Beruflich Dokumente

Kultur Dokumente

Litek Product Catalogue - ANSI - 2018

Hochgeladen von

prateekmuleOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Litek Product Catalogue - ANSI - 2018

Hochgeladen von

prateekmuleCopyright:

Verfügbare Formate

WWW.FRPSUPPLY.

COM

PREMIUM QUALITY

FRP PIPE, FITTING

&

ACCESSORY

FOR CORROSION RESISTANT APPLICATION

2018 © Litek Composites Corp. ANSI BV.1.0.0

FRP Stub Flange

◆ Manufactured to conform to PS 15-69 & ASTM D5421

◆ C-veil and Nexus + 2 Mats 100mil resin rich corrosion liner

◆ Hand laid, integral type construction, woven roving used continuously from

flange face to hub for 3 inches size and larger

◆ Uniform external surface and stub end surface prepared for immediate bonding

◆ Bolt holes of drilled flanges are spot-faced and coated with resin

◆ Standard inventory available in Vinyl Ester Resin, Derakane Momentum 411-350,

470-300, 510C-350, & Hetron 922. To supply equivalent resin system can be

available upon request

◆ MEKP (C + N Liner) & BPO (C + 2N Liner) cure systems

Corrosion Resistance Structure Composition

Chemical

FRP PIPING

100 mil Chemical Resistance Liner

(C-veil and Nexus, Glass Fiber

content about 10%)

(2 Mats, Glass Fiber content

about 20 to 30%)

ACCESSORY

Structure Layer

(Glass Fiber Content about 30%

Hand Lay-Up, 65% FW)

Exterior Layer

(C-veil with UV inhibitor for pipes only)

L

T S

D d C

S

HT

HL n Holes x h Hole Diameter

01 2018 © Litek Composites Corp.

FRP Stub Flange

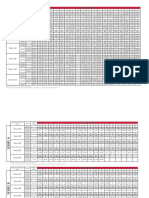

Nominal Flange Flange Stub Stub Hub Hub No. of Bolt Hole Washer Bolt Circle

Pressure

Diameter Diameter Thickness Length Thickness Length Thickness Holes Diameter Diameter Diameter

Rating

(d) (D) (T) (L) (t) ( HL ) ( HT ) (n) (h) (S) (C)

inch psi inch inch inch inch inch inch pcs inch inch inch

1/2 150 3- 3/4 5/8 12 3/16 2- 1/2 5/16 4 5/8 1- 1/4 2- 3/8

3/4 150 4- 1/8 5/8 12 3/16 2- 1/2 5/16 4 5/8 1- 1/4 2- 3/4

1 150 4- 1/2 5/8 12 3/16 2- 1/2 5/16 4 5/8 1- 1/4 3- 1/8

1- 1/2 150 5- 1/2 11/16 12 3/16 2- 3/4 11/32 4 5/8 1- 1/4 3- 7/8

2 150 6- 1/2 11/16 12 1/4 2- 3/4 11/32 4 3/4 1- 1/2 4- 3/4

2- 1/2 150 7- 1/2 3/4 12 1/4 3 3/8 4 3/4 1- 1/2 5- 1/2

3 150 8 13/16 12 1/4 3- 1/4 13/32 4 3/4 1- 1/2 6

4 150 9- 1/2 15/16 12 1/4 3- 3/4 15/32 8 3/4 1- 1/2 7- 1/2

FRP PIPING

5 150 10- 1/2 1 12 3/8 4 1/2 8 7/8 1- 3/4 8- 1/2

50 11- 1/2 5/8 12 3/16 2- 1/2 5/16 8 7/8 1- 3/4 9- 1/2

6

150 11- 1/2 1- 1/16 12 3/8 4- 1/4 17/32 8 7/8 1- 3/4 9- 1/2

50 14 3/4 12 1/4 3 3/8 8 7/8 1- 3/4 11- 3/4

8

150 14 1- 1/4 12 7/16 5 5/8 8 7/8 1- 3/4 11- 3/4

ACCESSORY

50 16- 1/2 7/8 12 1/4 3- 1/2 7/16 12 1 2 14- 1/4

10

150 16- 1/2 1- 7/16 12 1/2 5- 3/4 23/32 12 1 2 14- 1/4

50 19- 1/2 1 12 1/4 4 1/2 12 1 2 17

12

150 19- 1/2 1- 3/4 12 5/8 7 7/8 12 1 2 17

50 21- 1/2 1- 1/16 12 5/16 4- 1/4 17/32 12 1- 1/8 2- 1/4 18- 3/4

14

150 21- 1/2 1- 7/8 12 3/4 7- 1/2 15/16 12 1- 1/8 2- 1/4 18- 3/4

50 24 1- 3/16 12 5/16 4- 3/4 19/32 16 1- 1/8 2- 1/4 21- 1/4

16

150 24 2 12 13/16 7 1 16 1- 1/8 2- 1/4 21- 1/4

50 25- 1/2 1- 1/4 12 3/8 5 5/8 16 1- 1/4 2- 1/2 22- 3/4

18

150 25- 1/2 2- 1/4 12 7/8 7- 7/8 1- 1/8 16 1- 1/4 2- 1/2 22- 3/4

50 28 1- 5/16 12 3/8 5- 1/4 21/32 20 1- 1/4 2- 1/2 25

20

150 28 2- 7/16 12 15/16 7- 5/16 1- 7/32 20 1- 1/4 2- 1/2 25

50 32- 1/2 1- 1/2 12 7/16 6 3/4 20 1- 3/8 2- 3/4 29- 1/2

24

150 32- 1/2 2- 13/16 12 1- 1/8 8- 7/16 1- 13/32 20 1- 3/8 2- 3/4 29- 1/2

50 39- 1/4 1- 7/8 12 1/2 7- 1/2 15/16 28 1- 3/8 2- 3/4 36

30

150 39- 1/4 3 12 1- 3/8 7- 1/2 1- 1/2 28 1- 3/8 2- 3/4 36

50 46 2 12 5/8 8 1 32 1- 5/8 3- 1/4 42- 3/4

36

150 46 3- 1/2 12 1- 5/8 8- 3/4 1- 3/4 32 1- 5/8 3- 1/4 42- 3/4

2018 © Litek Composites Corp. 02

FRP Manway

◆ Manufactured to conform to PS 15-69 & ASTM D5421

◆ C-veil and Nexus + 2 Mats 100mil resin rich corrosion liner

◆ Hand laid, integral type construction, woven roving used continuously from

flange face to hub for reinforcement

◆ Uniform external surface and stub end surface prepared for immediate bonding

◆ Bolt holes of drilled flanges are spot-faced and coated with resin

◆ Standard inventory available in Vinyl Ester Resin, Derakane Momentum 411-350,

470-300, 510C-350, & Hetron 922. To supply equivalent resin system can be

available upon request

◆ MEKP (C + N Liner) & BPO (C + 2N Liner) cure systems

L S

T

t

FRP PIPING

D d C

ACCESSORY

HT

E n Holes x h Hole Diameter

Nominal Flange Flange Stub Stub Hub Hub No.of Bolt Hole Washer Bolt Circle

Pressure

Diameter Diameter Thickness Length Thickness Length Thickness Holes Diameter Diameter Diameter

