Beruflich Dokumente

Kultur Dokumente

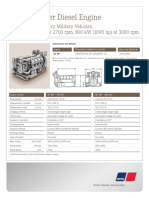

12V V-engine with 31.8L displacement

Hochgeladen von

irdawanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

12V V-engine with 31.8L displacement

Hochgeladen von

irdawanCopyright:

Verfügbare Formate

Réf.

IC 03/A

LD SC - 04-2016

12 M26.2

4 stroke diesel engine, direct injection

Bore and stroke 150 x 150 mm

Number of cylinders 12 in V

Total displacement 31.8 litres

Compression ratio 15/1

Engine rotation (ISO 1204 standard) Counterclockwise

Idle speed 700 rpm

Weight (without water & oil) 3400 kg

Flywheel housing SAE 0

Not contractual picture Flywheel SAE 18"

RATED POWER: E3 cycle (FPP propeller) Please contact us for information regarding the E2 cycle (CPP propeller).

Duty rpm kW hp Peak torque / speed Full load fuel IMO CE 97 / 68 CCNR

(N.m / rpm) consumption (g / kW.h)

P1 1800 662 900 4353 / 1300 198 II IIIA II

P1 1800 736 1000 4798 / 1300 197 II IIIA II

P2 1900 808 1100 5087 / 1400 200 II IIIA II

P2 1950 883 1200 5260 / 1400 201 II - -

Power definition (Standard ISO 3046/1 - 1995 (F) Our ratings also comply with classification societies maximum temperature definition without

power derating.

Reference conditions

Ambiant temperature 25 °C / 77 °F Ambient temperature 45 °C / 113 °F

Barometric pressure 100 kPa Raw water temperature 32 °C / 90 °F

Relative humidity 30 %

Raw water temperature 25 °C / 77 °F P1 duty P2 duty

Fuel oil Application unrestricted continuous continuous

Relative density 0,840 ± 0,005 Engine load variations very little or none numerous

Lower calorific power 42 700 kJ/kg Mean engine load factor 80 to 100 % 30 to 80 %

Consumption tolerances 0±5% Annual working time more than 5000 h 3000 to 5000 h

Inlet limit temperature 35 °C / 95 °F Time at full load unlimited 8 h each 12 h

STANDARD EQUIPMENTS

Engine and block Lubrification system

Cast iron cylinder block Full flow screwable oil filters

One inspection door per cylinder for access to conrod cap Lube oil purifier with replaceable cartridge

Cast iron cylinder liners, wet type Fresh water cooled lube oil cooler

Separate cast iron cylinder heads equipped with 4 valves

Replaceable valves guides and seats Fuel system

8 cylinders head tightening bolts In line injection pump with flanged mechanical governor

Hardened steel forged crankshaft with induction hardened journals, Double wall injection bundle with leakage collector

crankpins and radius Duplex fuel filters replaceable engine running

Camshaft with polynomial cams profile

Distribution with tempered, hardened and grinded helicoïdal gears

Intake air and exhaust system

Chromium-Molibdenum steel conrods

Lube oil cooled light alloy pistons with high performance piston rings Fresh water cooled turbo blower

Double flow raw water cooled intake air cooler

Cooling system

Fresh / raw water heat exchanger with integrated thermostatic valves Electrical system

and expansion tank Voltage: 24Vcc

Cast iron centrifugal fresh water pump, mechanically driven Electrical starter on flywheel crown

Bronze self-priming raw water pump, mechanically driven 175A battery charger

OPTIONAL EQUIPMENTS (extract) *

Cooling system adapted for box / keel cooling Free end PTO

Connection for emergency raw water and lube oil circuits Resilient mounts under engine

Bilge pump Equipment and factory trial according to Major Classification Societies rules

12 M26.2

DIMENSIONS

885

534

1355 2446

PERFORMANCES

P1 rating - 662 kW / 900 hp @ 1800 rpm P1 rating - 736 kW / 1000 hp @ 1800 rpm

P2 rating - 808 kW / 1100 hp @ 1900 rpm P2 rating - 883 kW / 1200 hp @ 1950 rpm

Moteurs Baudouin reserve the right to modify these specifications, without notice. Document not contractual.

