Beruflich Dokumente

Kultur Dokumente

VHP 5904 Gsi Gsid

Hochgeladen von

Fabricio RubioOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

VHP 5904 Gsi Gsid

Hochgeladen von

Fabricio RubioCopyright:

Verfügbare Formate

GE Power & Water

Waukesha* gas engines

VHP Series Four * *

*

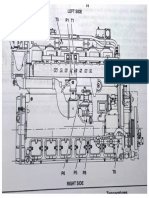

Enginator generating system Engine supplied with 3-way catalyst but

without exhaust piping. Engine-out and

catalyst-out exhaust piping shown for

VHP5904GSI/GSID

illustrative purposes only

with emPact Emission Control System

860 - 980 kW

GE’s Waukesha VHP generator sets are built for efficiency, exhaust and automatically adjusts the air/fuel ratio to keep

durability and longevity providing reliable power for the catalyst operating at maximum efficiency, even as

continuous and intermittent power applications. Reliable speed, load, fuel, and ambient conditions change.

12 cylinder VHP generator sets, rated at 500-1100 kWe at

50 Hz (1000 rpm) continuous duty to 1200 kWe at 60 Hz The emPact display panel provides real-time engine

(1200 rpm) intermittent duty, are ideal for remote sites. operating parameters, including faults, alarms, and

shutdowns. A logging function allows all data—including

Standard on the GSI configuration, Waukesha’s emPact catalyst temperature and pressure differential—to be

Emission Control System combines an engine, catalyst, saved to a USB device to simplify emissions reporting.

and air/fuel ratio control, factory-designed for optimal

interaction and maximum performance. It consists of a GE- Waukesha’s emPact Emission Control System provides a

supplied catalyst, pre- and post-catalyst oxygen sensing, one-stop shop for compliance and the simplest method of

and differential temperature and pressure sensors. obtaining and meeting emission permits.

emPact’s closed-loop control system measures the engine

technical data

Waukesha engine L5794GSI, four cycle Dimensions l x w x h inch (mm)

Cylinders V12 Heat exchanger 235 (5970) x 85 (2160) x 103 (2620)

Piston displacement 5788 cu. in. (95 L) Water connection 205 (5208) x 85 (2160) x 103 (2620)

Radiator 260 (6600) x 124 (3150) x 160 (4060)

Compression ratio 8.25:1

Bore & stroke 8.5” x 8.5” (216 mm x 216 mm) Weights lb (kg)

Jacket water system capacity 107 gal. (405 L) Heat exchanger 40000 (18140)

Lube oil capacity 190 gal. (719 L) Water connection 38000 (17230)

Starting system 24V electric Radiator 46,000 (20860)

*Trademark of General Electric Company

performance data

Continuous Power

60 Hz 50 Hz

Intercooler Water Temperature 130°F (54°C)

1200 RPM 1000 RPM

Power kW (heat exchanger/water connection cooling) 980 900

Power kW (radiator cooling) 940 860

BSFC (LHV) Btu/bhp-hr (kJ/kWh) 7665 (10843) 7433 (10515)

Fuel Consumption Btu/hr x 1000 (kW) 10578 (3100) 9403 (2754)

NOx g/bhp-hr (mg/Nm3 @ 5% O2) 0.5 (185)

Catalyst-Out

Emissions

(GSI only)

CO g/bhp-hr (mg/Nm3 @ 5% O2) 1.0 (370)

emPact

NMHC g/bhp-hr (mg/Nm3 @ 5% 02) 0.14 (58)

THC g/bhp-hr (mg/Nm3 @ 5% O2) 1.26 (477)

NOx g/bhp-hr (mg/Nm @ 5% O2)

3

13.50 (5011) 12.80 (4736)

Engine-Out

Emissions

CO g/bhp-hr (mg/Nm3 @ 5% O2) 10.20 (3770) 10.40 (3849)

NMHC g/bhp-hr (mg/Nm @ 5% 02)

3

0.28 (105) 0.29 (109)

THC g/bhp-hr (mg/Nm3 @ 5% O2) 1.80 (682) 2.00 (725)

Heat to Jacket Water Btu/hr x 1000 (kW) 3037 (890) 2699 (791)

