Beruflich Dokumente

Kultur Dokumente

KSK Power Plant Turbine Barring Gear SOP

Hochgeladen von

SonratOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

KSK Power Plant Turbine Barring Gear SOP

Hochgeladen von

SonratCopyright:

Verfügbare Formate

-1–

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 1 of 1

STANDARD OPERATING

INSTRUCTIONS

FOR

TURBINE-GENERATOR BARRING(TURNING)GEAR

SYSTEM

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

-2–

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 2 of 1

STANDARD OPERATING PROCEDURE FOR BARRING GEAR(TURNING GEAR) OF

STEAM TURBINE GENERATOR

OBJECTIVE: For Safe & Smooth Operation of Turbine-generator Barring gear system.

SCOPE: This SOP is applicable for Turning Gear system for the steam turbine & generator Make DEC

China,Type: N600-16.7/538/538, of subcritical three cylinder/four flow, single shaft/single intermediate

reheat, condensing type.This procedure covers all the standard operating procedures related with

Turning gear system of T.G.

INTRODUCTION:

Turning gear is utilized on turbines to reduce eccentricity of the rotor due to uneven heating or cooling

would lead to bending and misalignment of shafts with possible fouling of stationary and moving parts of

Turbo Generator. Turning gear is used to drive the rotor rotate at low speed in order to heat the rotor

evenly, or maintain the rotor cooling evenly when it‘s rolling after downtime, reducing the deformation

possibility of rotor.

Turning gear located in bearing bracket between LP cylinder and generator. Turning gear drive turbo-

generator rotor rotating by driving gear mounted on coupling which between LP rotor and generator

rotor. Running speed is 1.5 rpm. Turning gear has chains, set of reducing gears & pneumatically

operated engage or disengage gear.

PRE CHECKS:

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

-3–

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 3 of 1

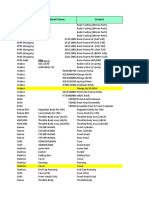

TECHNICAL DATA:-

TURNING GEAR

Make Dong Fang Steam Quantity 1 set

Turbines Company

Type MOTOR DRIVEN Code 1066.8-50AH

Gear Box Reduction

ratio 1/664

Motor Rating 15 KW SYN. Speed 1.5 RPM

TURNING GEAR MOTOR

Type Power 15 kW

Voltage 415V Current 28.9 Amp.

Rotating speed 975 r/min Efficiency

RESPONSIBILITY: Unit Control Engineer, Field Engineer and Desk Engineer.

SAFTEY PRECAUTIONS:

Ensure no permit to work is pending on regarding this system by checking with EE/MRSE.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

-4–

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 4 of 1

SAFTEY PPE’s: Ear Plugs, Safety Goggles, Hand Gloves, etc.

SPECIAL TOOLS/ EQUIPMENTS: NIL

PRECHECKS AND ACTION BY FIELD ENGINEER

S No Description Ok Not Ok Remarks

1 All permits and cross permits have been returned.

2 All mechanical/electrical/C&I work has completed &

working area is clear of any combustible or non

combustible Materials(Housekeeping).

3 All equipment interlock protection tests are completed

and qualified

4 Turbine rotor speed must be zero.

5 Lube oil system is in service check following parameters

1.Check lube oil pressure to individual bearing.

2.Lube oil return flow from individual bearing through

sight glass.

3.Check bearing metal temperature.

4.Check axial shift, differential expansion and

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

-5–

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 5 of 1

eccentricity.

5 Lube oil to barring gear assembly is Normal.

6 Start AC JOP and check pressure for individual supply

line. Check for shaft lifting value for each bearing i.e. for

bearing no.3,4,5,6,7,8.

Set the pressures accordingly.

7 DC JOP must be interlock with AC JOPS.

8 Seal oil system must be in service prior to turning gear

startup.

PRECHECKS AND ACTION BY DESK ENGINEER

S No Description Ok Not Ok Remarks

1 All permits and cross permits have been returned.

2 Main oil tank is filled with suitable amount of qualified Oil

and Oil level is normal (DCS).

