Beruflich Dokumente

Kultur Dokumente

10 Point Guide To Humidity Control in Textile Manufacturing en RT

Hochgeladen von

Alvaro Elias BaquedanoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

10 Point Guide To Humidity Control in Textile Manufacturing en RT

Hochgeladen von

Alvaro Elias BaquedanoCopyright:

Verfügbare Formate

10-POINT GUIDE TO

HUMIDITY CONTROL IN

TEXTILE MANUFACTURING

Humidification and Evaporative Cooling

MANAGE HUMIDITY,

INCREASE PROFITABILITY

Every textile product is affected by the resulting in a lower quality yarn. Drier As a global leader in humidification

relative humidity of the environment in fibres during spinning causes a higher technology, Condair has developed

which it is produced, particularly hairiness of the yarn, lower strength successful humidification strategies for

natural fibres. and a low pilling resistance of the end textile manufacturers around the

product. This all contributes to a world. This document present an

Low air humidity can dry a fibre causing reduced market value for the textile. introductory 10-point guide for

its internal moisture content to fall. If production managers looking to

this moisture content drops below the As well as impairing quality, low enhance their factory’s profitability

optimum level during processing, a humidity during production will also with improved humidity.

manufacturer can experience a drop in directly reduce yield. A 4% evaporation

productivity for a number of reasons. of a textile’s internal moisture content

requires 4% more product to be

As fibres dry their tensile strength is manufactured to meet a required

impaired, they become less flexible, production weight. As dry fibres are

thinner and more brittle. If a fibre or more prone to shedding, this again

thread breaks while being processed, reduces yield, as more fibres are lost to

textile machinery needs to be manually

rethreaded, leading to downtime and

the atmosphere. product yield

reduced efficiency. Both these factors contribute to a

textile manufacturer requiring more

is optimised

During weaving, every time a machine raw materials, energy and labour to

needs to be rethreaded and tied-off, satisfy an order, thus increasing and quality

loom stop marks are produced, overheads and reducing profits.

By correctly humidifying a textile

production facility, product yield is

improved

optimised and quality improved.

© Copyright Condair plc

No part of this document may be reproduced, published or distributed in any material form,

including inclusion on social media or distribution via the internet, without prior consent of Condair plc.

1 WHY HUMIDIFY?

LOW AIR HUMIDITY EQUILIBRIUM RELATIVE HUMIDITY HIGH AIR HUMIDITY

AIR

AIR AIR

FIBRE FIBRE FIBRE

Moisture loss from the Moisture gain by

No moisture movement

fibre and shrinkage the fibre (regain)

Textile fibres have an internal equilibrium relative humidity and is the

moisture content and will gain or lose ideal processing environment for

water to the air depending on whether textile manufacturing.

there is equilibrium between the air’s

relative humidity and the textile’s However, if the air’s relative humidity is

maintain

moisture content. lower than this ideal level, moisture will

be drawn from the textile’s exposed equilibrium

If a fibre’s surface is exposed to the air surface and evaporate into the air.

and there is balance between these

two factors, no moisture movement Moisture loss from a textile can happen

between the

will occur. This is referred to as quickly during processing (see fig. 1).

Cotton and wool can lose up to 4% in

air’s relative

18%

16%

Wool

under 10 minutes when exposed.

Carding, spinning, winding and humidity and

weaving expose a huge amount of the

14%

13% Cotton

fibre’s surface area to rapidly moving the textile’s

Water content

air. This provides great potential for

11%

9%

evaporative losses from the fibre

should the ambient humidity be lower moisture

7%

than the equilibrium relative humidity.

5%

4%

Porous Acrylic content

The objective of humidifying a textile

2% Polypropylene

factory is to maintain equilibrium

0% between the air’s relative humidity and

0 10 20 30 40 50 60 70 80 90

the textile’s moisture content.

Time (min)

Fig. 1 - Speed of change for moisture loss from

different textiles when exposed to dry air

2 WHAT’S THE IDEAL MILL

HUMIDITY LEVEL?

