Beruflich Dokumente

Kultur Dokumente

Tank Calibration

Hochgeladen von

Prince0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

82 Ansichten5 SeitenThe document discusses calibration tables for tank volumes and potential reasons they may be inaccurate. It notes calibration tables are sometimes based on preliminary drawings before construction and the actual location of sounding pipes or ullage ports could differ. Tables may also have inaccurate trim and list corrections which are important for determining loaded quantities. Software used to prepare tables may not properly handle cases where a tank's top or bottom plating is partly wet or dry. A tank's full capacity may have changed due to modification.

Originalbeschreibung:

Originaltitel

Tank Calibration.docx

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document discusses calibration tables for tank volumes and potential reasons they may be inaccurate. It notes calibration tables are sometimes based on preliminary drawings before construction and the actual location of sounding pipes or ullage ports could differ. Tables may also have inaccurate trim and list corrections which are important for determining loaded quantities. Software used to prepare tables may not properly handle cases where a tank's top or bottom plating is partly wet or dry. A tank's full capacity may have changed due to modification.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

82 Ansichten5 SeitenTank Calibration

Hochgeladen von

PrinceThe document discusses calibration tables for tank volumes and potential reasons they may be inaccurate. It notes calibration tables are sometimes based on preliminary drawings before construction and the actual location of sounding pipes or ullage ports could differ. Tables may also have inaccurate trim and list corrections which are important for determining loaded quantities. Software used to prepare tables may not properly handle cases where a tank's top or bottom plating is partly wet or dry. A tank's full capacity may have changed due to modification.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

CALIBRATION

To determine, check, or rectify the graduation of (any instrument giving

quantitative measurements).

To divide or mark with gradations, graduations, or other indexes of

degree, quantity, etc., as on a thermometer, measuring cup, or the like.

To determine the correct range for (an artillery gun, mortar, etc.) by

observing where the fired projectile hits.

To plan or devise (something) carefully so as to have a precise use,

application, appeal, etc. : a sales strategy calibrated to rich investors.

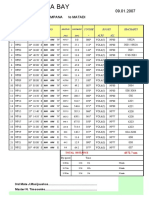

Tank Calibration - Sounding & Ullage Tables

Tank Volume Calculations for each level and angle of trim / heel

Are the existing Calibration Tables correct?

There are many reasons that calibration tables of a specific tank could be

in error but the most frequently met are the following:

Sounding Pipe or Ullage Reference Point is considered at a different

location from the place that is finally fitted. Many times the calibration

tables are based on the preliminary drawings of the ship (prepared

before construction) but some sounding pipes or Ullage ports have been

fitted at a different location due to technical obstructions at the studied

location. Many cases have been resolved with an onboard survey

determining the exact location of the sounding pipe or Ullage reference

point.

Calibration tables are correct when the ship is evenly loaded, but trim

and list corrections are in error or not available. These corrections are of

major importance in most of the cases for an accurate determination of

the loaded quantity of bunkers or cargo. Many calibration tables use the

method of correcting the gauged Ullage or sounding. This method

assumes the vessel evenly loaded in order to determine the correction to

the Ullage or sounding when the vessel is listed and could be in error

when tank's top plating is partly wet or bottom plating is partly dry by

its content.

The calibration tables have been prepared with software which is not

capable of handling the case where tank's top plating is partly wet or

bottom plating is partly dry by its content. In many cases the tanks are

modelled by means of some standard transverse sections but for the

above case additional transverse sections are required in order to

determine the extent that the top or bottom plating is partly wet or dry.

Tanks full capacity has changed due to a modification or is not

accurately calculated. In this case, the Internal Electro-Optical Distance

Ranging Method by laser scanning supported by powerful software is

required. This method is ideal for every ship but especially for floating

storage vessels, delivery barges, chemical tankers, bunker tanks etc.,

where accuracy is very important.

