in exercise 4.

6) A square aluminum rod (side L = 50 cm, infinite length), is separated from a half copper

rod by a thin layer of insulation material (thickness δ = 1 cm), see the figure below. The

two rods, initially at T0 = 300 K, are cooled by a fluid at Tf = 300 K. At time t = 0 s a current

IAl = 700 kA starts flowing inside the aluminum rod while at time t = 200 s a current ICu =

ICHT – Lab #13

4

400 kA starts flowing inside the copper rod until time t = 350 s, when both the currents are

switched off and the system evolves to steady-state. Write a FreeFEM++ script (to be saved

in a single file named EX6_yoursurname.edp) that:

– Computes the 2D temperature evolution on the cross section of the system composed

by the two rods and the insulation (reducing as much as possible the computational

domain).

– Checks the time convergence of the scheme adopted.

– Plots the 2D temperature distribution at time t = 350 s and save the plot as

EX6_yoursurname_2Dplot.properextension.

– Evaluates the evolution of the maximum temperature inside each rod in three cases:

1. Heat transfer coefficient with the fluid h1 = 50 W/m2/K.

2. Heat transfer coefficient with the fluid h2 = 1 kW/m2/K.

3. Heat transfer coefficient with the fluid h3 = 10 kW/m2/K.

Material properties Al Cu Ins

Thermal conductivity

250 380 0.1

k (W/m/K)

Density ρ (kg/m3) 2700 8920 2500

cp (J/kg/K) 890 390 1800

Electrical resistivity

2.82e-8 1.68e-8 0

ρel (Ωm)

ICHT – Lab #13

Das könnte Ihnen auch gefallen

- Assignment 1Dokument7 SeitenAssignment 1AdarshpatankarNoch keine Bewertungen

- CHG 2314 Heat Transfer Operations Winter 2012: Assignment 3Dokument3 SeitenCHG 2314 Heat Transfer Operations Winter 2012: Assignment 3Clinton OkereNoch keine Bewertungen

- Donnee Exo SupplDokument5 SeitenDonnee Exo SupplMohamud LhafNoch keine Bewertungen

- NR 310803 Heat TransferDokument8 SeitenNR 310803 Heat TransferSrinivasa Rao GNoch keine Bewertungen

- Ejercicios TransferenciaDokument5 SeitenEjercicios TransferenciaPablo RuizNoch keine Bewertungen

- CHE 210 Midterm Exam SolutionsDokument11 SeitenCHE 210 Midterm Exam SolutionsJaspreet SandhuNoch keine Bewertungen

- 3.044 Problem Set 1: Heat Conduction Due Monday February 14, 2005Dokument3 Seiten3.044 Problem Set 1: Heat Conduction Due Monday February 14, 2005Carlos CastilloNoch keine Bewertungen

- Tutorial 1-13 PDFDokument27 SeitenTutorial 1-13 PDFPavanNoch keine Bewertungen

- Mech302-Heat Transfer Homework-7 SolutionsDokument8 SeitenMech302-Heat Transfer Homework-7 SolutionsJake OkuyeNoch keine Bewertungen

- ConductionDokument4 SeitenConductionjaibalayyaNoch keine Bewertungen

- Heat Transfer Nov2004 NR RR 310803Dokument8 SeitenHeat Transfer Nov2004 NR RR 310803Nizam Institute of Engineering and Technology LibraryNoch keine Bewertungen

- Chn-201 Tutorial 2 - Autumn 16-17-1Dokument2 SeitenChn-201 Tutorial 2 - Autumn 16-17-1Prashant RajNoch keine Bewertungen

- Heat Transfer Tutorial Conduction ConvectionDokument2 SeitenHeat Transfer Tutorial Conduction Convectionpushkal0% (2)

- HT Student Notes-Part1Dokument72 SeitenHT Student Notes-Part1Arvind Rebel75% (4)

- Tutorial 2-1Dokument4 SeitenTutorial 2-1chandan rajNoch keine Bewertungen

- Tutorial SheetDokument5 SeitenTutorial Sheetpradeep.kumarNoch keine Bewertungen

- Heat and Mass Transfer AssignmentDokument7 SeitenHeat and Mass Transfer AssignmentAnkit SharmaNoch keine Bewertungen

- We M5Dokument14 SeitenWe M5knyogishNoch keine Bewertungen

- Assignment 5-A22Dokument5 SeitenAssignment 5-A22viky kavaNoch keine Bewertungen

- Heat and Mass Transfer Practice Questions 1Dokument2 SeitenHeat and Mass Transfer Practice Questions 1Lucky 230503Noch keine Bewertungen

- Heat Transfer May2004 NR 310803Dokument8 SeitenHeat Transfer May2004 NR 310803Nizam Institute of Engineering and Technology LibraryNoch keine Bewertungen

- Files-5-Exams Quizzes Examples Problems Me315Dokument44 SeitenFiles-5-Exams Quizzes Examples Problems Me315TortelliniTimNoch keine Bewertungen

