Beruflich Dokumente

Kultur Dokumente

12 04 Justin Bukowski Presentation

Hochgeladen von

rrs6339Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

12 04 Justin Bukowski Presentation

Hochgeladen von

rrs6339Copyright:

Verfügbare Formate

17th INTERNATIONAL CONFERENCE & EXHIBITION ON

17th INTERNATIONAL CONFERENCE & EXHIBITION

LIQUEFIED NATURAL GAS (LNG 17)

ON LIQUEFIED NATURAL GAS (LNG 17)

Natural Gas Liquefaction Technology

for Floating LNG Facilities

<Title

<TitleofofPresentation>

Presentation>

By: Dr. Justin D. Bukowski

By:<Author

<AuthorName>,

Name>,<Organization>

<Organization>

Air Products & Chemicals

<Date>

<Date>

April 19, 2013

© Copyright 2013 - Air Products and Chemicals, Inc.

FLNG Facility

Fuel

Endflash

Undersea Refrigeration

Inlet Facility

Pipeline

AGRU, Driers, NGL Liquefaction/

Precooling

Hg Removal Removal Subcooling

LNG

NGL LNG

Fractionation Storage

Storage

What liquefaction process to select for FLNG?

© Copyright 2013 - Air Products and Chemicals, Inc. 2

Process Evaluation

• Process efficiency

LNG production

Refrigeration power

– Strong impact on plant efficiency

LNG production

NG feed rate

• Train capacity

• Equipment count

© Copyright 2013 - Air Products and Chemicals, Inc. 3

Challenges for Floating LNG

• Weight, size and layout limits

– Impact of process capacity and equipment count

• Wave and wind induced vessel motions

– Mechanical strength requirements

– Effect on two-phase flow

• Flammable inventory

– Propane may attract concern

• Corrosive marine environment

Solutions

• Robust equipment design

• Appropriate selection of process cycle

© Copyright 2013 - Air Products and Chemicals, Inc. 4

Coil Wound Exchangers

for Safety and Reliability

• Liquefying hydrocarbons can cause high

thermal stresses

– CWHE proven to resist these stresses

• Dual containment (tubes inside shell)

• Tubes resistant to blockages

• Stable operation at significant turndown

• Small footprint

• High availability = higher revenues

© Copyright 2013 - Air Products and Chemicals, Inc. 5

Challenges for Floating LNG

• Weight, size and layout limits

– Impact of process capacity and equipment count

• Wave and wind induced vessel motions

– Mechanical strength requirements

– Effect on two-phase flow

• Flammable inventory

– Propane may attract concern

• Corrosive marine environment

Solutions

• Robust equipment design

• Appropriate selection of process cycle

© Copyright 2013 - Air Products and Chemicals, Inc. 6

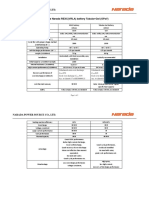

Process Cycle Scorecard

• Process efficiency/capacity

• Equipment count

• Flammable refrigerant, C3 inventory

• Motion sensitivity (Two-phase refrigerant)

Process Relative Train Equipment Flammable Significant Motion

Efficiency Capacity Count Refrigerant C3 Sensitivity

MTPA Inventory

© Copyright 2013 - Air Products and Chemicals, Inc. 7

Liquefaction Processes

Mixed Refrigerant

N2 Recycle

Single Pre-cooled

Refrigerant

© Copyright 2013 - Air Products and Chemicals, Inc. 8

Pre-cooled Mixed Refrigerant

• C3MR process – propane precooling

– Highest efficiency, large capacity – 5+ MTPA

– Propane inventory, footprint

• DMR – use 2nd MR for precooling

– Same efficiency and capacity

– Propane inventory can be minimized

• Motion sensitivity of two-phase flow?

