Beruflich Dokumente

Kultur Dokumente

Condenser Ball Cleaning System

Hochgeladen von

SonratOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Condenser Ball Cleaning System

Hochgeladen von

SonratCopyright:

Verfügbare Formate

KSK Mahanadi Power Company Ltd.

Power from knowledge 6 X 600 MW Power Plant KMPCL / Opr. /CONDENSER BALL

SOP FOR CONDENSER BALL CLEANING/ 01

CLEANING

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 1 of 1

STANDARD OPERATING INSTRUCTION

FOR

CONDENSER BALL CLEANING SYSTEM

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Anshumaan Vatsa Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

Power from knowledge 6 X 600 MW Power Plant KMPCL / Opr. /CONDENSER BALL

SOP FOR CONDENSER BALL CLEANING/ 01

CLEANING

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 2 of 1

STANDARD OPERATING PROCEDURE FOR CONDENSER BALL

CLEANING system

OBJECTIVE: For Smooth Operation of Condenser ball cleaning system

SCOPE: This SOP is applicable for ball cleaning of all units.

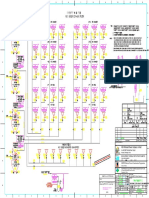

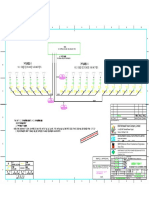

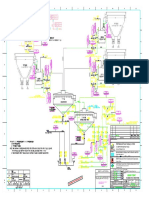

INTRODUCTION: Rubber ball cleaning system is used for online continuous cleaning of inner

surface of cooling water pipes inside the condenser to reach the designed heat exchange rate of

condenser. Rubber ball cleaning system of condenser consists of rubber ball pump, ball-loading

chamber, ball-collecting screen, valves & corresponding piping .

PRE CHECKS:

TECHNICAL DATA:-

Make Qingdao Huatai Power Quantity 2

Equipment Co., Ltd

Type 125JQ-27 Outlet flow 108m3/h

Shaft power 13.5 KW Rotating speed 1460

PUMP motor

Type Y180M-4 Power 18.5

Voltage 415V Current 35.9A

Rotating speed 1460 rpm Make Shanghai electromotor Co.,

Ltd

RESPONSIBILITY: Unit Control Engineer, Field Engineer and Desk Engineer.

SAFTEY PRECAUTIONS:

1. Ensure no permit to work is pending on regarding this system by checking with EE/MRSE.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Anshumaan Vatsa Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

Power from knowledge 6 X 600 MW Power Plant KMPCL / Opr. /CONDENSER BALL

SOP FOR CONDENSER BALL CLEANING/ 01

CLEANING

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 3 of 1

SAFTEY PPE’s: Ear Plugs, Safety Goggles, Hand Gloves, etc.

SPECIAL TOOLS/ EQUIPMENTS: NIL

PRECHECKS AND ACTION BY FIELD ENGINEER

S No Description Ok Not Ok Remarks

1. All permits and cross permits have been returned .

2. Check bearing oil level carefully before starting rubber

ball pump

3. Area is clear of any other materials.

4. Condenser CW system is in service

5. Ball collecting strainer is ready for operation.

6. Hand rotate ball cycle pump rotor, the rotor should rotate

freely, without rocking or seizure.

7. Check that inlet and outlet valves of ball recycle pump

act normally

8. Before put in, rubber balls should be dipped in water for

24 hours

Fill the ball injection chamber with a certain number of

balls as required, the changeover valve is set to “Clean”

9. position, the water drain valve should be closed, and the

air release valve should be fully open.

PRECHECKS AND ACTION BY DESK ENGINEER

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Anshumaan Vatsa Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

Power from knowledge 6 X 600 MW Power Plant KMPCL / Opr. /CONDENSER BALL

SOP FOR CONDENSER BALL CLEANING/ 01

CLEANING

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 4 of 1

S No Description Ok Not Ok Remarks

1 Ball pumps power supply is in ON condition

Ball pumps I/L MOV, O/L MOV, Switch MOV & ball-

2 collecting screen actuator power is in ON condition

OPERATING PROCEDURE -

Sr. RESPONSIBILITY

Description

No. UCE DE FE EE

PRE- START CHECKS:

1 All permits and cross permits have been returned. √ √ √ √

2 Power supply and control power supply available. √ √

3 Check the power switch of programmable controller cabinet is On and

the indicator lights on display screen normal. √ √

4 Condenser CW system is in service √

5 Check bearing oil level carefully before starting rubber ball pump √ √

6 Check that the condenser tube rubber ball cleaning system is through √ √

7 Ensure sufficient balls are available in system.( 10%-13% of no. of √

√

tubes of condenser

START PERMISSIVE :NIL

START UP SEQUENCE :

1 Open outlet valve of ball pump; fill ball injection chamber, and then √

close air release valve of ball injection when water is flowing out. √

Close outlet valve of ball pump

2 Open inlet valve of inlet line, then close air release valve of ball √

injection when water is flowing out. Close inlet valve. √

3 Start up rubber ball pump, and check it is rotating normally √ √

4 Open outlet valve of rubber ball pump, set changeover valve of ball √

injection chamber to “Cleaning”, and open outlet valve of ball injection √

chamber.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Anshumaan Vatsa Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

Power from knowledge 6 X 600 MW Power Plant KMPCL / Opr. /CONDENSER BALL

SOP FOR CONDENSER BALL CLEANING/ 01

CLEANING

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 5 of 1

5 Through observation window watch the movement of rubber balls. It is √

normal that balls should be seen every several minutes. Cleaning √

should last for about 60 minutes every time

6 Check ball collecting rate, the percentage ratio of the number of balls √

put in to the number of balls collected. √

7 Observe pump and motor for any abnormal sound & considerable √

vibration √

8 Observe for bearing overheating in local as no remote indicator is

mounted √

9 Observe pumps discharge pressure in local gauge. It should be more

√

than condenser I/L CW duct pressure.

10 Keep system in operation for 4-6 hours in a day or as desired √ √

SHUTDOWN SEQUENCE:

1. PLANNED SHUTDOWN :

1 After cleaning completed, set changeover valve of ball injection √

chamber to “Collecting” position to perform about 30 minutes of ball √

collecting.

2 Close outlet valve of rubber ball pump, stop rubber ball pump, and √

close inlet valve of rubber ball pump. √

3 Close outlet valve of ball injection chamber √ √

4 Open air release valve and water drain valve of ball injection chamber. √

After water is drained away, count the balls and note down ball √

collecting rate and cleaning time.

2. TRIPPING :nil

3.EMERGENCY SHUT DOWN:

1 During running of condenser tube rubber ball cleaning system, it is √ √ √

required that all devices be closely monitored ,and adjusted as soon

as deviation from the normal operation is discovered, thus ensuring

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Anshumaan Vatsa Name: Name:

Designation: Designation: Designation:

KSK Mahanadi Power Company Ltd.

Power from knowledge 6 X 600 MW Power Plant KMPCL / Opr. /CONDENSER BALL

SOP FOR CONDENSER BALL CLEANING/ 01

CLEANING

Issue No: 1 Issue Date: Revision: 0 Revision Date: File no: Page 6 of 1

optimal operation of system

2 On occurrence of such conditions as abnormal noise from running √ √

pump, severe vibration on equipment or pipeline, and parameter

exceeding limit

INTERLOCKS :NIL Remarks

ABRIVIATIONS / NOTATIONS:-

o SOP: Standard Operating Procedure

o UCE: Unit Control Engineer

o DE: Desk Engineer

o FE: Field Engineer

o DCS: Distributed Control System

o EE: Electrical Shift Engineer

o MFT: Main Fuel Trip.

o RB : Run Back

Important Note:

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Anshumaan Vatsa Name: Name:

Designation: Designation: Designation:

Das könnte Ihnen auch gefallen

- TECS-W IOM ManualDokument60 SeitenTECS-W IOM Manualxuyen tran100% (4)

- Tech DiaryDokument121 SeitenTech DiaryhahaaNoch keine Bewertungen

- SMP For Sealing Water Pump Multi Stage.Dokument13 SeitenSMP For Sealing Water Pump Multi Stage.SonratNoch keine Bewertungen

- Mill Reject SystemDokument22 SeitenMill Reject SystemgangatharanNoch keine Bewertungen

- Turbine RollingDokument3 SeitenTurbine RollingAnudeep Chittluri100% (1)

- SMP For Fluidizing Air BlowerDokument20 SeitenSMP For Fluidizing Air BlowerSonrat100% (1)

