Beruflich Dokumente

Kultur Dokumente

Crack Width2

Hochgeladen von

Rajesh0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten1 Seitecalculation

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldencalculation

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten1 SeiteCrack Width2

Hochgeladen von

Rajeshcalculation

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

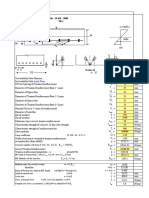

Crack Width Check

(For Quasi Permanent Combinations)

(i) Minimum Reinforcement for Crack Control

Area of steel required for crack control (Cl.

A s,min

12.3.3) = kc k fct,eff Act / ss

Where,

Coefficient accounts for stress distributionk c = 0.40

Coefficient accounts for non-uniform self-equilibrium

k = stresses 0.65

Mean value of tensile strength of concretef ct,eff = 3.00 MPa

Area of of concrete within tensile zone A ct = 0.39 m2

Total depth at section considered h = 1.75 m

Width of section b = 1.00 m

Max. stress permitted in steel immediatelysafter

s formation

= of crack 500.00 MPa

Min. Area of steel required for crack control

A smin = 607.62 mm2

2

Area of steel provided (on tension face) A st = 12057.6 mm SAFE

(ii) Calculation of Crack Width

Crack width (Cl. 12.3.4) wk = Sr,max ( esm - ecm )

Clear cover to the reinforcement c = 40 mm

Dia of reinforcement φ = 32 mm

Spacing of reinforcement s = 150 mm

Max. Spacing of reinforcement 5 (c +φ/2) = 280 mm

Hence, following formula can be used for calculation of maximum crack spacing.

Max. crack spacing S r, max 531 mm

Depth = min. of 2.5(h-d), (h-x)/3, h/2 h c,eff = 875 mm

2

Effective area of concrete in tension A c,eff = 875000 mm

Ratio ρ eff = 0.01378

s sc

Stress in tension reinf. assuming cracked section = 153.00000 MPa

E cm' = 16154.00000 MPa

Ratio ae = Es/Ecm = 12.00 MPa

Factor dependent on duration of the load k t 0.50

esm - ecm = Max. ofssc - kt fct,eff ( 1+ ae rP,eff ) / rP,eff and 0.6 ssc / Es

Es

= 0.00046

Calculated crack width wk = 0.244 mm

Das könnte Ihnen auch gefallen

- 7 Check For Crack Width: A) Deck SlabDokument2 Seiten7 Check For Crack Width: A) Deck SlabAnonymous jLLjBdrNoch keine Bewertungen

- Mechanical Science for Technicians: Volume 1Von EverandMechanical Science for Technicians: Volume 1Bewertung: 5 von 5 Sternen5/5 (1)

- QT200 Bored Piles Sls Crack Width - Pile: Section SpecificationDokument1 SeiteQT200 Bored Piles Sls Crack Width - Pile: Section SpecificationMohamedAbdelnasserNoch keine Bewertungen

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Von EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Bewertung: 4.5 von 5 Sternen4.5/5 (5)

- Calcul MH 800Dokument6 SeitenCalcul MH 800Mihai AndreiasNoch keine Bewertungen

- 8 Check For Crack Width: B) Bottom SlabDokument2 Seiten8 Check For Crack Width: B) Bottom SlabAnonymous jLLjBdrNoch keine Bewertungen

- Calculation of Slab ReinforcementDokument2 SeitenCalculation of Slab ReinforcementwaquarstrNoch keine Bewertungen

- Crack Width Cal-T Beam-Euro CodeDokument10 SeitenCrack Width Cal-T Beam-Euro CodeGautham AllimuthuNoch keine Bewertungen

- Crack Width (Two Layer Reinf) - SLSDokument10 SeitenCrack Width (Two Layer Reinf) - SLSpsconsultantsNoch keine Bewertungen

- ShortColEC2 - 176 3 Feb 23 - 2Dokument1 SeiteShortColEC2 - 176 3 Feb 23 - 2maNoch keine Bewertungen

- Crack Width Check (CoP Concrete 2013) CPRDokument4 SeitenCrack Width Check (CoP Concrete 2013) CPRAndrew WtchengNoch keine Bewertungen

- E.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Dokument2 SeitenE.naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - V2.0.2Max100% (1)

- STANDAR - Diagram Interaksi Spun Pile Dia 1000 Kelas A1 R00 - F'C 52MPa - 2014Dokument11 SeitenSTANDAR - Diagram Interaksi Spun Pile Dia 1000 Kelas A1 R00 - F'C 52MPa - 2014Dwiki AdriyantoNoch keine Bewertungen