Das könnte Ihnen auch gefallen

- 05.00.005 Passage Plan - Port ArrivalDokument2 Seiten05.00.005 Passage Plan - Port ArrivalPHYO MIN Thant100% (1)

- Seatrain Inc.: Selandia Marine Services LTDDokument16 SeitenSeatrain Inc.: Selandia Marine Services LTDDiana Morales100% (2)

- Cargo Oil SystemDokument8 SeitenCargo Oil SystemAayush Agrawal100% (3)

- Passage Plan (Berth To Berth)Dokument5 SeitenPassage Plan (Berth To Berth)hgm100% (2)

- SIRIUS - Crew Document Checklist As of 10.05.2023Dokument3 SeitenSIRIUS - Crew Document Checklist As of 10.05.2023Ardi Bernardo Olores100% (1)

- Nav 08 - Arrival ChecklistDokument3 SeitenNav 08 - Arrival ChecklistCORIN EDWARD100% (1)

- 01 0002Dokument7 Seiten01 0002opytnymoryakNoch keine Bewertungen

- Allianz Middle East Ship Management LLC: 500 Meter ChecklistDokument3 SeitenAllianz Middle East Ship Management LLC: 500 Meter ChecklistJeet SinghNoch keine Bewertungen

- DraftSurvey BargeDokument1 SeiteDraftSurvey BargeAnda LankuNoch keine Bewertungen

- ABS Sample Certificate - GuidesDokument27 SeitenABS Sample Certificate - GuidesHemonNoch keine Bewertungen

- Nav 05 - Master - Pilot Exchange of Essential InformationDokument3 SeitenNav 05 - Master - Pilot Exchange of Essential InformationCORIN EDWARD100% (1)

- nav 02 - passage plan (berth to berth) - копияDokument5 Seitennav 02 - passage plan (berth to berth) - копияКонстантин Кулаков100% (2)

- Admiralty Vector Chart Service AVCS FactsheetDokument4 SeitenAdmiralty Vector Chart Service AVCS FactsheetVisveswaran Inbasekaran100% (4)

- How To Conduct A GMDSS Inspection: X X X XDokument16 SeitenHow To Conduct A GMDSS Inspection: X X X XDevesh Khare100% (1)

- Calculation of Draft SurveyDokument27 SeitenCalculation of Draft Surveysaif100% (1)

- PASSAGE PLANNING. Rastannurah To Jabal AliDokument4 SeitenPASSAGE PLANNING. Rastannurah To Jabal AliKunal Singh100% (2)

- Nav 3 Passage Plan FormDokument2 SeitenNav 3 Passage Plan FormGrey Pasibe100% (1)

- TEC-25B Passage Plan (Landscape Format)Dokument7 SeitenTEC-25B Passage Plan (Landscape Format)Anonymous 4V7bQB2100% (2)

- OIL TANKER OPERATIONS (Loading) - Conventional Tanker BasicsDokument3 SeitenOIL TANKER OPERATIONS (Loading) - Conventional Tanker BasicsShoaib100% (2)

- Voyage Plan: Way Point (WP) InformationDokument5 SeitenVoyage Plan: Way Point (WP) InformationAhmed Ibrahim100% (2)

- Danelec Dm-800e EcdisDokument4 SeitenDanelec Dm-800e EcdisAto ToaNoch keine Bewertungen

- Why Captain's Cabin Is Always On Starboard SideDokument2 SeitenWhy Captain's Cabin Is Always On Starboard SideKunal SinghNoch keine Bewertungen

- DP Operator Manual: Section 14 Checklists, Standing Orders, and Procedures. DP Operational ProceduresDokument18 SeitenDP Operator Manual: Section 14 Checklists, Standing Orders, and Procedures. DP Operational ProceduresKunal SinghNoch keine Bewertungen

- Passage Plan Flow Chart 2Dokument1 SeitePassage Plan Flow Chart 2Кирилл Ананченко100% (2)

- Nav-00 PASSAGE PLANDokument25 SeitenNav-00 PASSAGE PLANIrakli BakuridzeNoch keine Bewertungen

- United Ocean Ship Management Pte. LTD., SingaporeDokument2 SeitenUnited Ocean Ship Management Pte. LTD., Singaporejrjenniferraj100% (2)

- What Is Abort Point and How You Can Use It For Safe NavigationDokument30 SeitenWhat Is Abort Point and How You Can Use It For Safe NavigationUtkarsh Mathur100% (1)

