Beruflich Dokumente

Kultur Dokumente

MO-6800S Series

Hochgeladen von

DanielOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MO-6800S Series

Hochgeladen von

DanielCopyright:

Verfügbare Formate

SPECIFICATIONS

Model name MO-6804S MO-6814S MO-6816S MO-6843S

MO-6800S Series

Stitch type 1-needle overlock 2-needle overlock Safety stitching 3-needle safety stitching

Stitch style in the U.S.A. 504 514 516 −

Max. sewing speed 7,000sti/min

High-speed, Overlock / Safety Stitch Machine Stitch length 0.6 ~ 3.8 (4.5) mm

Needle gauge (mm) — 2.0 3.0, 5.0 3.0+2.0, 5.0+2.0

Overedging width (mm) 1.5, 4.0 2.0, 3.0, 4.0 4.0, 5.0, 6.0 3.0

Differential feed ratio For gathering 1:2 (Max. 1:4), For stretching 1:0.7 (Max. 1:0.6)

Needle bar stroke 24.5mm(60H:27.0mm)

Inclination angle of the needle 20°

Needle bar bushing Lower bushing method

Needle DC×27 (excluding some subclass model)

The advanced overlock / safety stitch machine is Max. lift of the presser foot

Max. presser foot pressure

7mm (excluding some subclass model)

63.7N (6.5kgf)

easier to use and promises superior cost effectiveness.

Stitch adjusting method By push-button

Differential-feed adjusting method By lever (with micro-adjustment)

Weight of the machine head 27kg

Lubrication Automatic

Lubricating oil JUKI Machine Oil 18 (equivalent to ISO VG18)

Needle cooler Provided as standard

Needle thread heat remover Provided as standard

Micro-lifter Option

"sti/min" stands for "Stitches per Minute."

WHEN YOU PLACE ORDERS

Please note when placing orders, that the model name should be written as follows:

Stitch type U.S.A Code Type Code Device and attachment Code

1-needle overlock 504 04 Standard S Tape attaching presser foot (for sewing sharp curves) / Tape guide G44/Q143

2-needle overlock 514 14 Clean finish top and bottom N075

2-needle safety stitch 516 16

3-needle safety stitch 43

2-needle double chain stitch 45

MO68 S /

Needle Overedging Material Application Special machine Code

gauge width Feed Code

dog Extra light- to

(mm) (mm)

light-weight Light-weight materials Rolled hemming Standard 150

— 1.5 2-row 0A4 Specific to knits Tape attaching Standard 24H

— 4.0 2-row 0E4 Standard Standard 30H

2.0 2.0 3-row BB6 Light- to

medium-weight Standard Anti-marerial-slip 30P

For general fabrics

2.0 3.0 3-row BD6 Tape attaching Standard 34H

2.0 4.0 3-row BE6 Rolling-in tape Standard 360

3.0 4.0 2-row DE4 Specific to knits Standard Standard 40H

3.0 4.0 3-row DE6 Medium- to such as sweaters Tape attaching Standard 44H

5.0 5.0 3-row FF6 heavy-weight Medium- to heavy-weight Standard Standard 50H

5.0 6.0 3-row FH6 materials such as denim

5.0+2.0 3.0 3-row 1D6

heavy-weight heavy-weight Standard Standard 60H

3.0+2.0 3.0 3-row 2D6

MO-6816S

JUKI ECO PRODUCTS The MO-6800S is an eco-friendly product which complies with JUKI ECO PRODUCTS standards for protecting the environment.

MO-6800S

The sewing machine complies with the "Juki Group Green Procurement Guidelines" on the use of hazardous substances,

which is stricter than other restrictions, such as those of the RoHS Directive.

For details of JUKI ECO PRODUCTS, refer to: http://www.juki.co.jp/eco_e/index.html

The RoHS Directive is an EU Directive limiting the use of 6 hazardous substances (lead, hexavalent chromium, mercury, cadmium, PBB and PBDE) in electrical and electronic equipment.