- Files-5-Exams Quizzes Examples Problems Me315Dokument44 SeitenFiles-5-Exams Quizzes Examples Problems Me315AndrestorpNoch keine Bewertungen

- 16.050 Thermal Energy: Problem Set #8 - Fall 2002Dokument4 Seiten16.050 Thermal Energy: Problem Set #8 - Fall 2002abbani1959Noch keine Bewertungen

- Tutorial 1Dokument2 SeitenTutorial 1David Ng Qing KaiNoch keine Bewertungen

- Tutorial 2Dokument0 SeitenTutorial 2xhotdogzxNoch keine Bewertungen

- HMT 7th Sem NIT Raipur QPaperDokument28 SeitenHMT 7th Sem NIT Raipur QPaperShashi Bhushan PatelNoch keine Bewertungen

- 4363 112 Heat TransferDokument6 Seiten4363 112 Heat Transferyogesh_b_kNoch keine Bewertungen

- Mech302hw3s PDFDokument7 SeitenMech302hw3s PDFSUMANTNoch keine Bewertungen

- MIN-305 Heat & Mass Transfer Tutorial - 3Dokument3 SeitenMIN-305 Heat & Mass Transfer Tutorial - 3Ayush JaiswalNoch keine Bewertungen

- Heat and Mass Transfer (MCC 15102) Assignmnet - 1: A F B C D EDokument4 SeitenHeat and Mass Transfer (MCC 15102) Assignmnet - 1: A F B C D ERotten AppleNoch keine Bewertungen

- C and RDokument7 SeitenC and Rinba oli50% (2)

- Example 2-Heat ConductionDokument4 SeitenExample 2-Heat Conductionqusai almshaqbehNoch keine Bewertungen

- Heat Transfer (HT) QueDokument6 SeitenHeat Transfer (HT) QueAshutosh KushwanshiNoch keine Bewertungen

- MEHB323 Tutorial Assignment 2Dokument3 SeitenMEHB323 Tutorial Assignment 2Amzar Aizad100% (1)

- MAE 4171: Principles of Heat Transfer Solution-Assignment #1Dokument4 SeitenMAE 4171: Principles of Heat Transfer Solution-Assignment #1Bo100% (5)

- Seminar 2 Transport PhenomenaDokument9 SeitenSeminar 2 Transport PhenomenaAlexandraNoch keine Bewertungen

- Tutorial 3Dokument1 SeiteTutorial 3Lavjit JainNoch keine Bewertungen

- Temperature Distributions in Solids and in Laminar FlowDokument4 SeitenTemperature Distributions in Solids and in Laminar FlowSambasiva Rao KaturiNoch keine Bewertungen

- Chapter 3 Heat Trasnfer 4001Dokument45 SeitenChapter 3 Heat Trasnfer 4001Maria Camila De la RosaNoch keine Bewertungen

- End-Semester Question PaperDokument4 SeitenEnd-Semester Question PaperRabey The physicistNoch keine Bewertungen

- Updated ProblemsDokument3 SeitenUpdated Problemsmahmoud koriemNoch keine Bewertungen

- Figure 1 Schematic of A Hair DryerDokument2 SeitenFigure 1 Schematic of A Hair DryerIcy45Noch keine Bewertungen

- HT TUT2 SolutionDokument9 SeitenHT TUT2 SolutionAsim UstadNoch keine Bewertungen

- Tugas Perpindahan PanasDokument7 SeitenTugas Perpindahan PanasAnonymous DpmprYqkuNoch keine Bewertungen

- 4.tutorial HMTDokument5 Seiten4.tutorial HMTdearsaswatNoch keine Bewertungen

- T.E. (Mechanical) (Semester - I) Examination, 2011 Heat Transfer (2008 Pattern) (New)Dokument4 SeitenT.E. (Mechanical) (Semester - I) Examination, 2011 Heat Transfer (2008 Pattern) (New)saurabhNoch keine Bewertungen

- Me52102 - HMT Sheet - I Conduction Jul-Dec'23Dokument3 SeitenMe52102 - HMT Sheet - I Conduction Jul-Dec'23HarshNoch keine Bewertungen

- Sheet 1Dokument10 SeitenSheet 1محمود بسيوني نصارNoch keine Bewertungen

- Heat and Mass Transfer ProblemsDokument3 SeitenHeat and Mass Transfer ProblemsRiyasNoch keine Bewertungen

- HEAT TRANSFER - Chapter 2Dokument2 SeitenHEAT TRANSFER - Chapter 2ghostlenyNoch keine Bewertungen

- Heat Transfer Document AnalysisDokument8 SeitenHeat Transfer Document Analysisbhaskar5377Noch keine Bewertungen

- Ex. No 1) Thermal Conductivity of Metal RodDokument8 SeitenEx. No 1) Thermal Conductivity of Metal RodGaurav Sonawane0% (1)