Heat to Lube Oil Btu/hr x 1000 (kW) 470 (138) 391 (115)

Balance

Heat

Heat to Intercooler Btu/hr x 1000 (kW) 132 (39) 95 (28)

Heat to Radiation Btu/hr x 1000 (kW) 674 (198) 630 (185)

Total Exhaust Heat Btu/hr x 1000 (kW) 2959 (867) 2568 (753)

Induction Air Flow scfm (Nm3/hr) 2001 (3014) 1784 (2687)

Intake/Exhaust

Exhaust Flow lb/hr (kg/hr) 8984 (4075) 8011 (3634)

System

Exhaust Temperature °F (°C) 1136 (613) 1101 (594)

Radiator Air Flow scfm (m3/min) (radiator cooling) 100000 (2832) 85000 (2407)

Rating Standard: The Waukesha Enginator ratings are based on ISO 3046/1-1995 with an engine mechanical efficiency of 90% and auxiliary water temperature Tcra as

specified limited to ±10°F (±5°C). Ratings also valid for ISO 8528 and DIN 6271, BS 5514 standard atmospheric conditions.

Continuous Power Rating: The highest electrical power output of the Enginator available for an unlimited number of hours per year, less maintenance. It is permissable to

operate the Enginator with up to 10% overload for two hours in each 24 hour period.

All data according to full load and subject to technical development and modification.

emPact catalyst-out emissions valid from 100% - 75% load and 1200 rpm to 900 rpm and assume proper engine/catalyst maintenance and manual adjustment as necessary

Consult your local GE Power & Water’s representative for system application assistance. The manufacturer reserves the right to change or modify without notice, the design

or equipment specifications as herein set forth without incurring any obligation either with respect to equipment previously sold or in the process of construction except

where otherwise specifically guaranteed by the manufacturer.

GE Power & Water Visit us online at:

1101 West Saint Paul Ave. www.ge-waukesha.com

Waukesha, WI 53188-4999

P: 1.262.547.3311 ©2013 General Electric Company

F: 1.262.549.2759 All Rights Reserved

0214 GEA-18921

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- N20 Engine BMWDokument134 SeitenN20 Engine BMWSang Phan100% (1)

- Mercury Mariner 1Dokument54 SeitenMercury Mariner 1Shoaib Ahmed100% (1)

- D1146, P086Dokument314 SeitenD1146, P086griffithNoch keine Bewertungen

- MR2207 Atd1 Q&aDokument33 SeitenMR2207 Atd1 Q&ajeffreysingh jdNoch keine Bewertungen

- VHP 7100Dokument1 SeiteVHP 7100Fabricio RubioNoch keine Bewertungen

- Panel 625x625 Multipower SylvaniaDokument6 SeitenPanel 625x625 Multipower SylvaniaFabricio RubioNoch keine Bewertungen

- Zym GM23 5RDokument18 SeitenZym GM23 5RFabricio RubioNoch keine Bewertungen

- Electrical Solutions: Underground Hazard TapeDokument1 SeiteElectrical Solutions: Underground Hazard TapeFabricio RubioNoch keine Bewertungen

- Mvi56 MCM User Manual PDFDokument193 SeitenMvi56 MCM User Manual PDFViick MartinezNoch keine Bewertungen

- Power Over Ethernet (POE) Pinout For Cisco IP Phones and SwitchesDokument1 SeitePower Over Ethernet (POE) Pinout For Cisco IP Phones and SwitchesFabricio RubioNoch keine Bewertungen

- Piping Class Ratings Based On ASME B16Dokument1 SeitePiping Class Ratings Based On ASME B16Fabricio RubioNoch keine Bewertungen

- pc6104s - 01apr15 6155JDokument764 Seitenpc6104s - 01apr15 6155Jmiguelcastillo100% (1)

- (TIBU8169) Discontinue Use of The 447-6264 Tool As When Installing Crankshaft Seals On 3500 Engines PDFDokument2 Seiten(TIBU8169) Discontinue Use of The 447-6264 Tool As When Installing Crankshaft Seals On 3500 Engines PDFvictor.ciprianiNoch keine Bewertungen

