Beruflich Dokumente

Kultur Dokumente

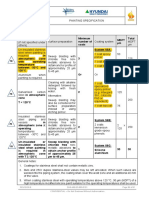

A.6 Coating System No. 6: Title: Coating and Painting Specification Rev.: Date: Doc. No.: 05-1 - EPC-SV-AEI-M-SA-00001

Hochgeladen von

Tien Tran Kha Tien0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

44 Ansichten1 SeiteThis document provides specifications for 6 coating systems for various surfaces and operating temperatures. Coating system 6A is for uninsulated stainless steel up to 120°C and includes an epoxy primer, high build epoxy, and acrylic polyurethane coats. Coating system 6B is for galvanized and aluminum surfaces up to 120°C and includes 2 phenolic epoxy coats. Coating system 6C is for insulated stainless steel up to 150°C and includes sweep blasting and 2 coats of phenolic epoxy totaling 300 microns.

Originalbeschreibung:

Type 6D

Originaltitel

Coating

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document provides specifications for 6 coating systems for various surfaces and operating temperatures. Coating system 6A is for uninsulated stainless steel up to 120°C and includes an epoxy primer, high build epoxy, and acrylic polyurethane coats. Coating system 6B is for galvanized and aluminum surfaces up to 120°C and includes 2 phenolic epoxy coats. Coating system 6C is for insulated stainless steel up to 150°C and includes sweep blasting and 2 coats of phenolic epoxy totaling 300 microns.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

44 Ansichten1 SeiteA.6 Coating System No. 6: Title: Coating and Painting Specification Rev.: Date: Doc. No.: 05-1 - EPC-SV-AEI-M-SA-00001

Hochgeladen von

Tien Tran Kha TienThis document provides specifications for 6 coating systems for various surfaces and operating temperatures. Coating system 6A is for uninsulated stainless steel up to 120°C and includes an epoxy primer, high build epoxy, and acrylic polyurethane coats. Coating system 6B is for galvanized and aluminum surfaces up to 120°C and includes 2 phenolic epoxy coats. Coating system 6C is for insulated stainless steel up to 150°C and includes sweep blasting and 2 coats of phenolic epoxy totaling 300 microns.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

Title: COATING AND PAINTING SPECIFICATION Rev.

: Date: Page:

Doc. No.: 05-1_EPC-SV-AEI-M-SA-00001 D1 02.02.18 35 of 40

A.6 Coating system no. 6

Minimum

Surface DFT

Application (if not specified under others) Coating system

preparation

[μm]

Coating system no. 6A:

st

Un-insulated stainless steel surfaces of 1 coat: Epoxy primer 50

structural items and other equipment with nd

operating temperatures up to 120 °C when 2 coat: High build 125

painting is required (Note 8) epoxy

rd

3 coat : Acrylic aliphatic 50

Coating system no. 6B:

polyurethane

Galvanized and aluminium surfaces except

Total 225

gratings, bolts, nuts with operating temperature

up to 120 °C when painting is required.

Coating system no. 6C: Sweep blasting 2 coats of phenolic 2 x 150

with non- epoxy:

Insulated stainless steel exterior surfaces of

vessels, piping, valves and other equipment with metallic and Total

chloride free 300

operating temperature up to 150 °C (Note 8)

grit to obtain

Un-insulated exterior surfaces of stainless steel anchor profile

vessels, piping and valves with OT >120°C and of

≤150°C (Note 8) approximately

37μm to 65μm. 1st Coat : Heat resistant 25

Coating system no. 6D: silicone aluminium

Insulated and un-insulated stainless steel nd

2 Coat : Heat resistant

exterior surfaces of exhaust piping, other silicone aluminium 25

equipment with operating temperature >150°C to

540°C (Note 8) Total

50

Coating system no. 6E: st

1 coat: Phenolic epoxy 125

Un-insulated stainless steel exterior surfaces of nd

2 coat: Phenolic epoxy 125

vessels, piping, valves with operating rd

temperatures up to 120°C when painting is 3 coat : Acrylic aliphatic

required (Note 8) polyurethane 50

Total 300

NOTE 1 Coatings for stainless steel shall not contain metallic zinc.