- E.Naldoza Design of Singly Reinforced Rectangular Section-ACI318M-14 (NSCP 2015) V2.1.2-08june2021Dokument2 SeitenE.Naldoza Design of Singly Reinforced Rectangular Section-ACI318M-14 (NSCP 2015) V2.1.2-08june2021RL SanNoch keine Bewertungen

- Crack Width Cal-Rectangle Beam-Euro CodeDokument1 SeiteCrack Width Cal-Rectangle Beam-Euro CodeGautham AllimuthuNoch keine Bewertungen

- Control of Cracking Due To End Restraint: Input Parameters Symbol Unit ValueDokument1 SeiteControl of Cracking Due To End Restraint: Input Parameters Symbol Unit ValuedsureshcivilNoch keine Bewertungen

- Annexure-2 (Section Design Calcs)Dokument107 SeitenAnnexure-2 (Section Design Calcs)blisscutest beagleNoch keine Bewertungen

- Beam1 Working StressDokument36 SeitenBeam1 Working Stresssoumi bhattacharyaNoch keine Bewertungen

- Crack Width Calc BS 8110Dokument1 SeiteCrack Width Calc BS 8110mvap2856Noch keine Bewertungen

- Maximum Working Tension in The Section (Serviceability) KN: Calculation For Crack Width For PilecapDokument1 SeiteMaximum Working Tension in The Section (Serviceability) KN: Calculation For Crack Width For PilecapsivaNoch keine Bewertungen

- E.Naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - v2.1.1Dokument2 SeitenE.Naldoza Design of Singly Reinforced Rectangular Section-ACI-318M-14 (NSCP 2015) - v2.1.1Johny Mark AsuncionNoch keine Bewertungen

- Valve Pit Wall DesignDokument3 SeitenValve Pit Wall DesignersivarajNoch keine Bewertungen

- Design of Singly Reinforced Concrete Beam PDFDokument3 SeitenDesign of Singly Reinforced Concrete Beam PDFAnton_Young_1962Noch keine Bewertungen

- Retaining Wall ExcelDokument82 SeitenRetaining Wall ExcelOuseppachan AmbookenNoch keine Bewertungen

- Crack Width For MX - Outer - MaxDokument1 SeiteCrack Width For MX - Outer - Maxmhazarath murariNoch keine Bewertungen

- Crack Width CheckDokument2 SeitenCrack Width CheckJitendra SinghNoch keine Bewertungen

- Design of Outlet ChamberDokument7 SeitenDesign of Outlet ChamberHemant SonawadekarNoch keine Bewertungen

- Singly Reinforced BeamDokument31 SeitenSingly Reinforced BeamSparsh ShukalNoch keine Bewertungen

- Shear CheckDokument22 SeitenShear CheckAJAY SHINDENoch keine Bewertungen

- Crack Width Check BS5400 4Dokument4 SeitenCrack Width Check BS5400 4fontec.info2023Noch keine Bewertungen

- Design of BearingsDokument24 SeitenDesign of BearingsFarrukh RizwanNoch keine Bewertungen

- 341+265 Design Report - 32Dokument1 Seite341+265 Design Report - 32VivekNoch keine Bewertungen

- Calculation of Flexural Crack Width - IS 456: 2000 TB-1: Axial ForceDokument66 SeitenCalculation of Flexural Crack Width - IS 456: 2000 TB-1: Axial ForceSrishti Project ConsultantsNoch keine Bewertungen

- 341+265 Design Report - 18Dokument1 Seite341+265 Design Report - 18VivekNoch keine Bewertungen

- Ribbed Slab Design-1Dokument2 SeitenRibbed Slab Design-1HAITHAM ALI100% (2)

- Crack WidthDokument3 SeitenCrack WidthWasim KaziNoch keine Bewertungen

- RDSODokument8 SeitenRDSOVikasNoch keine Bewertungen

- Crack WidthDokument21 SeitenCrack WidthBalaji HariNoch keine Bewertungen

- Slab Design Strip Method v1.0Dokument4 SeitenSlab Design Strip Method v1.0Kyra AlesonNoch keine Bewertungen

- DG - Slab Design SDokument7 SeitenDG - Slab Design Ssaaz adil100% (1)