The Juki Green Procurement Guideline is the voluntarily established criteria to eliminate not only the aforementioned six substances, but also other ones which also adversely affect the environment.

Registered Organization : Head Office

The Scope of the Registration : The activities of research,

development, design, sales, distribution, and maintenance

services of industrial sewing machines, household sewing

machines and industrial robots, etc., including sales and

maintenance services of data entry systems.

2-11-1, TSURUMAKI, TAMA-SHI,

TOKYO 206-8551, JAPAN

PHONE : (81) 42-357-2370

FAX : (81) 42-357-2274

High-speed, Overlock / Safety Stitch Machine

SERIES

SEWING MACHINERY & SYSTEMS BUSINESS UNIT http://www.juki.com

Specifications and appearance are subject to change without prior notice for improvement.

Read the instruction manual before putting the machine into service to ensure safety.

This catalogue prints with environment-friendly soyink on recycle paper.

Paper from responsible sources FSC™ C001712 FEBRUARY, 2019 Printed in Japan(TN)

MO-6800S

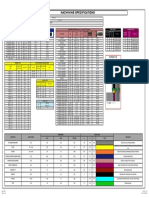

SUBCLASS MACHINE LIST

SERIES Seams Model No. Materials Number Number

of of

(mm)

Needle

gauge

(mm)

Overedging Number Stitch

width

Bottom

(mm)

Presser

of feed length differentialfeed lifting

Needle

system

(sti/min)

Max

sewing

Remarks

This advanced overlock / safety stitch machine is

needles threads dog rows ratio amount speed

easier to use and promises superior cost effectiveness. [ 1-needle overlock ]

For runstitching in general fabric

The MO-6800S Series responds to various kinds of sewing materials and processes,

producing delicate and beautiful soft-to-the-touch seams while further reducing MO-6804S-0E4-30H L~M 1 3 — 4.0 2 3.8 1:0.7~1:2 6.0 DC×27 7,000

#11

operating noise as well as increasing durability. This advanced overlock / safety stitch

machine is easier to use and promises superior cost-effectiveness. For rolled hemming (folded downward)

MO-6804S-0A4-150 EL~L 1 3 — 1.5 2 3.8 1:0.7~1:2 6.0 DC×1 7,000

The machine achieves beautifully finished seams of #8

improved quality even when run at a high speed.

The machine is widely applicable to the sewing of light- to heavy-weight

[ 2-needle overlock ]

For runstitching in general fabric

materials. Since the machine is provided with a needle thread take-up

mechanism and a looper thread take-up lever, it ensures high-quality, 3.0+2.0, 5.0+2.0 DC×27 7,000

MO-6814S-BD6-30H L~M 2 4 2.0 3.0 3 3.8 1:0.7~1:2 5.5 #11

3.0

well-tensed and soft seams with a beautiful texture which flexibly

correspond to the elasticity of the materials even when run at speeds MO-6814S-BE6-40H M~H 2 4 2.0 4.0 3 3.8 1:0.7~1:2 5.5 DC×27 6,500

#11

as high as 7,000 sti/min. In addition, the machine has a wider and MO-6814S

brighter needle entry and provides improved responsiveness to the MO-6814S-BB6-30P 2 4 2.0 2.0 3 3.8 1:0.7~1:2 5.0 DC×27 7,000

#11

materials, thereby helping the operator use the machine more easily. L~M Anti-material-slip

The optimally-balanced design of the machine reduces both operating MO-6814S-BE6-30P 2 4 2.0 4.0 3 3.8 1:0.7~1:2 5.0 DC×27 7,000

#11

noise and vibration, contributing to more comfortable sewing work.

