Beruflich Dokumente

Kultur Dokumente

9101 Conventional Combination Heat Photoelectric Smoke Detector Issue

Hochgeladen von

nagulanmurugan_38134Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

9101 Conventional Combination Heat Photoelectric Smoke Detector Issue

Hochgeladen von

nagulanmurugan_38134Copyright:

Verfügbare Formate

C-9101 Conventional Combination

Heat/Photoelectric Smoke Detector

Features

Drift compensation to suit environment changing

extensively.

Integrated algorithm for analyzing fire, improving

the sensitivity highly.

Self-diagnostic.

Removable innovative sensing chamber, easy for

maintenance.

0832-CPD-2156

Reporting dirt fault for contaminated chamber.

Remote indicator output available.

3 levels sensitivities programmable; Level 1

complies with EN 54-7. Fix temperature or rate of

rise programmable, rate of rise mode complies

548q/01

with EN 54-5.

Description

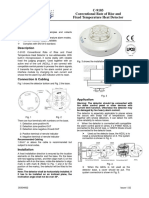

C-9101 Conventional Combination Heat/Photoelectric Fig. 3 shows mounting of the detector.

Conduit

Smoke Detector is consisted of smoke sensing and

semi-conductor temperature sensing parts in

processing and circuitry. Matching with P-9907 Active Back Box

End of Line Unit (AEOL), it can be connected with

conventional fire alarm control panel or intelligent fire Base

alarm control panels through I-9319 Addressable Zone

Detector

Monitor Unit to execute signal processing. This

non-addressable detector has the advantages of both

conventional photoelectric detector and rate of rise

and fixed temperature heat detector. Just because of

the combination technology of smoke detector and

heat detector, it overcomes the non-sensitivity to dark Fig. 3

smoke particles of ordinary scattering type

photoelectric detectors. It can also pick up fire with Applications

obvious rise of temperature such as alcohol fire, thus Warning: The alarm current depends on the

extending the application range.

current limit of the control panel. 24VDC cannot

Connection and Cabling power the detector directly. Otherwise the detector

will be blown up for lack of current limit resistor.

Fig.1 shows the detector bottom and Fig. 2 the base.

Level 1 is defaulted, which can be modified by

45mm~75mm

03

P-9910B programmer. Please refer to P-9910B Hand

100mm m

m Held Programmer Installation and Operation Manual

for details.

In power-on state of the programmer, input unlocking

5mm

25mm password and press Clear to unlock. Press Function,

then press “3”, the screen shows “-” at the last digit.

Mounting DZ-03 Input corresponding sensitivity or parameter and press

Hole Program, the screen will show a “P”, the

C corresponding sensitivity or parameter is programmed.

Press Clear to clear the "P". Input locking password

Fig. 1 Fig. 2

and press Clear to return.

There are four terminals with numbers on the base.

1: Detection zone positive IN Parameters set using programmer

2: Detection zone positive OUT Input Number Smoke Heat Sensitive

3: Detection zone negative IN and OUT Sensitivity

2: Positive terminal of remote indicator 1 Level 1 Rate of rise

4: Negative terminal of remote indicator 2 Level 2 Rate of rise

Recommended Cabling 3 Level 3 Rate of rise

1.0mm2 or above fire cable for all the wires, laid out 11 Level 1 Fixed temperature

through metal conduit or flame retardant conduit, 12 Level 2 Fixed temperature

subject to local codes.

13 Level 3 Fixed temperature

Installation

Rate of rise and level 1 is defaulted.

A fixed installation direction is ensured by the location 1. When the detector is connected with conventional

elements on the detector and the base. Fix the base fire alarm control panel (those within the dotted line

with two tapping screws, and then align mark C on the are equivalent to a conventional fire alarm control

detector with A on the base, rotate the detector to align panel) or I-9319 addressable zone monitor unit in

mark C with mark B (Refer to Fig. 1 and 2 for the series, if a P-9907 AEOL is connected to the end of

position of the marks), the detector will be fitted to the output loop, an 1N5819 Diode should be connected to

base. the detector base.