- Physical Electronics: Handbook of Vacuum PhysicsVon EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckNoch keine Bewertungen

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Von EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Noch keine Bewertungen

- Topics1 12chem230Dokument450 SeitenTopics1 12chem230MelissaNoch keine Bewertungen

- Effects of Weather Systems in The PhilippinesDokument19 SeitenEffects of Weather Systems in The PhilippinesCaloykOoy Danday Dueñas100% (1)

- Activity 9.1: OIL Eeming With IFEDokument16 SeitenActivity 9.1: OIL Eeming With IFEAlisha ChopraNoch keine Bewertungen

- Planetary Atmospheric ElectricityDokument521 SeitenPlanetary Atmospheric ElectricityArmando Heilmann100% (1)

- Thermal KineticsDokument37 SeitenThermal KineticsgowthamiNoch keine Bewertungen

- Physics NET/JRF Practice QuestionsDokument44 SeitenPhysics NET/JRF Practice QuestionsSibadatta MaharanaNoch keine Bewertungen

- Petroleum Systems of South Atlantic Marginal BasinsDokument13 SeitenPetroleum Systems of South Atlantic Marginal Basinszulma_anayaNoch keine Bewertungen

- Fire Safety 5Dokument22 SeitenFire Safety 5Lino CornejaNoch keine Bewertungen

- Poultry Meal MSDSDokument7 SeitenPoultry Meal MSDSyousria.ahmed46Noch keine Bewertungen

- Topic:-Structuree of Atom Made By: - Nikunj Agarwal 1XDDokument16 SeitenTopic:-Structuree of Atom Made By: - Nikunj Agarwal 1XDUday GuptaNoch keine Bewertungen

- 1 s2.0 S0001868613001140 Main PDFDokument11 Seiten1 s2.0 S0001868613001140 Main PDFBEN DUNCAN MALAGA ESPICHANNoch keine Bewertungen

- Fundamental Chemistry ConceptsDokument99 SeitenFundamental Chemistry ConceptsMazar KhanNoch keine Bewertungen

- Environmental Aspects and Impacts Assessment Guide: PTS 60.3202 June 2006Dokument34 SeitenEnvironmental Aspects and Impacts Assessment Guide: PTS 60.3202 June 2006enviroNoch keine Bewertungen

- Soulbio 4D MSDSDokument6 SeitenSoulbio 4D MSDSMinal HadiNoch keine Bewertungen

- Wood Wide WebDokument6 SeitenWood Wide WebGurleen Hora100% (1)

- Ocean's Impact On Climate Activity Worksheet: Part OneDokument3 SeitenOcean's Impact On Climate Activity Worksheet: Part OneAaron CoxNoch keine Bewertungen

- Ev02007 4601 FRPDokument199 SeitenEv02007 4601 FRPVincent UlleroNoch keine Bewertungen

- Unit 5 SustainabilityDokument9 SeitenUnit 5 SustainabilityLaura PonsNoch keine Bewertungen

- Chap 3 BDokument32 SeitenChap 3 BMike BelayNoch keine Bewertungen

- EMS Brochure by SchneiderDokument4 SeitenEMS Brochure by SchneiderPratik SarkarNoch keine Bewertungen

- ME 395 2015 Solutions #4Dokument2 SeitenME 395 2015 Solutions #4me395Noch keine Bewertungen

- General Physics 1 - Course OutlineDokument2 SeitenGeneral Physics 1 - Course OutlineFeliph Angelo Sinfuego CalunodNoch keine Bewertungen

- Freezing and Refrigerated Storage in Fisheries - 8. Calculation of Cold Store Refrigeraion Load PDFDokument3 SeitenFreezing and Refrigerated Storage in Fisheries - 8. Calculation of Cold Store Refrigeraion Load PDFPrateekNoch keine Bewertungen

- Tài Liệu Livestream: A. B. C. DDokument3 SeitenTài Liệu Livestream: A. B. C. Dphananhthu1301Noch keine Bewertungen

- r050210801 Fluid Mechanics For Chemical EngineeringDokument7 Seitenr050210801 Fluid Mechanics For Chemical EngineeringSrinivasa Rao GNoch keine Bewertungen

- M3 - Refrigeration CycleDokument133 SeitenM3 - Refrigeration CycleKrishna KumarNoch keine Bewertungen

- Project SynopsisDokument6 SeitenProject Synopsislive userNoch keine Bewertungen

- Numerical Predictions of The Rollover Phenomenon Using CFDDokument7 SeitenNumerical Predictions of The Rollover Phenomenon Using CFDThefairman UnkownNoch keine Bewertungen

- Group 1 ELS FIDPDokument16 SeitenGroup 1 ELS FIDPjayson babaran100% (1)

- 9th Class Chemistry Notes.Dokument3 Seiten9th Class Chemistry Notes.Faheem RajpootNoch keine Bewertungen