NOTE 2 6Mo and Super duplex stainless steel valves may be left uncoated. When such valves are

welded into the piping system, the coating shall cover the weld zone and an additional 40 mm of

the valve.

NOTE 3 Aluminium handrails located in living quarter shall be anodised.

NOTE 4 Aluminium, including handrails and ladders, shall only be painted if required by specific reason,

i.e. due to safety requirements etc.

NOTE 5 Hot dip galvanized steel may be coated with a 75µm polyester powder coating. Surface

preparation of the zinc prior to powder coating: Zinc manganese phosphate conversion coating.

NOTE 6 Aluminium may be coated with a 75 µm polyester coating. Surface preparation of the aluminium

prior to powder coating: Chromate conversion coating.

NOTE 7 Only topcoats already pre-qualified in coating system no. 1 shall be used for coating system 6A

and system no. 6B

NOTE 8 Use of solid SS 316/316L is restricted to maximum operating temperature limit of 60˚C. However

as per Technical Query 05-1_EPC-GE-AEI-Z-TQ-00003, solid SS 316/316L can be used above

60˚C operating temperature for low pressure, low criticality services such as lube oil, vent,

exhaust and cooling water (for diesel engines) with external coating.

NOTE 9 When perforated guards are used for personnel protection (NORSOK R-004 Insulation class 3

with OT < 150 °C), coating system to be selected as for un-insulated pipes and vessels.

File Name: 05-1_EPC-SV-AEI-M-SA-00001_Coating and Painting Specification_Rev D1.doc

Das könnte Ihnen auch gefallen

- 3.3 Secondary and Localized Surface Preparation: 3.3.1 General DescriptionDokument8 Seiten3.3 Secondary and Localized Surface Preparation: 3.3.1 General DescriptionAlex KuvoricNoch keine Bewertungen

- G16S-0205-01 - Repair Hot Drip Galv SurfaceDokument5 SeitenG16S-0205-01 - Repair Hot Drip Galv Surfacepuwarin naja100% (1)

- Paint Types - Important NotesDokument3 SeitenPaint Types - Important Notesmushroom0320Noch keine Bewertungen

- Paint System Recommendations PDFDokument6 SeitenPaint System Recommendations PDFKumarNoch keine Bewertungen

- Removing Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncDokument46 SeitenRemoving Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncMilagros MorantesNoch keine Bewertungen

- Welding CoatingDokument69 SeitenWelding CoatingphillipskincaidNoch keine Bewertungen

- Sania InternshipDokument28 SeitenSania InternshipZareen RehanNoch keine Bewertungen

- QADokument21 SeitenQAms rooNoch keine Bewertungen

- 1.2.4 HDG - Painting Issues PDFDokument2 Seiten1.2.4 HDG - Painting Issues PDFAnonymous 1AAjd0Noch keine Bewertungen

- SATIP H 002 08 Pipe Internal CoatingDokument3 SeitenSATIP H 002 08 Pipe Internal CoatinghossamalsherbinyNoch keine Bewertungen

- B Gas Grade 3 QuestionsDokument2 SeitenB Gas Grade 3 QuestionsMathew Cherian100% (1)

- 18B. Protegol UR 32.55R Data SheetDokument3 Seiten18B. Protegol UR 32.55R Data SheetClarkFedele27Noch keine Bewertungen

- Saes H 200Dokument9 SeitenSaes H 200راجہ شہزاد انورNoch keine Bewertungen

- Pew-105.03 (P)Dokument88 SeitenPew-105.03 (P)Raj BindasNoch keine Bewertungen

- SAIC-H-2001 Rev 7Dokument3 SeitenSAIC-H-2001 Rev 7Satheesh Rama SamyNoch keine Bewertungen

- Paint Slip Coefficient PDFDokument28 SeitenPaint Slip Coefficient PDFRk Sabarinathan100% (1)

- Painting STDSDokument4 SeitenPainting STDSAshok KsNoch keine Bewertungen

- Visco-Elastic Coating MaterialDokument17 SeitenVisco-Elastic Coating Materialosmanmop100% (1)

- Saudi Aramco Test ReportDokument2 SeitenSaudi Aramco Test ReportMoghal AliNoch keine Bewertungen