30309172 Issue 1.06

1) Used as the detector base, the AEOL is to install a After cleaning, install the detector again, and test after

conventional detector on it. The system re-installing. Notify the proper authorities when the system

connection is shown in Fig. 4. is back in service.

Diode Diode

Fire simulation test should be made to the detector once

Addressable Zone Monitor Unit

half a year.

Fire Alarm Control Panel

Output+

+ - + - Specification

I-9319

Output-

Operating Voltage 24VDC (16VDC~28VDC)

Standby Current ≤100μA

Remote Indicator

Remote Indicator

Conventional Detector Conventional Detector Conventional MCP P-9907 AEOL

Alarm Current 10mA≤I≤40mA

Maximum Ripple Voltage 2V (peak-to-peak value)

Fig. 4 Red: flashes in normal and

2) When the AEOL is not used as the detector base, illuminates in alarm.

a cover should be added, the system connection The LED is quiet in fault. And it

is shown in Fig. 5. Indicator lights and then turns out about

every three seconds

Diode Diode

periodically when reported

Addressable Zone Monitor Unit

dirty.

Fire Alarm Control Panel

Output+

+ - + -

Remote Indicator Output Directly connecting with

indicator (built-in 5.1kΩ

I-9319

Output-

resistor, maximum output

Remote Indicator Remote Indicator

current is 5.0mA). Quiet in

Conventional Detector Conventional Detector Conventional MCP P-9907 AEOL normal condition. Flashes in

alarm.

Fig. 5 Instantaneous Power-off (10s

Alarm Clear MAX., 1.5VDC MAX.)

2. When the detector is connected with conventional

fire alarm control panel (those within the dotted line Power-up Time ≤10s

are equivalent to a conventional fire alarm control

panel) or I-9319 Addressable zone monitor unit in Action Temperature 62℃

series, if an end of line resistor is connected to the end Class A2R

of output loop, then no diode is connected to the Polarized 2-core for detection

detector base. The system connection is shown in Wiring zone cable.

Fig. 6. Polarized 2-core for remote

indicator.

Addressable Zone Monitor Unit

Ingress Protection Rating IP22

Fire Alarm Control Panel

4.7kΩ Resistor

Output+

+ - + - Environment -10℃~+50℃

Temperature

I-9319

Output-

Relative Humidity ≤95%, non condensing

Material of Enclosure ABS

Remote Indicator Remote Indicator

Conventional MCP Conventional Detector Conventional Detector

Dimensions Diameter: 100mm

Height: 56mm (with base)

Fig. 6 Mounting Hole Distance 45mm~75mm

Maximum 15 detectors can be connected in one zone.

Cooperating with end of line device, the compatible Weight 126g

panel can monitor the cable for open circuit and short

circuit. Panel will report if any detector is removed.

Accessories and Tools

With the AEOL, the functioning of other device will not Model Name Remark

be affected by the detector removal. P-9907 Active End of Line Unit Order separately

P-9910B Hand Held Programmer Order separately

Maintenance DZ-03 Base Order separately

The detector should be installed just before DZ-03D Base Order separately

commissioning and kept well before installation,

taken corresponding measures for dust-proof, WEEE Information

damp-proof and corrosion-proof.

The dust cover cannot be removed until the 2012/19/EU (WEEE directive): Products marked with

project has been plunged into usage, otherwise it this symbol cannot be disposed of as unsorted

cannot alarm normally. municipal waste in the European Union. For proper

The detector should be cleaned at least once a recycling, return this product to your local supplier

year to ensure normal operation of the system. upon the purchase of equivalent new equipment, or

If nuisance alarms are often found of the detector dispose of it at designated collection points.

on site, the sensing chamber should be cleaned Limited Warranty

and replaced when necessary.

Before cleaning, notify the proper authorities that GST warrants that the product will be free of charge for repairing

the system is undergoing maintenance and will or removing from defects in design, materials and workmanship

temporarily be out of service. Disable the zone or during the warranty period. This warranty doesn’t cover any

system undergoing maintenance to avoid product that is found to have been improperly installed or used

unwanted alarms. in any way not in accordance with the instructions supplied with

the product. Anybody, including the agents, distributors or

employees, is not in the position to amend the contents of this

warranty. Please contact your local distributor for products not

covered by this warranty.