3 Turbine must be at zero speed.

4 Power supply is healthy from.Turbine MCC.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

-6–

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 6 of 1

5 Instrument functioning properly namely: eccentricity,

axial displacement, differential expansion, bearing metal

temperature, shaft vibrations, lube oil temperature

6 Lube oil system & seal oil system must be in service

7 Start AC JOP and check pressure for individual supply

line. Check for all parameters. DC JOP must be

interlock with AC JOPS.

OPERATING PROCEDURE -

RESPONSIBILITY

Sr.

Description UCE DE FE E

No.

E

PRE- START CHECKS:

1 All the mechanical/electrical/C&I work has completed properly. √ √ √

2 All permits and cross permits have been returned. √ √ √ √

3 Power supply and control power supply available. √ √

4 Lube oil system & seal oil system must be in service. Check all the relevant

parameters.The turning gear motor not allowed to start until lube oil √ √

pr.>0.137 Mpa & JOP dis. Pr.>7 Mpa.

5 Jacking oil pump (JOP) is in running condition. All parameters & lifts at

individual bearings are OK. DC JOP must be interlock with AC JOPS √ √

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

-7–

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 7 of 1

6 Instrument functioning properly namely eccentricity, axial displacement,

differential expansion, bearing metal temperature, shaft vibrations, lube oil √ √ √

temperature.

7 Turbine must be at zero RPM. √ √ √

8 Interlock of DC EOP auto start Ok. √ √

START PERMISSIVE :

1 MSVs are fully closed i.e. Turbine is in TRIP condition. √ √ √

2 Turbine rotor must be at ZERO R.P.M. √ √ √

3 Lube oil system is in service. Lube oil pr.>0.137 Mpa. Indication by lamp. √ √

4 JOP is in running condition & JOP dis. Pr. must be >7 Mpa. Indication by

√ √

lamp.

5 Manual turning gear is unchain.

√ √

TURNING GEAR START UP SEQUENCE

1 The barring gear Motor auto start at turbine speed ZERO rpm (Time Delay -

30 S.) or start the motor from OIS if motor is not started in interlock. √ √

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

-8–

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 8 of 1

2 After the turning gear motor starts,use the electric interlock to energize the

solenoid valve to engage the turning gear (Time Delay -10 S after Turning

Gear motor start),In this case the red lamp on OIS will turn on,indicating the √

barring gear engage SOV energized.

3 When launch machine make the gear in gear box joggle the gear at Turbine

shaft, launch completed. Then send out “TSS OK” digital signal, lamp(HL1)

is on, and de-energize the solenoid valve. At this time turning gear start √ √

complete.

3 After barring gear engage, barring gear will turn the rotor,Record the

following parameters at regular interval.

I. Barring gear speed is 1.5 rpm.

II. Lube oil pressure to bearings.

III. Jacking oil pressure to individual bearing.

√ √ √

IV. JOP current.

V. Eccentricity

VI. All bearing vibrations.

VII. Barring gear drive motor current.

4 Observe for any other abnormal sound of rubbing,fouling coming of T.G. √

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

-9–

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 9 of 1

SHUTDOWN SEQUENCE:

PLANNED SHUTDOWN :

1 Barring gear will auto disengage during turbine start.,if signal “TSS OK” is

OFF & Zero rpm is Off also, the Turning Gear motor will De-enerzige after √ √

30 S & turning gear willl auto disengage.

2 Check out whether barring gear disengaged or not ,otherwise disengage it

from local by pulling the lever. If any problem persists, immediately stop the √ √

turbine and find the causes.

3 Put the barring gear motor in Interlock √

4 During turbine shutdowns for overhauls T.G. barring gear can stopped

manually by Pushing the “TGM STOP” button in DCS, turning gear motor

√ √

stopped, the turning gear will keep at the position of initialization.This can be

done if & only the temperature of HPT Inner casing is below 120 deg. C.