- Route Planing From CAMPANA To MATADI: Lat. Long. Course Books Seacharts Alrs ALL WP. - No. Marks NameDokument1 SeiteRoute Planing From CAMPANA To MATADI: Lat. Long. Course Books Seacharts Alrs ALL WP. - No. Marks NameABDUL ALIM100% (1)

- BASSnet Fleet Management System PDFDokument14 SeitenBASSnet Fleet Management System PDFpravenNoch keine Bewertungen

- Port STBD Mean: Sea CondDokument4 SeitenPort STBD Mean: Sea CondAldo SitorusNoch keine Bewertungen

- Passage Planner Version 7Dokument22 SeitenPassage Planner Version 7Manoj Kumar Kalamegam100% (1)

- DNV PSC Preparation ChecklistDokument64 SeitenDNV PSC Preparation ChecklistCharalampos Chatzivasileiou100% (2)

- How To Mark Abort Point PDFDokument3 SeitenHow To Mark Abort Point PDFLaga Pratama100% (1)

- IBS - IMO SEEMP Part II - Template (Blank Form)Dokument10 SeitenIBS - IMO SEEMP Part II - Template (Blank Form)sakis papasNoch keine Bewertungen

- 2-Elements of ECDIS Cont PDFDokument14 Seiten2-Elements of ECDIS Cont PDFamir mouradNoch keine Bewertungen

- Bulk Quest Rev2 2018Dokument4 SeitenBulk Quest Rev2 2018Capt Pradeep Bhatnagar100% (1)

- ISM Code All Circulars MS NOTICE - 09 - 2014Dokument38 SeitenISM Code All Circulars MS NOTICE - 09 - 2014Nilesh DalviNoch keine Bewertungen

- VN-03 Passage PlanDokument12 SeitenVN-03 Passage PlanKlent Jison100% (2)

- Bridge Telegraph FailureDokument3 SeitenBridge Telegraph FailureDato Tabagua100% (1)

- Nav 02e - Ecdis Passage Plan (Berth To Berth)Dokument6 SeitenNav 02e - Ecdis Passage Plan (Berth To Berth)nikita danilov100% (1)

- Log Book AbbreviationsDokument1 SeiteLog Book AbbreviationsupespsmNoch keine Bewertungen

- Example Ballast Water Reporting Form From 2017 Guidelines For Ballast Water Exchange g6Dokument2 SeitenExample Ballast Water Reporting Form From 2017 Guidelines For Ballast Water Exchange g6123Noch keine Bewertungen

- Ship Energy Efficiency Managemenjhh43t Plan PDFDokument10 SeitenShip Energy Efficiency Managemenjhh43t Plan PDFbehzad parsiNoch keine Bewertungen

- SIRE Observations For 2018, 02 Jan'19Dokument14 SeitenSIRE Observations For 2018, 02 Jan'19Romāns BogdanovsNoch keine Bewertungen

- Engineering AuditDokument14 SeitenEngineering AuditBiplab MohantyNoch keine Bewertungen

- Ecdis and The Integrated BridgeDokument6 SeitenEcdis and The Integrated BridgeSukma Sarjono100% (2)

- Ecdis: Electronic Chart Display and Information SystemDokument23 SeitenEcdis: Electronic Chart Display and Information SystemShubham100% (1)

- Recent Developments in Loading ComputersDokument3 SeitenRecent Developments in Loading ComputersanandreevNoch keine Bewertungen

- Tanker Calculation PDFDokument2 SeitenTanker Calculation PDFSipuNoch keine Bewertungen

- Voy 038D Callao - TalaraDokument35 SeitenVoy 038D Callao - TalaraHendra TambunanNoch keine Bewertungen

- Types of BottomDokument4 SeitenTypes of BottomAnakin Skywalker100% (1)

- Ship Risk Review: PTSC Offshore ServiceDokument35 SeitenShip Risk Review: PTSC Offshore ServiceNguyễn QuânNoch keine Bewertungen

