Beruflich Dokumente

Kultur Dokumente

Float Tape Level Gauges 1 PDF

Hochgeladen von

pippalla aswiniOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Float Tape Level Gauges 1 PDF

Hochgeladen von

pippalla aswiniCopyright:

Verfügbare Formate

Float & Tape Level Gauges

Features

n Float and tape gauge are applicable for upto 50 bar pressure and upto 400 deg cent

n NACE, H2S service compatibility applicable

n Applicable for refinery, petrochemical, chemical, power, radioactive, fertilizer, food,

pharma, metal industry applications

n Options with switch version available

Float and tape Type level Indicator is the version applicable for level

indication system in Water, Furnace oil, Chemicals, Acids storage tank level

measurement.

Available in two types:

n Guided Type

n Unguided Type

Tank Gauge Installation:

Float and tape gauging is suitable for almost all product It is an economical mechanical gauge provides high accuracy in

applications and tank types mm. Largely used in Refineries, Oil Depots, Chemical and Fertilizer

n Accuracy ±2 mm with 400 mm Industries. Useful for medium and large size charged or empty tanks.

n diameter float It may be cone roof, floating roof, underground or gas holding tank.

n Least Count 1 mm It covers critical applications like corrosive & aggressive acids (using

n Measuring range 0 to 20 meters non-metallic wetted parts) & liquids with fumes (using vapor seal).

n with dial / counter (Optional: 0 to 30 meters with counter) Less Maintenance:

n Suitable for for upto 50 kg/cm2 pressure Once carefully installed gives trouble free operations for a number of

n Suitable for upto 400 deg cent temperature years (with periodic maintenance). A specially designed cylindrical

n Dial size max upto 500mm and other on special accuracy body floats on liquid surface on account of its buoyancy. The liquid

and demand level is transmitted by means of a tape connected to float on one side

and gear mechanism on the other side. Gears rotate the pointer on

a dial or counter mechanism to display readings. A drum and spring

mechanism provides constant tension on tape to keep it straight and

thus balancing the force due to apparent float weight on one side and

spring tension on other side.

Float Guide wires:

Guide wires provide stability for the float during turbulent conditions

and increased accuracy by reducing the horizontal movement of the

float across the surface of the product. Accessories are available to

allow in-service installations, such as weighted anchors that maintain

tension in the guide wires without the need for welding inside the tank.

10/17 REV.: 00

www.generalinstruments.co.in 346 www.general-gauges.com

Float & Tape Level Gauges

Technical Specifications:

Type of Gauge Guided type ------- FBI/G

Unguided type ------ FBI/U

Mounting Top

Pressure Upto 50 kg/cm2

Temperature Upto 400C

Measuring range Max. upto 25000mm

Accuracy 1%

MOC Of Float SS316, SS316L, PP, PTFE, Monel, Titanium, Alloy 20

MOC Of Wire (Float & Guide) SS316, SS316L, SS304L, PTFE

MOC Of Flange SS316, SS316L, PP, PTFE, Monel, Titanium, Alloy 20, PVDF

Dial Counter 150mm up to 500mm

MOC Of Dial Counter Die cast aluminium with anticorrosion powder coat

Dial Enclosure IP 65

Dial Counter holder SS316, GI, A106, SS316L

Anchor plate for Guide & Float Wire SS304, A106, SS316, SS316L, SS304L, Monel, hastelloy, Alloy 20

Process Connection Flanged

Special Materials Product Type

Standard, moderate, severe and extreme service kits are available for Due to the float and tape measurement technique, the following are

applications involving extreme temperatures, pressures or just some of the products suitable for level measurement using a float

aggressive products. There kits include material options for specific and tape device:

parts that make contact with the product in the tank, tape piping or n Crudes

gauge head, such as: n Gasoline

n Steel n Jet fuel

n Aluminium n AV (Aviation) gas - high octane gas for small aircraft

n Stainless steel n Diesel

n Chemicals

n Additives

n Solvents

n Water

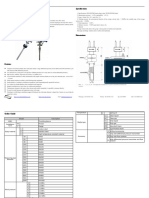

G A Drawing Applicable

Indicator system with scale board for long distance viewing and metric dial counter for ground reading purpose