TRIPPING OF TURNING GEAR :If suddenly turning gear trips

1 Tripping can be due to Motor overload current or any other reason like lube √ √

√

oil/jack oil system malfunctioning.

2 Find out the reasons for malfunctioning of any √ √

equipments/parameters,rectify the same.Turn the rotor by hand barring

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

- 10 –

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 10 of 1

lever.JOP & lube oil should be in service otherwise manual barring may

damage Rotor/Journal bearings.

2 If cause of tripping is due to unavailability of electrical power due to any

reasons, rotate the turning gear manually till restoration of electric √ √

supply.DC JOP & lube oil system will be in service in this duration.

EMERGENCY SHUT DOWN:

1 During emergency conditions turn the T.G. rotor by hand barring if √

√

temperature of HPT Inner casing is above 120 deg. C.

2 JOP & lube oil should be in service during manual rotation.(Hand Barring) √ √

3

4

INTERLOCKS & PROTECTIONS : Remarks

1 MSVS are full closed i.e. Turbine is in TRIP condition.

2 Lube oil & Jacking oil system in in service.

2 The turning gear motor not allowed to start until lube oil pr.>0.137 Mpa &

JOP dis. Pr.>7 Mpa.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

- 11 –

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 11 of 1

ABRIVIATIONS / NOTATIONS:-

o SOP: Standard Operating Procedure

o UCE: Unit Control Engineer

o DE: Desk Engineer

o FE: Field Engineer

o DCS: Distributed Control System

o EE: Electrical Shift Engineer

o MFT: Main Fuel Trip.

o RB : Run Back

Important Note:

1 Run turbine on Turning Gear at least for 24 hrs. before rolling

2 Gland sealing steam is not allowed to supply without turning gear.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

- 12 –

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 12 of 1

Signature Signature Signature

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

- 13 –

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL / Opr. /

TURBINE GENERATOR

BARRING GEAR

SYSTEM/ 01

SOP FOR TURBINE-GENERATOR BARRING GEAR SYSTEM

Power from knowledge

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 13 of 1

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Saurabh Shrivastava Name: Name:

Designation: Asst. Manager Designation: Designation:

Das könnte Ihnen auch gefallen

- Sop LRSB BlowerDokument6 SeitenSop LRSB BlowerApnrl maincontrolroom100% (1)

- KSK Mahanadi Power Company Ltd. Vacuum Conveying System SOPDokument8 SeitenKSK Mahanadi Power Company Ltd. Vacuum Conveying System SOPSonratNoch keine Bewertungen

- PocketDiary SantaldihDokument198 SeitenPocketDiary SantaldihJoydev GangulyNoch keine Bewertungen

- SOP For Turbine ChecklistDokument11 SeitenSOP For Turbine Checklistpradeep.selvarajanNoch keine Bewertungen

- Turbine Protection & InterlockDokument7 SeitenTurbine Protection & InterlockSony RamaNoch keine Bewertungen

- Presentation Title Mundra UMPP: Presentation Subtitle CGPL, Tata Power Company LimitedDokument34 SeitenPresentation Title Mundra UMPP: Presentation Subtitle CGPL, Tata Power Company LimitedJay JobanputraNoch keine Bewertungen

- Sop For Dry Ash Pressure Conveying SystemDokument7 SeitenSop For Dry Ash Pressure Conveying SystemSonratNoch keine Bewertungen

- Drum Level Pressure Compensation System Gyanendra Sharma Npti DelhiDokument36 SeitenDrum Level Pressure Compensation System Gyanendra Sharma Npti DelhiNPTI100% (1)

- FSSSDokument63 SeitenFSSSdipdesire100% (1)

- 660MW Turbo Generator & Its AuxiliariesDokument88 Seiten660MW Turbo Generator & Its AuxiliariesAshvani ShuklaNoch keine Bewertungen

- Major Overhaul of LP Turbine and Generator: Unit-4, (250 MW) OPJSTPP JPL Tamnar-Raigarh (15/07/2012 To 31/07/2012)Dokument134 SeitenMajor Overhaul of LP Turbine and Generator: Unit-4, (250 MW) OPJSTPP JPL Tamnar-Raigarh (15/07/2012 To 31/07/2012)Gaurav SinghNoch keine Bewertungen

