Beruflich Dokumente

Kultur Dokumente

Structural Design Short Formula

Hochgeladen von

MIslamMonirOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Structural Design Short Formula

Hochgeladen von

MIslamMonirCopyright:

Verfügbare Formate

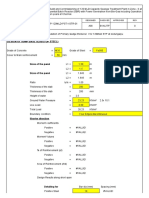

WORKING STRESS DESIGN

ONE WAY SOLID SLAB DESIGN:

According to ACI Code minimum thickness of one way RCC Slab is:

1

a. Minimum Thickness of Simply supported slab t=

25

1

b. Minimum Thickness of Semi-continuous slab t=

30

1

c. Minimum Thickness of Fully continuous slab t=

35

1

d. Minimum Thickness of Cantilever slab t=

12

Assumed minimum depth of Slab = .033L meter to .04L meter.

Effective depth of Slab, d=

√ M

Rb

Here, d= Effective depth of slab

b= Width of Considered Strip

M= Bending Moment

1

R= fc j k

2

n

K= fs

n+

fc

fc=

K

j= 1 -

3

W.S.D Method

Step-1: Design Load :

Step-2: maximum shear force :

For Simply Supported & Continuous Slab

W

Maximum Shear force, V =

2

For Semi-Continuous Slab

At free end V=0.40W

At Continuous end V=0.60W

For Cantilever Slab V= W

STEP-3: MAXIMUM BENDING MOMENT

WL

For Simply Supported Slab maximum bending Moment M=

8

WL

For Semi-continuous Slab maximum bending Moment, M=

10

WL

For Continuous Slab maximum bending Moment M=

12

STEP-4: FIND DEPTH OF SLAB:

Effective depth of Slab, d=

√ M

Rb

Here, d= Effective depth of slab

b= Width of Considered Strip

M= Bending Moment

1

R= fc j k

2

n

K= fs

n+

fc

fc=

K

j= 1 -

3

¯

Dia of ¿

Total Depth = Effective depth + Clear Covering+ 2

¿

STEP-5: AREA OF TENSILE REINFORCEMENT :

M

Area of reinforcement for assumed strip, As =

fsjd

bas

Spacing of bar S=

As

b= assumed strip width

as=Sectional area of one Rod

As=Total Sectional area of assumed Strip.

STEP-6: SHEAR STRESS :

V

Shear Stress at support ν = bd

Vcr

Shear stress at a distance d from Support ν = bd

V= Shear force at support

Vcr= Shear force at distance d from support

Allowable shear stress of concrete Vc=0.292 √f ' c

Step-7: Bond Stress:

V

Bond Stress u=

Σajd

Σa = Sum of Perimeter for cross section of main rod in a

strip

Allowable bond stress

2.29 √ f ' c

For top bar =

D

3.23 √ f ' c

For Bottom Bar =

D

And Maximum =35.2 kg/cm2

Here,

D = Diameter of Rod

STEP-8:AREA OF SHRINKAGE & TEMPERATURE REINFORCEMENT

For Deformed Bar A’s= 0.002bt

For Plain Bar A’s = 0.0025bt

100 as

Spacing of Temperature rod S =

A' s

Here,

as = Cross sectional area of one rod

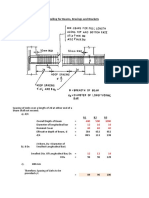

STEP-9: DETAIL SKETCH

U.S.D METHOD OF DESIGN

1. Design Load :

Ultimate Load Wu = 1.7L+ 1.4D

2. Maximum Shear Force :

3. Maximum Bending Moment :

4. Depth of Slab :

f 'c 6117

Balanced Steel Ratio ρb=0.85β1 x

fy (6117 +fy)

Here,

β1= Ratio of Stress

Max Steel Ratio, ρmax = 0.75 ρb

¿ fy

Maximum Nominal Resisting Moment, Mn = ρfy bd2 ¿ 1-0.59

f 'c

]

Maximum Bending Moment or Factored Load Moment, Mu = ФMn

Ф= Moment factor

Mu

Area of Tension Reinforcement As= a

Ф fy( d− )

