Beruflich Dokumente

Kultur Dokumente

Iso Fits: Fit Preferred All Description Use

Hochgeladen von

José M Esteban0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten1 SeiteISO Fits description/use

Originaltitel

Iso Fits Notes

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenISO Fits description/use

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten1 SeiteIso Fits: Fit Preferred All Description Use

Hochgeladen von

José M EstebanISO Fits description/use

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

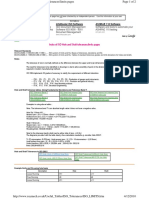

ISO FITS

mercredi 8 juillet 2015 12:40

ISO FITS

Fit Preferred All Description Use

Clearance H11/c11, H11/a11, H11/c11, H11/c9, Fits with great clearances with parts having great tolerances. Pivots, latches, fits of parts exposed to corrosive effects,

C11/h11 H11/d11, A11/h11, C11/h11, contamination with dust and thermal or mechanical

D11/h11 deformations.

Clearance H9/d9, H9/C9, H9/d10, H9/d9, H8/d9, Running fits with greater clearances without any special requirements for Multiple fits of shafts of production and piston machines, parts

D10/h9 H8/d8, D10/h9, D9/h9, D9/h8 accuracy of guiding shafts. rotating very rarely or only swinging.

Clearance H9/e9, H9/e9, H8/e8, H7/e7, E9/h9, Running fits with greater clearances without any special requirements for fit Fits of long shafts, e.g. in agricultural machines, bearings of

H8/e8, E9/h9 E8/h8, E8/h7 accuracy. pumps, fans and piston machines.

Clearance H8/f7, H7/f7, H9/f8, H8/f8, H8/f7, H7/f7, Running fits with smaller clearances with general requirements for fit Main fits of machine tools. General fits of shafts, regulator

F8/h6 F8/h7, F8/h6 accuracy. bearings, machine tool spindles, sliding rods.

Clearance H7/g6, H8/g7, H7/g6, G7/h6 Running fits with very small clearances for accurate guiding of shafts. Without Parts of machine tools, sliding gears and clutch disks,

G7/h6 any noticeable clearance after assembly. crankshaft journals, pistons of hydraulic machines, rods sliding

in bearings, grinding machine spindles.

Clearance None H11/h11, H11/h9 Slipping fits of parts with great tolerances. The parts can easily be slid one Easily demountable parts, distance rings, parts of machines

into the other and turn. fixed to shafts using pins, bolts, rivets or welds.

Clearance H7/h6 H8/h9, H8/h8, H8/h7, H7/h6 Sliding fits with very small clearances for precise guiding and centring of Precise guiding of machines and preparations, exchangeable

parts. Mounting by sliding on without use of any great force, after lubrication wheels, roller guides.

the parts can be turned and slid by hand.

Transition H7/j6 H8/j7, H7/js6, H7/j6, J7/h6 Tight fits with small clearances or negligible interference. The parts can be Easily dismountable fits of hubs of gears, pulleys and bushings,

assembled or disassembled manually. retaining rings, frequently removed bearing bushings.

Transition H7/k6, K7/h6 H8/k7, H7/k6, K8/h7, K7/h6 Similar fits with small clearances or small interferences. The parts can be Demountable fits of hubs of gears and pulleys, manual wheels,

assembled or disassembled without great force using a rubber mallet. clutches, brake disks.

Transition H7/n6, H8/p7, H8/m7, H8/n7, H7/m6, Fixed fits with negligible clearances or small interferences. Mounting of fits Fixed plugs, driven bushings, armatures of electric motors on

N7/h6 H7/n6, M8/h6, N8/h7, N7/h6 using pressing and light force. shafts, gear rims, flushed bolts.

Interference H7/p6, H8/r7, H7/p6, H7/r6, P7/h6, Pressed fits with guaranteed interference. Assembly of the parts can be Hubs of clutch disks, bearing bushings.

H7/r6, P7/h6 R7/h6 carried out using cold pressing.

Interference H7/s6, S7/h6 H8/s7, H8/t7, H7/s6, H7/t6, Pressed fits with medium interference. Assembly of parts using hot pressing. Permanent coupling of gears with shafts, bearing bushings.

S7/h6, T7/h6 Assembly using cold pressing only with use of large forces.

Interference None H8/u8, H8/u7, H8/x8, H7/u6, Pressed fits with big interferences. Assembly using pressing and great forces permanent couplings of gears with shafts, flanges.