See Enlarged View 'A' 01 Guide Wire

485±5

02 Float

06 03 Guide Rope Tension Assembly

05

04 Float Rope

07 03

05 Protection Limb

TANK TOP 06 Pulleys

07 Flange

08 Anchor Plate

09 Scale Board

01 10 Pointer

1250MM APPRX

04

02 175±5

150±5

08

Guide/ Measuring

Nozzle Arrangement

450

Enlarged View A

10/17 REV.: 00

TANK BOTTOM

www.generalinstruments.co.in 347 www.general-gauges.com

Ordering Information

FTLG GT-XD-WQ-F01-ZA-XX-Z

Type Range

GT Guided Type XX Please Specify

UT Unguided Type Z NIL

MOC of Float MOC of Connection

XD SS316 ZA CS (A105)

XE SS316L ZB CS (A106)

XF PP ZC SS 304

XH Monel 500 ZD SS 304L

XI Titanium ZE SS 316

XK Hastelloy C ZF SS 316L

MOC of Wire

WQ SS304

WR SS304L

WS SS316

WT SS316L

WU PP

Process Connection

Flanged Connection

F01 1/2", 150# RF

F02 3/4", 150# RF

F03 1", 150# RF

F04 1.5", 150# RF

F05 2", 150# RF

F09 1/2", 300# RF

F10 3/4", 300# RF

F11 1", 300# RF

F12 1.5", 300# RF

F13 2", 300# RF

10/17 REV.: 00

www.generalinstruments.co.in 348 www.general-gauges.com

Das könnte Ihnen auch gefallen

- Float & Tape Level Gauges: FeaturesDokument3 SeitenFloat & Tape Level Gauges: Featurespippalla aswiniNoch keine Bewertungen

- M15 Spec Sheet (Eng)Dokument2 SeitenM15 Spec Sheet (Eng)Youssef AdnaneNoch keine Bewertungen

- Magnetic Level Indicator BrochureDokument8 SeitenMagnetic Level Indicator Brochureelia nugraha adiNoch keine Bewertungen

- Magtech Magnetic Level Indicator (For Light Oil Tank)Dokument12 SeitenMagtech Magnetic Level Indicator (For Light Oil Tank)engremilfrancismNoch keine Bewertungen

- 2014 10 09 19 08 Nuflo-Liquid-Turbine-Flow-MetersDokument7 Seiten2014 10 09 19 08 Nuflo-Liquid-Turbine-Flow-Metersichi ezzahraNoch keine Bewertungen

- Red Line Class D Extinguishers: FeaturesDokument2 SeitenRed Line Class D Extinguishers: FeaturesEduleofNoch keine Bewertungen

- SATAM-zc17-12 24 48 80 150 250 330Dokument2 SeitenSATAM-zc17-12 24 48 80 150 250 330Mr. AlferditomaNoch keine Bewertungen

- Catalogo Transductores SwagelokDokument17 SeitenCatalogo Transductores Swagelokjulio cesar medinaNoch keine Bewertungen

- S 1266Dokument48 SeitenS 1266Andreea UdreaNoch keine Bewertungen

- Specifications M-30 Meters: Superior Performance FeaturesDokument2 SeitenSpecifications M-30 Meters: Superior Performance FeaturesFredwash RichardNoch keine Bewertungen

- Ficha Tecnica FlujometroDokument2 SeitenFicha Tecnica FlujometroTatiana Mejías SeguraNoch keine Bewertungen

- AN3000 SeriesDokument2 SeitenAN3000 SeriesdanishaslNoch keine Bewertungen

- Nixon Col Brochure 2003 PDFDokument32 SeitenNixon Col Brochure 2003 PDFShiau FenNoch keine Bewertungen