Rating

(d) (D) (T) (L) (t) (E) ( HT ) (n) (h) (S) (C)

inch psi inch inch inch inch inch inch pcs inch inch inch

15

28 3/4 12 1/4 3 3/8 20 3/4 1- 1/2 25

(RTP‐1, 10)

20

25

28 1 12 3/8 4 1/2 20 3/4 1- 1/2 25

(RTP‐1, 15)

ATM

32- 1/2 3/8 12 1/4 1- 1/2 3/16 20 1/2 1 29- 1/2

(RTP‐1, 0.5)

15

24 32- 1/2 3/4 12 1/4 3 3/8 20 3/4 1- 1/2 29- 1/2

(RTP‐1, 10)

25

32- 1/2 1- 1/4 12 3/8 5 5/8 20 3/4 1- 1/2 29- 1/2

(RTP‐1, 15)

30 25 39- 1/4 1- 3/8 12 3/8 5- 1/2 11/16 28 3/4 1- 1/2 36

36 25 46 1- 3/4 12 3/8 7 7/8 32 3/4 1- 1/2 42- 3/4

03 2018 © Litek Composites Corp.

FRP Manway Cover

◆ Manufactured to conform to PS 15-69 & ASTM D5421

◆ C-veil and Nexus + 2 Mats 100mil resin rich corrosion liner

◆ Hand laid, integral type construction, woven roving used continuously for

reinforcement

◆ Uniform external surface

◆ Bolt holes of drilled flanges are spot-faced and coated with resin

◆ Standard inventory available in Vinyl Ester Resin, Derakane Momentum 411-350,

470-300, 510C-350, & Hetron 922. To supply equivalent resin system can be

available upon request

◆ MEKP (C + N Liner) & BPO (C + 2N Liner) cure systems

T S

FRP PIPING

t m d D C

ACCESSORY

n Holes x h Hole Diameter

Nominal Cover Cover Cover Cover No.of Bolt Hole Washer Bolt Circle

Pressure

Diameter Diameter Thickness Thickness in Height Holes Diameter Diameter Diameter

Rating

(d) (D) (T) (t) (m) (n) (h) (S) (C)

inch psi inch inch inch inch pcs inch inch inch

15

28 3/4 1/4 3- 3/16 20 3/4 1- 1/2 25

(RTP‐1, 10)

20

25

28 1 3/8 3- 3/16 20 3/4 1- 1/2 25

(RTP‐1, 15)

ATM

32- 1/2 3/8 1/4 3- 3/16 20 1/2 1 29- 1/2

(RTP‐1, 0.5)

15

24 32- 1/2 3/4 1/4 3- 3/16 20 3/4 1- 1/2 29- 1/2

(RTP‐1, 10)

25

32- 1/2 1- 1/4 3/8 3- 3/16 20 3/4 1- 1/2 29- 1/2

(RTP‐1, 15)

30 25 39- 1/4 1- 3/8 3/8 3- 3/16 28 3/4 1- 1/2 36

36 25 46 1- 3/4 3/8 3- 3/16 32 3/4 1- 1/2 42- 3/4

2018 © Litek Composites Corp. 04

FRP Blind Flange

◆ Manufactured to conform to PS 15-69 & ASTM D5421

◆ C-veil and Nexus + 2 Mats 100mil resin rich corrosion liner

◆ Hand laid, integral type construction, Woven roving used continuously for 3

inches size and larger

◆ Uniform external surface

◆ Bolt holes of drilled flanges are coated with resin

◆ Standard inventory available in Vinyl Ester Resin, Derakane Momentum 411-350,

470-300, 510C-350, & Hetron 922. To supply equivalent resin system can be

available upon request

◆ MEKP (C + N Liner) & BPO (C + 2N Liner) cure systems

T

FRP PIPING

D C

ACCESSORY

n Holes x h Hole Diameter

Flange Flange No.of Bolt Hole Bolt Circle

Nominal Pressure

Diameter Thickness Holes Diameter Diameter

Diameter Rating

(D) (T) (n) (h) (C)

inch psi inch inch pcs inch inch

1 150 4- 1/2 5/8 4 5/8 3- 1/8

1- 1/2 150 5- 1/2 11/16 4 5/8 3- 7/8

2 150 6- 1/2 11/16 4 3/4 4- 3/4

2- 1/2 150 7- 1/2 3/4 4 3/4 5- 1/2

3 150 8 13/16 4 3/4 6

4 150 9- 1/2 15/16 8 3/4 7- 1/2

5 150 10- 1/2 1 8 7/8 8- 1/2

6 150 11- 1/2 1- 1/16 8 7/8 9- 1/2

8 150 14 1- 1/4 8 7/8 11- 3/4

10 150 16- 1/2 1- 7/16 12 1 14- 1/4

12 150 19- 1/2 1- 3/4 12 1 17

14 150 21- 1/2 1- 7/8 12 1- 1/8 18- 3/4

16 150 24 2 16 1- 1/8 21- 1/4

18 150 25- 1/2 2- 1/4 16 1- 1/4 22- 3/4

20 150 28 2- 7/16 20 1- 1/4 25

24 150 32- 1/2 2- 13/16 20 1- 3/8 29- 1/2

30 150 39- 1/4 3 28 1- 3/8 36

36 150 46 3- 1/2 32 1- 5/8 42- 3/4

05 2018 © Litek Composites Corp.

FRP 90 Degree Elbow

◆ Manufactured to conform to PS 15-69 & ASTM D6041

◆ C-veil and Nexus + 2 Mats 100mil resin rich corrosion liner

◆ 90º Elbow radius equals to 2 times of the Inside Diameter for sizes not larger than

3 inches, and 1.5 times of the Inside Diameter for sizes for 4 inches and larger

◆ Hand laid one piece construction

◆ Standard inventory available in Vinyl Ester Resin, Derakane Momentum 411-350,

470-300, 510C-350, & Hetron 922. To supply equivalent resin system can be

available upon request

◆ MEKP (C + N Liner) & BPO (C + 2N Liner) cure systems

T D

FRP PIPING

R

ACCESSORY

°

90

Nominal Wall

Pressure Radius

Diameter Thickness

Rating (R)

(D) (T)

inch psi inch inch

1 150 2 3/16

1- 1/2 150 3 3/16

2 150 4 1/4

2- 1/2 150 5 1/4

3 150 6 1/4

4 150 6 1/4

5 150 7- 1/2 3/8

6 150 9 3/8

8 150 12 7/16

10 150 15 1/2

12 150 18 5/8

14 150 21 3/4

16 150 24 13/16

18 150 27 7/8

20 150 30 15/16

24 150 36 1- 1/8

30 150 45 1- 3/8

36 150 54 1- 5/8

2018 © Litek Composites Corp. 06

FRP Equal Tee

◆ Manufactured to conform to PS 15-69 & ASTM D6041

◆ C-veil and Nexus + 2 Mats 100mil resin rich corrosion liner

◆ Hand laid one piece construction

◆ Standard inventory available in Vinyl Ester Resin, Derakane Momentum 411-350,

470-300, 510C-350, & Hetron 922. To supply equivalent resin system can be

available upon request

◆ MEKP (C + N Liner) & BPO (C + 2N Liner) cure systems

A A

D t

FRP PIPING

A t

ACCESSORY

D D

Nominal Wall

Pressure

Diameter (A) Thickness

Rating

(D) (t)

inch psi inch inch

1 150 4- 1/2 3/16

1- 1/2 150 5 3/16

2 150 6 1/4

2- 1/2 150 6- 1/2 1/4

3 150 7 1/4

4 150 8 1/4

5 150 9 3/8

6 150 10 3/8

8 150 12 7/16

10 150 14 1/2

12 150 16 5/8

14 150 18 3/4

16 150 20 13/16

18 150 21 7/8

20 150 22 15/16

24 150 24 1- 1/8

07 2018 © Litek Composites Corp.