This Data Sheet is subject to change without notice. Please contact GST for more information or questions.

Gulf Security Technology Co., Ltd.

No. 80, Changjiang East Road, QETDZ, Qinhuangdao, Hebei, P. R. China 066004

Tel: +86 (0) 335 8502434 Fax: +86 (0) 335 8502532 service.gst@fs.utc.com www.gst.com.cn

30309172 Issue 1.06

Das könnte Ihnen auch gefallen

- Subordination, Non - Disturbance and Attornment AgreementDokument7 SeitenSubordination, Non - Disturbance and Attornment AgreementDavid CromwellNoch keine Bewertungen

- Augusta Issue 1145 - The Jail ReportDokument24 SeitenAugusta Issue 1145 - The Jail ReportGreg RickabaughNoch keine Bewertungen

- Activities For Learner-Centered TeachingDokument56 SeitenActivities For Learner-Centered TeachingAmiga Mi100% (1)

- Pipe Support Reference 8-29-14Dokument108 SeitenPipe Support Reference 8-29-14HITESHNoch keine Bewertungen

- Pit Viper 351Dokument6 SeitenPit Viper 351Sebastian Robles100% (2)

- Sd119 ManualDokument2 SeitenSd119 ManualVictor PatsiNoch keine Bewertungen

- Sinotimer Mc401 - 611 User ManualDokument4 SeitenSinotimer Mc401 - 611 User ManualIanes Florentiu0% (1)

- Smartpilot s1 s1g Service ManualDokument30 SeitenSmartpilot s1 s1g Service Manualmalte winbaldNoch keine Bewertungen

- Aw-Cmc2166-6 Estacion Manual AsenwareDokument1 SeiteAw-Cmc2166-6 Estacion Manual AsenwareMartin Llontop100% (1)

- TODO Data Sheet PDFDokument70 SeitenTODO Data Sheet PDFJake ZyrusNoch keine Bewertungen

- Mitsubishi IC Pneumatic Forklift PDFDokument5 SeitenMitsubishi IC Pneumatic Forklift PDFfdpc1987Noch keine Bewertungen

- Sense and NonsenseDokument263 SeitenSense and NonsenseAbdulRehmanKhilji100% (1)

- C-9101 Conventional Combination Heat/Photoelectric Smoke DetectorDokument2 SeitenC-9101 Conventional Combination Heat/Photoelectric Smoke DetectorHiteshgangeleNoch keine Bewertungen

- DI-9103E Intelligent Rate of Rise and Fixed Temperature Heat Detector Issue1.05Dokument2 SeitenDI-9103E Intelligent Rate of Rise and Fixed Temperature Heat Detector Issue1.05duongNoch keine Bewertungen

- DI-9101E Intelligent Combination Heat Photoelectric Smoke DetectorDokument2 SeitenDI-9101E Intelligent Combination Heat Photoelectric Smoke DetectorHiteshgangeleNoch keine Bewertungen

- Features: C-9103 Conventional Rate of Rise and Fixed Temperature Heat DetectorDokument2 SeitenFeatures: C-9103 Conventional Rate of Rise and Fixed Temperature Heat Detectorfirex spNoch keine Bewertungen

- I-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01Dokument2 SeitenI-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01HiteshgangeleNoch keine Bewertungen

- DI-9102E Intelligent Photoelectric Smoke Detector Installation and Operation Manual Issue1.06Dokument2 SeitenDI-9102E Intelligent Photoelectric Smoke Detector Installation and Operation Manual Issue1.06Communications ShipyardNoch keine Bewertungen

- C-9102 Conventional Photoelectric Smoke Detector: FeaturesDokument2 SeitenC-9102 Conventional Photoelectric Smoke Detector: Featuresfirex spNoch keine Bewertungen

- DI-9102E Intelligent Photoelectric Smoke Detector Issue1.05Dokument2 SeitenDI-9102E Intelligent Photoelectric Smoke Detector Issue1.05duongNoch keine Bewertungen

- Conventional Photoelectric Smoke Detector D-C401Dokument2 SeitenConventional Photoelectric Smoke Detector D-C401Altayyeb AlfaryjatNoch keine Bewertungen