© Copyright 2013 - Air Products and Chemicals, Inc. 9

Coil Wound Exchangers

with FLNG Vessel Motion

• Thorough mechanical analysis and testing

• Process effects of motion on two-phase

flow are mitigated by proper design

– Detailed design verification program

– Lab-scale and pilot-scale experiment

– Analysis including CFD and dynamic hydraulic

modeling

– Suite of exchanger design tools for FLNG

• Independent internal and external reviews

© Copyright 2013 - Air Products and Chemicals, Inc. 10

Pre-cooled Mixed Refrigerant

• C3MR process – propane precooling

– High efficiency, large capacity – 5+ MTPA

– Propane inventory, footprint

• DMR – use 2nd MR for precooling

– Same efficiency and capacity

– Propane inventory can be minimized

• Motion sensitivity of two-phase flow

– Mitigated with proper CWHE design

© Copyright 2013 - Air Products and Chemicals, Inc. 11

Liquefaction Processes

Mixed Refrigerant

N2 Recycle

Single Pre-cooled

Refrigerant

© Copyright 2013 - Air Products and Chemicals, Inc. 12

Single Mixed Refrigerant

• Reduced equipment count

• 1-2 MTPA capacity for single train

• ~ 87% of C3MR/DMR process efficiency

• Like DMR, propane can be minimized

• Motion sensitivity of two-phase flow

– Mitigated with proper CWHE design

© Copyright 2013 - Air Products and Chemicals, Inc. 13

Liquefaction Processes

Mixed Refrigerant

N2 Recycle

Single Pre-cooled

Refrigerant

© Copyright 2013 - Air Products and Chemicals, Inc. 14

N2 Recycle Process

• N2 expansion process for refrigeration

– Multiple turboexpanders

• No HC refrigerant

• All vapor refrigerant

– No motion sensitivity

– Higher flow rates and larger piping

• ~ 1.5 MTPA single train capacity

• ~ 75% of C3MR/DMR process efficiency

© Copyright 2013 - Air Products and Chemicals, Inc. 15

Liquefaction Processes

Mixed Refrigerant

N2 Recycle

Single Pre-cooled

Refrigerant

© Copyright 2013 - Air Products and Chemicals, Inc. 16

Precooled N2 Recycle

• No HC refrigerant

– CO2, HFC, or LiBr precooling

• Motion sensitivity only for precooler

– Mitigate with proper design

• ~ 2 MTPA single train capacity

• ~ 85% of C3MR/DMR process efficiency

© Copyright 2013 - Air Products and Chemicals, Inc. 17

Process Cycle Scorecard

Process Relative Train Equipment Flammable Significant Motion

Efficiency Capacity Count Refrigerant C3 Sensitivity

MTPA Inventory

C3MR 100 5+ Typical Yes Yes Mitigated

DMR 100 5+ Typical Yes No Mitigated

SMR 87 1-2 Lower Yes No Mitigated

Precooled N2 85 ~2 Higher No No Mitigated

N2 Recycle 75 ~1.5 Higher No No No

© Copyright 2013 - Air Products and Chemicals, Inc. 18

Summary

• A variety of process cycles are suitable for FLNG

– DMR: High efficiency, high capacity, low C3 inventory

– SMR: Simple and compact, low C3 inventory

– N2 Recycle: No flammable refrigerants, insensitive to vessel motion

– Precooled N2 Recycle: Improved efficiency and capacity, no HC

refrigerants

• CWHE provides robust design for FLNG

– Able to resist thermal stresses in liquefaction service

– Small footprint

– Motion effects on process/equipment are mitigated

– Air Products is the process licensor and CWHE supplier for the two

FLNG facilities now in EPC phase

© Copyright 2013 - Air Products and Chemicals, Inc. 19

Conclusion

There are many suitable

processes for FLNG –

Select the best one for you.

© Copyright 2013 - Air Products and Chemicals, Inc. 20

Thank you

© Copyright 2013 - Air Products and Chemicals, Inc.

Das könnte Ihnen auch gefallen

- Prodem Chapter 7 Gas Dehydration: Presented By: Rr. Sri Hastiyatisatiyah Ecp/Pro April 13th, 2015Dokument64 SeitenProdem Chapter 7 Gas Dehydration: Presented By: Rr. Sri Hastiyatisatiyah Ecp/Pro April 13th, 2015andi dipayadnya100% (1)

- Piping and Instrumentation Diagram (Pnid)Dokument19 SeitenPiping and Instrumentation Diagram (Pnid)ridzuanzabah0% (1)

- JT15D Ata 71Dokument20 SeitenJT15D Ata 71Egor85Noch keine Bewertungen

- ESCAVADEIRA KOMATSU PC200-6 - Catálogo de PeçasDokument396 SeitenESCAVADEIRA KOMATSU PC200-6 - Catálogo de PeçasJPJF100% (4)

- Total-Presentation (LNG17) Small Capacity FLNG DesignDokument15 SeitenTotal-Presentation (LNG17) Small Capacity FLNG DesignbradnonshinNoch keine Bewertungen

- Selection and Design of CondensersDokument27 SeitenSelection and Design of Condensersjdgh1986Noch keine Bewertungen

- Pacific Process Engineering ProfileDokument27 SeitenPacific Process Engineering ProfileTegar Arief PratamaNoch keine Bewertungen