The machine is provided with functions

which contribute to easier operation. For tape attaching G44: Tape attaching presser foot Q143: Tape guide

The differential-feed micro-adjustment MO-6814S-BD6-24H/ DC×27 7,000

2 4 2.0 3.0 3 3.8 1:0.7~1:2 5.5 #9

mechanism, external increasing of the G44/Q143

differential feed ratio and the main feed MO-6814S-BE6-24H/

2 4 2.0 4.0 3 3.8 1:0.7~1:2 5.5 DC×27 7,000

dog height can all be adjustable on the G44/Q143 #9

front face of the sewing machine with a L~M

MO-6814S-BD6-34H/ DC×27 7,000

screwdriver. The machine is provided 2 4 2.0 3.0 3 3.8 1:0.7~1:2 5.5 #11

G44/Q143

as standard with functions which enable

MO-6814S-BE6-34H/ DC×27 7,000

easy and best-suited adjustments 2 4 2.0 4.0 3 3.8 1:0.7~1:2 5.5 #11

G44/Q143

according to the material to be used.

MO-6814S-BE6-44H/ DC×27 6,500

For runstitch / MO-6816S-FF6-30H Differential-feed micro-adjustment mechanism M~H 2 4 2.0 4.0 3 3.8 1:0.7~1:2 7.0 #14

G44/Q143

[ Safety stitching ]

For runstitching in general fabric

DEVICES AND ATTACHMENTS MO-6816S-DE6-30H 2 5 3.0 4.0 3 3.8 1:0.7~1:2 5.5 DC×27 7,000

#11

L~M

Model Part No. Description MO-6816S-FF6-30H 2 5 5.0 5.0 3 3.8 1:0.7~1:2 5.5 DC×27 7,000

#11

Chain-off thread trimming device [Reference]

Combination table of “chain-off thread suction device” MO-6816S-FF6-50H 2 5 5.0 5.0 3 3.8 1:0.7~1:2 7.0 DC×27 6,500

T053 70000081 Pneumatic flat cutter and “auto-lifer” which correspond to “chain-off thread #16

trimming device”. M~H

T054 70000082 Pneumatic side cutter (for overlock machine) Chain-off MO-6816S-FH6-50H 2 5 5.0 6.0 3 3.8 1:0.7~1:2 7.0 DC×27 6,500

thread Chain-off thread #16

trimming suction device Auto-lifter

Pneumatic chain-off thread suction device device

MO-6816S-FF6-60H 2 5 5.0 5.0 3 4.5 1:0.9~1:1.7 7.0 DC×27 6,000

Model Part No.

Pneumatic chain-off thread +

Air type auto-lifter Clutch motor Servo motor

#21

cloth chips clutch motor MC906 Clutch motor H

MO-6816S-FH6-60H 2 5 5.0 6.0 3 4.5 1:0.9~1:1.7 7.0 DC×27 6,000

MC906 70000085 ● ●

T053 MC909 servo motor #21

or

MC909 70000104 ● ●

T054 MC910

Air type auto-lifter DC×27 7,000 Anti-material-slip

clutch motor MO-6816S-DE4-30P L~M 2 5 3.0 4.0 2 3.8 1:0.7~1:2 5.0 #11

MC910 70000106 ● ● ●

MC911

Air type auto-lifter

servo motor

MC911 70000107 ● ● ●

For rolling-in tape N075: Clean finish top and bottom

MO-6845S-FF6-360/ DC×27 7,000 2-needle type for

M~H 2 4 5.0 5.0 3 3.8 1:0.7~1:2 5.0 #14 double-chainstitch

Model Part No. Description Feature N075 on pocket bags

Gathering device

S206 70000089

Swing-type gathering device [ 3-needle safety stitching ]

(interlocked with pedal / for overlock machine)(with BE6 gauge)

Swing-type gathering device The attachment opens with the presser foot pedal. This MO-6843S-1D6-40H 3 6 5.0+2.0 3.0 3 3.8 1:0.7~1:2 6.5 DC×27 7,000

S207 70000090 (interlocked with pedal / for safety stitch machine)(with DF6 gauge) #11

facilitates material setting on the machine.

Swing-type gathering device M~H

S208 70000091 (interlocked with pedal / for safety stitch machine)(with FF6 gauge) DC×27 7,000

MO-6843S-2D6-40H 3 6 3.0+2.0 3.0 3 3.8 1:0.7~1:2 6.5 #11

Guide, tape guide "sti/min" stands for "Stitches per Minute."