- Heavy Duty Pressure Gauges With Bourdon Tube and Glycerine FillingDokument3 SeitenHeavy Duty Pressure Gauges With Bourdon Tube and Glycerine FillingRolando Jara YoungNoch keine Bewertungen

- DB GB NK10Dokument4 SeitenDB GB NK10cadhoaNoch keine Bewertungen

- Satam Zc17-B037-Bro-Gb-Rev3Dokument2 SeitenSatam Zc17-B037-Bro-Gb-Rev3warung1bensinNoch keine Bewertungen

- Pressure Measurement Techniques and Devices ExplainedDokument33 SeitenPressure Measurement Techniques and Devices ExplainedMaher Abu-ElolaNoch keine Bewertungen

- Familyoverview LFV300 g149993 enDokument7 SeitenFamilyoverview LFV300 g149993 enLeo PastinNoch keine Bewertungen

- Catalogo HBM ExtensometrosDokument52 SeitenCatalogo HBM ExtensometrosEdipo SantosNoch keine Bewertungen

- Annubar Flow MeterDokument2 SeitenAnnubar Flow MeterEran MeiriNoch keine Bewertungen

- Halliburton Liquid Turbine Meters Data SheetDokument6 SeitenHalliburton Liquid Turbine Meters Data SheetPaul Alejandro CampoverdeNoch keine Bewertungen

- Aquaflux Electromagnetic Flowmeters: ... The Specialist For Water and Wastewater MeasurementsDokument9 SeitenAquaflux Electromagnetic Flowmeters: ... The Specialist For Water and Wastewater MeasurementsVijay Chander GopuNoch keine Bewertungen

- R83pqty5 Magnetic Flowmeter FDLDGAM 3 PDFDokument38 SeitenR83pqty5 Magnetic Flowmeter FDLDGAM 3 PDFFelix DanielNoch keine Bewertungen

- Accuracy Standard Test GaugeDokument2 SeitenAccuracy Standard Test GaugeRajeeb MohammedNoch keine Bewertungen

- Wafer Stainless ANSI V919Dokument1 SeiteWafer Stainless ANSI V919Kamel AliNoch keine Bewertungen

- Types of Flow Measurements AND Their ApplicationsDokument44 SeitenTypes of Flow Measurements AND Their ApplicationsRaghNoch keine Bewertungen

- Magnetic Level Gauges & Level Transmitters: FeaturesDokument3 SeitenMagnetic Level Gauges & Level Transmitters: Featuressunshine dreamNoch keine Bewertungen

- Sour ServiceDokument24 SeitenSour ServicesundachaosNoch keine Bewertungen

- Install PlusV9Dokument16 SeitenInstall PlusV9Ben ZithaNoch keine Bewertungen

- Liquid Turbine Flow Meter: Subject To Change Without NoticeDokument27 SeitenLiquid Turbine Flow Meter: Subject To Change Without Noticenew587Noch keine Bewertungen

- Specifications: M-60 MetersDokument2 SeitenSpecifications: M-60 MetersDeonNoch keine Bewertungen

- RAMC GS01R01B02-00E-E Ed28 Pub22032019Dokument24 SeitenRAMC GS01R01B02-00E-E Ed28 Pub22032019zaffarNoch keine Bewertungen

- PIEZOMETERDokument2 SeitenPIEZOMETERAN FadlyNoch keine Bewertungen

- RNDC Cylinder Series - MetalworkDokument5 SeitenRNDC Cylinder Series - MetalworkMohab AhmedNoch keine Bewertungen

- M5 LC Flow MeterDokument1 SeiteM5 LC Flow MeteribrahimfahadNoch keine Bewertungen

- Vortex Flow Meter Catalog Dalian Zero Instrument Technology Co., LTD ChinaDokument21 SeitenVortex Flow Meter Catalog Dalian Zero Instrument Technology Co., LTD ChinaMichael SunNoch keine Bewertungen

- Emf NewDokument12 SeitenEmf Newrajendra amaravathiNoch keine Bewertungen

- Level Transmitter: DescriptionDokument2 SeitenLevel Transmitter: DescriptionvitovasquezNoch keine Bewertungen