- Standard Operating InstructionDokument8 SeitenStandard Operating InstructionSonratNoch keine Bewertungen

- Turbine Trip LogicDokument2 SeitenTurbine Trip Logicdilbagh_scribd50% (2)

- Ball and Race Mill PDFDokument76 SeitenBall and Race Mill PDFNemoNoch keine Bewertungen

- 3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDokument15 Seiten3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDSGNoch keine Bewertungen

- Ash Handling System OverviewDokument24 SeitenAsh Handling System OverviewAshish UppuNoch keine Bewertungen

- STPP Boiler, Turbine and Auxiliaries Protection and InterlocksDokument64 SeitenSTPP Boiler, Turbine and Auxiliaries Protection and InterlocksHari Prasad100% (1)

- Bhel PPTDokument34 SeitenBhel PPTMayur TapadiaNoch keine Bewertungen

- 98676767Dokument89 Seiten98676767HiltonNoch keine Bewertungen

- Presentation On Turbine Protection System: Prepared by Subir BiswasDokument29 SeitenPresentation On Turbine Protection System: Prepared by Subir BiswasJitu Jena100% (2)

- ESP Hopper Heaters Are Continuously Energised Due To Insulation FailureDokument3 SeitenESP Hopper Heaters Are Continuously Energised Due To Insulation FailuresanjeevchhabraNoch keine Bewertungen

- Generator CoolingDokument7 SeitenGenerator CoolingPrudhvi RajNoch keine Bewertungen

- Turbine Governing System Components and FunctionsDokument24 SeitenTurbine Governing System Components and Functionslrpatra100% (1)

- 3 Esp .Dokument6 Seiten3 Esp .Mithun Singh RajputNoch keine Bewertungen

- 020-SOP of H2 CYLINDER Room ChargingDokument4 Seiten020-SOP of H2 CYLINDER Room ChargingsambhuNoch keine Bewertungen

- Boiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDokument11 SeitenBoiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan SundararajNoch keine Bewertungen

- Docslide - Us K Karthikeyan Manager Controls Instrumentation Bhel TiruchirappalliDokument97 SeitenDocslide - Us K Karthikeyan Manager Controls Instrumentation Bhel TiruchirappallimanojkumarmurlidharaNoch keine Bewertungen

- Esp Test ProceduressssDokument10 SeitenEsp Test Proceduresssssumit bhagatNoch keine Bewertungen

- Central Electricity Authority Notification on Technical StandardsDokument291 SeitenCentral Electricity Authority Notification on Technical StandardsHariprasad gantyala100% (2)

- Max IoDokument76 SeitenMax IoDeepak Gupta100% (1)

- SOP of LDOSystemDokument7 SeitenSOP of LDOSystemsambhu100% (1)

- PLTU KALTIM - 2 SOP for Coal Mill and Coal Feeder OperationDokument5 SeitenPLTU KALTIM - 2 SOP for Coal Mill and Coal Feeder OperationChandra PratamaNoch keine Bewertungen

- CMC NTPC Unchahar PDFDokument48 SeitenCMC NTPC Unchahar PDFDinoNoch keine Bewertungen

- Sop For Oil Purification SystemDokument8 SeitenSop For Oil Purification SystemSonrat100% (1)

- Commissioning Fans Procedure SimhadriDokument17 SeitenCommissioning Fans Procedure SimhadriSara LopezNoch keine Bewertungen

- SCED Pilot Study Lowers Generation Costs by Rs. 2.59 Cr DailyDokument11 SeitenSCED Pilot Study Lowers Generation Costs by Rs. 2.59 Cr DailyPRAGNoch keine Bewertungen

- Cleaning NTPC's Seal Oil System PipingDokument18 SeitenCleaning NTPC's Seal Oil System Pipingnetygen1Noch keine Bewertungen