2

ρdfy

a= 0.85 f ' c

d

Critical Shear at distance d from internal support, Vu (critical) = Vu – W X

100

Vu

Shear Stress, Ʋu = bd

Allowable Shear stress by Concrete, Ʋuc = 0.53 Ф √ f ' c

6.39 √ f ' c

Allowable Ultimate Bond stress, Uall =

D

Das könnte Ihnen auch gefallen

- P-Delta CheckDokument22 SeitenP-Delta CheckKeshab BadalNoch keine Bewertungen

- Stair Stringer DesignDokument2 SeitenStair Stringer DesignTerry CheukNoch keine Bewertungen

- Final DocumentDokument82 SeitenFinal Documentsudarshan royalNoch keine Bewertungen

- Solution Manual for an Introduction to Equilibrium ThermodynamicsVon EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNoch keine Bewertungen

- Example J.7 Base Plate Bearing On Concrete: = P / (Φ · 0.85f') = Bn = B D = Φ · 0.85f' A min (2, (A / A) )Dokument2 SeitenExample J.7 Base Plate Bearing On Concrete: = P / (Φ · 0.85f') = Bn = B D = Φ · 0.85f' A min (2, (A / A) )Martin VenichNoch keine Bewertungen

- Isoloated Footing DesignDokument7 SeitenIsoloated Footing Designvijay moreNoch keine Bewertungen

- Design of Brick Wall For Ware House:-: 1 DataDokument3 SeitenDesign of Brick Wall For Ware House:-: 1 DataSovan PramanickNoch keine Bewertungen

- Wind Load CalculationDokument17 SeitenWind Load CalculationNIHARIKA JAINNoch keine Bewertungen

- DBR PDFDokument72 SeitenDBR PDFharshNoch keine Bewertungen

- ACI Beam LedgeDokument7 SeitenACI Beam LedgeMahmoud ShakerNoch keine Bewertungen

- Design of Flush Extended End Plate ConnectionsDokument3 SeitenDesign of Flush Extended End Plate ConnectionsMai CNoch keine Bewertungen

- Max Absolute Stress in Plate Contour - RAM - STAAD Wiki - RAM - STAAD - Bentley CommunitiesDokument3 SeitenMax Absolute Stress in Plate Contour - RAM - STAAD Wiki - RAM - STAAD - Bentley CommunitiesvijaykumarzNoch keine Bewertungen

- Anchor Bolt CheckDokument1 SeiteAnchor Bolt CheckihpeterNoch keine Bewertungen

- Quikjoint - Eaves Haunch Calculations PDFDokument9 SeitenQuikjoint - Eaves Haunch Calculations PDFvtalexNoch keine Bewertungen

- Copenhagen Interpretation - WikipediaDokument12 SeitenCopenhagen Interpretation - WikipediaYn Foan100% (1)

- Chladni Pattern: Wence Xiao Supervisor:Anders MadsenDokument56 SeitenChladni Pattern: Wence Xiao Supervisor:Anders MadsenAlexis AlvarezNoch keine Bewertungen

- Fractional Distillation of An Ethanol - Water MixtureDokument7 SeitenFractional Distillation of An Ethanol - Water Mixturekrupa_patel_8784% (25)

- Glass Panel (2-Side Supported) : Calculation SheetDokument1 SeiteGlass Panel (2-Side Supported) : Calculation SheetMichaeluiMichaeluiNoch keine Bewertungen

- Shear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationDokument4 SeitenShear Connection For Ismb 300 TO ISMB350 COL: Bolt CalculationNitin SakpalNoch keine Bewertungen

- Lab Conservation of Mechanical EnergyDokument10 SeitenLab Conservation of Mechanical EnergyNNoch keine Bewertungen

- Cladding& Runner DesignDokument1 SeiteCladding& Runner DesignDeepmalaJayeshNoch keine Bewertungen