FRP Coupling

◆ Manufactured to conform to PS15-69

◆ NPT Threads are Filament Wound

◆ C-veil and Nexus resin rich liner is built after threads for maximum Corrosion

service

◆ Hand laid one piece construction with higher resin content (about 65%) suitable

for high corrosion application

◆ Reinforcement is continuous throughout

◆ Exterior machined finish, without top coat

OL OD

WT1 ID

FRP PIPING

L1

L0

ID OD

ACCESSORY

Inside O.D. of Wall Length at Overall Length

Pressure Overall Length

Diameter Pipe Thickness Beginning of Thread

Rating ( OL )

( ID ) ( OD ) ( WT1 ) ( L0 ) ( L1 )

inch psi inch inch inch inch 4 inch 6 inch 8 inch

3/8 150 1- 1/16 3/16 1/8 5/8 ● ●

1/2 150 1- 1/4 3/16 3/16 7/8 ● ●

3/4 150 1- 7/16 3/16 3/16 7/8 ● ●

1 150 1- 3/4 3/16 3/16 1- 1/8 ● ● ●

1- 1/4 150 2- 1/16 3/16 3/16 1- 3/16 ● ● ●

1- 1/2 150 2- 5/16 3/16 3/16 1- 3/16 ● ● ●

2 150 2- 7/8 1/4 3/16 1- 3/16 ● ● ●

2- 1/2 150 3- 3/8 1/4 1/4 1- 9/16 ● ●

3 150 4 1/4 1/4 1- 5/8 ● ●

4 150 5 1/4 5/16 1- 7/8 ● ●

6 150 7- 3/8 3/8 5/16 2 ● ●

2018 © Litek Composites Corp. 08

FRP Nipple TBE (Thread Both Ends)

◆ Manufactured to conform to PS15-69

◆ NPT Threads

◆ C-veil and Nexus + 2 Mats 100mil resin rich corrosion liner

◆ Hand laid one piece construction; Reinforcement is continuous throughout

◆ Exterior machined finish, without top coat

L OD

T el ID

FRP PIPING

ID OD

ACCESSORY

Inside Outside Wall Thread Wall

Pressure Length

Diameter Diameter Thickness Length Thickness

Rating (L)

( ID ) ( OD ) (T) ( el ) (t)

inch psi inch inch inch inch inch

3/8 150 7/8 8 1/4 0.613 3/16

1/2 150 1 8 1/4 0.832 3/16

3/4 150 1- 1/4 8 1/4 0.860 3/16

1 150 1- 1/2 8 1/4 1.045 3/16

1- 1/4 150 1- 3/4 8 1/4 1.132 3/16

1- 1/2 150 2 8 1/4 1.132 3/16

2 150 2- 5/8 8 5/16 1.175 1/4

09 2018 © Litek Composites Corp.

FRP Nipple TOE (Thread One End)

◆ Manufactured to conform to PS15-69

◆ NPT Threads

◆ C-veil and Nexus + 2 Mats 100mil resin rich corrosion liner

◆ Hand laid one piece construction; Reinforcement is continuous throughout

◆ Exterior machined finish, without top coat

L OD

T el ID

FRP PIPING

ID OD

ACCESSORY

t

Inside Outside Wall Thread Wall

Pressure Length

Diameter Diameter Thickness Length Thickness

Rating (L)

( ID ) ( OD ) (T) ( el ) (t)

inch psi inch inch inch inch inch

2- 1/2 150 3- 1/8 6 5/16 1.571 1/4

3 150 3- 5/8 6 5/16 1.634 1/4

4 150 4- 5/8 6 5/16 1.752 1/4

6 150 6- 7/8 6 7/16 1.946 3/8

2018 © Litek Composites Corp. 10

FRP U-Vent

◆ Manufactured to conform to PS15-69

◆ C-veil and Nexus + 2 Mats 100mil resin rich corrosion liner

◆ Hand laid one piece construction; 90º Elbow radius equals to 1.5 times of the ID

◆ Standard inventory available in Vinyl Ester Resin, Derakane Momentum 411-350,

470-300, 510C-350, & Hetron 922. To supply equivalent resin system can be

available upon request

◆ MEKP (C + N Liner) & BPO (C + 2N Liner) cure systems

OD

FRP PIPING

PL ID

SD

t

GL

ACCESSORY

ID

OH

Inside O.D. of Wall Overall Sweep Pipe Grinding

Pressure

Diameter Pipe Thickness Height Diameter Length Length

Rating

( ID ) ( OD ) (t) ( OH ) ( SD ) ( PL ) ( GL )

inch psi inch inch inch inch inch inch

2 25 2- 3/8 3/16 14- 3/16 8- 3/8 10 3

3 25 3- 3/8 3/16 16- 3/16 12- 3/8 10 3

4 25 4- 3/8 3/16 18- 3/16 16- 3/8 10 3

6 25 6- 3/8 3/16 22- 3/16 24- 3/8 10 4

8 25 8- 3/8 3/16 26- 3/16 32- 3/8 10 4

10 25 10- 3/8 3/16 30- 3/16 40- 3/8 10 4

12 25 12- 3/8 3/16 34- 3/16 48- 3/8 10 4

14 25 14- 1/2 1/4 40- 1/4 56- 1/2 12 5

16 25 16- 1/2 1/4 44- 1/4 64- 1/2 12 5

11 2018 © Litek Composites Corp.