H253 40159861 Cloth edge guide ruler (for overlock machine) Sewn product pictogram

A swing type edge guide.

H254 40159862 Cloth edge guide ruler (for safety stitch machine)

This attachment is used attached on the machine head

Q143 40159863 Tape guide (face plate). It is used for tapes with the width of 7mm UNDER DRESS POLO SPORTS KNIT KNIT

or less. SHIRTS T-SHIRTS TROUSERS ONE-PIECE SKIRT SHIRTS BLOUSE SHIRTS JUMPER WEAR PAJAMA SHIRTS WEAR SUIT COAT JEANS HANDKERCHIEF SCARF

Das könnte Ihnen auch gefallen

- Successful Serging: From Setup to Simple and Specialty StitchesVon EverandSuccessful Serging: From Setup to Simple and Specialty StitchesBewertung: 3 von 5 Sternen3/5 (1)

- MO-6800D Series: JUKI's Dry-Head Technology Protects The Sewing Products From Oil StainsDokument2 SeitenMO-6800D Series: JUKI's Dry-Head Technology Protects The Sewing Products From Oil StainsShafikul IslamNoch keine Bewertungen

- Complete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterVon EverandComplete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterBewertung: 4 von 5 Sternen4/5 (3)

- MO-6900S SeriesDokument8 SeitenMO-6900S Seriesvijay maharNoch keine Bewertungen

- Juki Series C Mo6900cDokument2 SeitenJuki Series C Mo6900cKabir MahlotraNoch keine Bewertungen

- FLATBED Sewing Machine JUKI-lu2800v7 (For Non Apparel)Dokument4 SeitenFLATBED Sewing Machine JUKI-lu2800v7 (For Non Apparel)Sayantan RahaNoch keine Bewertungen

- Apw 895 NeDokument2 SeitenApw 895 NeCarlos Paul TorresNoch keine Bewertungen

- Mo 6700 DaDokument2 SeitenMo 6700 DafatagiuNoch keine Bewertungen

- ASK ASM200-20230614pdfDokument2 SeitenASK ASM200-20230614pdfdroessaert_stijnNoch keine Bewertungen

- Globe & Angle Irrigation Valves - NetafimDokument4 SeitenGlobe & Angle Irrigation Valves - NetafimraxiblairNoch keine Bewertungen

- Maquina ManuliDokument1 SeiteMaquina ManuliIlse SaavedraNoch keine Bewertungen

- Meb 3200 PDFDokument6 SeitenMeb 3200 PDFWajid WajidNoch keine Bewertungen

- Brother Bas-311h Leaflet PDFDokument2 SeitenBrother Bas-311h Leaflet PDFAshraaf aushiNoch keine Bewertungen

- LH-4500C SeriesDokument4 SeitenLH-4500C SeriesZaid StoreNoch keine Bewertungen

- 1 NW8803GMGDokument2 Seiten1 NW8803GMGmajochepe25Noch keine Bewertungen

- Buttonholing Machine Juki Lbh1790anDokument4 SeitenButtonholing Machine Juki Lbh1790anSayantan RahaNoch keine Bewertungen

- Insstruction Manual Zoje Zj-5780Dokument30 SeitenInsstruction Manual Zoje Zj-5780MaskusyaniNoch keine Bewertungen

- Milwaukee Hand Tools: Ultimate Productivity. Superior PerformanceDokument36 SeitenMilwaukee Hand Tools: Ultimate Productivity. Superior PerformanceMauricio BonillaNoch keine Bewertungen

- Gravograph CuttersDokument6 SeitenGravograph CuttersOpor SoloNoch keine Bewertungen

- Daewoo CatalogDokument15 SeitenDaewoo CatalogsebducretNoch keine Bewertungen

- OTC 5 Series II Robotic Welding 2021 1Dokument16 SeitenOTC 5 Series II Robotic Welding 2021 1richard ortega villasmilNoch keine Bewertungen