Speed: rpm

Société Internationale des Moteurs Baudouin

Technoparc du Brégadan - CS 50001 - 13711 Cassis Cedex - France - tél. +33 488 688 500 - fax +33 488 588 501 - www.baudouin.com

Das könnte Ihnen auch gefallen

- 8M26 2-GB PDFDokument2 Seiten8M26 2-GB PDFIrda OnesNoch keine Bewertungen

- The New Marine Power Reference: Customer Benefi TsDokument2 SeitenThe New Marine Power Reference: Customer Benefi TsCarlos PariNoch keine Bewertungen

- Powerkit Engine 12M26 Series: General SpecificationsDokument3 SeitenPowerkit Engine 12M26 Series: General SpecificationsstorkbNoch keine Bewertungen

- 4 Stroke Diesel Engine, Direct Injection: 126 X 155 MM 6 in Line 11.6 Litres 17/1 CCW 600 RPM 1200 KG Sae 1 SAE 14"Dokument2 Seiten4 Stroke Diesel Engine, Direct Injection: 126 X 155 MM 6 in Line 11.6 Litres 17/1 CCW 600 RPM 1200 KG Sae 1 SAE 14"NarcisaNoch keine Bewertungen

- 12 M26.3 With SCR: IMO III / EPA IV - CompliantDokument2 Seiten12 M26.3 With SCR: IMO III / EPA IV - CompliantAlbertoNoch keine Bewertungen

- 6M16 BaudouinDokument3 Seiten6M16 BaudouinsustrasNoch keine Bewertungen

- N67 TM3A: Engine For Power Generation ApplicationsDokument4 SeitenN67 TM3A: Engine For Power Generation ApplicationsВладислав ЛеоновNoch keine Bewertungen

- 4 Stroke Diesel Engine, Direct Injection, Common-RailDokument2 Seiten4 Stroke Diesel Engine, Direct Injection, Common-RailSANTOSA MARINENoch keine Bewertungen

- WP4CD-1Dokument2 SeitenWP4CD-1Manuel Del aguilaNoch keine Bewertungen

- C87te1d P4a04c011eDokument4 SeitenC87te1d P4a04c011eSharen Robert GardnerNoch keine Bewertungen

- IBG.T.143 Specs 220V 60Hz 96W60 96WS60 Rev1-1Dokument6 SeitenIBG.T.143 Specs 220V 60Hz 96W60 96WS60 Rev1-1Mohamed ShafeeqNoch keine Bewertungen

- APD2750MDokument4 SeitenAPD2750MParinyaNoch keine Bewertungen

- WD10 Marine Diesel Engine SpecsDokument3 SeitenWD10 Marine Diesel Engine Specsservice alatberatNoch keine Bewertungen

- 9976 Weichai WP7 Spec Sheet RevmDokument3 Seiten9976 Weichai WP7 Spec Sheet Revmmurjani macindoNoch keine Bewertungen

- V10 1100 CRMDokument4 SeitenV10 1100 CRMditer najarNoch keine Bewertungen

- Marine Engine-8170 Series: General SpecificationsDokument2 SeitenMarine Engine-8170 Series: General SpecificationsMd. Arefin ShawonNoch keine Bewertungen

- LDW 2204/T diesel engine specificationsDokument4 SeitenLDW 2204/T diesel engine specificationsCristianTeodorescuNoch keine Bewertungen

- Spe 15 LD 350Dokument4 SeitenSpe 15 LD 350António AbrunhosaNoch keine Bewertungen

- Diesel Engines Series 4000 R04: For Push-Pull Trains and Locomotives Eu Stage IiibDokument2 SeitenDiesel Engines Series 4000 R04: For Push-Pull Trains and Locomotives Eu Stage IiibJavier Quintero100% (1)

- IBG.T.145 Specs 220V 60Hz 150W60 150WS60 Rev1-1Dokument6 SeitenIBG.T.145 Specs 220V 60Hz 150W60 150WS60 Rev1-1Mohamed ShafeeqNoch keine Bewertungen

- WP6 Series Marine Diesel Engine SpecsDokument3 SeitenWP6 Series Marine Diesel Engine Specsarf89Noch keine Bewertungen

- Weichai Marine Engine - WD12 SeriesDokument3 SeitenWeichai Marine Engine - WD12 SeriesAT Solution TechnologyNoch keine Bewertungen

- TM1540TDokument4 SeitenTM1540Tdargom salamanNoch keine Bewertungen

- Marine Engine-WP12 Series: General SpecificationsDokument2 SeitenMarine Engine-WP12 Series: General SpecificationsDolfin YohanesNoch keine Bewertungen

- IBG.U.253 Rev0 127WS60 3phase 220VDokument6 SeitenIBG.U.253 Rev0 127WS60 3phase 220VMohamed ShafeeqNoch keine Bewertungen