- Air Cooled Heat Exchanger DesignDokument80 SeitenAir Cooled Heat Exchanger Designjdgh1986100% (3)

- EPC Execution of Borealis Ethane Tank Project TGE enDokument20 SeitenEPC Execution of Borealis Ethane Tank Project TGE enLEENoch keine Bewertungen

- LNG Process Overview ShortDokument46 SeitenLNG Process Overview ShortRobert Waters100% (2)

- Multi-Stage Reciprocating CompressorsDokument14 SeitenMulti-Stage Reciprocating CompressorsSajad FalahNoch keine Bewertungen

- Feed Heaters PerformanceDokument57 SeitenFeed Heaters Performancemvpngp100% (1)

- 1 151125221535 Lva1 App6892Dokument40 Seiten1 151125221535 Lva1 App6892Darmawan PutrantoNoch keine Bewertungen

- Manage Gas Feedstock and NGL Quality at Treating PlantsDokument9 SeitenManage Gas Feedstock and NGL Quality at Treating PlantsidiotstrialNoch keine Bewertungen

- 7-LNG Large Capacity Single Train AP-X Hybrid LNG ProcessDokument9 Seiten7-LNG Large Capacity Single Train AP-X Hybrid LNG ProcesshfNoch keine Bewertungen

- Modeling, Control, and Optimization of Natural Gas Processing PlantsVon EverandModeling, Control, and Optimization of Natural Gas Processing PlantsBewertung: 5 von 5 Sternen5/5 (1)

- Hydraulic Calculation For FFDokument2 SeitenHydraulic Calculation For FFArshath FleminNoch keine Bewertungen

- Gas Sweetening and Processing Field ManualVon EverandGas Sweetening and Processing Field ManualBewertung: 4 von 5 Sternen4/5 (7)

- Scheme Selection Logic Diagram Pressure Control For Liquid Storage TanksDokument46 SeitenScheme Selection Logic Diagram Pressure Control For Liquid Storage Tanksanto3harrish3fdoNoch keine Bewertungen

- Digital TwinsDokument17 SeitenDigital Twinsmartin100% (1)

- Lin AssistDokument4 SeitenLin AssistSynyster Patar SulivanNoch keine Bewertungen

- FLNG Technology ReviewDokument65 SeitenFLNG Technology Reviewscorpen100% (2)

- Are Floating LNG Facilities ViableDokument8 SeitenAre Floating LNG Facilities Viableihllhm100% (1)

- A New Frontier, Offshore Natural Gas Liquefaction - DR Chen Hwa Chiu (Chevron)Dokument20 SeitenA New Frontier, Offshore Natural Gas Liquefaction - DR Chen Hwa Chiu (Chevron)xajoNoch keine Bewertungen

- En LNG Air Products MCR Coil Wound Heat Exchangers PDFDokument10 SeitenEn LNG Air Products MCR Coil Wound Heat Exchangers PDFJoan Andrey Bolaños CruzNoch keine Bewertungen

- Innovations in LNG TechnologyDokument15 SeitenInnovations in LNG TechnologyCraigUnderwoodNoch keine Bewertungen

- Sop For H2 and Co2 Charging: Standard Operating ProcedureDokument9 SeitenSop For H2 and Co2 Charging: Standard Operating ProceduresambhuNoch keine Bewertungen

- Theory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlVon EverandTheory and Technology of Multiscale Dispersed Particle Gel for In-Depth Profile ControlNoch keine Bewertungen

- THE Liquefaction Plant: Fig. 5-1. Natural Gas Liquefaction Ow Diagram (Source: Poten & Partners)Dokument27 SeitenTHE Liquefaction Plant: Fig. 5-1. Natural Gas Liquefaction Ow Diagram (Source: Poten & Partners)Alex CadareNoch keine Bewertungen

- 5 - Duqm RefineryDokument17 Seiten5 - Duqm RefineryLien Nguyen100% (3)

- SCR PresentationDokument85 SeitenSCR PresentationariyaNoch keine Bewertungen

- Hydraulic TurbinesDokument57 SeitenHydraulic TurbinesJoshua Saladi100% (1)

- Process Gas CompressorsDokument24 SeitenProcess Gas CompressorsMSNoch keine Bewertungen

- Firing Diagram Based On Design Load PDFDokument2 SeitenFiring Diagram Based On Design Load PDFxaver lawNoch keine Bewertungen

- LNG FundamentalsDokument25 SeitenLNG FundamentalsDiego Alvaro De la Cruz JimenezNoch keine Bewertungen

- Extending The Life of Your LNG Assets: March 2016Dokument24 SeitenExtending The Life of Your LNG Assets: March 2016aleNoch keine Bewertungen