- Where Does NBDP Fit in GMDSS and How To Use ItDokument14 SeitenWhere Does NBDP Fit in GMDSS and How To Use ItKunal SinghNoch keine Bewertungen

- Green Dolphin - Brochure - tcm4-518925Dokument12 SeitenGreen Dolphin - Brochure - tcm4-518925GregoryPapoutsakisNoch keine Bewertungen

- Charts: Electronic Chart Display and Information System (ECDIS)Dokument62 SeitenCharts: Electronic Chart Display and Information System (ECDIS)roken100% (1)

- Dra Aft Surve Ey: Proc Cedures and Cal Lculation N: Readi Ing The Draf Ftmark of TH He ShipDokument4 SeitenDra Aft Surve Ey: Proc Cedures and Cal Lculation N: Readi Ing The Draf Ftmark of TH He ShiprubinoestelaNoch keine Bewertungen

- PSC Advice IhoDokument13 SeitenPSC Advice IhoSat Partner100% (1)

- ECDISDokument26 SeitenECDISahikmath33% (3)

- Guidelines For Voyage PlanningDokument3 SeitenGuidelines For Voyage PlanningGwen Avila Adizas100% (2)

- A Sales Strategy Calibrated To Rich Investors.: CalibrationDokument5 SeitenA Sales Strategy Calibrated To Rich Investors.: CalibrationPrinceNoch keine Bewertungen

- Coefficient "A": Variation TypeDokument3 SeitenCoefficient "A": Variation TypePrinceNoch keine Bewertungen

- Rule 19 - Conduct of Vessels in Restricted VisibilityDokument1 SeiteRule 19 - Conduct of Vessels in Restricted VisibilityPrince100% (1)

- Ropes and WiresDokument13 SeitenRopes and WiresPrinceNoch keine Bewertungen

- Parallel IndexingDokument2 SeitenParallel IndexingPrinceNoch keine Bewertungen

- Arpa Related TermsDokument2 SeitenArpa Related TermsPrince100% (1)

- Navigation With Pilot EmbarkedDokument5 SeitenNavigation With Pilot EmbarkedPrince100% (1)

- TY BSC VPCP TestDokument2 SeitenTY BSC VPCP TestPrince100% (1)

- FUEL:-: Fire Is A Chemical Reaction Involving Rapid Oxidation or Burning of A Fuel. It Needs Three Element To OccurDokument15 SeitenFUEL:-: Fire Is A Chemical Reaction Involving Rapid Oxidation or Burning of A Fuel. It Needs Three Element To OccurPrinceNoch keine Bewertungen

- A Sales Strategy Calibrated To Rich Investors.: CalibrationDokument5 SeitenA Sales Strategy Calibrated To Rich Investors.: CalibrationPrinceNoch keine Bewertungen

- Accommodation - Inspection of ShipDokument8 SeitenAccommodation - Inspection of ShipPrinceNoch keine Bewertungen

- Maintenanace of Crew AccommodationDokument3 SeitenMaintenanace of Crew AccommodationPrinceNoch keine Bewertungen

- Loadline Calculations - Finding Various Drafts From Loadline Certificate ParticlarsDokument1 SeiteLoadline Calculations - Finding Various Drafts From Loadline Certificate ParticlarsPrinceNoch keine Bewertungen

- A Davit Is A System That Is Used To Lower An Emergency Lifeboat To The Embarkation Level To Be BoardedDokument9 SeitenA Davit Is A System That Is Used To Lower An Emergency Lifeboat To The Embarkation Level To Be BoardedPrinceNoch keine Bewertungen

- Passage Planning ArticlesDokument37 SeitenPassage Planning ArticlesPrince100% (2)

- Passage Planning ArticlesDokument37 SeitenPassage Planning ArticlesPrince100% (2)

- Advanced Spoken English Class #2 - Luck, Superstition: TranscriptDokument5 SeitenAdvanced Spoken English Class #2 - Luck, Superstition: TranscriptPrinceNoch keine Bewertungen

- USArmy NKvsUSTacticsDokument33 SeitenUSArmy NKvsUSTacticszacklawsNoch keine Bewertungen