- NNCF 5010 CV: Cylindrical Roller Bearings, Double Row, Full ComplementDokument4 SeitenNNCF 5010 CV: Cylindrical Roller Bearings, Double Row, Full ComplementDennis MedinaNoch keine Bewertungen

- Setup Plan Technical Center: Mold +Dokument4 SeitenSetup Plan Technical Center: Mold +Victor MorenNoch keine Bewertungen

- MB137 PDFDokument2 SeitenMB137 PDFRobert Castillo MuñozNoch keine Bewertungen

- AAP S3 Buttweld SDokument17 SeitenAAP S3 Buttweld Salimsaadun alimsaadunNoch keine Bewertungen

- 570 590 LeafletDokument12 Seiten570 590 LeafletfgfgfgNoch keine Bewertungen

- Mo 804Dokument16 SeitenMo 804Josue YangNoch keine Bewertungen

- Asn 690Dokument2 SeitenAsn 690fikriimam1Noch keine Bewertungen

- SDR41 - J: Size (3')Dokument6 SeitenSDR41 - J: Size (3')Frederick Atienza ReyesNoch keine Bewertungen

- Astm Reference Block For MetalDokument10 SeitenAstm Reference Block For MetalrupamNoch keine Bewertungen

- Habasitlink M2480 Flush Grid 1": (1.6") PossibleDokument2 SeitenHabasitlink M2480 Flush Grid 1": (1.6") PossiblerizqiNoch keine Bewertungen

- Height Depth: The World's Is Determined by Our DrillingDokument2 SeitenHeight Depth: The World's Is Determined by Our DrillingrU sNoch keine Bewertungen

- Aggregates FMDokument5 SeitenAggregates FMabualamalNoch keine Bewertungen

- L K 1 9 0 0 S S 0 0 0: Good Value Models With JUKI Quality and Friendly To OperatorsDokument4 SeitenL K 1 9 0 0 S S 0 0 0: Good Value Models With JUKI Quality and Friendly To Operatorsdharmik borisagarNoch keine Bewertungen

- FSN34100LM2 Flyer HorizontalDokument1 SeiteFSN34100LM2 Flyer Horizontaljoel borlandNoch keine Bewertungen

- MOULDMACHINEACCESSORIESDokument19 SeitenMOULDMACHINEACCESSORIESDhimas KLSNoch keine Bewertungen

- Soil Classification Report-NewDokument12 SeitenSoil Classification Report-NewSoundar PachiappanNoch keine Bewertungen

- Profometer LinkDokument1 SeiteProfometer LinkJohan SonNoch keine Bewertungen

- Daewoo AR110CDokument20 SeitenDaewoo AR110CJustin100% (1)

- Pneumatic Pin Packages, Enclosed Single Units With 32mm Diameter Cylinders Models: Application: Key Areas of ApplicationDokument4 SeitenPneumatic Pin Packages, Enclosed Single Units With 32mm Diameter Cylinders Models: Application: Key Areas of ApplicationBe HappyNoch keine Bewertungen

- Sany sr235 TerbaruDokument2 SeitenSany sr235 TerbaruJose LopezNoch keine Bewertungen

- QMFX22J407S TheTimkenCompany 2DSalesDrawing 02 06 2023Dokument1 SeiteQMFX22J407S TheTimkenCompany 2DSalesDrawing 02 06 2023Mech08 DesignerNoch keine Bewertungen

- O-Ring SelectorDokument1 SeiteO-Ring SelectorVratislav Němec ml.Noch keine Bewertungen

- Job Sheet OverhaulDokument8 SeitenJob Sheet Overhaulfanny ozziNoch keine Bewertungen

- Mechanical PullersDokument1 SeiteMechanical PullersSanjayNoch keine Bewertungen

- CoaxStrip 5300 RX DS 2018 10 15 EN A4Dokument2 SeitenCoaxStrip 5300 RX DS 2018 10 15 EN A4omarrg7Noch keine Bewertungen

- Catalogo GPC CatalogoDokument11 SeitenCatalogo GPC CatalogoFrancisco RodriguezNoch keine Bewertungen