- KROHNE Optiflux 2000R11Dokument8 SeitenKROHNE Optiflux 2000R11janithNoch keine Bewertungen

- Flow Meter PDFDokument20 SeitenFlow Meter PDFJoe Mari CapaNoch keine Bewertungen

- Desplazamiento Positivo PDFDokument20 SeitenDesplazamiento Positivo PDFMelina SbhNoch keine Bewertungen

- Optiflux 4000: Electromagnetic Flow SensorDokument8 SeitenOptiflux 4000: Electromagnetic Flow SensoryashNoch keine Bewertungen

- SFC1480FX SFC2480FX: SeriesDokument8 SeitenSFC1480FX SFC2480FX: SeriesRekha KNoch keine Bewertungen

- dp15 Variable Reluctance Pressure Sensor Capable of Range ChangesDokument2 Seitendp15 Variable Reluctance Pressure Sensor Capable of Range ChangesGuillaume HaddadNoch keine Bewertungen

- Orifice Assembly: Let The Restriction Do MeasurementDokument29 SeitenOrifice Assembly: Let The Restriction Do MeasurementRajesh ViswanNoch keine Bewertungen

- Bermad Combination Air Valve C70 - Product-Page - English - 9-2018Dokument4 SeitenBermad Combination Air Valve C70 - Product-Page - English - 9-2018M MNoch keine Bewertungen

- Global Valves BrochureDokument12 SeitenGlobal Valves BrochureBOUZAIDANoch keine Bewertungen

- Products Catalogue EN 2019 Pressostats HiresDokument105 SeitenProducts Catalogue EN 2019 Pressostats Hiresromulus berdeiNoch keine Bewertungen

- Coriolis Mass Flow Meter With Uncompromising Performance: Features ApplicationsDokument6 SeitenCoriolis Mass Flow Meter With Uncompromising Performance: Features ApplicationsJhon SierraNoch keine Bewertungen

- KH15 Pressure Transmitter: Wetted Parts SUS316L AvailableDokument19 SeitenKH15 Pressure Transmitter: Wetted Parts SUS316L AvailableTỉnh NgôNoch keine Bewertungen

- UK Supplier of Klinger Process Level GaugesDokument8 SeitenUK Supplier of Klinger Process Level GaugesDavid BaughNoch keine Bewertungen

- New Hydrovar7bDokument36 SeitenNew Hydrovar7bSedfrey PekitpekitNoch keine Bewertungen

- Parker HoseDokument2 SeitenParker HoseSEPTADONAI TRISNANoch keine Bewertungen

- PS01Dokument11 SeitenPS01Sherry HenryNoch keine Bewertungen

- FlowMon Catalogue 2 PDFDokument12 SeitenFlowMon Catalogue 2 PDFsimbamikeNoch keine Bewertungen

- PRO026 Float and Tape Brochure WebDokument6 SeitenPRO026 Float and Tape Brochure WebRobert ArnoldNoch keine Bewertungen

- Nuflo Liquid Turbine Flow Meters DatasheetDokument8 SeitenNuflo Liquid Turbine Flow Meters Datasheetadewunmi olufemiNoch keine Bewertungen

- Transducer Handbook: User's Directory of Electrical TransducersVon EverandTransducer Handbook: User's Directory of Electrical TransducersNoch keine Bewertungen

- P&ID For LearnersDokument1 SeiteP&ID For Learnerspippalla aswiniNoch keine Bewertungen

- Blind Flange Design Calculations - by Abdel Halim GalalaDokument6 SeitenBlind Flange Design Calculations - by Abdel Halim GalalaNirmalraj Manoharan67% (3)

- TN 842634faa13191f748 477Dokument59 SeitenTN 842634faa13191f748 477pippalla aswiniNoch keine Bewertungen

