Beruflich Dokumente

Kultur Dokumente

Tubing Hanger Completion Checklist

Hochgeladen von

Ahmed OusamaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tubing Hanger Completion Checklist

Hochgeladen von

Ahmed OusamaCopyright:

Verfügbare Formate

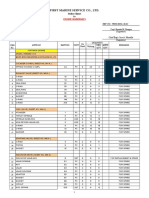

Completion Check List

Tubing Hanger

Type ………………………...…. O.D. ……………..……………………Working Pressure ……………..………… P/N……..…………… S/N …………...……………….…….….

Is Tubing Hanger Compatible with Tubing Spool on well (Circle one) yes no

Tubing Spool Type ………………………...……………………………...Size …………………………………………………...Working Pressure …………………….…….……….

Is Tubing Hanger Neck Compatible with seal Pocket in Bottom of Seal Flange (circle one) Yes No

Neck O.D ………………………………………………………………….. Seal Pocket I.D ……………………………………………………………………………………………...………...

Bottom Thread: Size …………………………….………. Type …………….…………………………. Weight ……………….………………….. Grade ………………….………...

Landing Thread: Size …………………….………………. Type …………………..……………………..Weight ………………………………….. Grade …………………………...

Back Pressure Valve Prep Size ………………………………………….. Drifted with BPV ………………………..…………………….. Drifted with TWC………………….

Ran Rabbit Through Hanger: (circle one) Yes No O.D of Rabbit …………………………….…………….………………………………….…………………...

Type of Neck Seal (circle one) T S O-Ring Other (list type of neck seal) …………………………………………………………………………

If SRL Seal Is Used, Size. ………………………….………..…………… P/N ………………………………………...……… Drift with BPV &TWC (circle one) Yes NO

Fit Tested by Hand Neck and Seal Pocket (Circle one) Yes No SRL Protector on Location (circle one) Yes No

Inspected Neck Seal (circle one) Compression Plastic Energized

Inspected Body Seal (circle one) Yes No Drifted Neck Seal in Bottom of Tree (circle one) Yes No

Is hanger prepared for Control Line (circle one) Yes No If yes pump through C/L Port (circle one) Yea No

Size (circle one) 1/8”, ¼”, 7/8” Continuous Other (name) ……………………………………………………

If Continuous Control Drifted Through Tubing Hanger (circle one) Yes No

Is Top of Hanger Through Ported (circle one) Yes No Size (circle one) 1/8”, ¼”

Landing Sleeve Required (circle one) Yes No

(Dummy Run) made (circle one) Yes No

Lift Sub Required (circle on) Yes No Cross-over Sub Required (circle one) Yes No

Seal Flange

P/N …………………………………………………… S/N ……………………………………………………………

Bottom Connection: Size ………………………………….… Working Pressure ……………………… (circle one) Flanged Studded ……………………………

O.D ……………………………….……………………... Thickness ……………………………………………………………………………………………

Is Bottom connection compatible with Tubing Spool Top Flange (circle one) Yes No

Ring Groove for Bottom Connection Inspected (circle one) Yes No Size ……………………Fit Tested (circle one) Yes No

If Flange Studs and Nuts On Location (circle one) Yes No Installed In Flange.

Quantity Required …………………On Hand …………………… O.D. Required O.D. …………………O.D. on Hand ………….…………...…………………

Length Required ……………………………… Length on Bolts Holes Drifted with Stud (circle one) Yes No

Top Connection: Size …………………………………... Working Pressure ……………………………… (circle one) Flanged studded

Seal Pocket Pep: I.D. …………………………………... Depth …………………………………... Pocket Pitted or Scared (circle one) Yes No

Seal Pocket Compatible with Tubing Hanger Neck (circle one) Yes No

IS Seal Flange Prepared for Control Line (circle one) Yes No

If Yes outlet on Side of Seal Flange to Access Control Line (circle one below)

½” NPT 9/16 Autoclave External Block Needle Valve Built Needle Valve

Pumped Fluid Through All Ports: Packing Test and Control Line (circle one) Yes No

Christmas Tree

Tree Run Size …………………………………... Working Pressure …………………………………...

Loose Valve Tree Assay /Part Number …………………………………...S/N …………………………………...

Lower Master P/N ………………………………….. S/N ………………………………….. Required Amount of Turns ………. Actual

Upper Master P/N ………………………………….. S/N ………………………………….. Required Amount of Turns ………. Actual……………………….….……...

P/N ………………………………….. S/N ………………………………….. Function Actuator (circle one) Yes No

Swab Valve P/N…………………………………... S/N…………………………………... Required Amount of Turns ……………………Actual…………………………….

Tee or Cross Run Size ………………………………….. Wing Size …………………………………..