FRP Filament Wound Pipe

◆ Manufactured to conform to ASTM D2996

◆ C-veil and Nexus + 2 Mats 100mil resin rich corrosion liner

◆ 150psi ratings are suitable for operating temperatures to 220° F

◆ 54 to 56 degrees Helical Winding for maximum strength suitable for high

working pressure

◆ C-veil + UV Inhibitor Glossy exterior finishing for extra weathering and corrosion

protection

L D

t

FRP PIPING

D

ACCESSORY

Nominal Diameter Wall Thickness Pipe Length

(D) (t) (L)

inch

inch foot

50psi 150psi

2 - 3/16 20

3 - 3/16 20

4 - 3/16 20

6 3/16 1/4 20

8 3/16 1/4 20

10 3/16 5/16 20

12 3/16 3/8 20

14 3/16 7/16 20

16 3/16 7/16 20

18 3/16 1/2 20

20 3/16 1/2 20

24 1/4 5/8 20

2018 © Litek Composites Corp. 12

FRP Hand Laid Pipe

◆ Manufactured to conform to PS 15-69 and ASTM-D6041

◆ C-veil and Nexus + 2 Mats 100mil resin rich corrosion liner

◆ 150psi ratings are suitable for operating temperatures to 220° F

◆ Uniform thickness and 100mil resin rich liner hand laid up suitable for high

corrosion application

◆ C-veil + UV Inhibitor with resin (no wax) top coat for superior corrosion resistance

L D

t

FRP PIPING

D

ACCESSORY

Nominal Diameter Wall Thickness Pipe Length

(D) (t) (L)

inch

inch foot

50psi 150psi

1 - 3/16 20

1- 1/2 - 3/16 20

2 3/16 1/4 20

3 3/16 1/4 20

4 3/16 1/4 20

6 3/16 3/8 20

8 1/4 7/16 20

10 1/4 1/2 20

12 1/4 5/8 20

14 5/16 3/4 20

16 5/16 13/16 20

18 3/8 7/8 20

20 3/8 15/16 20

24 7/16 1- 1/8 20

13 2018 © Litek Composites Corp.

Custom-Made Products

◆ We work for FRP fabricators as a subcontractor for full

line of corrosion resistance FRP Piping Spools. If your

project requires fast installation, we can subcontract

pre-spooled components with butt or flange

connection according to your Isometric drawings,

made in China and shipped directly to your destined

location to save on lead time and cost. Our US office

can help to handle all shipping and importation

process.

◆ We have been making high quality and detailed OEM

FRP Products for over 30 years. Our experienced

custom-made team will help you to improve cost and

productivity tremendously.

FRP PIPING

ACCESSORY

2018 © Litek Composites Corp. 14

Reinforcement

C-veil

◆ Mainly used on the surface layers of FRP products

◆ Provides a smooth surface and quick resin soaked

◆ Helps improve the product surface property on corrosion resistance, compressive strength,

seepage resistance and exhibits a long surface life

Area Weight Width Pre-cut Length (yard) Roll Length (yard)

30 g/m²² 0.9 oz/yd²² 39" 5 10 20 565

Nexus

◆ Superior corrosion and stress corrosion resistance ◆ Fast wet-out

◆ Winds readily with less web breakage ◆ Designed for optimum neck-down

properties

FRP PIPING

◆ Improves cyclic pressure strength of piping systems

◆ Print blocker

◆ Superior direct and reverse impact strength

Area Weight Width Pre-cut Length (yard) Roll Length (yard)

37 g/m²² 1.1 oz/yd²² 57" 5 10 20 500

ACCESSORY

Chopped Strand Mat

◆ Quick wetting and rapid air release

◆ Ease of handling and ability for complex molds

◆ Lloyd's Register for Marine application

◆ Superior corrosion resistance

Area Weight Width Pre-cut Length (yard) Roll Length (yard)

300 g/m²² 1 oz/ft²²² 148

38" 5 10 20

450 g/m²²² 1.5 oz/ft²²² 115

Woven Roving

◆ Compatible with most resin systems

◆ To increase the flexural and impact strength of laminates

◆ For multi-layer hand lay-up applications

◆ Good drapeability, wet out and cost effective

Area Weight Width Pre-cut Length (yard) Roll Length (yard)

600 g/m²²² 18 oz/yd²²² 70

38" 5 10 20

800 g/m²²² 24 oz/yd²²² 49

15 2018 © Litek Composites Corp.

FRP Pipe Butt Joint Fiberglass Kit

1 2

FRP PIPING

3 4

Product Description Package Includes

ACCESSORY

FRP Butt Joint Fiberglass Kit is a package of fiberglass strips precut for FRP technician on ◆ Fiberglass layer sets.

the field or shop as ready use Fiberglass reinforcement to fabricate Butt Joint FRP Pipes and ◆ A pack of Silica powder.

Fittings lamination without going through time consumed preparation of cutting different ◆ Installation guide/ Data sheet.

types and sizes of Fiberglass material.

◆ Desiccant.

The specifications meet PS 15-69 "Custom Contact-Molded Reinforced Polyester Chemical-

Resistant Process Equipment" minimum total width. It is for customer's option to select

suitable pressure type of kits for joining both FRP Hand-Lay and FW piping system. FRP Butt Joint Kit

All fiberglass materials are the highest quality commercial grade meet FRP industry and Lamination Tutorial

Marine standard. It can work with almost all types of Unsaturated Polyester and Epoxy resin.

FRP Pipe Butt Joint Lay-Up Sequence & Dimension Table

Interior Structural Exterior Lamination Layer

Pressure Product Joint Structural

Diameter Width Width Width Length C=C-veil, N=Nexus

Rate Thickness Thickness Width

(C+N+2M) (C) (Each end) M=Chopped Strand Mat ( 1.5 oz / ft² )

R=Woven Roving ( 24 oz / yd² )

inch psi inch inch inch inch inch inch inch

2 150 1/4 5/16 5 6 7 3 3/4 9 1/2 CNMM+MMM+MMM+MMC

4 150 1/4 5/16 5 6 7 3 3/4 17 CNMM+MRMM+MRMMC

50 3/16 1/4 4 5 6 3 1/4 24 CNMM+MRMM+MMC

6

150 3/8 7/16 7 8 9 4 3/4 25 CNMM+MRMM+MRMM+MRMMC

50 1/4 5/16 5 6 7 3 3/4 32 CNMM+MRMM+MRMMC

8

150 7/16 1/2 8 9 10 5 1/4 33 CNMM+MRMM+MRMM+MRMM+MMC

50 1/4 5/16 5 6 7 3 3/4 40 CNMM+MRMM+MRMMC

10

150 1/2 5/8 10 11 12 6 1/4 42 CNMM+MRMM+MRMM+MRMM+MRMMMC

50 1/4 5/16 5 6 7 3 3/4 47 CNMM+MRMM+MRMMC

12

150 5/8 11/16 11 12 13 6 3/4 50 CNMM+MRMM+MRMM+MRMM+MRMM+MMMC

2018 © Litek Composites Corp. 16

FRP Pipe Butt Joint Fiberglass Kit

Dia : 1-2 inch

MMC ④

MMM

MMM

CNMM ①

ID=2�

1/4�

5/16�

Pressure Rate : 150 psi

FRP PIPING

Dia : 2.5-4 inch

MRMMC ③

MRMM

CNMM ①

ACCESSORY

ID=4�

1/4�

5/16�

Pressure Rate : 150 psi

Dia : 5-6 inch

MRMMC ④

MMC ③ MRMM

MRMM MRMM

CNMM ① CNMM ①

ID=6�

ID=6�

3/16�

3/8�

7/16�

1/4�

Pressure Rate : 50 psi Pressure Rate : 150 psi

17 2018 © Litek Composites Corp.