U8/h7, U7/h6 under different temperatures of the parts.

JOINTS Page 1

Das könnte Ihnen auch gefallen

- AR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualVon EverandAR's Honda NPS50/Ruckus/Zoomer GY6 Swap ManualBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Method Statement For Equipmemt Routine & Preventive Maintenance.Dokument15 SeitenMethod Statement For Equipmemt Routine & Preventive Maintenance.OGBONNAYA MARTINS75% (4)

- Lindsay Technical Books Last CatalogDokument75 SeitenLindsay Technical Books Last Catalogkjdhjodhuihhhhhuu100% (8)

- Fits Si Tables Ansi b4.2-1978 r1994 0Dokument10 SeitenFits Si Tables Ansi b4.2-1978 r1994 0SebastiánGarcíaNoch keine Bewertungen

- CMRT Candidate Guide For Certification and Recertification 2-17 PDFDokument26 SeitenCMRT Candidate Guide For Certification and Recertification 2-17 PDFÂñçhūlä SrïkâñthNoch keine Bewertungen

- FITSDokument11 SeitenFITSArun51092Noch keine Bewertungen

- Compressor Instruction Manual XATS 1050 2654 5440 00 - C9 - LP - EN PDFDokument104 SeitenCompressor Instruction Manual XATS 1050 2654 5440 00 - C9 - LP - EN PDFAnie EkpenyongNoch keine Bewertungen

- Fits and TolerancesDokument2 SeitenFits and TolerancesMiki0% (1)

- Troubleshooting Training 870Dokument545 SeitenTroubleshooting Training 870guillermo springNoch keine Bewertungen

- HST Cone Crusher ManualDokument177 SeitenHST Cone Crusher ManualJuliano Monteiro100% (1)

- Bettis HD-Series ActuatorsDokument6 SeitenBettis HD-Series Actuatorstxlucky80Noch keine Bewertungen

- Powder Filling Machinery LeaderDokument16 SeitenPowder Filling Machinery Leaderchien_yu_leeNoch keine Bewertungen

- The Recent History of The Machine ToolDokument60 SeitenThe Recent History of The Machine Toolsmhvaa939100% (1)

- Ajustes y ToleranciasDokument1 SeiteAjustes y ToleranciasRay Rodriguez SanchezNoch keine Bewertungen

- D9R Track-Type Tractor-Machine SafetyDokument19 SeitenD9R Track-Type Tractor-Machine SafetyMecatrónicoNoch keine Bewertungen

- Hole and Shaft Basis Limits and Fits, Hole Limits and Fits, Hole and Shaft, ToleranceDokument2 SeitenHole and Shaft Basis Limits and Fits, Hole Limits and Fits, Hole and Shaft, ToleranceNagendra PrasadNoch keine Bewertungen

- R999000216 09 2015 Automation Media PDFDokument124 SeitenR999000216 09 2015 Automation Media PDFJose Manuel Barroso PantojaNoch keine Bewertungen

- Multivac 225/245Dokument28 SeitenMultivac 225/245freddyoviedo33% (3)

- Instructions AKS134 Date 2008 02 EN PDFDokument101 SeitenInstructions AKS134 Date 2008 02 EN PDFAdmir MatoshiNoch keine Bewertungen

- Limits and Fits Pr1171 - 1172Dokument1 SeiteLimits and Fits Pr1171 - 1172Teguh Nugraha KusnanNoch keine Bewertungen

- Hole Basis Limits and Fits With Shaft Basis Limits and Fits Have Been Given As An Example in The Chart BelowDokument2 SeitenHole Basis Limits and Fits With Shaft Basis Limits and Fits Have Been Given As An Example in The Chart Belowgauravme1983Noch keine Bewertungen

- Tolerances TablesDokument16 SeitenTolerances TablesRavi DalaiNoch keine Bewertungen

- Machine Drawing Clearances and Fits GuidelinesDokument16 SeitenMachine Drawing Clearances and Fits GuidelinesWong DaNoch keine Bewertungen

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyDokument16 SeitenClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyMadhuNoch keine Bewertungen

- Guidelines for Shaft and Hole FitsDokument16 SeitenGuidelines for Shaft and Hole Fitsyair Enrique Romero OspinoNoch keine Bewertungen

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyDokument16 SeitenClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyThanhluan NguyenNoch keine Bewertungen

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyDokument16 SeitenClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyBill WhiteNoch keine Bewertungen