- SMP For Vacuum PumpDokument9 SeitenSMP For Vacuum PumpSonratNoch keine Bewertungen

- SMP For Agitator (Slurry Sump)Dokument9 SeitenSMP For Agitator (Slurry Sump)SonratNoch keine Bewertungen

- Sop For Ba-Hp Pump (r1)Dokument6 SeitenSop For Ba-Hp Pump (r1)SonratNoch keine Bewertungen

- Failure and Fracture of Short Flass Fibre Reinforced Nylon Composites MooreDokument8 SeitenFailure and Fracture of Short Flass Fibre Reinforced Nylon Composites MooreGerardo XZNoch keine Bewertungen

- Turbine Trip LogicDokument2 SeitenTurbine Trip Logicdilbagh_scribd50% (2)

- UNIT 4 Raman Spectroscopy 12309Dokument24 SeitenUNIT 4 Raman Spectroscopy 12309NathanianNoch keine Bewertungen

- Standard Operating Instruction: Sop For Condenser Ball CleaningDokument6 SeitenStandard Operating Instruction: Sop For Condenser Ball CleaningSonratNoch keine Bewertungen

- Final Ea R-Infra Dahanu TpsDokument84 SeitenFinal Ea R-Infra Dahanu TpsLakshmi NarayanNoch keine Bewertungen

- Ace Your Food Science Projects PDFDokument367 SeitenAce Your Food Science Projects PDFashqNoch keine Bewertungen

- Generator AuxDokument85 SeitenGenerator Auxjp mishraNoch keine Bewertungen

- SMP For Slurry PumpDokument14 SeitenSMP For Slurry PumpSonrat100% (1)

- ESP ManualDokument158 SeitenESP ManualSinter PlanningNoch keine Bewertungen

- Stopping of One Pa FanDokument1 SeiteStopping of One Pa FanShift Incharge BrbclNoch keine Bewertungen

- FluidizingDokument13 SeitenFluidizingSonratNoch keine Bewertungen

- FluidizingDokument13 SeitenFluidizingSonratNoch keine Bewertungen

- Bioburden Recovery Method Using Swabbing TechniqueDokument8 SeitenBioburden Recovery Method Using Swabbing TechniquePiruzi MaghlakelidzeNoch keine Bewertungen

- CC Pump Manual-Full (Original)Dokument109 SeitenCC Pump Manual-Full (Original)friendbce100% (1)

- Sop For LP PumpDokument5 SeitenSop For LP PumpSonratNoch keine Bewertungen

- 057 - SOP of Boiler Circulating Pump FlushingDokument6 Seiten057 - SOP of Boiler Circulating Pump FlushingsambhuNoch keine Bewertungen

- Chapter 15 Condensate SystemDokument11 SeitenChapter 15 Condensate SystemsambhuNoch keine Bewertungen

- Gland Sealing Systeam011Dokument6 SeitenGland Sealing Systeam011SonratNoch keine Bewertungen

- SMP For Ba Overflow PumpDokument14 SeitenSMP For Ba Overflow PumpSonratNoch keine Bewertungen

- Station Black Out Handling and Restoration St1Dokument8 SeitenStation Black Out Handling and Restoration St1Shift Incharge BrbclNoch keine Bewertungen

- Jindal Power Limited, Tamnar: JPL/OPN-250/SOP/.. 01/29.07.2019 00/00Dokument4 SeitenJindal Power Limited, Tamnar: JPL/OPN-250/SOP/.. 01/29.07.2019 00/00Chandramani PatelNoch keine Bewertungen

- Flexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCDokument27 SeitenFlexible Operation in Coal Based Plant: By-SNEHESH BANERJEE, Operation Services, CCLakshmi NarayanNoch keine Bewertungen

- Turbine Working & ItsComponentsDokument88 SeitenTurbine Working & ItsComponentsHimanshu spoliaNoch keine Bewertungen

- Final KSK Sop Instrument CompressorDokument10 SeitenFinal KSK Sop Instrument CompressorSonratNoch keine Bewertungen

- Transformer Insulation Oil ReclamationDokument49 SeitenTransformer Insulation Oil Reclamationravi100% (3)

- Turbine Drains SOPDokument6 SeitenTurbine Drains SOPSonratNoch keine Bewertungen