FRP Pipe Butt Joint Fiberglass Kit

Dia : 8 inch

MMC ⑤

MRMM

MRMMC ③ MRMM

MRMM MRMM

CNMM ① CNMM ①

ID=8�

ID=8�

7/16�

1/4�

5/16�

1/2�

Pressure Rate : 50 psi Pressure Rate : 150 psi

FRP PIPING

Dia : 10 inch

MRMMMC ⑤

MRMM

MRMMC ③ MRMM

MRMM MRMM

CNMM ① CNMM ①

ACCESSORY

ID=10�

ID=10�

1/4�

1/2�

5/16�

5/8�

Pressure Rate : 50 psi Pressure Rate : 150 psi

Dia : 12 inch

MMMC ⑥

MRMM

MRMM

MRMMC ③ MRMM

MRMM MRMM

CNMM ① CNMM ①

ID=12�

ID=12�

11/16�

1/4�

5/8�

5/16�

Pressure Rate : 50 psi Pressure Rate : 150 psi

2018 © Litek Composites Corp. 18

Vinyl Ester Resin

5 Gallon

1 Gallon

1 Quart

FRP PIPING

ACCESSORY

Product Description Applications And Use

DERAKANE MOMENTUM 411-350 ◆ DERAKANE 411-350 resin is designed for use in fabricating

DERAKANE 411-350 epoxy vinyl ester resin is based on FRP storage tanks, vessels, ducts and on-site maintenance

bisphenol-A epoxy resin and has become the "industry projects, particularly in chemical processing and pulp and

standard" due to its wide range of end-use applications and paper operations.

ability to be used in a wide range of fabrication techniques.

◆ The resin is designed for ease of fabrication using hand lay-up,

The raw materials used in the manufacture of this resin are

spray-up, filament winding, compression molding and resin

listed as acceptable in FDA regulation Title 21 CFR 177.2420 for

transfer molding techniques, pultrusion and molded grating

repeated use in contact with food, subject to user's compliance

applications.

with the prescribed limitations of that regulation.

◆ All resin will include hardener in package.

MEKP Catalyst Mixing Chart

Catalyst Concentration Resin Quantity

% 1 Quart 1 Gallon 5 Gallon

1% 10 cc 1/3 oz 40 cc 1 1/3 oz 200 cc 6 2/3 oz

1.25% 12.5 cc 2/5 oz 50 cc 1 2/3 oz 250 cc 8 1/3 oz

1.5% 15 cc 1/2 oz 60 cc 2 oz 300 cc 10 oz

2% 20 cc 2/3 oz 80c c 2 2/3 oz 400 cc 13 1/4 oz

30 drops is approximately equal to one cc; cc = cubic centimeter; oz =fluid ounce

NOTE : Using drops for catalyst measurement is only an estimate. In critical applications MEKP should be measured using cc's or fluid

oz's which are volume measurements. The percentages in the chart: 1% thru 2%, are percentages of resin or gelcoat by weight. The cc

and oz values in the chart have been converted from weights of MEKP to volumes of MEKP to make mixing easier.

19 2018 © Litek Composites Corp.

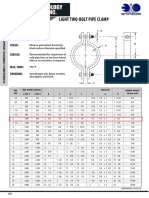

Hex Bolt & Nut Set

Half Thread Full Thread

FRP PIPING

Dimension Table Product Description

◆ Material Grade : Stainless steel SS316

Bolt & Nut Specification Flange & Manway Specification

◆ Dimensional standard : ASME B18.2.1

Bolt Nominal Pressure Bolt Hole Flange

Length Half Full Amount of

Size Diameter Rating Diameter Thickness Remarks

(inch) Thread Thread Bolt Holes

(inch) (inch) (psi) (inch) (inch)

ACCESSORY

5/8 2 3/4 ● 2 150 3/4 4 11/16

5/8 3 ● ● 3 150 3/4 4 13/16

Dimension

5/8 3 1/4 ● 4 150 3/4 8 15/16

3/4 2 3/4 ● 50 7/8 8 5/8

6

3/4 3 1/2 ● ● 150 7/8 8 1 1/16

3/4 3 ● 50 7/8 8 3/4

8

3/4 4 ● ● 150 7/8 8 1 1/4

7/8 3 1/4 ● 50 1 12 7/8

10

7/8 4 1/2 ● 150 1 12 1 7/16

7/8 3 1/2 ● 50 1 12 1

12 Length Length

7/8 5 ● 150 1 12 1 3/4 Flange

1 4 ● 50 1 1/8 12 1 1/16

14

1 5 3/4 ● 150 1 1/8 12 1 7/8

1 4 1/4 ● 50 1 1/8 16 1 3/16

16

1 6 ● 150 1 1/8 16 2

1 1/8 4 1/2 ● 50 1 1/4 16 1 1/4

18

1 1/8 6 1/2 ● 150 1 1/4 16 2 1/4

1 1/8 4 3/4 ● 50 1 1/4 20 1 5/16

20 Bolt Hole Bolt Hole

1 1/8 7 ● 150 1 1/4 20 2 7/16

Diameter Diameter

1 1/4 5 1/4 ● 50 1 3/8 20 1 1/2

24

1 1/4 8 ● 150 1 3/8 20 2 13/16

Half Full

Thread Thread

5/8 3 ● ● 20 10PSI 3/4 20 3/4

3/8 1 3/4 ● ● ATM 1/2 20 3/8

Manway

5/8 3 ● ● 24 10PSI 3/4 20 3/4

5/8 4 ● ● 25PSI 3/4 20 1 1/4

2018 © Litek Composites Corp. 20

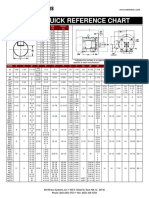

Full Face Gasket Series

EPDM Gasket Neoprene Gasket

FRP PIPING

Dimension Table

Gasket Gasket Bolt

Gasket Bolt Hole

Flange EPDM Neoprene Inside Outside Circle No. of Holes

Thickness Diameter

Diameter Gasket Gasket Diameter Diameter Diameter N (pcs)

T (inch) H (inch)

B (inch) D (inch) C (inch)

ACCESSORY

1 ● ● 1 1/8 4 1/2 3 1/8 1/8 4 5/8

1 1/2 ● ● 1 5/8 5 1/2 3 7/8 1/8 4 5/8

2 ● ● 2 1/8 6 1/2 4 3/4 1/8 4 3/4

2 1/2 ● ● 2 5/8 7 1/2 5 1/2 1/8 4 3/4

3 ● ● 3 1/8 8 6 1/8 4 3/4

4 ● ● 4 1/8 9 1/2 7 1/2 1/8 8 7/8

5 ● ● 5 1/8 10 1/2 8 1/2 1/8 8 7/8

6 ● ● 6 1/8 11 1/2 9 1/2 1/8 8 7/8

8 ● ● 8 1/8 14 11 3/4 3/16 8 7/8

10 ● ● 10 1/8 16 1/2 14 1/4 3/16 12 1

12 ● ● 12 1/8 19 1/2 17 3/16 12 1

14 ● ● 14 1/8 21 1/2 18 3/4 3/16 12 1 1/8

16 ● ● 16 1/8 24 21 1/4 3/16 16 1 1/8

18 ● ● 18 1/8 25 1/2 22 1/4 3/16 16 1 1/4

20 ● ● 20 1/8 28 25 3/16 20 1 1/4

24 ● ● 24 1/8 32 1/2 29 1/2 1/4 20 1 3/8

30 ● ● 30 1/8 39 1/4 36 1/4 28 1 3/8

36 ● ● 36 1/8 46 42 3/4 1/4 32 1 5/8

21 2018 © Litek Composites Corp.