- Supreme SP-3020ASDokument2 SeitenSupreme SP-3020ASAlexandruNoch keine Bewertungen

- DDL 8000 ADokument2 SeitenDDL 8000 AYM Tsai100% (1)

- PDF 1440580617Dokument1 SeitePDF 1440580617skf urbanoNoch keine Bewertungen

- Height Depth: The World's Is Determined by Our DrillingDokument2 SeitenHeight Depth: The World's Is Determined by Our DrillingSiva ChellamNoch keine Bewertungen

- S-Touch eDokument10 SeitenS-Touch eQuang NguyenNoch keine Bewertungen

- MISA Metal Processing, Inc. FactsheetDokument2 SeitenMISA Metal Processing, Inc. Factsheetjafranklin-1Noch keine Bewertungen

- Mo 6900 GJDokument4 SeitenMo 6900 GJAlice aikoNoch keine Bewertungen

- 2tr Fe Engine MechanicalDokument4 Seiten2tr Fe Engine Mechanicalalexander bayuNoch keine Bewertungen

- NR9902 3gu UtaDokument1 SeiteNR9902 3gu UtaYair Garcia GómezNoch keine Bewertungen

- S6 Ecoline - DC - enDokument2 SeitenS6 Ecoline - DC - enRobert Utrecht HutapeaNoch keine Bewertungen

- Settlement AnalysisDokument4 SeitenSettlement AnalysisErikson MoralesNoch keine Bewertungen

- UID-21.1 Machining SpecsDokument1 SeiteUID-21.1 Machining SpecsNestor SerranoNoch keine Bewertungen

- GYRO - Trajectometry Instrument: Operating PrincipleDokument2 SeitenGYRO - Trajectometry Instrument: Operating Principleum erNoch keine Bewertungen

- Model: Illustrated Spare Parts List FOR Overlook MachineDokument44 SeitenModel: Illustrated Spare Parts List FOR Overlook MachineHector Rios100% (1)

- Lz2290asr Ip100d Sc916 eDokument33 SeitenLz2290asr Ip100d Sc916 eMuhammad IrfanNoch keine Bewertungen

- Shoe Machinery Unit II & IIIDokument106 SeitenShoe Machinery Unit II & IIIashutosh100% (1)

- Partsbook Juki Zigzag 2280aDokument8 SeitenPartsbook Juki Zigzag 2280aMaskusyaniNoch keine Bewertungen

- DLP Sewing MachineDokument4 SeitenDLP Sewing MachineYvonneGraceArnaiz-NavaresNavarroNoch keine Bewertungen

- JUKI HZL-G Series Service ManualDokument34 SeitenJUKI HZL-G Series Service Manualneotoxin100% (1)

- Sewing Terms GlossaryDokument12 SeitenSewing Terms GlossaryMorshed MahamudNoch keine Bewertungen

- Service Manual & Parts List MODEL: Cover Pro 2000CPX: Second Edition: 8 Jun 2015Dokument39 SeitenService Manual & Parts List MODEL: Cover Pro 2000CPX: Second Edition: 8 Jun 2015Eladio BelloNoch keine Bewertungen

- Janome-Parts List For Model 3160QDCDokument45 SeitenJanome-Parts List For Model 3160QDCMauricio ChirichignoNoch keine Bewertungen

- Seam Finishes 2Dokument8 SeitenSeam Finishes 2riteshbansal23Noch keine Bewertungen

- Needle Heating.Dokument46 SeitenNeedle Heating.Rahul RajNoch keine Bewertungen

- TLE-Dressmaking: Module 1: MELC LO 1Dokument23 SeitenTLE-Dressmaking: Module 1: MELC LO 1Shane Ann V. EugenioNoch keine Bewertungen

- JUKI 8100b 7 ManualDokument34 SeitenJUKI 8100b 7 ManualUsman Khan100% (1)

- Highlead GC24618, - 1Dokument55 SeitenHighlead GC24618, - 1Hristo Stoichkov Rosmel RicraNoch keine Bewertungen