- Sop For Vent FilterDokument6 SeitenSop For Vent FilterSonratNoch keine Bewertungen

- Boiler Protection Gyanendra Sharma NPTI DelhiDokument24 SeitenBoiler Protection Gyanendra Sharma NPTI DelhiNPTINoch keine Bewertungen

- Deh System CommissioningDokument11 SeitenDeh System Commissioningdreamboy87Noch keine Bewertungen

- Generator ProtectionDokument24 SeitenGenerator ProtectionSantoshkumar Gupta100% (1)

- Sop For Ash Slurry Pump (r1)Dokument6 SeitenSop For Ash Slurry Pump (r1)SonratNoch keine Bewertungen

- SMP For Supply Water PumpDokument13 SeitenSMP For Supply Water PumpSonratNoch keine Bewertungen

- Condensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDokument8 SeitenCondensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan SundararajNoch keine Bewertungen

- Turbine Protection & InterlockDokument7 SeitenTurbine Protection & InterlockSony RamaNoch keine Bewertungen

- Chapter 14 Governing SystemDokument7 SeitenChapter 14 Governing Systemsambhu100% (1)

- Pulkit PPT Steam Turbine3Dokument42 SeitenPulkit PPT Steam Turbine3Abhishek KumarNoch keine Bewertungen

- Boiler Ga, Specification & Line Up For Light Up: by Rahul R MungaleDokument11 SeitenBoiler Ga, Specification & Line Up For Light Up: by Rahul R MungaleMukesh Kumar VaishnavNoch keine Bewertungen

- Flood Test of CondenserDokument6 SeitenFlood Test of CondensersambhuNoch keine Bewertungen

- One PA Fan TrippingDokument3 SeitenOne PA Fan TrippingSubrahmanyam100% (1)

- Turbine Drains SOPDokument6 SeitenTurbine Drains SOPSonratNoch keine Bewertungen

- U4OHREPORT2008Dokument88 SeitenU4OHREPORT2008Anonymous pKsr5vNoch keine Bewertungen

- FD ID Logic System Gyanendra Sharma NPTI DelhiDokument40 SeitenFD ID Logic System Gyanendra Sharma NPTI DelhiNPTINoch keine Bewertungen

- U 3 Turbine Trip ReportDokument1 SeiteU 3 Turbine Trip ReportKarthi KeyanNoch keine Bewertungen

- Write Up On EHC - REV-01Dokument11 SeitenWrite Up On EHC - REV-01jp mishra100% (2)

- Knowledge Management Series-Low Vacuum in Steam Turbine PDFDokument4 SeitenKnowledge Management Series-Low Vacuum in Steam Turbine PDFMadhusudhan Pasumarty100% (1)

- Turbine Prestartup ChecklistDokument4 SeitenTurbine Prestartup ChecklistSCE SOLAPURNoch keine Bewertungen

- Gen-Seal&cool-New - 500 MWDokument98 SeitenGen-Seal&cool-New - 500 MWharisankar100% (2)

- Control Write Up HCSDDokument10 SeitenControl Write Up HCSDSonratNoch keine Bewertungen

- Power Plant Operation Turbine & Auxiliaries: 18 February 2013 PMI Revision 00 1Dokument43 SeitenPower Plant Operation Turbine & Auxiliaries: 18 February 2013 PMI Revision 00 1Alok Ranjan Tripathi100% (1)

- Cold Start Up Check ListDokument6 SeitenCold Start Up Check ListSreekanthMylavarapuNoch keine Bewertungen

- Korba - BAH Online Temp MonitoringDokument7 SeitenKorba - BAH Online Temp Monitoringrama jenaNoch keine Bewertungen

- CHM1 Structure & Bonding QDokument115 SeitenCHM1 Structure & Bonding QGoutham SivagnanamNoch keine Bewertungen

- Sop For Eco-Hp Pump (r1)Dokument6 SeitenSop For Eco-Hp Pump (r1)SonratNoch keine Bewertungen

- Generator Turbine Shutdown ProcedureDokument3 SeitenGenerator Turbine Shutdown ProcedureAfifexNoch keine Bewertungen

- APHDokument3 SeitenAPHMallinatha PNNoch keine Bewertungen

- NTPC Vindhyachal ReportDokument13 SeitenNTPC Vindhyachal Reportblackswan_07Noch keine Bewertungen