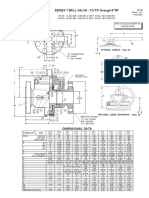

Full Face EPDM+PTFE Gasket Series

Product Description

The EPDM+PTFE gaskets are manufactured with the highest

quality of EPDM rubber and PTFE for maximum chemical and

corrosion resistance.

The gaskets are designed with dual, concentric, convex sealing

rings to aid optimum sealing at lower bolt loads. It offers superior

sealing for hazard media at low bolt torque. The unique inner

PTFE sealing ring provided an additional sealing safety for both

gases and liquids. It is ideally suited for fiberglass, glass lined and

steel full face flanges. These gaskets will virtually eliminate cracked

flanges, reducing installation cost, while maintaining a high

performance seal for corrosion resistance.

Specification

◆ Gasket Standard: ASME B16.21 Class ASA 150

Product Features

FRP PIPING

◆ Dimension : ANSI B16.5 drilling

◆ Low Bolt Torque with superior Sealing ◆ Pressure : 150 PSI Plus

◆ PTFE bonded to EPDM for high corrosion resistance ◆ Temperature : - 22° F/-30° C to 300° F/150° C

◆ Peroxide Cure EPDM for higher temperature resistance ◆ Color : Black (EPDM) + Blue (PTFE)

◆ Dual, Concentric, Convex Sealing Rings ◆ Materials : Premium quality PTFE bonded with EPDM Rubber

◆ Extra Ring Tab to assist positioning while installation ◆ Applications : Excellent corrosion resistance to all chemicals

ACCESSORY

Dimension Material

EPDM

D

C

B

PTFE

NxH T

Dimension Table

Gasket Gasket Bolt Gasket Bolt Hole

Flange No.of Holes

Inside Diameter Outside Diameter Circle Diameter Thickness Diameter

Diameter N (pcs)

B (inch) D (inch) C (inch) T (inch) H (inch)

1 1 1/8 4 3 1/8 3/16 4 5/8

2 2 3/16 5 3/4 4 3/4 3/16 4 3/4

2 1/2 2 3/4 6 3/4 5 1/2 3/16 4 3/4

3 3 3/16 7 3/8 6 3/16 4 3/4

4 4 1/16 8 3/4 7 1/2 3/16 8 3/4

6 6 10 3/4 9 1/2 3/16 8 7/8

8 7 7/8 13 1/4 11 3/4 3/16 8 7/8

10 9 7/8 15 3/4 14 1/4 1/4 12 1

12 11 7/8 18 3/4 17 1/4 12 1

2018 © Litek Composites Corp. 22

Taiwan Head Office

INTERLAND COMPANY, LTD.

23F, No. 27-10, Sec. 2, Zhong Zheng E. Rd.,

Tamsui Dist., New Taipei City 251, Taiwan

Tel : +886 (2)8809-8355

Fax : +886 (2)8809-8366

E-mail : info@interlandco.com

http://www.interlandco.com

U.S. Office

LITEK COMPOSITES CORP.

13970 Benson Ave., Chino, CA 91710, USA

Tel : 909-591-4977

Fax : 909-591-4990

E-mail : info@litekco.com

http://www.litekco.com

China Factory

LITEK COMPOSITE (XIAMEN) CO., LTD.

No.215 Shanmei Road, Guankou, Jimei District,

Xiamen, 361023 China

Tel : +86 (592)531-0077

Fax : +86 (592)531-0769

E-mail : info@litekco.com

http://www.litekco.com

REMARKS

Information appearing in this literature concerning our products are based on

facts and data believed to be accurate; however, it is the user's responsibility

to determine the suitability for his own use of the products described herein.

No guarantee, expressed or implied, is made by Litek Composites Corp.(LCC)

as to the effects of such use, not does LCC assume any liability arising out of

the use of the products described herein.

FRPSUPPLY.COM

Das könnte Ihnen auch gefallen

- PLANO ELECTRICO Cat - Dcs.sis - Controller.Dokument4 SeitenPLANO ELECTRICO Cat - Dcs.sis - Controller.ctorres_505746Noch keine Bewertungen

- Nema Quick Reference Chart: Leading Provider of Energy Efficient Industrial Electric Motors and DrivesDokument1 SeiteNema Quick Reference Chart: Leading Provider of Energy Efficient Industrial Electric Motors and DrivesrsanjuanNoch keine Bewertungen

- NEMA Motor Dimensions - Reference ChartDokument2 SeitenNEMA Motor Dimensions - Reference ChartMOTORES, MOTORREDUCTORES Y COMPONENTES GUADALAJARANoch keine Bewertungen

- Pocket Bolt Reference ChartDokument6 SeitenPocket Bolt Reference ChartVictor GarciaNoch keine Bewertungen

- Bleed Ring - ANSI Class 150-2500 (In)Dokument2 SeitenBleed Ring - ANSI Class 150-2500 (In)ulfatNoch keine Bewertungen

- Washer Dimensions PDFDokument2 SeitenWasher Dimensions PDFTarunNoch keine Bewertungen

- Baldor Nema ChartDokument1 SeiteBaldor Nema ChartHNoch keine Bewertungen

- What Is The Difference Between Lateral Tee and True WyeDokument11 SeitenWhat Is The Difference Between Lateral Tee and True WyeYaneYangNoch keine Bewertungen

- Flange Data: Bolt Reference Charts For ASME B16.5 FlangesDokument4 SeitenFlange Data: Bolt Reference Charts For ASME B16.5 FlangesMilena Lemus FonsecaNoch keine Bewertungen

- Stud Bolt ChartDokument2 SeitenStud Bolt ChartDI DI100% (1)

- Enterprise Rental Agreement 8FB73XDokument2 SeitenEnterprise Rental Agreement 8FB73XprateekmuleNoch keine Bewertungen

- Ams 2412 KDokument8 SeitenAms 2412 KThaís FalcãoNoch keine Bewertungen

- NEMA FrameDokument1 SeiteNEMA Frameriff100% (9)

- API 650 Tank Nozzle Stand OutDokument5 SeitenAPI 650 Tank Nozzle Stand Outgplese0Noch keine Bewertungen

- BedZED Housing, Sutton, London BILL DUNSTER ARCHITECTS PDFDokument3 SeitenBedZED Housing, Sutton, London BILL DUNSTER ARCHITECTS PDFflavius00Noch keine Bewertungen

- Audi Q2 Owner ManualDokument364 SeitenAudi Q2 Owner ManualSnap Blue75% (4)

- Astm d696Dokument5 SeitenAstm d696prateekmuleNoch keine Bewertungen

- Padeyes: Engineered & CertifiedDokument4 SeitenPadeyes: Engineered & CertifiedMahmoudNoch keine Bewertungen