- MEB 3900 Series Low CatalogDokument4 SeitenMEB 3900 Series Low CatalogOtavio SantosNoch keine Bewertungen

- TN-842B, 845B, 872B, 875B InstructionsDokument136 SeitenTN-842B, 845B, 872B, 875B InstructionsDani Perry (Dinara)Noch keine Bewertungen

- Alfa Smart Sewing Machine Instruction ManualDokument39 SeitenAlfa Smart Sewing Machine Instruction ManualiliiexpugnansNoch keine Bewertungen

- Ze-855a BrochureDokument6 SeitenZe-855a BrochureDani Perry (Dinara)Noch keine Bewertungen

- Spme Denim TrouserDokument45 SeitenSpme Denim TrouserSupriya Nanda50% (2)

- Classification of Machine FeedDokument11 SeitenClassification of Machine FeedNitta MallikNoch keine Bewertungen

- Singer 337 Sewing Machine ManualDokument38 SeitenSinger 337 Sewing Machine ManualThomas R Cow100% (1)

- Manual Singer Tradition 2282Dokument64 SeitenManual Singer Tradition 2282Eva Muñoz RosúaNoch keine Bewertungen

- Beginning Garment MakingDokument69 SeitenBeginning Garment MakingHanisha Mulchandani100% (4)

- Operation Manual: Compact Overlock MachineDokument40 SeitenOperation Manual: Compact Overlock Machinelatif yusofNoch keine Bewertungen

- Use of Sewing ToolsDokument85 SeitenUse of Sewing ToolsReymond G. Balilu100% (1)

- Janome Memory Craft 350E Sewing Machine Instruction ManualDokument52 SeitenJanome Memory Craft 350E Sewing Machine Instruction ManualiliiexpugnansNoch keine Bewertungen

- SP100 enDokument52 SeitenSP100 ensamking838Noch keine Bewertungen

- Sewing MachineDokument3 SeitenSewing MachinePRINTDESK by Dan100% (2)

- Overlock12 Machine - PpsDokument24 SeitenOverlock12 Machine - Ppsمصطفى عبدالرحيمNoch keine Bewertungen

- A Guide To: SewingDokument17 SeitenA Guide To: SewingMohammad KamruzzamanNoch keine Bewertungen

- Wear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedVon EverandWear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedBewertung: 5 von 5 Sternen5/5 (1)

- Bulletproof Seduction: How to Be the Man That Women Really WantVon EverandBulletproof Seduction: How to Be the Man That Women Really WantBewertung: 4.5 von 5 Sternen4.5/5 (169)

- African Fashion, Global Style: Histories, Innovations, and Ideas You Can WearVon EverandAfrican Fashion, Global Style: Histories, Innovations, and Ideas You Can WearBewertung: 5 von 5 Sternen5/5 (1)

- Wear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedVon EverandWear It Well: Reclaim Your Closet and Rediscover the Joy of Getting DressedBewertung: 4 von 5 Sternen4/5 (1)

- The Kingdom of Prep: The Inside Story of the Rise and (Near) Fall of J.CrewVon EverandThe Kingdom of Prep: The Inside Story of the Rise and (Near) Fall of J.CrewBewertung: 4.5 von 5 Sternen4.5/5 (26)

- The 10 Habits of Happy Mothers: Reclaiming Our Passion, Purpose, and SanityVon EverandThe 10 Habits of Happy Mothers: Reclaiming Our Passion, Purpose, and SanityBewertung: 4.5 von 5 Sternen4.5/5 (6)

- The Ultimate Book of Outfit Formulas: A Stylish Solution to What Should I Wear?Von EverandThe Ultimate Book of Outfit Formulas: A Stylish Solution to What Should I Wear?Bewertung: 5 von 5 Sternen5/5 (23)

- Metric Pattern Cutting for Women's WearVon EverandMetric Pattern Cutting for Women's WearBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsVon EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsBewertung: 4.5 von 5 Sternen4.5/5 (4)