- Conventional Intelligent HeatSmoke Detector D C400 PDFDokument2 SeitenConventional Intelligent HeatSmoke Detector D C400 PDFMeisam NabiNoch keine Bewertungen

- I-9102 Intelligent Photoelectric Smoke Detector Issue1.03Dokument2 SeitenI-9102 Intelligent Photoelectric Smoke Detector Issue1.03Seagull MarineNoch keine Bewertungen

- OXY3690MPDokument6 SeitenOXY3690MPrinthusNoch keine Bewertungen

- Installation Wiring Diagram: DetectorDokument2 SeitenInstallation Wiring Diagram: Detectorparallax1957Noch keine Bewertungen

- Fuente Fcps 24s6eDokument12 SeitenFuente Fcps 24s6eGuido RuizNoch keine Bewertungen

- Globalfire - AD Series Manual PDFDokument2 SeitenGlobalfire - AD Series Manual PDFAdrian Oprisan100% (1)

- 7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsDokument2 Seiten7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsAakash JunejaNoch keine Bewertungen

- VAR TEC FDR Series User ManualDokument2 SeitenVAR TEC FDR Series User ManualmicrajacutNoch keine Bewertungen

- Hd912 ManualDokument2 SeitenHd912 ManualrhomadonaNoch keine Bewertungen

- 3102465-EN R003 KI-PD Intelligent Photoelectric Smoke Detector Installation SheetDokument2 Seiten3102465-EN R003 KI-PD Intelligent Photoelectric Smoke Detector Installation SheetAlejandro coronelNoch keine Bewertungen

- EDC-M9102 Detector Manual F3.780.1099ASY Issue1.01Dokument2 SeitenEDC-M9102 Detector Manual F3.780.1099ASY Issue1.01EDWIN100% (1)

- PP 2070 XP Multi PinDokument2 SeitenPP 2070 XP Multi PinManuel RiNoch keine Bewertungen

- ApolloFire XP95 MultisensorDokument2 SeitenApolloFire XP95 MultisensorfasiwiNoch keine Bewertungen

- FSP951 I56-6519Dokument2 SeitenFSP951 I56-6519Marcelo Fabián OrtizNoch keine Bewertungen

- NOTIFIER Addressable Multi-Criteria SMART3 Detector SpecificationDokument2 SeitenNOTIFIER Addressable Multi-Criteria SMART3 Detector Specificationnambi.kumresan1Noch keine Bewertungen

- C-9105 Conventional Linear Beam Smoke Detector Installation and Operation ManualDokument14 SeitenC-9105 Conventional Linear Beam Smoke Detector Installation and Operation ManualkatulaNoch keine Bewertungen

- Pac ExDokument8 SeitenPac Exs.kurpishNoch keine Bewertungen

- Intelligent Photoelectric Smoke SensorsDokument2 SeitenIntelligent Photoelectric Smoke Sensorsmubs73Noch keine Bewertungen

- F220 Series: EN Photoelectric Smoke/Heat DetectorsDokument16 SeitenF220 Series: EN Photoelectric Smoke/Heat DetectorsSergioCaceresNoch keine Bewertungen

- FM4000E - CI-146 Iss3 FM4000E InstallationDokument15 SeitenFM4000E - CI-146 Iss3 FM4000E InstallationHans RughoonathNoch keine Bewertungen

- H365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsDokument2 SeitenH365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsAlexamder CalleNoch keine Bewertungen

- H365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsDokument2 SeitenH365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsAngel Jorge LLopiz IbarraNoch keine Bewertungen

- Codesec Dd501 Addressable Photoelectric Smoke Detector: Security TechnologiesDokument2 SeitenCodesec Dd501 Addressable Photoelectric Smoke Detector: Security Technologiesdamarg.khanNoch keine Bewertungen

- Kir PD Kidde Manual Instalacion SH IngenieriaDokument2 SeitenKir PD Kidde Manual Instalacion SH IngenieriaLuis RamirezNoch keine Bewertungen