- Fuel Handling ProcedureDokument12 SeitenFuel Handling ProcedureSyed IftekharNoch keine Bewertungen

- Booster Basics PresentationDokument49 SeitenBooster Basics PresentationbinhjukiNoch keine Bewertungen

- POTENTIAM GIGANTIO Volume 1E3Dokument84 SeitenPOTENTIAM GIGANTIO Volume 1E3Radosław KwiecińskiNoch keine Bewertungen

- Warhammer Lesson - Army List DiscussionDokument20 SeitenWarhammer Lesson - Army List Discussionerikn89nlNoch keine Bewertungen

- Astm D 140Dokument6 SeitenAstm D 140FranklinNoch keine Bewertungen

- Lightnin: Fermentation: Critical Process Phenomena and New Technology Developments That Affect Yield and ProductivityDokument6 SeitenLightnin: Fermentation: Critical Process Phenomena and New Technology Developments That Affect Yield and ProductivityAkash PagareNoch keine Bewertungen

- War Machine 1Dokument24 SeitenWar Machine 1wfrad100% (16)

- German Army - FallschirmpionierkompanieDokument18 SeitenGerman Army - FallschirmpionierkompanieNey AlencarNoch keine Bewertungen

- Army Make Projects 2021Dokument44 SeitenArmy Make Projects 2021Robin WadhwaNoch keine Bewertungen

- Walk Through and Weapon Desc EDF 2017Dokument17 SeitenWalk Through and Weapon Desc EDF 2017Busted11290Noch keine Bewertungen

- MiniArt 2017Dokument52 SeitenMiniArt 2017JoãoGilbertoAraújoPontes100% (1)

- Fate of A Nation PDFDokument28 SeitenFate of A Nation PDFcityoflight11Noch keine Bewertungen

- Army Men Combat - Core Rules v1.1 PDFDokument3 SeitenArmy Men Combat - Core Rules v1.1 PDFrafaelmusicoNoch keine Bewertungen

- Steering and StabilisationDokument11 SeitenSteering and StabilisationSeena Zharaa100% (1)

- US Army Bolt ActionDokument3 SeitenUS Army Bolt ActionboblongfordNoch keine Bewertungen

- The Evolution of French Army Doctrine, 1919-1939Dokument61 SeitenThe Evolution of French Army Doctrine, 1919-1939naxo2ableNoch keine Bewertungen

- Z - Single Player Game Guide PDFDokument26 SeitenZ - Single Player Game Guide PDFkdkdkdNoch keine Bewertungen

- Steel Tank BrochureDokument8 SeitenSteel Tank BrochureclintNoch keine Bewertungen

- Risk Battlefield Rogue RulesDokument8 SeitenRisk Battlefield Rogue RulesMichael HuynhNoch keine Bewertungen

- XM1 Tank ProgramDokument2 SeitenXM1 Tank Programnedia24ytNoch keine Bewertungen

- JaxfunDokument91 SeitenJaxfunCasper ManNoch keine Bewertungen

- FM71 1Dokument462 SeitenFM71 1Adis Selman100% (1)

- Amuay Re Nery Disaster The Aftermaths and Challenges AheadDokument6 SeitenAmuay Re Nery Disaster The Aftermaths and Challenges AheadRavi Mohan SharmaNoch keine Bewertungen

- Evolution of The Armored Infantry Rifle SquadDokument94 SeitenEvolution of The Armored Infantry Rifle SquadAaron ParkerNoch keine Bewertungen

- Walkthrough Call of Duty WWII PDFDokument60 SeitenWalkthrough Call of Duty WWII PDFNuno PinhoNoch keine Bewertungen

- Modern WarfareDokument7 SeitenModern WarfareOvidiuValentinNoch keine Bewertungen

- Somnium Void USR Space Opera SettingDokument73 SeitenSomnium Void USR Space Opera SettingBrian LaiNoch keine Bewertungen

- Field Artillery Journal - Sep 1943Dokument83 SeitenField Artillery Journal - Sep 1943CAP History Library100% (1)

- Irjet V5i11255 PDFDokument5 SeitenIrjet V5i11255 PDFRamkumar KumaresanNoch keine Bewertungen