- Session 10 - Verghese JoeDokument12 SeitenSession 10 - Verghese JoePawan ChaturvediNoch keine Bewertungen

- LNG TechnologyDokument17 SeitenLNG TechnologySittichaiNoch keine Bewertungen

- Gitl Iocl 58 PL Do Pro 0013 Pre HydroDokument8 SeitenGitl Iocl 58 PL Do Pro 0013 Pre HydroilavarasanNoch keine Bewertungen

- En LNG Air Products Floating LNG Plant CapabilitiesDokument2 SeitenEn LNG Air Products Floating LNG Plant CapabilitiesMshelia M.Noch keine Bewertungen

- 230 19 002 GLB Technology Equipment and Service OfferingsDokument4 Seiten230 19 002 GLB Technology Equipment and Service OfferingsEvans Azka FNoch keine Bewertungen

- GAS BIT Praug Sep04 PDFDokument2 SeitenGAS BIT Praug Sep04 PDFNazeeh Abdulrhman AlbokaryNoch keine Bewertungen

- Applied Thermal Engineering: Q.Y. Li, Y.L. JuDokument8 SeitenApplied Thermal Engineering: Q.Y. Li, Y.L. Juthlim19078656Noch keine Bewertungen

- 05 Dunlop Unique FeaturesDokument31 Seiten05 Dunlop Unique FeaturesFikret YenenNoch keine Bewertungen

- LNG Project Reference Snohvit Success StoryDokument8 SeitenLNG Project Reference Snohvit Success StoryKong LingweiNoch keine Bewertungen

- Accelerating Adoption of Natural Gas Fueling InfrastructureDokument13 SeitenAccelerating Adoption of Natural Gas Fueling InfrastructureQingming MaNoch keine Bewertungen

- BSS Solutions For Industry 01-2022 enDokument139 SeitenBSS Solutions For Industry 01-2022 encklee.djkaNoch keine Bewertungen

- BIANCO Presentation PDFDokument33 SeitenBIANCO Presentation PDFnothing1aNoch keine Bewertungen

- ACSI Analyzer Systems & Applications in LNG Processing Plants BrochureDokument2 SeitenACSI Analyzer Systems & Applications in LNG Processing Plants Brochuremohamed abourayaNoch keine Bewertungen

- SPE-188704-MS Coral South FLNG Technology From Screening To Real ApplicationDokument11 SeitenSPE-188704-MS Coral South FLNG Technology From Screening To Real ApplicationLawrence MbahNoch keine Bewertungen

- NLC Energy Operations at Denmark WI ProjectDokument13 SeitenNLC Energy Operations at Denmark WI ProjectManikandan SWMSNoch keine Bewertungen

- Osmr®: Liquefaction Process For LNG ProjectsDokument17 SeitenOsmr®: Liquefaction Process For LNG ProjectsVenkatesan NNoch keine Bewertungen

- 12 Nick Power BOCDokument12 Seiten12 Nick Power BOCPawan ChaturvediNoch keine Bewertungen

- Peranan LNG Sebagai Energi Masa Depan: Dr. Ir. Salis S. Aprilian, MSCDokument39 SeitenPeranan LNG Sebagai Energi Masa Depan: Dr. Ir. Salis S. Aprilian, MSCStevenFerrelNoch keine Bewertungen

- Gasconsult ZR-LNG Liquefaction TechnologyDokument1 SeiteGasconsult ZR-LNG Liquefaction TechnologyBill HoweNoch keine Bewertungen

- Elixir Engineering - Process Safety ConsultantDokument14 SeitenElixir Engineering - Process Safety ConsultantSathishNoch keine Bewertungen

- Ghana Ministry - Gas Options-PresentationDokument19 SeitenGhana Ministry - Gas Options-PresentationCheikh75Noch keine Bewertungen

- Day2 - 07 - Tor Ivar Guttulsrod - American Bureau of ShippingDokument26 SeitenDay2 - 07 - Tor Ivar Guttulsrod - American Bureau of Shippingaegean227Noch keine Bewertungen

- About XindiDokument41 SeitenAbout Xindimoch ardiansyahNoch keine Bewertungen

- Hydrogen BrochureDokument5 SeitenHydrogen BrochureannamalaiNoch keine Bewertungen

- A New Frontier, Offshore Natural Gas Liquefaction - DR Chen Hwa Chiu (Chevron)Dokument20 SeitenA New Frontier, Offshore Natural Gas Liquefaction - DR Chen Hwa Chiu (Chevron)Faishal Khairul UmamNoch keine Bewertungen