- Tolerances Tables PDFDokument16 SeitenTolerances Tables PDFPramod SaljoshiNoch keine Bewertungen

- Machine Drawing Clearances and Fits GuidelinesDokument16 SeitenMachine Drawing Clearances and Fits GuidelinesJoseph RaventhNoch keine Bewertungen

- Tolerances Tables PDFDokument16 SeitenTolerances Tables PDFmelvin ekboteNoch keine Bewertungen

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyDokument16 SeitenClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyPuji RiatnoNoch keine Bewertungen

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyDokument16 SeitenClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyJoseph RaventhNoch keine Bewertungen

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyDokument16 SeitenClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyShantaram PatilNoch keine Bewertungen

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyDokument16 SeitenClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata Reddyalok tandelNoch keine Bewertungen

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyDokument16 SeitenClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyAkash YallattiNoch keine Bewertungen

- Limit and Fit Data BooDokument18 SeitenLimit and Fit Data Booविशाल पुडासैनीNoch keine Bewertungen

- Tolerances and fits guideDokument2 SeitenTolerances and fits guideajujkNoch keine Bewertungen

- Preferred FitsDokument2 SeitenPreferred Fitssrnivasan.rajaskNoch keine Bewertungen

- Type of Fit Symbol of Fit Examples of Application Interference FitDokument1 SeiteType of Fit Symbol of Fit Examples of Application Interference FitDharmesh patelNoch keine Bewertungen

- Tol and Fits PDFDokument39 SeitenTol and Fits PDFjason RodricksNoch keine Bewertungen

- TolerancesDokument3 SeitenTolerancesHenry Chrisnash SsenjuleNoch keine Bewertungen

- Fit Tolerances and Applications - Mec Engineering SpreadsheetsDokument14 SeitenFit Tolerances and Applications - Mec Engineering Spreadsheetstemu ShashNoch keine Bewertungen

- Fits and ToleranceDokument21 SeitenFits and ToleranceMurali DharanNoch keine Bewertungen

- Engineering Tolerancing: Chapter OutlineDokument36 SeitenEngineering Tolerancing: Chapter OutlineZir BexehenNoch keine Bewertungen

- Clearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyDokument16 SeitenClearances and Fits: Guidelines and Tables Machine Drawing KL Narayana, P. Kannaiah, K. Venkata ReddyAxel DominiqueNoch keine Bewertungen

- Running and Sliding FitsDokument1 SeiteRunning and Sliding FitsapwaniNoch keine Bewertungen

- Toleranc e FitsDokument39 SeitenToleranc e FitsIvan SilvaNoch keine Bewertungen

- VD-000016-Fit Tolerances and Applications - Mec Engineering SpreadsheetsDokument8 SeitenVD-000016-Fit Tolerances and Applications - Mec Engineering SpreadsheetsThùyNoch keine Bewertungen

- ISO System of Limits and Fits - Tolerances and DeviationsDokument39 SeitenISO System of Limits and Fits - Tolerances and DeviationsAshish Kumar MishraNoch keine Bewertungen

- Iso GD&TDokument39 SeitenIso GD&TSanjay Kumar SinghNoch keine Bewertungen

- AjustesDokument1 SeiteAjustesedu1117Noch keine Bewertungen

- Mold and Die Casting Fit RecommendationsDokument6 SeitenMold and Die Casting Fit RecommendationsJyoti KaleNoch keine Bewertungen

- FitsDokument1 SeiteFitspmdesigns17Noch keine Bewertungen

- FitsDokument1 SeiteFitssaiemNoch keine Bewertungen

- Centaflex: Series BDokument4 SeitenCentaflex: Series Bjoseph anthony marca jacintoNoch keine Bewertungen

- 1070E / 1170E Harvesters: N O L T I ODokument12 Seiten1070E / 1170E Harvesters: N O L T I OMichal KabacinskiNoch keine Bewertungen

- Honing Deglazing 4 Stroke Engines Dec 2018Dokument5 SeitenHoning Deglazing 4 Stroke Engines Dec 2018Sashka AleksandrNoch keine Bewertungen

- Index of ISO Hole and Shaft tolerances pagesDokument2 SeitenIndex of ISO Hole and Shaft tolerances pagesNgoc BangNoch keine Bewertungen

- Spindle Tapes HandoutDokument58 SeitenSpindle Tapes HandoutThinh Vu DucNoch keine Bewertungen

- Hot Oil Brochure - 0Dokument2 SeitenHot Oil Brochure - 0JovMac ManzanoNoch keine Bewertungen