R/H Wing VALVE P/N …………………………………...S/N …………………………………... Required Amount of Turns ……………Actual…………………………...

L/H Wing VALVE P/N ………………………… S/N ………………………… Required Amount of Turns ………………………………Actual………………………………

Tree Cap: P/N …………………………………... S/N …………………………………... Size …………………………………... WP …………………………………………….……...

Internal Thread ………………………………….. External Thread …………………………………..

Tree Cap Seal Inspected (circle one) Yes No

Run of Tree Drifted with Back Pressure Valve (including tree cap) (circle one) Yes No

Dry Rods Required: (circle one) Yes No Elevation …….………………...

Customer………………………………….……………………………………. Well#....................................................Date ……………………………………………...

FSO# ………………………………………………………………………………Delta Service Rep …………………………………………………………………………….………....

Das könnte Ihnen auch gefallen

- Complation Check ListDokument1 SeiteComplation Check ListAhmed OusamaNoch keine Bewertungen

- Pour Card ConcreteDokument4 SeitenPour Card ConcreteSaiNoch keine Bewertungen

- Manual de Partes R165Dokument334 SeitenManual de Partes R165Fernando GaleanoNoch keine Bewertungen

- PA28 2 ChecklistDokument2 SeitenPA28 2 ChecklistarilNoch keine Bewertungen

- Denjet Zubehoer Katalog 2015Dokument46 SeitenDenjet Zubehoer Katalog 2015nutdh 94Noch keine Bewertungen

- MD-82 Default X-Plane 11Dokument3 SeitenMD-82 Default X-Plane 11Felipe RamosNoch keine Bewertungen

- KWSP2 valve chamber checklistDokument1 SeiteKWSP2 valve chamber checklistkevin JiaoNoch keine Bewertungen

- Wellbore Clean UpDokument77 SeitenWellbore Clean Upmvuka100% (4)

- B200Dokument7 SeitenB200Hector CarbajalNoch keine Bewertungen

- Normal Procedures Checklists C-172Sp: and DO," "Do and Verify," and "Critical To Flight."Dokument6 SeitenNormal Procedures Checklists C-172Sp: and DO," "Do and Verify," and "Critical To Flight."ChristerNoch keine Bewertungen

- R165 PDFDokument204 SeitenR165 PDFred100% (1)

- ZF 5 HP 19Dokument6 SeitenZF 5 HP 19Montero M. HectorNoch keine Bewertungen

- Piper PA28 ChecklistDokument9 SeitenPiper PA28 ChecklistAli HosseinabadiNoch keine Bewertungen

- Gardner Denver Triplex Plunger Pump Parts ListDokument28 SeitenGardner Denver Triplex Plunger Pump Parts ListRahmad DesmanNoch keine Bewertungen

- Normal Checklist A319/320/321Dokument4 SeitenNormal Checklist A319/320/321SLS Lawn careNoch keine Bewertungen

- Renault Dpo, Peugeot Citroen Al4 4 Speed FWDDokument4 SeitenRenault Dpo, Peugeot Citroen Al4 4 Speed FWDmillanzNoch keine Bewertungen

- Concorde Normal ChecklistDokument14 SeitenConcorde Normal ChecklistMatiasNoch keine Bewertungen

- BAe CHECKLIST PDFDokument2 SeitenBAe CHECKLIST PDFali4957270Noch keine Bewertungen

- 1648 Plus Asphalt Paver Parts Manual 918217BDokument112 Seiten1648 Plus Asphalt Paver Parts Manual 918217Btrina0% (1)

- Cessna 172 Skyhawk Checklist Mentone Flying Club, Inc. Preflight InspectionDokument2 SeitenCessna 172 Skyhawk Checklist Mentone Flying Club, Inc. Preflight InspectionAlexandre RochaNoch keine Bewertungen

- Yamaha WR 450 FW 2007 Service Data R EngDokument2 SeitenYamaha WR 450 FW 2007 Service Data R EngLuis FirminoNoch keine Bewertungen

- A320 ChecklistsDokument4 SeitenA320 Checklistsvasilisnikon70% (10)

- 196 248pDokument177 Seiten196 248pVitaliy YavdoshchukNoch keine Bewertungen

- Valves and ChokesDokument40 SeitenValves and Chokescreceptax50% (2)

- N93JS Checklist MPHDokument3 SeitenN93JS Checklist MPHjairo antonio lopez lopezNoch keine Bewertungen

- Checklist Boeing 737-800 15-04-2011Dokument2 SeitenChecklist Boeing 737-800 15-04-2011Hugo LenclenNoch keine Bewertungen

- Warrior ChecklistDokument3 SeitenWarrior Checklistjgills240100% (2)