Wool

20

Jute

Viscose

15

Moisture content %

Cotton

10 Acetate

(secondary)

Nylon 66

5

Acrylic

The ideal humidity level for any textile To achieve the required internal

production area will depend on the moisture content for any textile Polyester

moisture content of the textile being product, a sorption isotherm graph is 0

processed and the production used to calculate the correct air 0 20 40 60 80 100

process itself. humidity (see fig. 2). The curved line Relative humdity %

shows for any given moisture Fig. 2 - Moisture sorption data (median values

Natural fibres are far more content of the material what the between wetting and drying) in atmospheres

susceptible to moisture changes than corresponding air humidity ought to of various relative humidities

manmade fibres, in terms of be for perfect equilibrium.

performance. At the correct internal

moisture content there is less yarn The table below shows a general

breakage in spinning and twisting, and guide to the ideal humidity levels

higher efficiencies in weaving. for processing different textiles at

various stages of production.

Optimal humidity levels use a sorption

Spinning Twisting Winding Weaving isotherm

Wool 50-85%RH 60-65%RH 55-60%RH 50-60%RH

Cotton 35-65%RH 50-65%RH 55-65%RH 70-85%RH graph to

Man-made fibres 45-65%RH 45-65%RH 60-65%RH 60-70%RH

Silk 60-65%RH 60-65%RH 60-65%RH 60-65%RH calculate the

Jute

Linen

75%RH

80%RH

75%RH

80%RH

75%RH

80%RH

75%RH

80%RH

required air

humidity

3 HOW CAN HUMIDITY BE CONSISTENTLY

MANAGED ACROSS A LARGE FACTORY?

The characteristics of the atmosphere To achieve a consistent level of

across a single production area can vary humidity, across areas that can be

greatly. Any change in temperature will hundreds of metres long, it is important

impact on the relative humidity (RH). to have a humidification system with

Hot spots on machinery will cause a

localised drop in RH that can rapidly

many points of moisture injection.

Single “spot” humidifiers that introduce many points

decrease product weight and quality. a large amount of humidity from one or

just a few units, cannot maintain room of moisture

humidity as evenly as a system with

many lower capacity outlets. injection

Varying the quantity of moisture

introduced at different points of

injection, given the room’s specific

characteristics, can also help produce a

more even moisture distribution. For

example, it is important to introduce

more moisture close to where the dry

air enters the room and avoid over

humidifying areas near to the points

from where air is extracted.

Condair offer free expert advice on

humidity levels and system design

4 WHAT TYPE OF HUMIDIFIER IS

BEST FOR A TEXTILE FACTORY?

Spray humidifiers that combine Compressed air and water systems,

compressed air and water to create a such as the JetSpray from Condair,

series of fine aerosols are a popular also have the benefit of self-cleaning

choice for large textile production

areas. This type of humidifier has many

nozzles. A tiny pin is regularly

forced through the spray orifice,

combine

advantages over high pressure or

spinning disc systems for a

greatly reducing the possibility of

nozzle blockages. This reduces compressed

textile factory. necessary maintenance and the

associated downtime. air and water

The compressed air creates highly

directional sprays that evaporate

without needing fans, which can

Textile laboratories that need to

precisely control humidity in smaller

to create a

frequently block and require

maintenance in very dusty production

areas, often use electric steam

humidifiers. They can deliver humidity series of fine

environments. The droplet size of a either directly to a room with a fan unit

compressed air and water humidifier is

very small at between 5-7 microns, so

or to a ducted air conditioning system. aerosols

evaporates rapidly without drips or

wetting onto machinery, walls or the

floor of the room.

5 HOW MUCH WATER NEEDS TO

BE INTRODUCED TO THE AIR?

Once the ideal level of air humidity has The desired humidity level kilogram of dry air can be determined

been understood (see point 2), the (see point 2) along with the specific volume in m³/kg.

volume of moisture required to maintain The air volume of the room

this humidity will need to be calculated, (room height x width x length) The following equation is then used to

given the production area’s specific The temperature of the room calculate the required humidity load for

characteristics. This volume of moisture is The temperature of the outside air the room.

typically expressed in kilograms per hour The humidity of the outside air

and is referred to as the “humidity load”. Moisture x air vol x

The number of air exchanges the no. of air changes

In order to calculate an area’s humidity

room experiences per hour = Humidity load

Specific volume

load, and therefore what capacity

By plotting the internal and external air

humidifier is required, the following

conditions on a psychrometric chart,

parameters need to be noted: To ensure the humidification system is

the volume of moisture needed per

capable of meeting the needs of the

factory throughout the year, the

%RH internal and external air conditions

80 +40%RH 40 should be based on the hottest and

driest times.