- 2014.1 Bored PileDokument23 Seiten2014.1 Bored PileSurianshah shahNoch keine Bewertungen

- C 0 - 85 F ' C B A T A F: Reference: ACI 318-05 Reinforced Concrete Beam Design DefinitionsDokument116 SeitenC 0 - 85 F ' C B A T A F: Reference: ACI 318-05 Reinforced Concrete Beam Design DefinitionsIbrahim El SharNoch keine Bewertungen

- Doubly Reinforced BeamDokument2 SeitenDoubly Reinforced BeammariyaNoch keine Bewertungen

- Engineering and Development Corporation of The PhilippinesDokument4 SeitenEngineering and Development Corporation of The Philippinesmark ignacioNoch keine Bewertungen

- Imps - Short Wall (My - Vertical) : Calculation of SteelDokument12 SeitenImps - Short Wall (My - Vertical) : Calculation of Steelpearl kachhawahNoch keine Bewertungen

- Valve Pit DesignDokument3 SeitenValve Pit DesignersivarajNoch keine Bewertungen

- Limit State Design of Tank With Crack Check - 03.02.2020.Dokument14 SeitenLimit State Design of Tank With Crack Check - 03.02.2020.monaliNoch keine Bewertungen

- ACI Beam DesignDokument8 SeitenACI Beam DesignsujatNoch keine Bewertungen

- 341+265 Design Report - 21Dokument1 Seite341+265 Design Report - 21VivekNoch keine Bewertungen

- Appendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Dokument2 SeitenAppendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Md Nadeem Akhtar100% (1)

- Walk Way CalculationsDokument71 SeitenWalk Way CalculationszakariaalbashiriNoch keine Bewertungen

- Design of Doubly Reinforced RC Beam (ACI 318-14) : Particulars Remarks 1 Material Properties Codes and SectionsDokument71 SeitenDesign of Doubly Reinforced RC Beam (ACI 318-14) : Particulars Remarks 1 Material Properties Codes and SectionsLavender HoneyNoch keine Bewertungen

- Corner Wall Design - CulvertDokument5 SeitenCorner Wall Design - CulvertSuresh MahalingamNoch keine Bewertungen

- Concrete Beam Design Flow ChartsDokument16 SeitenConcrete Beam Design Flow Chartsayoub bahmani k80% (5)

- Design For TorsionDokument4 SeitenDesign For TorsionChhim RothyNoch keine Bewertungen

- Control of Cracking Due To End Restraint: Input Parameters Symbol Unit ValueDokument1 SeiteControl of Cracking Due To End Restraint: Input Parameters Symbol Unit ValuedsureshcivilNoch keine Bewertungen

- STP Rusayl Oman: Double Shell Combined Circular TankDokument1 SeiteSTP Rusayl Oman: Double Shell Combined Circular TankRahulNoch keine Bewertungen

- DESIGN OF FLOOR SLAB (0.15m Thick)Dokument9 SeitenDESIGN OF FLOOR SLAB (0.15m Thick)Living Life100% (1)

- Bridge No.164Dokument1 SeiteBridge No.164RajeshNoch keine Bewertungen

- Bridge No.169Dokument1 SeiteBridge No.169RajeshNoch keine Bewertungen

- Presentation RVNLDokument6 SeitenPresentation RVNLRajeshNoch keine Bewertungen

- A Bridge RuleDokument120 SeitenA Bridge RulemanishNoch keine Bewertungen

- Bridge No.121Dokument1 SeiteBridge No.121RajeshNoch keine Bewertungen

- Bridge No.136Dokument1 SeiteBridge No.136RajeshNoch keine Bewertungen

- BearingsDokument74 SeitenBearingskesharinareshNoch keine Bewertungen

- Rdso Guidelines For Carrying Out Rail-Structure Interaction Studies On Metro Systems Ver 1Dokument61 SeitenRdso Guidelines For Carrying Out Rail-Structure Interaction Studies On Metro Systems Ver 1RajeshNoch keine Bewertungen

- 1 Jan-2013Dokument102 Seiten1 Jan-2013RajeshNoch keine Bewertungen

- DEsign RSIDokument61 SeitenDEsign RSIRajeshNoch keine Bewertungen

- RSI Guidelines PDFDokument61 SeitenRSI Guidelines PDFanon_964784935Noch keine Bewertungen

- Dec 2013 PDFDokument124 SeitenDec 2013 PDFManoj DasNoch keine Bewertungen

- FREYSSINET Prestress ManualDokument53 SeitenFREYSSINET Prestress Manualras_deep100% (2)