- Construction ExecutiveDokument108 SeitenConstruction ExecutiveKrishna Rao VelagapudiNoch keine Bewertungen

- Hybrid Car ReportDokument52 SeitenHybrid Car ReportprateekmuleNoch keine Bewertungen

- AFR Conference - Mumbai - CII - FinalDokument65 SeitenAFR Conference - Mumbai - CII - FinalRaja Rao KamarsuNoch keine Bewertungen

- Directive 036 Drilling Blowout Prevention Requirements and ProceduresDokument211 SeitenDirective 036 Drilling Blowout Prevention Requirements and ProceduresFoad MirzaieNoch keine Bewertungen

- SBI Statement SampleDokument2 SeitenSBI Statement Sampleprateekmule50% (2)

- SBI Statement SampleDokument2 SeitenSBI Statement Sampleprateekmule50% (2)

- Sugar enDokument12 SeitenSugar enakhmad zaenudinNoch keine Bewertungen

- Stub End For FRP PipeDokument1 SeiteStub End For FRP PipeNABEEL ABDUL GAFFARNoch keine Bewertungen

- 1221 Standard Pipe NipplesDokument1 Seite1221 Standard Pipe NipplesmvinuNoch keine Bewertungen

- FYBROC-Series 5530 Vertical Pump Dry PitDokument8 SeitenFYBROC-Series 5530 Vertical Pump Dry PitAdi Toto HaryonoNoch keine Bewertungen

- Blind RTJ FlangeDokument7 SeitenBlind RTJ FlangeAMIRHUSAIN MOMINNoch keine Bewertungen

- Bronze Flanges - ASME/ANSI 150 LB: (Inches)Dokument6 SeitenBronze Flanges - ASME/ANSI 150 LB: (Inches)Karim ShamsNoch keine Bewertungen

- Ring Joint Flanges: ANSI B16.5, ANSI B16.20Dokument1 SeiteRing Joint Flanges: ANSI B16.5, ANSI B16.20QC RegianNoch keine Bewertungen

- Anchor Type PTP HD-1Dokument1 SeiteAnchor Type PTP HD-1ELINoch keine Bewertungen

- PTP Hd-1: Hold Down (Anchor Type)Dokument1 SeitePTP Hd-1: Hold Down (Anchor Type)bayzuraNoch keine Bewertungen

- Technical-Guides Shackle Inspection Spa 2003Dokument1 SeiteTechnical-Guides Shackle Inspection Spa 2003israel11288Noch keine Bewertungen

- Fig. Ptp-1: Short Variable SpringDokument1 SeiteFig. Ptp-1: Short Variable Springali murtadhoNoch keine Bewertungen

- Sch80ctech SDL80C TDokument9 SeitenSch80ctech SDL80C Thumberto.aranguiz2715Noch keine Bewertungen

- L Series BrochureWebDokument16 SeitenL Series BrochureWebmadhavikNoch keine Bewertungen

- Slip On Flange RTJ GasketDokument2 SeitenSlip On Flange RTJ GasketEDAC RFCLNoch keine Bewertungen

- API Specification 7-1 Addendum 1 20201221Dokument11 SeitenAPI Specification 7-1 Addendum 1 20201221deepeshtNoch keine Bewertungen

- Flange Size TableDokument1 SeiteFlange Size Tablediana.isbalNoch keine Bewertungen

- Bolt, Stud, Sealing, Gasketing and Nut Sizes For Piping: Class 150 Steel and 125 Cast IronDokument1 SeiteBolt, Stud, Sealing, Gasketing and Nut Sizes For Piping: Class 150 Steel and 125 Cast IronGiorgi KOGOSHVILINoch keine Bewertungen

- NEMA Motor Dim ChartDokument2 SeitenNEMA Motor Dim Chartmilind1983100% (2)

- LB&A CatalogueDokument127 SeitenLB&A CataloguekingdbmNoch keine Bewertungen

- ANSI B16.5 Flanges: Class 150Dokument17 SeitenANSI B16.5 Flanges: Class 150Djoko Dwi IrwantoNoch keine Bewertungen

- Fig50 PipeclampDokument1 SeiteFig50 PipeclampezhiljananiNoch keine Bewertungen

- Flange - Long Weld Neck, ANSI Class 600, ASME B16.5, 1 - 16 - Raised Face (In)Dokument2 SeitenFlange - Long Weld Neck, ANSI Class 600, ASME B16.5, 1 - 16 - Raised Face (In)Magin Idelfonso TorreblancaNoch keine Bewertungen

- Bridas Slip On Grandes b16.47Dokument1 SeiteBridas Slip On Grandes b16.47Nilton Inca TitoNoch keine Bewertungen

- LEESON Frame SizesDokument3 SeitenLEESON Frame SizesAnuragNoch keine Bewertungen

- TexasFlange - Bolt and Stud Dimensions ASME B16.5Dokument2 SeitenTexasFlange - Bolt and Stud Dimensions ASME B16.5cristinelbNoch keine Bewertungen

- Fig50 Pipeclamp PDFDokument1 SeiteFig50 Pipeclamp PDFMohamed GuezguezNoch keine Bewertungen

- How To Get High Quality Pipe TeesDokument11 SeitenHow To Get High Quality Pipe TeesYaneYangNoch keine Bewertungen

- Blind Flanges For FRP PipeDokument1 SeiteBlind Flanges For FRP PipeNABEEL ABDUL GAFFARNoch keine Bewertungen

- 101X Catalog 22 Kant Twist ClampsDokument1 Seite101X Catalog 22 Kant Twist ClampsAndargieNoch keine Bewertungen

- Desv - SubmittalDokument2 SeitenDesv - SubmittalALEX MIRANDANoch keine Bewertungen

- Nema - Quick Reference Chart: ESR Motor SystemsDokument2 SeitenNema - Quick Reference Chart: ESR Motor SystemsadolfNoch keine Bewertungen

- As SPT FS Sy EqrDokument2 SeitenAs SPT FS Sy EqrAndreyNoch keine Bewertungen

- KF Trunnion Ball Valve 1-8 900lbsDokument2 SeitenKF Trunnion Ball Valve 1-8 900lbsDiegoNoch keine Bewertungen

- TorqueDokument6 SeitenTorquelucianaNoch keine Bewertungen

- TorqueDokument6 SeitenTorquelucianaNoch keine Bewertungen

- Anchor - 0396Dokument44 SeitenAnchor - 0396Rudra PanditNoch keine Bewertungen

- Stud / Plate MountsDokument25 SeitenStud / Plate MountsnutanayaNoch keine Bewertungen

- Roller Hanger: Material: Service: How To Size: OrderingDokument1 SeiteRoller Hanger: Material: Service: How To Size: OrderingAsif HaqNoch keine Bewertungen

- Flanges and Bolt Dimensions - Class 150 To 2500 - ASME - ANSI B16 (Mat Bich)Dokument4 SeitenFlanges and Bolt Dimensions - Class 150 To 2500 - ASME - ANSI B16 (Mat Bich)Duong ThanhNoch keine Bewertungen

- Gaumer Flange Heater CatalogDokument70 SeitenGaumer Flange Heater CatalogRaul García (INNTELLIA)Noch keine Bewertungen