Desired room 80%RH

condition 30˚C

0.022

Specific volume +0.0035

Moisture content

kg water/kg dry air

(m³/kg) 0.0185

Outside air 40%RH

condition 38˚C calculate

the required

humidity load

30 -8°C 38

Dry bulb temperature (°C)

Example psychrometric calculation

Condair offer free expert advice on

product selection and sizing

6 HOW DOES HUMIDITY AFFECT

STATIC ELECTRICITY?

The occurrence of static can be a major uncomfortable but it can cause a

problem when processing textiles and person to jump and fall, which presents

it is directly related to levels of relative extreme risks when working with

humidity. The electrical sensitivity that

determines whether static

textile machinery. Static discharge is

also a risk to people with weak hearts

at around

electrification will occur is dependent

on the moisture content of the air and

or pace-makers fitted.

50%RH static

fibres. As fibres lose moisture, they As well as the danger to staff, static

increase their electrical resistance. They electrical build-up will cause materials build-up is

no longer readily dissipate electrical to stick together and be less

charge that is generated by frictional

contact on machinery.

manageable. This in turn will slow

machinery, directly affecting

naturally

In a textile production facility with low

production schedules. Also, as most

machines are now microprocessor dissipated

humidity, static discharges can jump up controlled, an uncontrolled electrical

to 4-5 inches. Although they have a low discharge in the wrong place can

current, discharges can be several damage the electronics of the unit

hundred thousand volts. resulting in expensive repair bills and

significant downtime.

This presents a danger to staff working

with the machines, as it is not only By maintaining humidity at around

50%RH static build-up is naturally

dissipated and these associated

problems are alleviated.

7 WILL HUMIDIFICATION AFFECT

FACTORY WORKERS?

A cold water humidifier will provide fibres shed during processing, therefore

the additional benefit of 680W of fewer particles are introduced to the

evaporative cooling for every 1kg of air. These benefits combine to make

water absorbed by the air. Across a

textile production area, this cooling

the air much less polluted, more

pleasant to breathe and healthier to

cooler

effect can reduce the ambient

temperature by between 5-12°C.

work in.

temperatures

This is a welcome improvement to the Cooler temperatures and reduced

working conditions for staff in the area. airborne pollution has a positive

impact on productivity, as staff are

and reduced

An increased air humidity will

encourage airborne lint, dust and fly to

healthier and happier.

airborne

fall out of the atmosphere and settle

faster. Maintaining the correct air pollution

humidity also reduces the amount of

Condair offers free expert advice on

static control and evaporative cooling

8 WHAT HYGIENE MEASURES

ARE REQUIRED?

As workers come into close proximity system or in the building’s pipework

to the sprays released from a textile feeding the system.

humidification system, and can

potentially inhale the aerosols, it is vital Alongside these necessary

the system is designed with hygiene as requirements, water treatment

a primary concern. systems can also be used that either

ALITY

filter the water to remove bacteria and

QU

Systems should always be fed by a viruses or sterilise the water through

water supply that is of drinking water dosing or exposure to ultra violet light.

quality and correctly filtered to remove

H2O particulate matter.

The humidifier’s water pipelines should

not incorporate any runs where water

A

D

PP

ROVE could potentially rest for an extended

period of time without draining away. exceptionally

Stagnant water is a potential breeding

ground for microbes that can be

dangerous to health if inhaled. The

high hygiene

humidifier should therefore have

automatic flush and drain cycles to

standards

ensure water does not remain in the

I HAVE AN AIR WASHER IN MY

9 AIR HANDLING UNIT. DO I STILL

NEED A HUMIDIFIER?

Many textile production facilities will load being required than the room’s air

incorporate a spray system or air handling unit was originally designed

washer inside the air handling unit that for.

feeds conditioned air into the building.

However, these older air treatment In-room systems, such as the JetSpray

systems can

systems are inefficient and rarely able

to control humidity to the ideal level

from Condair, accurately maintain

humidity levels across an area,

be added to

evenly across a production area. efficiently and economically. As a

factory’s capacity increases, additional precisely

Frequently, machinery upgrades within humidification systems can be added

a factory will also change the

characteristics of the air profile across a

to precisely meet the needs of the

production machinery.

meet the

room and result in a greater humidity

needs of the

production

machinery

10 WHAT’S THE PAYBACK OF A

HUMIDIFICATION SYSTEM?