- Wall DesignDokument10 SeitenWall DesignJames WilliamsNoch keine Bewertungen

- 8c. Sump Slab - Top SteelDokument10 Seiten8c. Sump Slab - Top Steelepe civil1Noch keine Bewertungen

- Counter Fort Retaining WallDokument3 SeitenCounter Fort Retaining WalljosefNoch keine Bewertungen

- Ductile Detailing Rect. ColDokument12 SeitenDuctile Detailing Rect. Colankkeshmundra1Noch keine Bewertungen

- Dayco - Hydraulic HosesDokument293 SeitenDayco - Hydraulic Hosesjbarr58Noch keine Bewertungen

- WIND LOADING ANALYSIS - Roof Components and CladdingDokument3 SeitenWIND LOADING ANALYSIS - Roof Components and CladdingdantevariasNoch keine Bewertungen

- Beam - Capacity Check - SumanDokument4 SeitenBeam - Capacity Check - Sumansuman_civilNoch keine Bewertungen

- Design of Shear Wall (Pier P1) : Check For MomentDokument6 SeitenDesign of Shear Wall (Pier P1) : Check For MomentNishan GajurelNoch keine Bewertungen

- Areva T& D India Limited: Design of Circular Sump Input DataDokument2 SeitenAreva T& D India Limited: Design of Circular Sump Input DatajatinNoch keine Bewertungen

- Beam Design (SSB)Dokument6 SeitenBeam Design (SSB)Er Sai KiranNoch keine Bewertungen

- Wse Ibps CV DD 2Dokument146 SeitenWse Ibps CV DD 2Lagnajit DasNoch keine Bewertungen

- 2.0 Sluice Valve Chamber Precast Panel DesignDokument2 Seiten2.0 Sluice Valve Chamber Precast Panel DesignGaurav BhabadNoch keine Bewertungen

- Client Name: Prepared By: Date: A Project Name: Location: DescriptionDokument1 SeiteClient Name: Prepared By: Date: A Project Name: Location: Descriptionvj8584Noch keine Bewertungen

- Allowable Drift or Side Sway Calculation According To Diff CodeDokument30 SeitenAllowable Drift or Side Sway Calculation According To Diff CodeKawser HossainNoch keine Bewertungen

- Earthquake Resistant StructuresDokument6 SeitenEarthquake Resistant StructuresAmith KeshvtakarNoch keine Bewertungen

- Slab Manual DesignDokument1 SeiteSlab Manual DesignAtul ShrivastavaNoch keine Bewertungen

- XyzDokument64 SeitenXyzP S HARSHITANoch keine Bewertungen

- Second Phase Presentation ON Design and Analysis 2.5lakh Litres Overhead Intze Type Water TankDokument96 SeitenSecond Phase Presentation ON Design and Analysis 2.5lakh Litres Overhead Intze Type Water TankHarsha DharmapalNoch keine Bewertungen

- Design of Pile: 400Mm Dia Pile Design (Applicable For 0M-0.5M Fill)Dokument3 SeitenDesign of Pile: 400Mm Dia Pile Design (Applicable For 0M-0.5M Fill)sivaNoch keine Bewertungen

- Design of FootingDokument15 SeitenDesign of FootingRumylo AgustinNoch keine Bewertungen

- Structural Analysis & Design: Structural Report On Dang ProjectDokument68 SeitenStructural Analysis & Design: Structural Report On Dang ProjectNishan GajurelNoch keine Bewertungen

- Aisc 01Dokument5 SeitenAisc 01amokhtaNoch keine Bewertungen

- Procedure of Steel Design PDFDokument13 SeitenProcedure of Steel Design PDFsiddy23692Noch keine Bewertungen

- Spring Value CalculationDokument16 SeitenSpring Value CalculationSrishti Project ConsultantsNoch keine Bewertungen

- Foundation LoadDokument2 SeitenFoundation LoadmathuNoch keine Bewertungen

- Flat Slab Punching Shear Check r1Dokument5 SeitenFlat Slab Punching Shear Check r1Usama ChauguleNoch keine Bewertungen