- Gaumer Flange Heater Catalog PDFDokument70 SeitenGaumer Flange Heater Catalog PDFRaul García (INNTELLIA)Noch keine Bewertungen

- Fig100 TPI UboltDokument1 SeiteFig100 TPI UboltYotselys LópezNoch keine Bewertungen

- Bolting Dimensions For 150lb 300lb 600lb 900lb Flanges-RevisedDokument2 SeitenBolting Dimensions For 150lb 300lb 600lb 900lb Flanges-RevisedRICARDO RUEDANoch keine Bewertungen

- Lasco Fittings - Tech80Dokument14 SeitenLasco Fittings - Tech80cario_mak_ainsworthNoch keine Bewertungen

- ThreadedDokument6 SeitenThreadedL Antonio Savino AthaydeNoch keine Bewertungen

- Flange Dimensions 250# & 300#Dokument1 SeiteFlange Dimensions 250# & 300#NathanNoch keine Bewertungen

- Bolt & Gasket Sets - Spec Sheet: Non-Asbestos Red RubberDokument3 SeitenBolt & Gasket Sets - Spec Sheet: Non-Asbestos Red RubberPatel MehulNoch keine Bewertungen

- "Int. Pressure - Bot. Sec." "Int. Pressure - Top. Sec." "Int. Pressure - Axial " Ift STR "PASS", "FAIL", Ift STR "PASS", "FAIL", Ift T "PASS", "FAIL"Dokument1 Seite"Int. Pressure - Bot. Sec." "Int. Pressure - Top. Sec." "Int. Pressure - Axial " Ift STR "PASS", "FAIL", Ift STR "PASS", "FAIL", Ift T "PASS", "FAIL"prateekmuleNoch keine Bewertungen

- Estimated Weights and CapacitiesDokument1 SeiteEstimated Weights and CapacitiesprateekmuleNoch keine Bewertungen

- Planned Component Laminate Thicknesses: ThermoDokument1 SeitePlanned Component Laminate Thicknesses: ThermoprateekmuleNoch keine Bewertungen

- A. Cylindrical ShellDokument1 SeiteA. Cylindrical ShellprateekmuleNoch keine Bewertungen

- Profile Gasket Data SheetDokument2 SeitenProfile Gasket Data SheetprateekmuleNoch keine Bewertungen

- Astm D5685 PDFDokument5 SeitenAstm D5685 PDFprateekmuleNoch keine Bewertungen

- Discharge of Title Deeds by The Authorized PersonDokument1 SeiteDischarge of Title Deeds by The Authorized PersonprateekmuleNoch keine Bewertungen

- Vinyl Catalog and Technical Information 2019Dokument245 SeitenVinyl Catalog and Technical Information 2019prateekmuleNoch keine Bewertungen

- Hetron Guide PC-9797Dokument76 SeitenHetron Guide PC-9797Peñaloz GustavoNoch keine Bewertungen

- Ineos Com 19 Dera Resin Selection Guide 002 PDFDokument68 SeitenIneos Com 19 Dera Resin Selection Guide 002 PDFprateekmuleNoch keine Bewertungen

- Technical Datasheet: DERAKANE® 510 B-400 Epoxy Vinyl Ester ResinDokument5 SeitenTechnical Datasheet: DERAKANE® 510 B-400 Epoxy Vinyl Ester ResinprateekmuleNoch keine Bewertungen

- Vinyl Catalog and Technical Information 2019Dokument245 SeitenVinyl Catalog and Technical Information 2019prateekmuleNoch keine Bewertungen

- Asymmetric Expansion1.5Dokument24 SeitenAsymmetric Expansion1.5prateekmuleNoch keine Bewertungen

- Perancangan Elevator Penumpang Pada Gedung Bertingkat Dengan Kapasitas 500 KG Di Yanglim Plaza MedanDokument11 SeitenPerancangan Elevator Penumpang Pada Gedung Bertingkat Dengan Kapasitas 500 KG Di Yanglim Plaza MedanWin ManikNoch keine Bewertungen

- Course DescriptionDokument24 SeitenCourse DescriptionleoyayNoch keine Bewertungen

- T S For Power TransformerDokument11 SeitenT S For Power TransformerAbhijeet Kumar SinghNoch keine Bewertungen

- Construction Stats 2014Dokument8 SeitenConstruction Stats 2014Daniel1713Noch keine Bewertungen

- Cat Probes NDT Engl SonotecDokument58 SeitenCat Probes NDT Engl SonotecamitNoch keine Bewertungen

- 3 Second Law of ThermodynamicsDokument6 Seiten3 Second Law of ThermodynamicsRaahiNoch keine Bewertungen

- Automobile Workshop PracticeDokument2 SeitenAutomobile Workshop PracticeSachi MensiNoch keine Bewertungen

- Haier Ab36nacbea Ac36nacbea Ad36nambea Ad36nahbea Ab42nacbea Ac42nacbea Ad42nambea Ad42nahbea Ap42nacbea Au36naibea Au42naibeaDokument143 SeitenHaier Ab36nacbea Ac36nacbea Ad36nambea Ad36nahbea Ab42nacbea Ac42nacbea Ad42nambea Ad42nahbea Ap42nacbea Au36naibea Au42naibeaZsooti0% (1)

- SlowspeedwatercooledDokument2 SeitenSlowspeedwatercooledapi-311397395Noch keine Bewertungen

- Evmsu Evmug L BRDokument9 SeitenEvmsu Evmug L BRzamdannNoch keine Bewertungen

- Paving and Surface TreatmentsDokument11 SeitenPaving and Surface TreatmentsLhaie BalasbasNoch keine Bewertungen

- Transformer Protection FudamentalsDokument8 SeitenTransformer Protection FudamentalsputrasejahtraNoch keine Bewertungen

- Fujitec Handrail MaintenanceDokument2 SeitenFujitec Handrail Maintenancea_salehiNoch keine Bewertungen

- Traditional Rural House in Kutch Region of IndiaDokument17 SeitenTraditional Rural House in Kutch Region of Indiaarchitectfemil6663Noch keine Bewertungen

- Commercial Use of STranded GasDokument6 SeitenCommercial Use of STranded GasaidanNoch keine Bewertungen

- 02 Reservoir ProblemsDokument30 Seiten02 Reservoir ProblemsEmad ZakiNoch keine Bewertungen

- "T I " A S M GL5606 O I A F P C P: HE NCH Utomatic Prinkler Odel NE NCH Djustable LAT Late Oncealed EndentDokument2 Seiten"T I " A S M GL5606 O I A F P C P: HE NCH Utomatic Prinkler Odel NE NCH Djustable LAT Late Oncealed EndentAli Y. Abu YeheaNoch keine Bewertungen

- W P ADokument8 SeitenW P ASardar PerdawoodNoch keine Bewertungen

- 081-100 Ramiro Sofronie - 20 PDokument20 Seiten081-100 Ramiro Sofronie - 20 PamaliaconstantinNoch keine Bewertungen

- Scott GroverDokument3 SeitenScott GroverJoe StephensNoch keine Bewertungen