- CBT 8Dokument5 SeitenCBT 8SUNIL RAJPUTNoch keine Bewertungen

- Pew 105.04 (P)Dokument174 SeitenPew 105.04 (P)Raj BindasNoch keine Bewertungen

- Coating Process QuizDokument2 SeitenCoating Process QuizMujjamil NakadeNoch keine Bewertungen

- Powder Coating TrainingDokument22 SeitenPowder Coating Trainingakash.vd.1603Noch keine Bewertungen

- Airless Spray PaintingDokument22 SeitenAirless Spray PaintingRajesh KarriNoch keine Bewertungen

- 09 SAMSS 089 (Final Draft - 2018)Dokument28 Seiten09 SAMSS 089 (Final Draft - 2018)lhanx2Noch keine Bewertungen

- Inspection Check List 2Dokument34 SeitenInspection Check List 2r.devendranNoch keine Bewertungen

- Coating Defects: Protective Coatings For Internal Use Only - Not To Be Circulated Outside AkzonobelDokument36 SeitenCoating Defects: Protective Coatings For Internal Use Only - Not To Be Circulated Outside Akzonobelrajesh100% (1)

- Painting Inspection GRADE 3/2: World Centre For Materials Joining TechnologyDokument71 SeitenPainting Inspection GRADE 3/2: World Centre For Materials Joining TechnologyAhmedA.HassanNoch keine Bewertungen

- CIP Work Experience FINALDokument2 SeitenCIP Work Experience FINALDeepak YadavNoch keine Bewertungen

- Blastline Institute of Surface Preparation & PaintingDokument12 SeitenBlastline Institute of Surface Preparation & PaintingKawish TamourNoch keine Bewertungen

- Site Coatings PPDokument124 SeitenSite Coatings PPUmaibalan100% (4)

- Inspection PDFDokument24 SeitenInspection PDFaminNoch keine Bewertungen

- Practical Assessment From Picture Shown, Please Answer All QuestionsDokument1 SeitePractical Assessment From Picture Shown, Please Answer All QuestionsBOBNoch keine Bewertungen

- Grade 3. Question Writing ExaminationDokument11 SeitenGrade 3. Question Writing ExaminationHau LeNoch keine Bewertungen

- 15-Common Coating ProblemsDokument40 Seiten15-Common Coating ProblemsDiego TunessiNoch keine Bewertungen

- CorrosionDokument14 SeitenCorrosionChalakAhmedNoch keine Bewertungen

- ASF-PA-14-Painting Repair Procedure (United Engineering Construction)Dokument5 SeitenASF-PA-14-Painting Repair Procedure (United Engineering Construction)SHAHIDALINoch keine Bewertungen

- Surface Preparation Standards - ComparasionDokument4 SeitenSurface Preparation Standards - ComparasiontaiNoch keine Bewertungen

- Underground Insulation Specification Data SheetDokument2 SeitenUnderground Insulation Specification Data Sheetadoptvn100% (1)

- 424QUIZ2Dokument6 Seiten424QUIZ2Magd Badr100% (1)

- Surface Profile Measurement by Replica Tape SSPC-SP10-Nace 2-Near - WhiteDokument5 SeitenSurface Profile Measurement by Replica Tape SSPC-SP10-Nace 2-Near - WhiteClyde CoopperNoch keine Bewertungen

- Saudi Aramco Typical Inspection PlanDokument10 SeitenSaudi Aramco Typical Inspection PlanMoghal AliNoch keine Bewertungen

- 2 Surface Preparation For Metals - Before Applying ARC Coatings - ChestertonDokument36 Seiten2 Surface Preparation For Metals - Before Applying ARC Coatings - ChestertonP. Hidayat HarahapNoch keine Bewertungen

- Zinc Silicate PrimersDokument9 SeitenZinc Silicate PrimersminhnnNoch keine Bewertungen

- Profile Measurement WebinarDokument39 SeitenProfile Measurement WebinarAlex CarreraNoch keine Bewertungen

- Hempadur Mastic 45880-45881Dokument3 SeitenHempadur Mastic 45880-45881David HoffmanNoch keine Bewertungen