- PV EliteDokument6 SeitenPV ElitevikrantgulhaneNoch keine Bewertungen

- AckoPolicy DBCR00295523037 - 00 2021Dokument1 SeiteAckoPolicy DBCR00295523037 - 00 2021pippalla aswiniNoch keine Bewertungen

- Ijsrp p2830 PDFDokument4 SeitenIjsrp p2830 PDFprasadgssNoch keine Bewertungen

- Staad Pro V8i Manual 2016Dokument775 SeitenStaad Pro V8i Manual 2016Larry89% (9)

- V2i3 Ijertv2is3311 PDFDokument8 SeitenV2i3 Ijertv2is3311 PDFkinjalpatel12345Noch keine Bewertungen

- Key Performance IndicatorsDokument1 SeiteKey Performance Indicatorspippalla aswiniNoch keine Bewertungen

- 4 - Water Storage Tank Safety StandardsDokument35 Seiten4 - Water Storage Tank Safety StandardsWidiyanto WidiyantiNoch keine Bewertungen

- Pub000 054 00 - 0712 PDFDokument12 SeitenPub000 054 00 - 0712 PDFsanchay2503Noch keine Bewertungen

- Some The Temperature Range: Thermal ANDDokument10 SeitenSome The Temperature Range: Thermal ANDJose Velasquez TeranNoch keine Bewertungen

- Microsoft Word - 6Dokument11 SeitenMicrosoft Word - 6pippalla aswiniNoch keine Bewertungen

- A Autoc Cad® P P&Id in Namu Ulti-Use Er Env Vironm MentDokument20 SeitenA Autoc Cad® P P&Id in Namu Ulti-Use Er Env Vironm Mentpippalla aswiniNoch keine Bewertungen

- Periodic Table PDFDokument1 SeitePeriodic Table PDFpreetamNoch keine Bewertungen

- ANSI HI Version2-2GuideDokument8 SeitenANSI HI Version2-2Guideariyamanjula40% (5)

- Tank Fabrication SpecsDokument21 SeitenTank Fabrication Specsjlcheefei9258100% (1)

- Microsoft Word - 6Dokument11 SeitenMicrosoft Word - 6pippalla aswiniNoch keine Bewertungen

- Engineering MaterialsDokument197 SeitenEngineering MaterialsSidiq BudhyNoch keine Bewertungen

- HeatEnginesVol 1 Chapter 3 RSDokument24 SeitenHeatEnginesVol 1 Chapter 3 RSmohsinsafiNoch keine Bewertungen

- Voluma CalculationsDokument2 SeitenVoluma Calculationspippalla aswiniNoch keine Bewertungen

- Voluma CalculationsDokument2 SeitenVoluma Calculationspippalla aswiniNoch keine Bewertungen

- You Will Be Able To Download The DocumentDokument215 SeitenYou Will Be Able To Download The Documentpippalla aswiniNoch keine Bewertungen

- Eaton Pipeline Strainer Pressure Drop CalculationsDokument3 SeitenEaton Pipeline Strainer Pressure Drop Calculationspippalla aswiniNoch keine Bewertungen

- Eaton Pipeline Strainer Pressure Drop CalculationsDokument1 SeiteEaton Pipeline Strainer Pressure Drop Calculationsreborn_willyNoch keine Bewertungen

- Live Online PDMS Administration TrainingDokument4 SeitenLive Online PDMS Administration TrainingThrow awayNoch keine Bewertungen

- Farm Model of Dairy Unit of 10 Crossbred CowsDokument3 SeitenFarm Model of Dairy Unit of 10 Crossbred CowsKarthik RamakrishnanNoch keine Bewertungen

- GEMS Calender 2019-20Dokument2 SeitenGEMS Calender 2019-20Rushiraj SinhNoch keine Bewertungen

- ABI BrochureDokument2 SeitenABI BrochureMartin EscolaNoch keine Bewertungen

- Introduction To Analog and Digital CommunicationsDokument80 SeitenIntroduction To Analog and Digital CommunicationsvijaNoch keine Bewertungen