There are many benefits in maintaining Fibre shedding will reduce yield but to

the optimum humidity in a textile mill, quantify this reduction and humidity’s

including increases in yield, machine impact upon it, will depend on the

uptime and product market value. It is

therefore difficult to precisely quantify

textile in question and its susceptibility

to damage from drying and shedding.

increases

the financial implications of them all in

advance but an informed estimate Production efficiency based upon in yield,

can be made. machine uptime is a factor that ought

The most obvious financial benefit is

to be considered when looking at a

payback period for maintaining

machine

the reduction in evaporative weight

loss from the raw material during

optimum humidity levels. How much

time is spent rethreading machines uptime and

processing. If a 4% loss is experienced, due to fibre breakage and what is the

the cost could be calculated on the

market value of 4% of end product but

estimated cost of this inefficiency? product

is most typically calculated on 4%

additional raw material cost. As well as

Lastly, an assessment of the potential

increase in market value of the end

market value

the raw material cost, the production product should be made. This can

cost to process the fibres should also take into account improvements in

be considered. yarn hairiness, tensile strength,

pilling resistance and a reduction in

loom stop marks.

Condair offers free expert ROI projections

for humidifier installations

ASK FOR A FREE

ON-SITE CONSULTATION

WORLD LEADING

HUMIDIFICATION

SPECIALIST

Condair is a world leader in available, clients are supported by local return on the investment in their

humidification and evaporative cooling. specialist humidification engineering humidification systems through

It has manufacturing facilities in Asia, teams, which can offer installation, improved productivity.

Europe and North America, sales commissioning, maintenance and

operations in 20 countries and spares support. Contact us today for a free expert

distributors in over 50 more. assessment of your manufacturing

The company has been serving the environment and discover how

As well as benefiting from the most global textile industry for many years improved humidity can enhance your

advanced humidifier technology and helps manufacturers achieve rapid profitability.

© Copyright Condair plc

No part of this document may be reproduced, published or distributed in any material form,

including inclusion on social media or distribution via the internet, without prior consent of Condair plc.

Condair plc

Artex Avenue, Rustington, Littlehampton, West Sussex, BN16 3LN, UK

Tel: +44 (0)1903 850200 - uk.sales@condair.com - www.condair.co.uk

02/2019

Das könnte Ihnen auch gefallen

- Ppe Hazard Assessment AnalysisDokument4 SeitenPpe Hazard Assessment AnalysisArief Firmansyah0% (1)

- RFU - Risk Management of Textile MillsDokument20 SeitenRFU - Risk Management of Textile MillsjonumaverickNoch keine Bewertungen

- Plant Safety Instructions PDFDokument16 SeitenPlant Safety Instructions PDFapsNoch keine Bewertungen

- Hira PDFDokument69 SeitenHira PDFvinod100% (1)

- Study Material On: Hydraulic SafetyDokument25 SeitenStudy Material On: Hydraulic SafetyPrakash KumarNoch keine Bewertungen

- ABC's of Fall Protection: Murray State University Susan MillerDokument24 SeitenABC's of Fall Protection: Murray State University Susan MillerSam SalesNoch keine Bewertungen

- Electrical Apparatus For Explosive Atmosphere (ETD 22) - Electrotechnical Division-Public Safety Standards of IndiaDokument4 SeitenElectrical Apparatus For Explosive Atmosphere (ETD 22) - Electrotechnical Division-Public Safety Standards of IndiamaninderpreetNoch keine Bewertungen

- The Major Accident Hazard Control Rules 1997Dokument47 SeitenThe Major Accident Hazard Control Rules 1997P.M.K anthNoch keine Bewertungen

- Safety Weekly Stats Report Upto 27 March 2021Dokument1 SeiteSafety Weekly Stats Report Upto 27 March 2021Sheri DiĺlNoch keine Bewertungen

- On-Site Emergency Plan: Captive Power Plant Angul, OdishaDokument67 SeitenOn-Site Emergency Plan: Captive Power Plant Angul, OdishaANILNoch keine Bewertungen