- What Is The Cause of Chalking in Epoxy CoatingDokument11 SeitenWhat Is The Cause of Chalking in Epoxy CoatingKalaiRazBalan100% (1)

- Question & Answers For Coating ExamsDokument17 SeitenQuestion & Answers For Coating Examsshoaib1985100% (1)

- Field Inspection and Repair of Transmission Pipeline CoatingsDokument35 SeitenField Inspection and Repair of Transmission Pipeline Coatingsangelufc99Noch keine Bewertungen

- CorrosionDokument57 SeitenCorrosionrahul72Noch keine Bewertungen

- Latest Revision Dates of SSPC StandardsDokument5 SeitenLatest Revision Dates of SSPC Standardssina_84Noch keine Bewertungen

- Rauf Aliyev - Coating, Painting and Insulation InspectorDokument11 SeitenRauf Aliyev - Coating, Painting and Insulation InspectorRauf AliyevNoch keine Bewertungen

- Painting Inspector: Passbooks Study GuideVon EverandPainting Inspector: Passbooks Study GuideNoch keine Bewertungen

- HHI Coat SystemDokument1 SeiteHHI Coat SystemAiman AhmadNoch keine Bewertungen

- SECTION 16640 Cathodic Protection (Boiler Plant/Outside Steam Distribution) Part 1 - General 1.1 DescriptionDokument7 SeitenSECTION 16640 Cathodic Protection (Boiler Plant/Outside Steam Distribution) Part 1 - General 1.1 Descriptionno nameNoch keine Bewertungen

- TM-0010F-M Rev 3 Non-Electrodeposited Zinc Flake CoatingsDokument8 SeitenTM-0010F-M Rev 3 Non-Electrodeposited Zinc Flake Coatings方綵樺Noch keine Bewertungen

- L-101 (Insulation Specification) Rev0Dokument48 SeitenL-101 (Insulation Specification) Rev0Herman SyahNoch keine Bewertungen

- TL245 English 2004Dokument8 SeitenTL245 English 2004Elliott RussellNoch keine Bewertungen

- 23S3 Ot D 220 Me SP 0570 00Dokument7 Seiten23S3 Ot D 220 Me SP 0570 00Mohammad ghanaatpisheNoch keine Bewertungen

- 1500 Pneumatic PumpDokument1 Seite1500 Pneumatic PumpTien Tran Kha TienNoch keine Bewertungen

- PowerFlex 6000Dokument20 SeitenPowerFlex 6000Tien Tran Kha Tien100% (1)

- Hitachi Medium Voltage Multi-Level IGBT DriveDokument8 SeitenHitachi Medium Voltage Multi-Level IGBT DriveTien Tran Kha TienNoch keine Bewertungen

- HA15 SeriesDokument2 SeitenHA15 SeriesTien Tran Kha TienNoch keine Bewertungen

- Company Profile PetracarbonDokument32 SeitenCompany Profile PetracarbonTien Tran Kha TienNoch keine Bewertungen

- Neway Valve (Suzhou) Co.,LtdDokument1 SeiteNeway Valve (Suzhou) Co.,LtdTien Tran Kha TienNoch keine Bewertungen

- Pds of Stabiace HTDokument5 SeitenPds of Stabiace HTTien Tran Kha TienNoch keine Bewertungen

- API PLAN "11" / "61" Api Plan "11" API PLAN 11/52: by VendorDokument1 SeiteAPI PLAN "11" / "61" Api Plan "11" API PLAN 11/52: by VendorTien Tran Kha Tien100% (1)

- PIP VEFV1100M Vessel - S&T Heat Exchanger Standard Details (Metric Units)Dokument55 SeitenPIP VEFV1100M Vessel - S&T Heat Exchanger Standard Details (Metric Units)Muhamad Amar Hakimmie SuhaimiNoch keine Bewertungen

- Cable Management Systems: Xtra Strength Xtra Stability Xtensive Solution X StockDokument16 SeitenCable Management Systems: Xtra Strength Xtra Stability Xtensive Solution X Stockkatiki216Noch keine Bewertungen