- Cold Start Up - CSTPS PDFDokument19 SeitenCold Start Up - CSTPS PDFAhemadNoch keine Bewertungen

- Rel 4 TPP431 - 11 Rev F0 MaxDNA Functions and Features - P20Dokument21 SeitenRel 4 TPP431 - 11 Rev F0 MaxDNA Functions and Features - P20ArjunNoch keine Bewertungen

- Introduction To Steam Seal System of 800Mw Kudgi TurbineDokument10 SeitenIntroduction To Steam Seal System of 800Mw Kudgi TurbineSCEKUDGI 800Noch keine Bewertungen

- Functional Change of Sac Into Iac: Standard Field Operating ProcedureDokument7 SeitenFunctional Change of Sac Into Iac: Standard Field Operating ProcedureMithun Singh RajputNoch keine Bewertungen

- Chapter 14 Governing SystemDokument7 SeitenChapter 14 Governing Systemsambhu100% (1)

- BHEL turbine operation manual 500 MWDokument2 SeitenBHEL turbine operation manual 500 MWAlam50% (2)

- 500 MW BOILER SALIENT FEATURESDokument8 Seiten500 MW BOILER SALIENT FEATURESKeyur PatelNoch keine Bewertungen

- ABG PresentationDokument28 SeitenABG PresentationSarah Frazier0% (1)

- Digital Control System of Plant Gyanendra Sharma NPTI DelhiDokument128 SeitenDigital Control System of Plant Gyanendra Sharma NPTI DelhiNPTINoch keine Bewertungen

- Ash Handling System 1Dokument18 SeitenAsh Handling System 1Farzeen Hallaj EdakalamattamNoch keine Bewertungen

- Automatic Turbine Runup System Gyanendra Sharma NPTI DelhiDokument32 SeitenAutomatic Turbine Runup System Gyanendra Sharma NPTI DelhiNPTI100% (1)

- Steam Turbine GovernorDokument25 SeitenSteam Turbine GovernorGanesh Dasara100% (2)

- NTPC Kahalgaon PlantDokument45 SeitenNTPC Kahalgaon Plantadilk100% (1)

- Korba - BAH Online Temp MonitoringDokument7 SeitenKorba - BAH Online Temp Monitoringrama jenaNoch keine Bewertungen

- Condenser Vacuum Improvement Stage-IDokument23 SeitenCondenser Vacuum Improvement Stage-Inetygen1100% (2)

- Motor Driven Boiler Feed Pump SOPDokument7 SeitenMotor Driven Boiler Feed Pump SOPAmit BiswasNoch keine Bewertungen

- Wet To Dry Mode Chage OverDokument4 SeitenWet To Dry Mode Chage OversambhuNoch keine Bewertungen

- 8.8 Boiler Efficiency TestDokument17 Seiten8.8 Boiler Efficiency TestRINJUNoch keine Bewertungen

- Lube Oil System and JOP SOP - Docx-1Dokument38 SeitenLube Oil System and JOP SOP - Docx-1SonratNoch keine Bewertungen

- SOP for Turbine Lube Oil SystemDokument34 SeitenSOP for Turbine Lube Oil SystemSonratNoch keine Bewertungen

- Final KSK Sop Instrument CompressorDokument10 SeitenFinal KSK Sop Instrument CompressorSonratNoch keine Bewertungen

- SMP For Agitator (Slurry Sump)Dokument9 SeitenSMP For Agitator (Slurry Sump)SonratNoch keine Bewertungen

- OCCW Pump SOP-1Dokument7 SeitenOCCW Pump SOP-1SonratNoch keine Bewertungen

- KSK Mahanadi Thermal Power Project Control Write UpDokument10 SeitenKSK Mahanadi Thermal Power Project Control Write UpSonratNoch keine Bewertungen

- SMP For Agitator (Slurry Sump)Dokument9 SeitenSMP For Agitator (Slurry Sump)SonratNoch keine Bewertungen