- Chemical - Regulations in India PDFDokument50 SeitenChemical - Regulations in India PDFSANDAMARNoch keine Bewertungen

- Complete ProjectDokument79 SeitenComplete ProjectMithun RajNoch keine Bewertungen

- GP 47.0 Ppe FormDokument1 SeiteGP 47.0 Ppe FormLarbi BelazizNoch keine Bewertungen

- SOP - 6 - Coal Charging ActivityDokument7 SeitenSOP - 6 - Coal Charging Activityfaraz ahmedNoch keine Bewertungen

- SG-14 Safety Guideline For Work On Electric Overhead Travelling (EOT) CraneDokument19 SeitenSG-14 Safety Guideline For Work On Electric Overhead Travelling (EOT) CraneAbhishek GadatiaNoch keine Bewertungen

- First Aid Risk AssessmentDokument4 SeitenFirst Aid Risk AssessmentJohn GeddesNoch keine Bewertungen

- OISD - Contarctor SafetyDokument55 SeitenOISD - Contarctor SafetyVarun AroraNoch keine Bewertungen

- HIRA-Assignment 2Dokument4 SeitenHIRA-Assignment 2Naveen PrakashNoch keine Bewertungen

- Hazop Study For Thermic Fluid Heater (At Industry by Heterogeneous Method)Dokument11 SeitenHazop Study For Thermic Fluid Heater (At Industry by Heterogeneous Method)IJRASETPublicationsNoch keine Bewertungen

- HIRADokument7 SeitenHIRAAkhilesh DubeyNoch keine Bewertungen

- JobSafetyAnalysisFM Mech TradesDokument83 SeitenJobSafetyAnalysisFM Mech TradestgvnayagamNoch keine Bewertungen

- Safety Induction 2019Dokument10 SeitenSafety Induction 2019Muhammad Rizky RamadhanNoch keine Bewertungen

- Boiler SafetyDokument24 SeitenBoiler SafetynagarajsumaNoch keine Bewertungen

- JHA SampleDokument1 SeiteJHA SampleJoseph PerezNoch keine Bewertungen

- 89.elevator Assembly & ErectionDokument12 Seiten89.elevator Assembly & ErectionMohammed Mostafa El HaddadNoch keine Bewertungen

- The Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8TDokument3 SeitenThe Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8Tpyrolysisoil100% (1)

- Int Detection Sys For O&G Fire FigthingDokument65 SeitenInt Detection Sys For O&G Fire FigthingRahmat IzaiziNoch keine Bewertungen

- Oisd STD 105Dokument23 SeitenOisd STD 105NarendrasinhNoch keine Bewertungen

- EHS-2035.Safety Management Procedure - 582020Dokument11 SeitenEHS-2035.Safety Management Procedure - 582020hoangmtbNoch keine Bewertungen

- 4 Safe Practices For ElecDokument8 Seiten4 Safe Practices For ElecSandeep GuptaNoch keine Bewertungen

- Compressed Gas Cylinder Safe Handling Use and StorageDokument25 SeitenCompressed Gas Cylinder Safe Handling Use and Storageponnada shanmukha pavan kumarNoch keine Bewertungen

- Hazard DatabaseDokument1.140 SeitenHazard DatabaseVero ColladoNoch keine Bewertungen

- SOP 17 - Idler & Pulley Cleaning ActivityDokument6 SeitenSOP 17 - Idler & Pulley Cleaning Activityfaraz ahmedNoch keine Bewertungen

- GPCB SOP For De-Contamination FacilityDokument9 SeitenGPCB SOP For De-Contamination FacilityEHS HalolNoch keine Bewertungen

- Health, Safety and Environment Policy ManualDokument3 SeitenHealth, Safety and Environment Policy ManualVikas SinghNoch keine Bewertungen

- Ayoki Safety Monthly Initiative 27.11.21slideDokument19 SeitenAyoki Safety Monthly Initiative 27.11.21slideAltafNoch keine Bewertungen

- Risk Cooling TowerDokument4 SeitenRisk Cooling TowerHariharan MuthukrishananNoch keine Bewertungen

- The Dive Business Guide To Safe Diving OperationsDokument25 SeitenThe Dive Business Guide To Safe Diving OperationsWale OyeludeNoch keine Bewertungen

- Caustic Soda LiquidDokument4 SeitenCaustic Soda LiquidJCL ROmanosNoch keine Bewertungen

- Corporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)Dokument6 SeitenCorporate Safety - Template: Job Safety & Environmental Analysis (JSEA) / Safe Work Method Statement (SWMS)yyyyyuil100% (1)

- Chain Pulley BlockDokument7 SeitenChain Pulley BlockMohamed AgrNoch keine Bewertungen

- JSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreaDokument8 SeitenJSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreaMohammed MinhajNoch keine Bewertungen

- Factories Act 1948Dokument70 SeitenFactories Act 1948akanungoNoch keine Bewertungen

- Belt Conveyor Troubleshooting: HGRS MASTER - MaintenanceDokument7 SeitenBelt Conveyor Troubleshooting: HGRS MASTER - MaintenanceJerry HukyNoch keine Bewertungen

- CTRA-23-STM-146 - TK - 11-995 - HotWorkDokument3 SeitenCTRA-23-STM-146 - TK - 11-995 - HotWorkMohamed RizwanNoch keine Bewertungen

- JHA Crosscut Saw Use & Maintenance - ROMODokument5 SeitenJHA Crosscut Saw Use & Maintenance - ROMORandy100% (1)

- 1.tech Pneumatic Tool Safety 20180207Dokument2 Seiten1.tech Pneumatic Tool Safety 20180207Ku RatheeshNoch keine Bewertungen

- Safety Manual For Electrostatic Precipitator: Approved Date: 06-Dec-2010 Created By: KSP Approved By: HFRDokument40 SeitenSafety Manual For Electrostatic Precipitator: Approved Date: 06-Dec-2010 Created By: KSP Approved By: HFRJuan Erwin Ccahuay Huamani100% (1)

- Electroclean EDokument1 SeiteElectroclean Edan antonNoch keine Bewertungen

- Hazard Identification and Risk Assessment (HIRA) in Textile IndustryDokument7 SeitenHazard Identification and Risk Assessment (HIRA) in Textile IndustryAjesh mohanNoch keine Bewertungen

- 06 - Tata Power Mobile Crane Safety ProcedureDokument27 Seiten06 - Tata Power Mobile Crane Safety Procedurehse bsj100% (1)

- Safety in Metallizing: Presentation By, A.Mohan RajDokument10 SeitenSafety in Metallizing: Presentation By, A.Mohan RajMohan RajNoch keine Bewertungen

- Safety Award ApplicationDokument7 SeitenSafety Award ApplicationJason Smith100% (1)

- Msds Saj Coshh 0383Dokument3 SeitenMsds Saj Coshh 0383Kannan Sasidharan PillaiNoch keine Bewertungen

- Fosroc - Nitocote PE 135Dokument8 SeitenFosroc - Nitocote PE 135guru sathya bharathyNoch keine Bewertungen

- Lead Exposure Control PlanDokument3 SeitenLead Exposure Control PlanShahzeb HassanNoch keine Bewertungen

- Exercise PDFDokument3 SeitenExercise PDFE-zat Ilman100% (1)

- FF-TextilesDokument1 SeiteFF-TextilesTony MartinNoch keine Bewertungen

- Carel OkDokument4 SeitenCarel OkIwan PrasetyoNoch keine Bewertungen

- Journal Moisture ManagementDokument9 SeitenJournal Moisture ManagementDiar HifdiNoch keine Bewertungen

- International Marketing Conference BrochureDokument8 SeitenInternational Marketing Conference BrochureAman DeepNoch keine Bewertungen

- H1: Information Seeking Will Positively Influence The Users' Intention To Share Content in Social MediaDokument5 SeitenH1: Information Seeking Will Positively Influence The Users' Intention To Share Content in Social MediaAman DeepNoch keine Bewertungen

- Factors Influencing Willingness-To-Pay For The Energy Stars LabelDokument1 SeiteFactors Influencing Willingness-To-Pay For The Energy Stars LabelAman DeepNoch keine Bewertungen

- An Empirical Study On Consumer Behaviour Towards Refrigerators in Bangalore City - January - 2013 - 1469176598 - 2001036Dokument4 SeitenAn Empirical Study On Consumer Behaviour Towards Refrigerators in Bangalore City - January - 2013 - 1469176598 - 2001036Aman DeepNoch keine Bewertungen