- NORMAL CHECKLIST FLY BY WIRE A320neoDokument3 SeitenNORMAL CHECKLIST FLY BY WIRE A320neoAntoni GarciaNoch keine Bewertungen

- Ti 500 Product Sheet 2018 Rev1 1519056345Dokument2 SeitenTi 500 Product Sheet 2018 Rev1 1519056345leo.johnsonNoch keine Bewertungen

- Ti 500 Product Sheet 2018 Rev1 1519056345Dokument2 SeitenTi 500 Product Sheet 2018 Rev1 1519056345eduardo.torresNoch keine Bewertungen

- Normais e ProcedimentosDokument18 SeitenNormais e ProcedimentosVictor MiguelNoch keine Bewertungen

- Normas e Procedimentos Do R22Dokument18 SeitenNormas e Procedimentos Do R22Victor MiguelNoch keine Bewertungen

- CTL55 Parts ManualDokument142 SeitenCTL55 Parts ManualPhilNoch keine Bewertungen

- CTL85 Compact Track Loader Parts Manual 917301CDokument154 SeitenCTL85 Compact Track Loader Parts Manual 917301CPhilNoch keine Bewertungen

- BergerDokument96 SeitenBergerlazybookwarmNoch keine Bewertungen

- C152 Quick Reference HandbookDokument4 SeitenC152 Quick Reference HandbookJoost BijlsmaNoch keine Bewertungen

- A320 Normal ProceduresDokument15 SeitenA320 Normal ProceduresLibya FreeNoch keine Bewertungen

- InFlight C310G Checklist Series 6 20 14 PDFDokument8 SeitenInFlight C310G Checklist Series 6 20 14 PDFMarcos ValdezNoch keine Bewertungen

- Ty 154 ChecklistDokument2 SeitenTy 154 ChecklisttoniNoch keine Bewertungen

- Reportsheet PengisianDokument2 SeitenReportsheet PengisianAhmad HanifNoch keine Bewertungen

- A320 Before and After Start ProceduresDokument16 SeitenA320 Before and After Start ProceduresAndrea Osito100% (1)

- Hill-Rom Affinity Bed - Service ManualDokument400 SeitenHill-Rom Affinity Bed - Service ManualJorgeNoch keine Bewertungen

- CTL65 Parts ManualDokument142 SeitenCTL65 Parts ManualPhilNoch keine Bewertungen

- T252PL - 69 NT20-284 69NT40-461-464Dokument39 SeitenT252PL - 69 NT20-284 69NT40-461-464CristiSarateanuNoch keine Bewertungen

- Before Engine Start ChecklistDokument4 SeitenBefore Engine Start Checklistjairo antonio lopez lopezNoch keine Bewertungen

- 2015 Catalog-Catálogo-Catalogue 457205. SKF Bearings and Seals - Rodamientos y Sellos SKF - Roulements Et Joints SKF PDFDokument487 Seiten2015 Catalog-Catálogo-Catalogue 457205. SKF Bearings and Seals - Rodamientos y Sellos SKF - Roulements Et Joints SKF PDFMyOpel PartsNoch keine Bewertungen

- Geely CK Sparepart CatalogDokument221 SeitenGeely CK Sparepart CatalogJorge Soto Batalla100% (1)

- B737 NG Exterior Preflight TrainingDokument115 SeitenB737 NG Exterior Preflight Trainingvictorbenites86% (22)

- 3CP1221-1241 SchematicDokument4 Seiten3CP1221-1241 Schematicab5951Noch keine Bewertungen

- Hosco Parts Catalog2021Dokument120 SeitenHosco Parts Catalog2021Raka ajaNoch keine Bewertungen

- C172SP Quick Reference HandbookDokument4 SeitenC172SP Quick Reference HandbookJoost BijlsmaNoch keine Bewertungen

- 9853 6202 50d Spare Part Catalogue COP 1838 C-VersionDokument28 Seiten9853 6202 50d Spare Part Catalogue COP 1838 C-VersionAnonymous iu95trpxNNoch keine Bewertungen

- C680-N149Js Normal Checklist C680-N149Js Normal ChecklistDokument3 SeitenC680-N149Js Normal Checklist C680-N149Js Normal ChecklistDon ParkerNoch keine Bewertungen

- CTL75 Parts ManualDokument134 SeitenCTL75 Parts ManualPhilNoch keine Bewertungen

- 31 SRC enDokument6 Seiten31 SRC enlggomezupbNoch keine Bewertungen

- Learjet 35 Learjet3 04 PreflightDokument16 SeitenLearjet 35 Learjet3 04 PreflightJose Ariel Chejanovich100% (1)