- Your Geosynthetics: Solutions PartnerDokument15 SeitenYour Geosynthetics: Solutions Partneryadav.arun0866908Noch keine Bewertungen

- Standard Details Parks Recreation ConstructionDokument100 SeitenStandard Details Parks Recreation ConstructionMhmd Abu-RajabNoch keine Bewertungen

- PFEIFER Tension Rod System: Data Sheet CollectionDokument16 SeitenPFEIFER Tension Rod System: Data Sheet Collectioncerbu_bass_cdcNoch keine Bewertungen

- Metaltech CatalogDokument68 SeitenMetaltech CatalogFabian MedranoNoch keine Bewertungen

- Rittal State-Of-The-Art Paint Plant 5 1332Dokument8 SeitenRittal State-Of-The-Art Paint Plant 5 1332jaganappuNoch keine Bewertungen

- OneSteel Cold Formed Sections Nov2004pDokument56 SeitenOneSteel Cold Formed Sections Nov2004pLizardladNoch keine Bewertungen

- Catalog Tevi Pag 1Dokument74 SeitenCatalog Tevi Pag 1GPNoch keine Bewertungen

- Peb Technical SpecificationDokument4 SeitenPeb Technical Specificationalankar ambwadeNoch keine Bewertungen

- FIRE-RESISTANCE RATINGS - UL Product w605 1hrsDokument3 SeitenFIRE-RESISTANCE RATINGS - UL Product w605 1hrsRoland James ArimadoNoch keine Bewertungen

- Magnelis Book ENDokument60 SeitenMagnelis Book ENSuvro ChakrabortyNoch keine Bewertungen

- Katalog by CV Awi JayaDokument13 SeitenKatalog by CV Awi JayaDea PratiwiNoch keine Bewertungen

- Swifts Laddercat UkDokument84 SeitenSwifts Laddercat Ukcharleselitb92Noch keine Bewertungen

- Enrolador de Cabos Com Mola - FLTDokument28 SeitenEnrolador de Cabos Com Mola - FLTadelmocoelhoNoch keine Bewertungen

- 4759 PDFDokument9 Seiten4759 PDFamitjustamitNoch keine Bewertungen

- Technical Data Sheet For HIT RE 500 V3 Injectable Mortar in Concrete Technical Information ASSET DOC 8257123Dokument42 SeitenTechnical Data Sheet For HIT RE 500 V3 Injectable Mortar in Concrete Technical Information ASSET DOC 8257123Vance KangNoch keine Bewertungen

- ZN Phosphate On Galvanized SteelDokument17 SeitenZN Phosphate On Galvanized SteelPiyanunNoch keine Bewertungen

- Piping Mat Specs Line Class Index Hb-202Dokument6 SeitenPiping Mat Specs Line Class Index Hb-202OswaldoDCBNoch keine Bewertungen

- Is 277 - 2003Dokument8 SeitenIs 277 - 2003chandrani_acsNoch keine Bewertungen

- Corrosion & Passivity - DhokDokument26 SeitenCorrosion & Passivity - DhokHenry OrozcoNoch keine Bewertungen

- Global Water Storage Tanks BrochureDokument44 SeitenGlobal Water Storage Tanks Brochureعبد السميع بن أحمد100% (1)

- Fischer FBN AnchorsDokument23 SeitenFischer FBN AnchorsIstván SzékelyNoch keine Bewertungen

- TS11 - CladdingDokument11 SeitenTS11 - CladdingSelmenNoch keine Bewertungen

- PIPE and TubesDokument11 SeitenPIPE and TubesnamNoch keine Bewertungen

- Kenguru Pro Catalog 2021Dokument47 SeitenKenguru Pro Catalog 2021adhiNoch keine Bewertungen

- Bright Cold Galvanising Spray: Technical DataDokument2 SeitenBright Cold Galvanising Spray: Technical Datasivagnanam sNoch keine Bewertungen

- Redman Fisher GuideDokument16 SeitenRedman Fisher Guideikirby77Noch keine Bewertungen

- Basteel Perimeter Systems: Citadel Security Fence SystemDokument5 SeitenBasteel Perimeter Systems: Citadel Security Fence SystemMathias OnosemuodeNoch keine Bewertungen