- A Lapidary of Sacred Stones: Their Magical and Medicinal Powers Based on the Earliest SourcesVon EverandA Lapidary of Sacred Stones: Their Magical and Medicinal Powers Based on the Earliest SourcesBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Glossy: Ambition, Beauty, and the Inside Story of Emily Weiss's GlossierVon EverandGlossy: Ambition, Beauty, and the Inside Story of Emily Weiss's GlossierBewertung: 4 von 5 Sternen4/5 (45)

- Freehand Fashion: Learn to sew the perfect wardrobe – no patterns required!Von EverandFreehand Fashion: Learn to sew the perfect wardrobe – no patterns required!Bewertung: 5 von 5 Sternen5/5 (3)

- Skincare for Your Soul: Achieving Outer Beauty and Inner Peace with Korean SkincareVon EverandSkincare for Your Soul: Achieving Outer Beauty and Inner Peace with Korean SkincareBewertung: 5 von 5 Sternen5/5 (2)

- 250 Japanese Knitting Stitches: The Original Pattern Bible by Hitomi ShidaVon Everand250 Japanese Knitting Stitches: The Original Pattern Bible by Hitomi ShidaBewertung: 5 von 5 Sternen5/5 (7)

- Amazing Japanese Crochet Stitches: A Stitch Dictionary and Design Resource (156 Stitches with 7 Practice Projects)Von EverandAmazing Japanese Crochet Stitches: A Stitch Dictionary and Design Resource (156 Stitches with 7 Practice Projects)Bewertung: 4.5 von 5 Sternen4.5/5 (11)

- The DERMAdoctor Skinstruction Manual: The Smart Guide to Healthy, Beautiful Skin and Looking Good at Any AgeVon EverandThe DERMAdoctor Skinstruction Manual: The Smart Guide to Healthy, Beautiful Skin and Looking Good at Any AgeBewertung: 4.5 von 5 Sternen4.5/5 (8)

- Self-Care for Men: How to Look Good and Feel GreatVon EverandSelf-Care for Men: How to Look Good and Feel GreatBewertung: 4 von 5 Sternen4/5 (4)

- The Basics of Corset Building: A Handbook for BeginnersVon EverandThe Basics of Corset Building: A Handbook for BeginnersBewertung: 4.5 von 5 Sternen4.5/5 (17)

- Modern Ladies' Tailoring: A basic guide to pattern draftingVon EverandModern Ladies' Tailoring: A basic guide to pattern draftingBewertung: 5 von 5 Sternen5/5 (13)

- Polish Your Poise with Madame Chic: Lessons in Everyday EleganceVon EverandPolish Your Poise with Madame Chic: Lessons in Everyday EleganceBewertung: 4 von 5 Sternen4/5 (80)

- How To Make Jewelry With Beads: An Easy & Complete Step By Step GuideVon EverandHow To Make Jewelry With Beads: An Easy & Complete Step By Step GuideBewertung: 3 von 5 Sternen3/5 (12)

- How to Macramé: The Essential Guide to Macramé Knots and TechniquesVon EverandHow to Macramé: The Essential Guide to Macramé Knots and TechniquesBewertung: 5 von 5 Sternen5/5 (1)

- Skincare Bible: Dermatologist's Tips For Cosmeceutical Skincare: Beauty Bible SeriesVon EverandSkincare Bible: Dermatologist's Tips For Cosmeceutical Skincare: Beauty Bible SeriesBewertung: 4 von 5 Sternen4/5 (14)

- Basic Black: 26 Edgy Essentials for the Modern WardrobeVon EverandBasic Black: 26 Edgy Essentials for the Modern WardrobeBewertung: 4 von 5 Sternen4/5 (10)

- 150 Favorite Crochet DesignsVon Everand150 Favorite Crochet DesignsMary Carolyn WaldrepBewertung: 3.5 von 5 Sternen3.5/5 (10)

- Vintage Knit Hats: 21 Patterns for Timeless FashionsVon EverandVintage Knit Hats: 21 Patterns for Timeless FashionsBewertung: 4 von 5 Sternen4/5 (4)