- 1 - Design of Purlins Engr. S. Olarte Cesd 443: Structural Design 2 (Steel and Timber Cesd 443: Structural Design 2 (Steel and Timber)Dokument9 Seiten1 - Design of Purlins Engr. S. Olarte Cesd 443: Structural Design 2 (Steel and Timber Cesd 443: Structural Design 2 (Steel and Timber)Amihan De GuzmanNoch keine Bewertungen

- Retrofitting Columns 20JAN09Dokument4 SeitenRetrofitting Columns 20JAN094geniecivilNoch keine Bewertungen

- Gusset BaseDokument2 SeitenGusset Basemanish mehtaNoch keine Bewertungen

- Design of Long Wall: Tank Full and No Soil PressureDokument6 SeitenDesign of Long Wall: Tank Full and No Soil PressureAshoka YadavNoch keine Bewertungen

- Footing Calculation PDFDokument10 SeitenFooting Calculation PDFVaishak KrishnanNoch keine Bewertungen

- Design of Combined Foundation For Column C7 & C8Dokument6 SeitenDesign of Combined Foundation For Column C7 & C8Sneha RedkarNoch keine Bewertungen

- Prof M G Gadgil Building Designed As Per Old Code and IS 16700-2017 PDFDokument128 SeitenProf M G Gadgil Building Designed As Per Old Code and IS 16700-2017 PDFankit kadamNoch keine Bewertungen

- Ismc 250 Channel-Rolled Steel Beams (Indian Standard)Dokument3 SeitenIsmc 250 Channel-Rolled Steel Beams (Indian Standard)keshabshrNoch keine Bewertungen

- STAAD Report - Beam Design-1Dokument11 SeitenSTAAD Report - Beam Design-1prabhuNoch keine Bewertungen

- Planning, Analysis and Design of Open Air Cricket Stadium: Presented byDokument12 SeitenPlanning, Analysis and Design of Open Air Cricket Stadium: Presented byCatherine J. RoseNoch keine Bewertungen

- Jim CK Load - Calc 052611Dokument19 SeitenJim CK Load - Calc 052611GSVNoch keine Bewertungen

- Design Report PDFDokument439 SeitenDesign Report PDFKhaled Abdel SalamNoch keine Bewertungen

- Beam - Deflection CheckDokument8 SeitenBeam - Deflection CheckEko Bayu AjiNoch keine Bewertungen

- Project: ต่อเติมบ้านพักอาศัย Date: Owner: 0 Slap No: Location: 0 FloorDokument13 SeitenProject: ต่อเติมบ้านพักอาศัย Date: Owner: 0 Slap No: Location: 0 FloorSurat WaritNoch keine Bewertungen

- Base ShearDokument3 SeitenBase ShearLaxman ShresthaNoch keine Bewertungen

- C5420 16 SSC S 110Dokument182 SeitenC5420 16 SSC S 110Hema Chandra IndlaNoch keine Bewertungen

- Four Pile Caps StructvilleDokument6 SeitenFour Pile Caps Structvillemabuhamd100% (1)

- Structure Design FormulaDokument7 SeitenStructure Design FormulaMIslamMonirNoch keine Bewertungen

- Structure Design FormulaDokument7 SeitenStructure Design FormulaMIslamMonirNoch keine Bewertungen

- Change Here: Ultimate Bearing Capacity 30.00 KSFDokument8 SeitenChange Here: Ultimate Bearing Capacity 30.00 KSFMIslamMonirNoch keine Bewertungen

- Work Order - Structura DesignDokument1 SeiteWork Order - Structura DesignMIslamMonirNoch keine Bewertungen

- RC Final Footing Md. Mahfujur RahmanDokument66 SeitenRC Final Footing Md. Mahfujur RahmanMIslamMonirNoch keine Bewertungen

- CE-317 Design of Concrete Structures-II: FootingsDokument66 SeitenCE-317 Design of Concrete Structures-II: FootingsMIslamMonirNoch keine Bewertungen

- CV MonirDokument3 SeitenCV MonirMIslamMonirNoch keine Bewertungen

- Structure Estimate FormatDokument3 SeitenStructure Estimate FormatMIslamMonirNoch keine Bewertungen