- Mtu MT 881Dokument2 SeitenMtu MT 881AndrewScotson100% (1)

- Marine Engine Specs WP4 Series 4.5L 4 Cylinder IMO Tier II CompliantDokument2 SeitenMarine Engine Specs WP4 Series 4.5L 4 Cylinder IMO Tier II Compliantarf89Noch keine Bewertungen

- P4a06n003e1010 N45 Sm1aDokument2 SeitenP4a06n003e1010 N45 Sm1aВладислав ЛеоновNoch keine Bewertungen

- N45 SM1A POWER GENERATION APPLICATIONSDokument2 SeitenN45 SM1A POWER GENERATION APPLICATIONSВладислав ЛеоновNoch keine Bewertungen

- N45 SM1A POWER GENERATION APPLICATIONSDokument2 SeitenN45 SM1A POWER GENERATION APPLICATIONSВладислав ЛеоновNoch keine Bewertungen

- Cummins 50kVADokument2 SeitenCummins 50kVAabdiNoch keine Bewertungen

- cw6250 0Dokument2 Seitencw6250 0tayfun atabeyNoch keine Bewertungen

- Heavy FV 51 MWB - 13sp Manual 12sp AMT Steel SuspensionDokument4 SeitenHeavy FV 51 MWB - 13sp Manual 12sp AMT Steel Suspensionajay dattNoch keine Bewertungen

- Kirloskar 80ws60Dokument6 SeitenKirloskar 80ws60crisNoch keine Bewertungen

- Motordatenblatt MTU 12V4000G63 PDFDokument2 SeitenMotordatenblatt MTU 12V4000G63 PDFTaz UddinNoch keine Bewertungen

- Weifang Ricardo Generator: Genset Model:HR-40GFDokument5 SeitenWeifang Ricardo Generator: Genset Model:HR-40GFFranco Chavez FerNoch keine Bewertungen

- WP13Dokument2 SeitenWP13Moris DavidNoch keine Bewertungen

- Apd1255m 6Dokument4 SeitenApd1255m 6Magaly PeraltaNoch keine Bewertungen

- C87 TE1D 275kW Stage II Power GeneratorDokument2 SeitenC87 TE1D 275kW Stage II Power GeneratorEvandro LinoNoch keine Bewertungen

- Lifan LF 1.3Dokument115 SeitenLifan LF 1.3Tomas Yanez ParraNoch keine Bewertungen

- PowerKit Engine 6M11 Series General Specifications and Dimensions Less Than 40 CharactersDokument3 SeitenPowerKit Engine 6M11 Series General Specifications and Dimensions Less Than 40 CharactersstorkbNoch keine Bewertungen

- NEF67 TE5 - 202kW - 217kWDokument3 SeitenNEF67 TE5 - 202kW - 217kWMatheus TonetaNoch keine Bewertungen

- Test Specification Data: Test Spec Number: Engine Serial Number: 67Z00776 Engine Model: Combustion: AspirationDokument3 SeitenTest Specification Data: Test Spec Number: Engine Serial Number: 67Z00776 Engine Model: Combustion: AspirationDhrubajyoti BoraNoch keine Bewertungen

- 6 M19.3 Marine EngineDokument3 Seiten6 M19.3 Marine EngineMuhammad RizkiNoch keine Bewertungen

- Perkins Engine ATP650 Diesel Genset Made in UK for Power GenerationDokument3 SeitenPerkins Engine ATP650 Diesel Genset Made in UK for Power Generationsaif loayNoch keine Bewertungen

- Diesel Power 50Hz Open Type Generator SetDokument8 SeitenDiesel Power 50Hz Open Type Generator Setchock channel 19Noch keine Bewertungen

- Número de Serie Del Motor 98Z24122Dokument4 SeitenNúmero de Serie Del Motor 98Z24122Dino Oporto PrudencioNoch keine Bewertungen

- C13TE2A DatasheetDokument3 SeitenC13TE2A DatasheetPowerTechNoch keine Bewertungen

- Spider LDokument5 SeitenSpider LrhianpermanaNoch keine Bewertungen

- KP-F D XXGV OperationManual EDokument7 SeitenKP-F D XXGV OperationManual EabathunNoch keine Bewertungen

- 2 CA4180P66K24E4Z 34C发动机 zj 译文Dokument85 Seiten2 CA4180P66K24E4Z 34C发动机 zj 译文Arash Shams100% (1)