- The Six Main Function of HR Are RecruitmentDokument2 SeitenThe Six Main Function of HR Are RecruitmentAman DeepNoch keine Bewertungen

- Etb 065-040-125 GGDokument5 SeitenEtb 065-040-125 GGAman DeepNoch keine Bewertungen

- Org Beh and Leadership PHDDokument5 SeitenOrg Beh and Leadership PHDAman DeepNoch keine Bewertungen

- Offer DriveDokument1 SeiteOffer DriveAman DeepNoch keine Bewertungen

- Subject:-Installation of AC Drive For Radial Fan For Carding H-PlantDokument1 SeiteSubject:-Installation of AC Drive For Radial Fan For Carding H-PlantAman DeepNoch keine Bewertungen

- GMPE - Atlantic Computer CaseDokument5 SeitenGMPE - Atlantic Computer CaseAman Deep100% (1)

- IE4 Motor Technical Data ABBDokument1 SeiteIE4 Motor Technical Data ABBAman DeepNoch keine Bewertungen

- Porter Five Forces - Textile Sector - 1Dokument1 SeitePorter Five Forces - Textile Sector - 1Aman Deep100% (1)

- CertificateDokument1 SeiteCertificateAman DeepNoch keine Bewertungen

- FPM 2017 Batch ProfileDokument6 SeitenFPM 2017 Batch ProfileAman DeepNoch keine Bewertungen

- MAINTENANCE MANUAL - Lakshmi Caipo Easy Slub Yarn UnitDokument2 SeitenMAINTENANCE MANUAL - Lakshmi Caipo Easy Slub Yarn UnitAman DeepNoch keine Bewertungen

- Efficiency DetailsDokument1 SeiteEfficiency DetailsAman DeepNoch keine Bewertungen

- Plant MotorDokument6 SeitenPlant MotorAman DeepNoch keine Bewertungen

- FSM Annual Fire Safety ReportDokument7 SeitenFSM Annual Fire Safety ReportAman DeepNoch keine Bewertungen

- Term - 2Dokument1 SeiteTerm - 2Aman DeepNoch keine Bewertungen

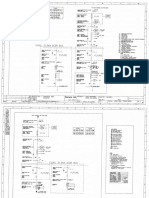

- SLDDokument3 SeitenSLDAman DeepNoch keine Bewertungen

- Quant Concepts FormulaeDokument12 SeitenQuant Concepts FormulaeAman DeepNoch keine Bewertungen

- IE4 Motor Technical Data ABBDokument1 SeiteIE4 Motor Technical Data ABBAman DeepNoch keine Bewertungen

- Technical Analysis CourseDokument51 SeitenTechnical Analysis CourseAkshay Chordiya100% (1)

- Transform Your Appraisal Management Process: Time-Saving. User-Friendly. Process ImprovementDokument10 SeitenTransform Your Appraisal Management Process: Time-Saving. User-Friendly. Process ImprovementColby EvansNoch keine Bewertungen

- Em Swedenborg THE WORD EXPLAINED Volume IX INDICES Academy of The New Church Bryn Athyn PA 1951Dokument236 SeitenEm Swedenborg THE WORD EXPLAINED Volume IX INDICES Academy of The New Church Bryn Athyn PA 1951francis batt100% (2)

- Napoleon Lacroze Von Sanden - Crony Capitalism in ArgentinaDokument1 SeiteNapoleon Lacroze Von Sanden - Crony Capitalism in ArgentinaBoney LacrozeNoch keine Bewertungen

- The Sacred Bee: Ancient Egypt: by Planet Bee FoundationDokument4 SeitenThe Sacred Bee: Ancient Egypt: by Planet Bee Foundationsoha elmahdyNoch keine Bewertungen

- Rule 108 Republic Vs TipayDokument1 SeiteRule 108 Republic Vs TipayShimi Fortuna100% (1)

- Studi Penanganan Hasil Tangkapan Purse Seine Di KM Bina Maju Kota Sibolga Study of Purse Seine Catches Handling in KM Bina Maju Sibolga CityDokument8 SeitenStudi Penanganan Hasil Tangkapan Purse Seine Di KM Bina Maju Kota Sibolga Study of Purse Seine Catches Handling in KM Bina Maju Sibolga CitySavira Tapi-TapiNoch keine Bewertungen