- GRW 10 / GRW 15: - Rubber Wheeled Roller - Rubber Wheeled RollerDokument2 SeitenGRW 10 / GRW 15: - Rubber Wheeled Roller - Rubber Wheeled RollerFelix SandersNoch keine Bewertungen

- Maurey Industries CatalogDokument112 SeitenMaurey Industries CatalogGuillaume JaNoch keine Bewertungen

- Preferred Tol and FitsDokument9 SeitenPreferred Tol and Fitsananda_beloshe75Noch keine Bewertungen

- Engineering Design I Lecture Part 5Dokument14 SeitenEngineering Design I Lecture Part 5Miguel Cruz IIINoch keine Bewertungen

- Aerospace Fastener Applications Instructor Notes Part1 R2010Dokument15 SeitenAerospace Fastener Applications Instructor Notes Part1 R2010thulasi_krishnaNoch keine Bewertungen

- Aerospace Fastener Applications Instructor Notes Part1 R2010Dokument15 SeitenAerospace Fastener Applications Instructor Notes Part1 R2010thulasi_krishnaNoch keine Bewertungen

- Aerospace Fastener Applications Instructor Notes Part1 R2010Dokument15 SeitenAerospace Fastener Applications Instructor Notes Part1 R2010thulasi_krishnaNoch keine Bewertungen

- Education For InmigrantsDokument3 SeitenEducation For InmigrantsJosé M EstebanNoch keine Bewertungen

- TX 01Dokument11 SeitenTX 01José M EstebanNoch keine Bewertungen

- Pre School For 1 To 5 YoDokument1 SeitePre School For 1 To 5 YoJosé M EstebanNoch keine Bewertungen

- Concept Paper in RoboticsDokument4 SeitenConcept Paper in Roboticsjommel vargasNoch keine Bewertungen

- MOT Series Manual PDFDokument22 SeitenMOT Series Manual PDFGabriel Reyes VasquezNoch keine Bewertungen

- All Mechanical Projects at 9890704605Dokument5 SeitenAll Mechanical Projects at 9890704605Webhub TechnologyNoch keine Bewertungen

- 2018 - 2017 Portfolio - Nyoman Anjani - MIT IDM 923364378 PDFDokument25 Seiten2018 - 2017 Portfolio - Nyoman Anjani - MIT IDM 923364378 PDFRendy PutraaaNoch keine Bewertungen

- Ep-25 Era PressDokument26 SeitenEp-25 Era PressLeonardNoch keine Bewertungen

- Zaber 2010 CatalogDokument59 SeitenZaber 2010 CatalogServo2GoNoch keine Bewertungen

- 1260 VMC JyotiDokument3 Seiten1260 VMC JyotiPavan KhengarNoch keine Bewertungen

- Cp15 Semester 6Dokument16 SeitenCp15 Semester 6mithunprayag0% (1)

- Brochure RZ 410Dokument8 SeitenBrochure RZ 410Harris ChackoNoch keine Bewertungen

- High Quality Double Shaft Shredder: General DescriptionDokument5 SeitenHigh Quality Double Shaft Shredder: General DescriptionErick AlvarezNoch keine Bewertungen

- Ram-70Dokument23 SeitenRam-70nestor gonzalez de leonNoch keine Bewertungen

- Centrifugal ClutchhDokument26 SeitenCentrifugal ClutchhKaranKumarNoch keine Bewertungen

- FRT607 Hydraulic TensionerDokument40 SeitenFRT607 Hydraulic TensionerComstar SupplyNoch keine Bewertungen

- Emco Maxxturn 95: Precision and Reliability - in SeriesDokument6 SeitenEmco Maxxturn 95: Precision and Reliability - in Seriesmarm37coNoch keine Bewertungen

- Dynamic Modeling of A Front-Loading Type Washing MDokument17 SeitenDynamic Modeling of A Front-Loading Type Washing MJashanpreet kaurNoch keine Bewertungen

- Synopsis: Design and Fabrication of Solenoid EngineDokument3 SeitenSynopsis: Design and Fabrication of Solenoid EngineJiteshNoch keine Bewertungen

- Bonfiglioli Solutions Heavy IndustryDokument16 SeitenBonfiglioli Solutions Heavy IndustryАлексей ГордиенкоNoch keine Bewertungen

- ISO 10816 - ChartsDokument13 SeitenISO 10816 - ChartslucasNoch keine Bewertungen