- 08 - MGS1000BMG 7PC 0819 1Dokument4 Seiten08 - MGS1000BMG 7PC 0819 1gondrayNoch keine Bewertungen

- Powerkit Engine 4M11 Series: General SpecificationsDokument2 SeitenPowerkit Engine 4M11 Series: General SpecificationsstorkbNoch keine Bewertungen

- Southern Marine Engineering Desk Reference: Second Edition Volume IiVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNoch keine Bewertungen

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Von EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Noch keine Bewertungen

- Fishing Vessel Design and Stability Evaluation in Palabuhanratu (Case Study of PSP 01 Training-Fishing Vessel)Dokument10 SeitenFishing Vessel Design and Stability Evaluation in Palabuhanratu (Case Study of PSP 01 Training-Fishing Vessel)irdawanNoch keine Bewertungen

- Sea Recovery - The trusted source for fresh waterDokument32 SeitenSea Recovery - The trusted source for fresh waterEsteban Medina LemosNoch keine Bewertungen

- Flexeon 210 LT Series Users ManualDokument35 SeitenFlexeon 210 LT Series Users ManualMfundo DlaminiNoch keine Bewertungen

- Sailor Compact EngDokument1 SeiteSailor Compact EngirdawanNoch keine Bewertungen

- Mutu Manajemen PDFDokument238 SeitenMutu Manajemen PDFirdawanNoch keine Bewertungen

- Ix T7A Installation Guide: 1 Safety PrecautionsDokument2 SeitenIx T7A Installation Guide: 1 Safety PrecautionsirdawanNoch keine Bewertungen

- Ix T7A Installation Guide: 1 Safety PrecautionsDokument2 SeitenIx T7A Installation Guide: 1 Safety PrecautionsirdawanNoch keine Bewertungen

- FilterDokument150 SeitenFilterirdawanNoch keine Bewertungen

- KontrakDokument5 SeitenKontrakirdawanNoch keine Bewertungen

- ReadmeDokument1 SeiteReadmeمحمد السيدNoch keine Bewertungen

- Ix T7A Installation Guide: 1 Safety PrecautionsDokument2 SeitenIx T7A Installation Guide: 1 Safety PrecautionsirdawanNoch keine Bewertungen

- Telescopic/knuckleboom Cranes: Shipboard Handling ExcellenceDokument4 SeitenTelescopic/knuckleboom Cranes: Shipboard Handling ExcellenceIrda OnesNoch keine Bewertungen

- Main Engine Maintenance and Repair Record: Form Ob 11Dokument2 SeitenMain Engine Maintenance and Repair Record: Form Ob 11irdawanNoch keine Bewertungen

- Marine Diesel Generators 6 W126S Technical SpecificationsDokument2 SeitenMarine Diesel Generators 6 W126S Technical SpecificationsirdawanNoch keine Bewertungen

- Air Reverse OsmosisDokument12 SeitenAir Reverse Osmosisirdawan100% (2)

- North Sea 150m3 Basic (Containerized) : Owner's ManualDokument239 SeitenNorth Sea 150m3 Basic (Containerized) : Owner's ManualirdawanNoch keine Bewertungen

- Marine Engine Brochure and Genset BrosureDokument4 SeitenMarine Engine Brochure and Genset BrosureirdawanNoch keine Bewertungen

- Specifications & Load Charts: 40 Ton Tele-Boom Crawler CraneDokument16 SeitenSpecifications & Load Charts: 40 Ton Tele-Boom Crawler CraneLauren'sclub EnglishBimbel Sd-smaNoch keine Bewertungen

- 6703 12853 1 SM PDFDokument9 Seiten6703 12853 1 SM PDFirdawanNoch keine Bewertungen

- Specifications & Load Charts: 40 Ton Tele-Boom Crawler CraneDokument16 SeitenSpecifications & Load Charts: 40 Ton Tele-Boom Crawler CraneLauren'sclub EnglishBimbel Sd-smaNoch keine Bewertungen

- TF 00001116Dokument1 SeiteTF 00001116irdawanNoch keine Bewertungen

- Nissan S13 SR20DET To Wolf V500 Pinouts With LinkDokument1 SeiteNissan S13 SR20DET To Wolf V500 Pinouts With Linkwolfems88% (8)

- 18R-G Engine Tune-Up GuideDokument30 Seiten18R-G Engine Tune-Up GuideJhonny VargasNoch keine Bewertungen