- BCP Installation & CommissioningDokument18 SeitenBCP Installation & CommissioningKrishnan SanthanarajNoch keine Bewertungen

- B. Prestart Checks of Boiler LightupDokument14 SeitenB. Prestart Checks of Boiler LightupPrudhvi RajNoch keine Bewertungen

- Seal Air FanDokument1 SeiteSeal Air FanAnkit MathurNoch keine Bewertungen

- Scanner Air FanDokument3 SeitenScanner Air FanSamNoch keine Bewertungen

- Lalitpur Superthermal Power Project - 3 X 660 MWDokument10 SeitenLalitpur Superthermal Power Project - 3 X 660 MWpramod_nandaNoch keine Bewertungen

- Nkeksnj ?KKVH Fuxe Cksdkjks Rki Fo - QR Dsunz: / Damodar Valley Corporation / Bokaro Thermal Power StationDokument7 SeitenNkeksnj ?KKVH Fuxe Cksdkjks Rki Fo - QR Dsunz: / Damodar Valley Corporation / Bokaro Thermal Power StationAbhishek KumarNoch keine Bewertungen

- SOP HP HeatersDokument1 SeiteSOP HP HeatersShailenderNoch keine Bewertungen

- Soot BlowerDokument6 SeitenSoot BlowerSamNoch keine Bewertungen

- Schematic Diagram of Sealing & Cooling Water For CepDokument12 SeitenSchematic Diagram of Sealing & Cooling Water For Cepjp mishraNoch keine Bewertungen

- CEP Isolation & Normalisation ProcedureDokument2 SeitenCEP Isolation & Normalisation ProcedureVishal GuptaNoch keine Bewertungen

- Dec 09Dokument35 SeitenDec 09Krishnan SanthanarajNoch keine Bewertungen

- Bhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC BoilersDokument41 SeitenBhel - Trichy: Training Programme FOR Power Sector Executives ON CFBC Boilersrashm006ranjanNoch keine Bewertungen

- Protection & InterlocksDokument18 SeitenProtection & InterlocksSanjay GuptaNoch keine Bewertungen

- Bah ElevationDokument1 SeiteBah ElevationSonratNoch keine Bewertungen

- Part List - BEL0800 PDFDokument1 SeitePart List - BEL0800 PDFSonratNoch keine Bewertungen

- Bah Side ViewDokument1 SeiteBah Side ViewSonratNoch keine Bewertungen

- HCSD PDFDokument1 SeiteHCSD PDFSonratNoch keine Bewertungen

- Pdi EspDokument1 SeitePdi EspSonratNoch keine Bewertungen

- SMP For Dry Ash UnloaderDokument8 SeitenSMP For Dry Ash UnloaderSonratNoch keine Bewertungen

- ECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFDokument1 SeiteECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFSonratNoch keine Bewertungen

- BAH JET PUMP DISCHAGE PIPE LINE-Model PDFDokument1 SeiteBAH JET PUMP DISCHAGE PIPE LINE-Model PDFSonratNoch keine Bewertungen

- ASH WATER PUMP HOUSE-Model PDFDokument1 SeiteASH WATER PUMP HOUSE-Model PDFSonratNoch keine Bewertungen

- PM For Fly Ash Dry SystemDokument31 SeitenPM For Fly Ash Dry SystemSonratNoch keine Bewertungen

- Over Flow Pump Concentrator Buffer Tank ModelDokument1 SeiteOver Flow Pump Concentrator Buffer Tank ModelSonratNoch keine Bewertungen

- Water & Slurry BalanceDokument1 SeiteWater & Slurry BalanceSonratNoch keine Bewertungen

- Compressor House ModelDokument1 SeiteCompressor House ModelSonratNoch keine Bewertungen

- StructureDokument1 SeiteStructureSonratNoch keine Bewertungen

- Silo Unloading ModelDokument1 SeiteSilo Unloading ModelSonratNoch keine Bewertungen

- ESP-FLD. BLOWER-Model PDFDokument1 SeiteESP-FLD. BLOWER-Model PDFSonratNoch keine Bewertungen

- Buffer Hopper & Air Lock Tank-ModelDokument1 SeiteBuffer Hopper & Air Lock Tank-ModelSonratNoch keine Bewertungen