- Drawings of Crash Barrier PDFDokument1 SeiteDrawings of Crash Barrier PDFRajeshNoch keine Bewertungen

- RFP For 6 ROB in Lieu of LC - 2.25 Cr.Dokument71 SeitenRFP For 6 ROB in Lieu of LC - 2.25 Cr.RajeshNoch keine Bewertungen

- Rdso Master List (Aug 2018) PDFDokument63 SeitenRdso Master List (Aug 2018) PDFAnindita ChatterjeeNoch keine Bewertungen

- 1 Strengthen Scheme PDFDokument3 Seiten1 Strengthen Scheme PDFRajeshNoch keine Bewertungen

- Comparative Performance of Seismic Design of Highway Bridge Piers Using Various CodesDokument1 SeiteComparative Performance of Seismic Design of Highway Bridge Piers Using Various CodesRajeshNoch keine Bewertungen

- Ussor 2012 Ecr CS-1 (BMK)Dokument291 SeitenUssor 2012 Ecr CS-1 (BMK)prasagnihotri100% (3)

- 1 Strengthen Scheme PDFDokument3 Seiten1 Strengthen Scheme PDFRajeshNoch keine Bewertungen

- 49988335Dokument2 Seiten49988335RajeshNoch keine Bewertungen

- FREYSSINET Prestress ManualDokument53 SeitenFREYSSINET Prestress Manualras_deep100% (2)

- Drawings of Crash Barrier PDFDokument1 SeiteDrawings of Crash Barrier PDFRajesh100% (1)

- Ussor 2012 Ecr Cs-1 (BMK)Dokument47 SeitenUssor 2012 Ecr Cs-1 (BMK)RajeshNoch keine Bewertungen

- Ussor 2012 Ecr CS-1 (BMK)Dokument291 SeitenUssor 2012 Ecr CS-1 (BMK)prasagnihotri100% (3)

- Near Fault Ground Motion Effects On Concrete Gravity Dam: S. Gorai and D. MaityDokument1 SeiteNear Fault Ground Motion Effects On Concrete Gravity Dam: S. Gorai and D. MaityRajeshNoch keine Bewertungen

- Performance Evaluation of RC Moment Resisting Frames by Development of Fragility CurvesDokument1 SeitePerformance Evaluation of RC Moment Resisting Frames by Development of Fragility CurvesRajeshNoch keine Bewertungen

- Railway Engineering DiaryDokument97 SeitenRailway Engineering DiaryDev Sharma67% (3)

- Model 900 Automated Viscometer: Drilling Fluids EquipmentDokument2 SeitenModel 900 Automated Viscometer: Drilling Fluids EquipmentJazminNoch keine Bewertungen

- DILG Opinion-Sanggunian Employees Disbursements, Sign Checks & Travel OrderDokument2 SeitenDILG Opinion-Sanggunian Employees Disbursements, Sign Checks & Travel OrderCrizalde de DiosNoch keine Bewertungen

- Verilog GATE AND DATA FLOWDokument64 SeitenVerilog GATE AND DATA FLOWPRIYA MISHRANoch keine Bewertungen

- Steve Jobs TalkDokument3 SeitenSteve Jobs TalkDave CNoch keine Bewertungen

- Skilled Worker Overseas FAQs - Manitoba Immigration and Economic OpportunitiesDokument2 SeitenSkilled Worker Overseas FAQs - Manitoba Immigration and Economic OpportunitieswesamNoch keine Bewertungen

- 8D & 7QC ToolsDokument117 Seiten8D & 7QC ToolsAshok Kumar100% (1)

- Newsela Teacher Review - Common Sense EducationDokument1 SeiteNewsela Teacher Review - Common Sense EducationJessicaNoch keine Bewertungen

- Technology 6 B Matrixed Approach ToDokument12 SeitenTechnology 6 B Matrixed Approach ToNevin SunnyNoch keine Bewertungen

- Financial Management of Public Sector Unit (PSU) - NotesDokument23 SeitenFinancial Management of Public Sector Unit (PSU) - Notesbiz19100% (1)

- Ducati WiringDokument7 SeitenDucati WiringRyan LeisNoch keine Bewertungen

- Southern California International Gateway Final Environmental Impact ReportDokument40 SeitenSouthern California International Gateway Final Environmental Impact ReportLong Beach PostNoch keine Bewertungen