- US. Peace Corps Tetun Language CourseDokument305 SeitenUS. Peace Corps Tetun Language CoursePeter W Gossner100% (1)

- IGCSE-Revision-Booklet-Part-1-2018-2019 - (New-Spec)Dokument69 SeitenIGCSE-Revision-Booklet-Part-1-2018-2019 - (New-Spec)MaryamNoch keine Bewertungen

- G.R. No. 178511 - Supreme Court of The PhilippinesDokument4 SeitenG.R. No. 178511 - Supreme Court of The PhilippinesJackie Z. RaquelNoch keine Bewertungen

- French Art of Not Giving A F-CK Chapter SamplerDokument19 SeitenFrench Art of Not Giving A F-CK Chapter SamplerAllen & UnwinNoch keine Bewertungen

- Aryaman Gupta: EducationDokument1 SeiteAryaman Gupta: EducationxoteviNoch keine Bewertungen

- Jacksonville's Taste 2012Dokument100 SeitenJacksonville's Taste 2012Ali KhanNoch keine Bewertungen

- Reading SkillsDokument8 SeitenReading SkillsBob BolNoch keine Bewertungen

- Top 10 Most Powerful Openings in Chess PDFDokument12 SeitenTop 10 Most Powerful Openings in Chess PDFsyaf file gwNoch keine Bewertungen

- s4c Project - Hollie MccorkellDokument7 Seitens4c Project - Hollie Mccorkellapi-662823090Noch keine Bewertungen

- Proximity Principle of DesignDokument6 SeitenProximity Principle of DesignSukhdeepNoch keine Bewertungen

- Dwnload Full Practicing Statistics Guided Investigations For The Second Course 1st Edition Kuiper Solutions Manual PDFDokument36 SeitenDwnload Full Practicing Statistics Guided Investigations For The Second Course 1st Edition Kuiper Solutions Manual PDFdavidkrhmdavis100% (11)

- BI410 Plant Developmental BiologyDokument41 SeitenBI410 Plant Developmental BiologyLaisla CagliariNoch keine Bewertungen

- Kenneth Dean Austin v. Howard Ray, Warden, Jackie Brannon Correctional Center and Attorney General of The State of Oklahoma, 124 F.3d 216, 10th Cir. (1997)Dokument8 SeitenKenneth Dean Austin v. Howard Ray, Warden, Jackie Brannon Correctional Center and Attorney General of The State of Oklahoma, 124 F.3d 216, 10th Cir. (1997)Scribd Government DocsNoch keine Bewertungen

- Suite 1 For Cello Solo For BB (Bass) Clarinet: Johann Sebastian Bach BWV 1007 PréludeDokument7 SeitenSuite 1 For Cello Solo For BB (Bass) Clarinet: Johann Sebastian Bach BWV 1007 Préludewolfgangerl2100% (1)

- Jewellery and ZakatDokument2 SeitenJewellery and ZakatTariq A MalikNoch keine Bewertungen

- TS-1326 (21581) MS For Dismantling Temporary Steel Platform at Grid P-7 To P-8 & P-AC To PTI-ADokument21 SeitenTS-1326 (21581) MS For Dismantling Temporary Steel Platform at Grid P-7 To P-8 & P-AC To PTI-AJiabing ZouNoch keine Bewertungen

- Rule 110 CasesDokument102 SeitenRule 110 Casesアブドゥルカリム エミールNoch keine Bewertungen

- Mercury and The WoodmanDokument1 SeiteMercury and The WoodmanLum Mei YeuanNoch keine Bewertungen

- MLHP Final ListDokument36 SeitenMLHP Final Listswapnitha tummaNoch keine Bewertungen

- FinTech and Banking DisruptionDokument13 SeitenFinTech and Banking DisruptionMaru MasNoch keine Bewertungen

- "Written Statement": Tanushka Shukla B.A. LL.B. (2169)Dokument3 Seiten"Written Statement": Tanushka Shukla B.A. LL.B. (2169)Tanushka shuklaNoch keine Bewertungen

- Snowman Card Game PDFDokument2 SeitenSnowman Card Game PDFFOANoch keine Bewertungen

- KNOLL and HIERY, The German Colonial Experience - IntroDokument6 SeitenKNOLL and HIERY, The German Colonial Experience - IntroGloria MUNoch keine Bewertungen