- Bah ElevationDokument1 SeiteBah ElevationSonratNoch keine Bewertungen

- Bah Side ViewDokument1 SeiteBah Side ViewSonratNoch keine Bewertungen

- FluidizingDokument13 SeitenFluidizingSonratNoch keine Bewertungen

- SMP For Slurry PumpDokument14 SeitenSMP For Slurry PumpSonrat100% (1)

- SMP For Sealing Water Pump Multi Stage.Dokument13 SeitenSMP For Sealing Water Pump Multi Stage.SonratNoch keine Bewertungen

- Part List - BEL0800 PDFDokument1 SeitePart List - BEL0800 PDFSonratNoch keine Bewertungen

- SMP For Ba Overflow PumpDokument14 SeitenSMP For Ba Overflow PumpSonratNoch keine Bewertungen

- SMP For Supply Water PumpDokument13 SeitenSMP For Supply Water PumpSonratNoch keine Bewertungen

- SMP For Dry Ash UnloaderDokument8 SeitenSMP For Dry Ash UnloaderSonratNoch keine Bewertungen

- PM For Fly Ash Dry SystemDokument31 SeitenPM For Fly Ash Dry SystemSonratNoch keine Bewertungen

- SMP For Vacuum PumpDokument9 SeitenSMP For Vacuum PumpSonratNoch keine Bewertungen

- SMP For Fluidizing Air BlowerDokument20 SeitenSMP For Fluidizing Air BlowerSonrat100% (1)

- Sop For Vent FilterDokument6 SeitenSop For Vent FilterSonratNoch keine Bewertungen

- HCSD PDFDokument1 SeiteHCSD PDFSonratNoch keine Bewertungen

- ECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFDokument1 SeiteECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFSonratNoch keine Bewertungen

- FluidizingDokument13 SeitenFluidizingSonratNoch keine Bewertungen

- Water & Slurry BalanceDokument1 SeiteWater & Slurry BalanceSonratNoch keine Bewertungen

- Over Flow Pump Concentrator Buffer Tank ModelDokument1 SeiteOver Flow Pump Concentrator Buffer Tank ModelSonratNoch keine Bewertungen

- BAH JET PUMP DISCHAGE PIPE LINE-Model PDFDokument1 SeiteBAH JET PUMP DISCHAGE PIPE LINE-Model PDFSonratNoch keine Bewertungen

- ASH WATER PUMP HOUSE-Model PDFDokument1 SeiteASH WATER PUMP HOUSE-Model PDFSonratNoch keine Bewertungen

- StructureDokument1 SeiteStructureSonratNoch keine Bewertungen

- Compressor House ModelDokument1 SeiteCompressor House ModelSonratNoch keine Bewertungen

- ESP-FLD. BLOWER-Model PDFDokument1 SeiteESP-FLD. BLOWER-Model PDFSonratNoch keine Bewertungen

- Pdi EspDokument1 SeitePdi EspSonratNoch keine Bewertungen

- Silo Unloading ModelDokument1 SeiteSilo Unloading ModelSonratNoch keine Bewertungen

- VP To Buffr Hopper-ModelDokument1 SeiteVP To Buffr Hopper-ModelSonratNoch keine Bewertungen

- Silo Blower Compressor ModelDokument1 SeiteSilo Blower Compressor ModelSonratNoch keine Bewertungen

- SEPCO Electric Power Construction Corporation and NORTHEAST ELECTRIC POWER DESIGN INSTITUTE As Built DrawingDokument1 SeiteSEPCO Electric Power Construction Corporation and NORTHEAST ELECTRIC POWER DESIGN INSTITUTE As Built DrawingSonratNoch keine Bewertungen

- Wosr Benefits Lexm0101-00 PDFDokument4 SeitenWosr Benefits Lexm0101-00 PDFJulio TovarNoch keine Bewertungen

- 337156Dokument73 Seiten337156Anderson BombistaNoch keine Bewertungen

- ME759Dokument2 SeitenME759Kišić SpasojeNoch keine Bewertungen

- Customer Model Name ProductDokument4 SeitenCustomer Model Name ProductVishal RajputNoch keine Bewertungen