- NOTIFIER Addressable Multi-Criteria SMART2 Detector SpecificationDokument2 SeitenNOTIFIER Addressable Multi-Criteria SMART2 Detector Specificationnambi.kumresan1Noch keine Bewertungen

- 4098-0038 Addresable HeatDokument4 Seiten4098-0038 Addresable HeatReda Hesham SamierNoch keine Bewertungen

- MPI 2ecom GF Specification-ECE FdasDokument2 SeitenMPI 2ecom GF Specification-ECE FdasadriannodaloNoch keine Bewertungen

- DS Gcu410 NRG Eng PDFDokument16 SeitenDS Gcu410 NRG Eng PDFZeeshan HasanNoch keine Bewertungen

- DMAX DH-4326 ManualDokument2 SeitenDMAX DH-4326 ManualMarcelo MachadoNoch keine Bewertungen

- DI-9300E Digital Single Input Module Installation and Operation Manual Issue 1.05Dokument3 SeitenDI-9300E Digital Single Input Module Installation and Operation Manual Issue 1.05Đỗ Tiến HùngNoch keine Bewertungen

- NOTIFIER Addressable Photoelectric Smoke Detector SpecificationDokument2 SeitenNOTIFIER Addressable Photoelectric Smoke Detector Specificationnambi.kumresan1Noch keine Bewertungen

- Manual de Instalare Bariera IR DOP 6001 - ENGDokument14 SeitenManual de Instalare Bariera IR DOP 6001 - ENGDorin SimioanaNoch keine Bewertungen

- Mic 25/IU/TCDokument3 SeitenMic 25/IU/TCpecf VOLTESTNoch keine Bewertungen

- Ba Eng Pico+xxxtf FDokument3 SeitenBa Eng Pico+xxxtf Fpecf VOLTESTNoch keine Bewertungen

- Switzer IndicatorDokument4 SeitenSwitzer IndicatorMohamed MeeranNoch keine Bewertungen

- 4098-9714 - Detector de Humo Simplex DireccionableDokument4 Seiten4098-9714 - Detector de Humo Simplex DireccionableLuisCabreraOroscoNoch keine Bewertungen

- English User Guide - 0044-033-05 - enDokument16 SeitenEnglish User Guide - 0044-033-05 - enZemouraMohamedNoch keine Bewertungen

- Installation Manual enUS 165636133387 PDFDokument16 SeitenInstallation Manual enUS 165636133387 PDFRicardo MercadoNoch keine Bewertungen

- Truealarm: Truealarm Analog Sensors - Photoelectric, Ionization, and Heat Standard Bases and AccessoriesDokument4 SeitenTruealarm: Truealarm Analog Sensors - Photoelectric, Ionization, and Heat Standard Bases and AccessoriesmotaNoch keine Bewertungen

- Truealarm Analog Sensing: FeaturesDokument4 SeitenTruealarm Analog Sensing: FeaturesMorella Rojas LinaresNoch keine Bewertungen

- RE316 Installation ManualDokument2 SeitenRE316 Installation Manualedwin_serpas2894Noch keine Bewertungen

- RE316 Installation Manual PDFDokument2 SeitenRE316 Installation Manual PDFmadhuNoch keine Bewertungen

- Gsti 9103Dokument2 SeitenGsti 9103aditgroupNoch keine Bewertungen

- ASSIGNMENT 3 - Security Alarm SystemDokument9 SeitenASSIGNMENT 3 - Security Alarm SystemTalha Yazdani100% (1)

- Automatic Home Application Controlling SystemDokument12 SeitenAutomatic Home Application Controlling Systemlana_salahadinNoch keine Bewertungen

- A) Fire Detection Cum Alarm SystemDokument11 SeitenA) Fire Detection Cum Alarm SystemhomesxxxNoch keine Bewertungen

- CEA Safety Regulations 2010Dokument203 SeitenCEA Safety Regulations 2010nagulanmurugan_38134Noch keine Bewertungen

- Fire Alarm SystemDokument32 SeitenFire Alarm Systemnagulanmurugan_38134Noch keine Bewertungen