- Air Entrainment in Vertical DropshaftsDokument199 SeitenAir Entrainment in Vertical DropshaftsZeroRecoNoch keine Bewertungen

- Thermodynamic RelationDokument7 SeitenThermodynamic RelationQuennie MaculaNoch keine Bewertungen

- Hydro Automation Erregung eDokument6 SeitenHydro Automation Erregung eLeonardo DemeraNoch keine Bewertungen

- Heating Effects of Short-Circuit Current Impulses On Contacts and Conductors-Part IDokument8 SeitenHeating Effects of Short-Circuit Current Impulses On Contacts and Conductors-Part IbertovalenNoch keine Bewertungen

- 1st Sem ExptsDokument10 Seiten1st Sem ExptsRavi Kanth M NNoch keine Bewertungen

- Chapter 13Dokument36 SeitenChapter 13Usep NuhNoch keine Bewertungen

- Technical Data Sheet R404A ENGLISH PDFDokument4 SeitenTechnical Data Sheet R404A ENGLISH PDFjane.yuchen8283100% (1)

- 0625 s10 QP 11Dokument22 Seiten0625 s10 QP 11Sam FordNoch keine Bewertungen

- Offshore HydrodynamicsDokument44 SeitenOffshore HydrodynamicsKtk ZadNoch keine Bewertungen

- Vocational Training Project: Durgapur Projects LimitedDokument116 SeitenVocational Training Project: Durgapur Projects LimitedaavikkNoch keine Bewertungen

- Effect of Lateral Load Distribution Pattern in Pushover AnalysisDokument6 SeitenEffect of Lateral Load Distribution Pattern in Pushover AnalysisAchilles TroyNoch keine Bewertungen

- Topology and Preliminary Design Slotless Brushless Motor: of DCDokument3 SeitenTopology and Preliminary Design Slotless Brushless Motor: of DCflorin91Noch keine Bewertungen

- CVE202 Lecture Notes-4 Leveling 1Dokument20 SeitenCVE202 Lecture Notes-4 Leveling 1Ashok NirmanNoch keine Bewertungen

- Triaxial Strength of Rocks: Prepared For: Akshay Chowdu & Shane LeeDokument16 SeitenTriaxial Strength of Rocks: Prepared For: Akshay Chowdu & Shane LeeAbhishek RayNoch keine Bewertungen

- Phys 23 T2 The Constant Volume Air ThermometerDokument4 SeitenPhys 23 T2 The Constant Volume Air ThermometerShashwat ChakrabortiNoch keine Bewertungen

- Introduction To: Transport PhenomenaDokument11 SeitenIntroduction To: Transport Phenomenadeepak patidarNoch keine Bewertungen

- Verification of Resistance in Series Apparatus Operating Instruction ManualDokument4 SeitenVerification of Resistance in Series Apparatus Operating Instruction ManualjassiscNoch keine Bewertungen

- Furnace AC Example PDFDokument5 SeitenFurnace AC Example PDFhanafiNoch keine Bewertungen

- Heat and Mass Transfer Fundamentals and Applications 8th Edition-BookreviewDokument8 SeitenHeat and Mass Transfer Fundamentals and Applications 8th Edition-Bookreviewashraf-84Noch keine Bewertungen

- Examples For Equation of StateDokument5 SeitenExamples For Equation of StateAntarim Dutta100% (1)

- Solutions Manual - Chapter 3 - RespostasDokument8 SeitenSolutions Manual - Chapter 3 - RespostasJPVSSNoch keine Bewertungen

- Exp 105 AnalysisDokument2 SeitenExp 105 AnalysisEriane GarciaNoch keine Bewertungen

- About Daniel BernoulliDokument2 SeitenAbout Daniel BernoulliIrfanNoch keine Bewertungen

- Oscillations: By-Tasneem Xi - A Roll-11138Dokument51 SeitenOscillations: By-Tasneem Xi - A Roll-11138Dilshad HussainNoch keine Bewertungen