- DENSO - Epair Manual Pump EDC V3-V5Dokument118 SeitenDENSO - Epair Manual Pump EDC V3-V5Bui NamNoch keine Bewertungen

- Historic Vehicle Clubs List 1Dokument18 SeitenHistoric Vehicle Clubs List 1mathewNoch keine Bewertungen

- Toyota 2nz-Fe Ecu PinoutDokument7 SeitenToyota 2nz-Fe Ecu PinoutMiguel ruiz86% (43)

- Engine: Aftermarket Parts ForDokument353 SeitenEngine: Aftermarket Parts ForJohn Maisonnett100% (2)

- Audi A6 c7 Engine ManualDokument258 SeitenAudi A6 c7 Engine ManualErti HariziNoch keine Bewertungen

- Thermal Engineering - I Jntua Question PapersDokument15 SeitenThermal Engineering - I Jntua Question PapersHimadhar SaduNoch keine Bewertungen

- New Beetle Wiring Diagram Fuel Injection SystemDokument10 SeitenNew Beetle Wiring Diagram Fuel Injection SystemGilberto Martinez ANoch keine Bewertungen

- Yuchai Marine EngineDokument4 SeitenYuchai Marine EngineClaudio100% (1)

- Engine V9X NavaraDokument394 SeitenEngine V9X Navaramichiganangola91% (11)

- Portable Compressor ManufacturerDokument2 SeitenPortable Compressor ManufacturerRotair spaNoch keine Bewertungen

- Quasiturbine Engine FinalDokument17 SeitenQuasiturbine Engine FinalChandan GuleriaNoch keine Bewertungen

- Injectores S 60 PDFDokument18 SeitenInjectores S 60 PDFfranciscoNoch keine Bewertungen

- Parts Manual: 312D2 L ExcavatorDokument455 SeitenParts Manual: 312D2 L ExcavatorDiego Montenegro100% (1)

- Valve Section (Boom) - (S - N 232512782 & Below, 232711433 & Below, 232612157 & Below) - 334Dokument2 SeitenValve Section (Boom) - (S - N 232512782 & Below, 232711433 & Below, 232612157 & Below) - 334EUROPARTSNoch keine Bewertungen

- E120a - Piston & CrankshaftDokument4 SeitenE120a - Piston & CrankshaftbennieNoch keine Bewertungen

- Precise. Innovative. Leading. Assembly and Test Stands: Ics Industrial Control SystemsDokument3 SeitenPrecise. Innovative. Leading. Assembly and Test Stands: Ics Industrial Control SystemsKevin TtitoNoch keine Bewertungen

- Weber CalibrationsDokument1 SeiteWeber CalibrationsdelboteNoch keine Bewertungen

- Bomba de Agua SubaruDokument2 SeitenBomba de Agua Subarurodrigo dubonNoch keine Bewertungen

- Understanding the fundamentals of camshafts in automotive enginesDokument8 SeitenUnderstanding the fundamentals of camshafts in automotive enginesanshaj singhNoch keine Bewertungen

- Rotor AssemblyDokument31 SeitenRotor AssemblyFebri SetiawanNoch keine Bewertungen

- Scania 420 Diesel EngineDokument19 SeitenScania 420 Diesel EngineFRANCISCO NIWTON BEZERRANoch keine Bewertungen

- Aircraft engine types and propeller performanceDokument1 SeiteAircraft engine types and propeller performanceChegrani AhmedNoch keine Bewertungen

- Jac Refine Motor 2.8 PDFDokument622 SeitenJac Refine Motor 2.8 PDFSebastián Andrés González Gallardo100% (4)

- Posobie Teplovoj Raschet 1 1Dokument95 SeitenPosobie Teplovoj Raschet 1 1abbeyNoch keine Bewertungen

- John Deere 6155RDokument5 SeitenJohn Deere 6155RGABRIELE GUALDINoch keine Bewertungen

- Mercruiser BellowsDokument11 SeitenMercruiser BellowsMarine Parts ChinaNoch keine Bewertungen