- Calculation of Chart:: (I Kwx1000/1.732Xline Voltagex PF) 1000/1.732X11000X0.8 KW 0.06561X1000 MW 65ADokument7 SeitenCalculation of Chart:: (I Kwx1000/1.732Xline Voltagex PF) 1000/1.732X11000X0.8 KW 0.06561X1000 MW 65Anagulanmurugan_38134Noch keine Bewertungen

- Calculation of Chart:: (I Kwx1000/1.732Xline Voltagex PF) 1000/1.732X11000X0.8 KW 0.06561X1000 MW 65ADokument7 SeitenCalculation of Chart:: (I Kwx1000/1.732Xline Voltagex PF) 1000/1.732X11000X0.8 KW 0.06561X1000 MW 65Anagulanmurugan_38134Noch keine Bewertungen

- Culture-Partners M&A EbookDokument12 SeitenCulture-Partners M&A EbookapachemonoNoch keine Bewertungen

- Bike LanesDokument12 SeitenBike LanesChitikala RajeshNoch keine Bewertungen

- Application of Geosynthetics in Pavement DesignDokument7 SeitenApplication of Geosynthetics in Pavement DesignAnonymous kw8Yrp0R5rNoch keine Bewertungen

- 310 311 320 321 Toilet Warranty Codes PDFDokument11 Seiten310 311 320 321 Toilet Warranty Codes PDFTerri MartinNoch keine Bewertungen

- EIC 3 Practice Exercises Unit 4Dokument3 SeitenEIC 3 Practice Exercises Unit 4Trần ChâuNoch keine Bewertungen

- Description Features: Maximizing IC PerformanceDokument1 SeiteDescription Features: Maximizing IC Performanceledaurora123Noch keine Bewertungen

- PapernathazDokument26 SeitenPapernathazAbelardo LapathaNoch keine Bewertungen

- Lab5.ipynb - ColaboratoryDokument8 SeitenLab5.ipynb - ColaboratoryMin YNoch keine Bewertungen

- Nurse Education Today: Natalie M. Agius, Ann WilkinsonDokument8 SeitenNurse Education Today: Natalie M. Agius, Ann WilkinsonSobiaNoch keine Bewertungen

- 2022+ACCF+111+Class+test+2 Moderated+versionDokument8 Seiten2022+ACCF+111+Class+test+2 Moderated+versionLucas LuluNoch keine Bewertungen

- Ebook Essentials of Kumar Clarks Clinical Medicine PDF Full Chapter PDFDokument67 SeitenEbook Essentials of Kumar Clarks Clinical Medicine PDF Full Chapter PDFjanet.cochran431100% (19)

- Simulado InglesDokument6 SeitenSimulado InglesWandercleyson da SilvaNoch keine Bewertungen

- A Randomised Clinical Trial Comparing Myoinositol and Metformin in PCOSDokument7 SeitenA Randomised Clinical Trial Comparing Myoinositol and Metformin in PCOSAtika NajlaNoch keine Bewertungen

- Water Determination in Gases and LPG: KF MaxDokument4 SeitenWater Determination in Gases and LPG: KF MaxMohamed MosbahNoch keine Bewertungen

- Nanoimprint Lithography: Presented by Group 7Dokument27 SeitenNanoimprint Lithography: Presented by Group 7Samia SafaNoch keine Bewertungen

- History of Communication - Project - File - 455 PDFDokument20 SeitenHistory of Communication - Project - File - 455 PDFlathaNoch keine Bewertungen

- Proplanner Assembly Planner PFEPDokument5 SeitenProplanner Assembly Planner PFEPAya MdimeghNoch keine Bewertungen

- 5EMA BB Dem&Sup VW Bu&Se - 2.35&48&PDDokument13 Seiten5EMA BB Dem&Sup VW Bu&Se - 2.35&48&PDkashinath09Noch keine Bewertungen

- Landis+Gyr Model EM5300 Class 0.5 Electricity Meter 14-2-63Dokument5 SeitenLandis+Gyr Model EM5300 Class 0.5 Electricity Meter 14-2-63kulukundunguNoch keine Bewertungen

- Particle FilterDokument16 SeitenParticle Filterlevin696Noch keine Bewertungen

- Conformational AnalysisDokument4 SeitenConformational AnalysisJinNoch keine Bewertungen