- Free Piston Engine Working PDFDokument2 SeitenFree Piston Engine Working PDFAmyNoch keine Bewertungen

- Part Book Mio 110Dokument10 SeitenPart Book Mio 110Rakhmad QurniawanNoch keine Bewertungen

- Automotive Maintenance Chapter 3&4Dokument22 SeitenAutomotive Maintenance Chapter 3&4MeleseNoch keine Bewertungen

- Raider Max 175sDokument43 SeitenRaider Max 175sTEXASBAGMANNoch keine Bewertungen

- Turbo Control Solutions (TCS) Gas Turbine Mark Vi Control System Training ProgramDokument15 SeitenTurbo Control Solutions (TCS) Gas Turbine Mark Vi Control System Training Programعبدالسلام المبروك ابوزنادNoch keine Bewertungen

- Kohler Quick Reference GuideDokument41 SeitenKohler Quick Reference GuideJohn Jones IIINoch keine Bewertungen

- Wolf SB 250 NiDokument242 SeitenWolf SB 250 NiShamsul FikriNoch keine Bewertungen

- MT 01Dokument864 SeitenMT 01Алексей ЗваричNoch keine Bewertungen

- NISSAN Pathfinder (R51) 4.0 V6 VQ40DE: Timing Chain: Removal/installationDokument27 SeitenNISSAN Pathfinder (R51) 4.0 V6 VQ40DE: Timing Chain: Removal/installationAlejandro PerezNoch keine Bewertungen

- Teknik Pengukuran Terbang Tugas I Alat Ukur Di Pesawat TerbangDokument25 SeitenTeknik Pengukuran Terbang Tugas I Alat Ukur Di Pesawat TerbangrikiNoch keine Bewertungen

- Anwar Report LapDokument8 SeitenAnwar Report Lap01094255175 01094255175Noch keine Bewertungen

- Module 14 PropulsionDokument3 SeitenModule 14 PropulsionKetanRaoNoch keine Bewertungen

- Product Broucher PDFDokument48 SeitenProduct Broucher PDFanjaneya bvkNoch keine Bewertungen

- System Too Lean - P0171 (FUEL CONSUMPTION ISSUES) - Technical Forums - PakWheels Forums PDFDokument5 SeitenSystem Too Lean - P0171 (FUEL CONSUMPTION ISSUES) - Technical Forums - PakWheels Forums PDFEmad SmsaahNoch keine Bewertungen

- Io-520 Table of LimitsDokument9 SeitenIo-520 Table of LimitsCarolina Rubi Tellez Hernandez100% (1)

- ToolsCat 74Dokument58 SeitenToolsCat 742791957Noch keine Bewertungen

- Bosch Diesel Catalogue Indian OEM Applications: Updated - September 2021Dokument28 SeitenBosch Diesel Catalogue Indian OEM Applications: Updated - September 2021Obby Aryasuci100% (1)

- Porsche 3.6L Final PresentationDokument25 SeitenPorsche 3.6L Final Presentation19stifler91_82364693Noch keine Bewertungen

- Manual Testing Adjusting Komatsu Wb146 5 Backhoe Loader Engine Chassis Tools SystemsDokument39 SeitenManual Testing Adjusting Komatsu Wb146 5 Backhoe Loader Engine Chassis Tools SystemsLuis Gustavo Escobar MachadoNoch keine Bewertungen

- Chapter 9 Gas Cycles - Part IDokument30 SeitenChapter 9 Gas Cycles - Part Iryanritchie35Noch keine Bewertungen

- Especificaciones Culata de Cilindros C-9Dokument3 SeitenEspecificaciones Culata de Cilindros C-9Alejandro ValenzuelaNoch keine Bewertungen

- 2009-06-17 232200 Ism Low Oil Pressure ChartDokument4 Seiten2009-06-17 232200 Ism Low Oil Pressure ChartrowanNoch keine Bewertungen

- Chapter 9 GAS Power CycleDokument87 SeitenChapter 9 GAS Power CyclezabidullahNoch keine Bewertungen

- Contoh JSU Tahap 1-3 (No Weightage)Dokument10 SeitenContoh JSU Tahap 1-3 (No Weightage)Bakal JenazahNoch keine Bewertungen