- C1 Accumulator Piston Kit: Toyota/Lexus U660E, U660F, U760E, U760FDokument1 SeiteC1 Accumulator Piston Kit: Toyota/Lexus U660E, U660F, U760E, U760FossoskiNoch keine Bewertungen

- 2006 Arctic Cat F7 PDF Repair ManualDokument692 Seiten2006 Arctic Cat F7 PDF Repair ManualJohn DawsonNoch keine Bewertungen

- Summer Carryover Exam of IC EnginesDokument3 SeitenSummer Carryover Exam of IC EnginessrishashankNoch keine Bewertungen

- SKODA SSP 057 EngDokument44 SeitenSKODA SSP 057 Engsorinenng100% (3)

- Spect Torque Cat 320DDokument8 SeitenSpect Torque Cat 320Dlilik100% (1)

- Detroit Diesel Two-Cycle Engines PDFDokument492 SeitenDetroit Diesel Two-Cycle Engines PDFMOHD NAJMAN BIN MUDA100% (1)

- Volvo Penta Tad1250ve Spare Parts ManualDokument20 SeitenVolvo Penta Tad1250ve Spare Parts Manualthomas100% (33)

- STIGA - Vue eclatée moteur BRIGGS & STRATTONDokument32 SeitenSTIGA - Vue eclatée moteur BRIGGS & STRATTONregis.petitjeanNoch keine Bewertungen

- 3408 Remove Injection Pumps PDFDokument6 Seiten3408 Remove Injection Pumps PDFmanu luvunga100% (1)

- Manual GE12V228 CompleteDokument752 SeitenManual GE12V228 CompletemoisesNoch keine Bewertungen

- PE3 Series ManualDokument149 SeitenPE3 Series Manualdebendra128nitrNoch keine Bewertungen

- Kawasaki KX125 KX250 Service Manual Repair 1999 2000 2001 2002 99924 1244 04Dokument260 SeitenKawasaki KX125 KX250 Service Manual Repair 1999 2000 2001 2002 99924 1244 04Grzegorz Korus70% (10)

- SM 6 PDFDokument162 SeitenSM 6 PDFcarlosm6669Noch keine Bewertungen

- CURTIS E23 PumpDokument8 SeitenCURTIS E23 PumprobertNoch keine Bewertungen

- Spare Parts Catalogue for LDW 2204 M TMC60 2,5:1 ES LM EngineDokument58 SeitenSpare Parts Catalogue for LDW 2204 M TMC60 2,5:1 ES LM EngineSamy AlorNoch keine Bewertungen

- 1514285118329-Notes ALP InductionDokument97 Seiten1514285118329-Notes ALP InductionKhirod SahuNoch keine Bewertungen

- Mazda 2sport2014Dokument90 SeitenMazda 2sport2014Tran Quang HuyNoch keine Bewertungen

- Limbach Lseries All Installationmanual en 2013-10-31Dokument41 SeitenLimbach Lseries All Installationmanual en 2013-10-31PASSOT【DUC Hélices Propellers】 AlexisNoch keine Bewertungen

- Third Engineer Interview QuestionsDokument6 SeitenThird Engineer Interview QuestionsAgrata YudhistiraNoch keine Bewertungen

- CATDokument42 SeitenCATsergio blandon lNoch keine Bewertungen

- Carb Turbo Kit InstructionsDokument11 SeitenCarb Turbo Kit InstructionsKevin ShankleNoch keine Bewertungen

- Farm Machinery Internal Combustion EnginesDokument67 SeitenFarm Machinery Internal Combustion Engineschoongwenkang100% (1)

- Especificaciones de Servicios Kia G6da g6db PDFDokument180 SeitenEspecificaciones de Servicios Kia G6da g6db PDFOliver Eduardo100% (1)

- Owners Handbook BUKH DV 48 RMEDokument24 SeitenOwners Handbook BUKH DV 48 RMErobertocarlos88100% (1)

- Sportage 2008 2.7LDokument135 SeitenSportage 2008 2.7LDiover Jose Chacin UrdanetaNoch keine Bewertungen

- Cummins 6cta8.3-G2 So20682 Parts CatalogueDokument12 SeitenCummins 6cta8.3-G2 So20682 Parts CatalogueChen CarolineNoch keine Bewertungen

- QSK50-G3 NR2 emissions dataDokument1 SeiteQSK50-G3 NR2 emissions dataacere18Noch keine Bewertungen

- OE Gasket Catalog PDFDokument79 SeitenOE Gasket Catalog PDFxxxxxxxxxxxxxxxxxxx100% (1)