- Silo Blower Compressor ModelDokument1 SeiteSilo Blower Compressor ModelSonratNoch keine Bewertungen

- VP To Buffr Hopper-ModelDokument1 SeiteVP To Buffr Hopper-ModelSonratNoch keine Bewertungen

- DELTA-FC 1022 Tds - EngDokument2 SeitenDELTA-FC 1022 Tds - EngAhmed HassanNoch keine Bewertungen

- CIO Vol.5 No.1-2 FinalDokument115 SeitenCIO Vol.5 No.1-2 FinalTrond ForeldrahNoch keine Bewertungen

- Who We Are: Case Study-Mahindra ChlorisDokument25 SeitenWho We Are: Case Study-Mahindra ChlorisSUNIDHI VERMANoch keine Bewertungen

- Ohm's Law and Circuits: 2. Conductance, Insulators and ResistanceDokument29 SeitenOhm's Law and Circuits: 2. Conductance, Insulators and ResistanceDita PramidaNoch keine Bewertungen

- Chemical Bonding Basic (Micro)Dokument37 SeitenChemical Bonding Basic (Micro)Anant JainNoch keine Bewertungen

- Multiparticulate Delayed Release Drug Delivery SystemDokument24 SeitenMultiparticulate Delayed Release Drug Delivery SystemAarti koramNoch keine Bewertungen

- (2017) Toxicological Effects of Glycyrrhiza Glabra (Licorice) A ReviewDokument16 Seiten(2017) Toxicological Effects of Glycyrrhiza Glabra (Licorice) A ReviewicaNoch keine Bewertungen

- DS335 - E - Earthing ImprovementDokument2 SeitenDS335 - E - Earthing ImprovementCarlos PintoNoch keine Bewertungen

- EagleBurgmann MG1 enDokument4 SeitenEagleBurgmann MG1 ensanjeevvangeNoch keine Bewertungen

- ICSE Chemistry Board Paper19 PDFDokument9 SeitenICSE Chemistry Board Paper19 PDFPrajakta DigheNoch keine Bewertungen

- Chromatography NotesDokument25 SeitenChromatography NotesGeetha AnjaliNoch keine Bewertungen

- A Rapid Accurate Method For The Analysis of An Iron OreDokument5 SeitenA Rapid Accurate Method For The Analysis of An Iron Oreilham_metallurgy6744Noch keine Bewertungen

- Four Factors Affecting The Rate of Chemical ReactionDokument5 SeitenFour Factors Affecting The Rate of Chemical ReactionFeliciano Tristan E.Noch keine Bewertungen

- Biological ManagementDokument27 SeitenBiological ManagementpatrickkayeNoch keine Bewertungen

- CRC 2-26Dokument2 SeitenCRC 2-26saranNoch keine Bewertungen

- Raw Materials-IronDokument22 SeitenRaw Materials-IronAilson Silva AlvesNoch keine Bewertungen

- Cell Wall: Presented by M. Vijaya LakshmiDokument9 SeitenCell Wall: Presented by M. Vijaya LakshmiATCHUNALA SAINoch keine Bewertungen

- A Brief Introduction To Pressure Vessels: (Clarification Needed)Dokument3 SeitenA Brief Introduction To Pressure Vessels: (Clarification Needed)daniNoch keine Bewertungen

- Agricultural Control Chemicals (1950)Dokument277 SeitenAgricultural Control Chemicals (1950)Sveti JeronimNoch keine Bewertungen

- The Motion of ColorDokument6 SeitenThe Motion of Colorapi-374832521Noch keine Bewertungen

- Cambridge International Examinations Cambridge International Advanced Subsidiary and Advanced LevelDokument20 SeitenCambridge International Examinations Cambridge International Advanced Subsidiary and Advanced LevelharshanauocNoch keine Bewertungen

- Publication PDFDokument80 SeitenPublication PDFakshatjain3001Noch keine Bewertungen

- Activated Sludge Combined With Powdered Activated Carbon (PACT Process) For The Petroleum Industry Wastewater Treatment: A ReviewDokument10 SeitenActivated Sludge Combined With Powdered Activated Carbon (PACT Process) For The Petroleum Industry Wastewater Treatment: A ReviewAmmr MahmoodNoch keine Bewertungen