- Technology ForecastingDokument38 SeitenTechnology ForecastingSourabh TandonNoch keine Bewertungen

- Sinamics g120p Cabinet Catalog d35 en 2018Dokument246 SeitenSinamics g120p Cabinet Catalog d35 en 2018Edgar Lecona MNoch keine Bewertungen

- Nuttall Gear CatalogDokument275 SeitenNuttall Gear Catalogjose huertasNoch keine Bewertungen

- Science Grade 10 (Exam Prep)Dokument6 SeitenScience Grade 10 (Exam Prep)Venice Solver100% (3)

- CO 101 Introductory Computing CO 102 Computing LabDokument17 SeitenCO 101 Introductory Computing CO 102 Computing Labadityabaid4Noch keine Bewertungen

- Learning Module - Joints, Taps and SplicesDokument9 SeitenLearning Module - Joints, Taps and SplicesCarlo Cartagenas100% (1)

- Coefficient of Restitution - Center of MassDokument3 SeitenCoefficient of Restitution - Center of MassMannyCesNoch keine Bewertungen

- State Farm Claims: PO Box 52250 Phoenix AZ 85072-2250Dokument2 SeitenState Farm Claims: PO Box 52250 Phoenix AZ 85072-2250georgia ann polley-yatesNoch keine Bewertungen

- R, Axn: Housingand RegulatoryDokument5 SeitenR, Axn: Housingand RegulatoryAce RamosoNoch keine Bewertungen

- Tutorial 3 MFRS8 Q PDFDokument3 SeitenTutorial 3 MFRS8 Q PDFKelvin LeongNoch keine Bewertungen

- Chapter 2Dokument69 SeitenChapter 2Lizi CasperNoch keine Bewertungen

- Preliminary Examination The Contemporary WorldDokument2 SeitenPreliminary Examination The Contemporary WorldJane M100% (1)

- OM Part B - Rev1Dokument45 SeitenOM Part B - Rev1Redouane BelaassiriNoch keine Bewertungen

- Assignment 4 Job Order Costing - ACTG321 - Cost Accounting and Cost ManagementDokument3 SeitenAssignment 4 Job Order Costing - ACTG321 - Cost Accounting and Cost ManagementGenithon PanisalesNoch keine Bewertungen

- Combining Wavelet and Kalman Filters For Financial Time Series PredictionDokument17 SeitenCombining Wavelet and Kalman Filters For Financial Time Series PredictionLuis OliveiraNoch keine Bewertungen

- Alienation Thesis StatementDokument8 SeitenAlienation Thesis Statementafbteepof100% (2)

- Ericsson For Sale From Powerstorm 4SA03071242Dokument8 SeitenEricsson For Sale From Powerstorm 4SA03071242wd3esaNoch keine Bewertungen

- Carbonate Platform MateriDokument8 SeitenCarbonate Platform MateriNisaNoch keine Bewertungen

- 2012 Conference NewsfgfghsfghsfghDokument3 Seiten2012 Conference NewsfgfghsfghsfghabdNoch keine Bewertungen

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseVon EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseBewertung: 5 von 5 Sternen5/5 (3)

- Building Construction Technology: A Useful Guide - Part 1Von EverandBuilding Construction Technology: A Useful Guide - Part 1Bewertung: 4 von 5 Sternen4/5 (3)

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionVon EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Guidelines for Chemical Process Quantitative Risk AnalysisVon EverandGuidelines for Chemical Process Quantitative Risk AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideVon Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideBewertung: 3.5 von 5 Sternen3.5/5 (7)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyVon EverandSodium Bicarbonate: Nature's Unique First Aid RemedyBewertung: 5 von 5 Sternen5/5 (21)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- Field Guide for Construction Management: Management by Walking AroundVon EverandField Guide for Construction Management: Management by Walking AroundBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesVon EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNoch keine Bewertungen

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftVon EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftBewertung: 5 von 5 Sternen5/5 (5)

- THE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEVon EverandTHE PROPTECH GUIDE: EVERYTHING YOU NEED TO KNOW ABOUT THE FUTURE OF REAL ESTATEBewertung: 4 von 5 Sternen4/5 (1)

- Water-Based Paint Formulations, Vol. 3Von EverandWater-Based Paint Formulations, Vol. 3Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyVon EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyBewertung: 4 von 5 Sternen4/5 (1)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishVon EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishBewertung: 4 von 5 Sternen4/5 (3)

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)