- P2E ProfileDokument10 SeitenP2E Profilepr1041Noch keine Bewertungen

- Constitutional Law I Case DigestDokument12 SeitenConstitutional Law I Case DigestMelcris Castro100% (1)

- Buddha LeaderDokument1 SeiteBuddha LeadersandeepbelovedNoch keine Bewertungen

- Switch Out of Band ManagementDokument10 SeitenSwitch Out of Band ManagementswsloanNoch keine Bewertungen

- Capacity Building Programme Methods Template Signed1Dokument14 SeitenCapacity Building Programme Methods Template Signed1REXNoch keine Bewertungen

- Latest JIG Standards issues releasedDokument2 SeitenLatest JIG Standards issues releasedPETENoch keine Bewertungen

- Fundamental of ICT: Study PresentationDokument12 SeitenFundamental of ICT: Study PresentationBikal ShresthaNoch keine Bewertungen

- CTA RulingDokument12 SeitenCTA RulingGhia TalidongNoch keine Bewertungen

- RRV DC: 3.54 In. (90 MM)Dokument7 SeitenRRV DC: 3.54 In. (90 MM)Trevor AdamsNoch keine Bewertungen

- 083E Relative Humidity Sensor Accurate and ReliableDokument2 Seiten083E Relative Humidity Sensor Accurate and Reliablehuguer1Noch keine Bewertungen

- ISO 26262 for Functional Safety Critical ProjectsDokument24 SeitenISO 26262 for Functional Safety Critical ProjectsZidane Benmansour100% (1)

- International Communications in Heat and Mass Transfer: Phani Krishna Kadiyala, Himadri ChattopadhyayDokument5 SeitenInternational Communications in Heat and Mass Transfer: Phani Krishna Kadiyala, Himadri ChattopadhyayhaabalmNoch keine Bewertungen

- Latest On LNG Liquefaction and Re-Gasification Technology: FLNG RouteDokument3 SeitenLatest On LNG Liquefaction and Re-Gasification Technology: FLNG RouteUJJWALNoch keine Bewertungen

- Secretary's Certificate in Re Board ResolutionsDokument2 SeitenSecretary's Certificate in Re Board Resolutionslucky joy domingoNoch keine Bewertungen

- Afl Fact SheetDokument1 SeiteAfl Fact Sheetapi-257609033Noch keine Bewertungen

- Bell Type Packoff: B & T Oilfield Products Wireline Product CatalogDokument5 SeitenBell Type Packoff: B & T Oilfield Products Wireline Product CatalogaminoNoch keine Bewertungen

- Asme B5.38-1958Dokument14 SeitenAsme B5.38-1958vijay pawarNoch keine Bewertungen

- Marcom Plan 2024Dokument7 SeitenMarcom Plan 2024Amith KoshyNoch keine Bewertungen

- Social marketing and entertainment-education strategyDokument15 SeitenSocial marketing and entertainment-education strategyBiji ThottungalNoch keine Bewertungen

- English For The Workplace: The Importance of English Language Skills For Effective PerformanceDokument16 SeitenEnglish For The Workplace: The Importance of English Language Skills For Effective Performanceบี'โอ' วายNoch keine Bewertungen

- 2020 Scrum Guide ArabicDokument15 Seiten2020 Scrum Guide Arabicnbo100% (1)

- LM - Top Voicemail HacksDokument5 SeitenLM - Top Voicemail HacksMaksi UnairNoch keine Bewertungen

- FACTORS Affecting The Entrepreneurial DynamicsDokument4 SeitenFACTORS Affecting The Entrepreneurial DynamicsAzraNoch keine Bewertungen

- Manila Bay accretion disputeDokument24 SeitenManila Bay accretion disputeRoman KushpatrovNoch keine Bewertungen

- Hippa Patient Consent FormDokument1 SeiteHippa Patient Consent FormbbiesNoch keine Bewertungen

- Trimble M3 UserGuide 100A English PDFDokument168 SeitenTrimble M3 UserGuide 100A English PDFVladan SpasenovicNoch keine Bewertungen