- Roots B Centrifugal BrochureDokument24 SeitenRoots B Centrifugal BrochureStephenson ViegasNoch keine Bewertungen

- Siggberg WartsilaDokument27 SeitenSiggberg WartsilaSenthil KumarNoch keine Bewertungen

- Gas ProcessingDokument2 SeitenGas ProcessingRashesh ShahNoch keine Bewertungen

- 7 CompressorDokument2 Seiten7 CompressorMithun Singh RajputNoch keine Bewertungen

- Ezstrip™: Api 676 PumpsDokument6 SeitenEzstrip™: Api 676 PumpsFendhik Budhi DhermawantoNoch keine Bewertungen

- GEA - Refrigeration in Oil & Gas Industry - tcm11-33981Dokument4 SeitenGEA - Refrigeration in Oil & Gas Industry - tcm11-33981Dhroov SharmaNoch keine Bewertungen

- GS12 SPECIAL PROCESSES - JC01 RevisiDokument20 SeitenGS12 SPECIAL PROCESSES - JC01 RevisiNathallyia InasNoch keine Bewertungen

- Customer Feed Form - HyCO Asia - V0Dokument1 SeiteCustomer Feed Form - HyCO Asia - V0vtdNoch keine Bewertungen

- Activity - 221130 - Exploration Geologist - MKEDokument8 SeitenActivity - 221130 - Exploration Geologist - MKESetia WirawanNoch keine Bewertungen

- 123 Subsurfacefoam PDFDokument8 Seiten123 Subsurfacefoam PDFkhalidwy6342Noch keine Bewertungen

- HTRI Membership ApplicationDokument2 SeitenHTRI Membership ApplicationManoj ManivasagamNoch keine Bewertungen

- Narada Power Source Co., LTD.: Item Rexc Battery (Vrla) Tubular-Gel Battery (Opzv)Dokument2 SeitenNarada Power Source Co., LTD.: Item Rexc Battery (Vrla) Tubular-Gel Battery (Opzv)Yongki Adi Pratama PutraNoch keine Bewertungen

- Reflective EssayDokument4 SeitenReflective Essayapi-3171525010% (1)

- Infrared Plastic Solarcell Seminar 001Dokument19 SeitenInfrared Plastic Solarcell Seminar 001Abhishek BendaleNoch keine Bewertungen

- Tmgyd 55Dokument3 SeitenTmgyd 55Andrew VitalNoch keine Bewertungen

- Pltu Suralaya Ke IDokument22 SeitenPltu Suralaya Ke IBimo AdhityaNoch keine Bewertungen

- Jet Engines - ExplainedDokument12 SeitenJet Engines - ExplainedAsamir AlHaidarNoch keine Bewertungen

- Conclusions Technical and Economic Study of Two Energy Storage Technologies in Spain - G Advisory SimulydeDokument24 SeitenConclusions Technical and Economic Study of Two Energy Storage Technologies in Spain - G Advisory SimulydeAtapuiecoNoch keine Bewertungen

- Flat Die Pellet MillDokument7 SeitenFlat Die Pellet MillDan Felix100% (1)

- Steam Power Plant 1Dokument17 SeitenSteam Power Plant 1MohammedNoch keine Bewertungen

- Ei6002 Power Plant Instrumentation Question BankDokument11 SeitenEi6002 Power Plant Instrumentation Question BankAyyar Kandasamy100% (2)

- Achmad Faisal 121424002Dokument4 SeitenAchmad Faisal 121424002Achmad FaisalNoch keine Bewertungen

- TOPIC 1 - Steam Generating UnitDokument121 SeitenTOPIC 1 - Steam Generating UnitCllyan ReyesNoch keine Bewertungen

- MEPS Standards at A Glance 2013 04 01Dokument1 SeiteMEPS Standards at A Glance 2013 04 01John WuNoch keine Bewertungen

- Farm Power PracticalDokument5 SeitenFarm Power PracticalSaliha SattiNoch keine Bewertungen

- Power Quality: Project ON Grid Connected PV SystemsDokument22 SeitenPower Quality: Project ON Grid Connected PV SystemsRahul Radhakrishnan100% (1)

- Geothermal IndonesiaDokument6 SeitenGeothermal IndonesiaJefanNoch keine Bewertungen

- Energies 14 01063 v3Dokument20 SeitenEnergies 14 01063 v3scribdgineerNoch keine Bewertungen

- Mech9761: Week 2 at University of New South WalesDokument5 SeitenMech9761: Week 2 at University of New South WalesKevin HuynhNoch keine Bewertungen