- Brass Methods: An Essential Resource for Educators, Conductors, and StudentsVon EverandBrass Methods: An Essential Resource for Educators, Conductors, and StudentsNoch keine Bewertungen

- Troubleshooting Switching Power Converters: A Hands-on GuideVon EverandTroubleshooting Switching Power Converters: A Hands-on GuideBewertung: 5 von 5 Sternen5/5 (2)

- OpenVMS Alpha Internals and Data Structures: Memory ManagementVon EverandOpenVMS Alpha Internals and Data Structures: Memory ManagementNoch keine Bewertungen

- KF Trunnion 150 300 PDFDokument16 SeitenKF Trunnion 150 300 PDFRominaNoch keine Bewertungen

- Model MH 70: Hydraulic Piston Actuator Operation and Maintenance ManualDokument35 SeitenModel MH 70: Hydraulic Piston Actuator Operation and Maintenance ManualAhmed Ousama100% (3)

- Manual Mantenimiento Valvulas Bola Series TDokument4 SeitenManual Mantenimiento Valvulas Bola Series Talex_santiago_6Noch keine Bewertungen

- Grasera Hypregun Plus 5g PDFDokument16 SeitenGrasera Hypregun Plus 5g PDFLuis EturaNoch keine Bewertungen

- 555 Tech Data SheetDokument1 Seite555 Tech Data SheetAhmed OusamaNoch keine Bewertungen

- FC WellheadDokument32 SeitenFC WellheadEfe Alexander Orieka100% (2)

- BallValveA2 05Dokument44 SeitenBallValveA2 05Denstar Ricardo SilalahiNoch keine Bewertungen

- Course Syllabus - Accounting Financial Reporting - 1.ALEX.H-EDokument34 SeitenCourse Syllabus - Accounting Financial Reporting - 1.ALEX.H-EAhmed OusamaNoch keine Bewertungen

- Course Syllabus - Accounting Financial Reporting - 1.ALEX.H-EDokument34 SeitenCourse Syllabus - Accounting Financial Reporting - 1.ALEX.H-EAhmed OusamaNoch keine Bewertungen

- PDF 2487338580Dokument1 SeitePDF 2487338580Ahmed OusamaNoch keine Bewertungen

- Eliminate Hazards Through Engineering and Administrative ControlsDokument1 SeiteEliminate Hazards Through Engineering and Administrative ControlsAhmed OusamaNoch keine Bewertungen

- Verbs+ PrepositionsDokument18 SeitenVerbs+ PrepositionsAhmed OusamaNoch keine Bewertungen

- CH 6Dokument18 SeitenCH 6Ahmed OusamaNoch keine Bewertungen

- Collocation Lists - Common Verbs and Expressions ExplainedDokument2 SeitenCollocation Lists - Common Verbs and Expressions ExplainedWaleed AllmNoch keine Bewertungen

- Users & Uses of Accounting InformationDokument2 SeitenUsers & Uses of Accounting InformationAhmed OusamaNoch keine Bewertungen

- The Economic Problem (Chapter 1) NotesDokument3 SeitenThe Economic Problem (Chapter 1) NotesAhmed OusamaNoch keine Bewertungen

- External UsersDokument2 SeitenExternal UsersAhmed OusamaNoch keine Bewertungen

- Collocation Lists - Common Verbs and Expressions ExplainedDokument2 SeitenCollocation Lists - Common Verbs and Expressions ExplainedWaleed AllmNoch keine Bewertungen

- PTC VR Tool Design SpecificationsDokument5 SeitenPTC VR Tool Design SpecificationsAhmed Ousama100% (1)

- Que Es Economia - Capt 1 - EconomiaDokument35 SeitenQue Es Economia - Capt 1 - EconomiaCarlos Soto-SantoniNoch keine Bewertungen

- A First Look at Macroeconomic Trends and IssuesDokument51 SeitenA First Look at Macroeconomic Trends and IssuesDianitha VentNoch keine Bewertungen

- Operation Procedure For VR - HammerDokument8 SeitenOperation Procedure For VR - HammerAhmed OusamaNoch keine Bewertungen

- VR Plug Installation and Removal GuideDokument10 SeitenVR Plug Installation and Removal GuideAhmed Ousama50% (2)

- Chapter 2 (Notes) GDP DefinitionsDokument20 SeitenChapter 2 (Notes) GDP DefinitionsAhmed OusamaNoch keine Bewertungen

- Hand Pump InformationsDokument7 SeitenHand Pump InformationsAhmed OusamaNoch keine Bewertungen

- VR Magnetic Socket DimsDokument1 SeiteVR Magnetic Socket DimsAhmed OusamaNoch keine Bewertungen

- VR Tool Assembly ProcedureDokument17 SeitenVR Tool Assembly ProcedureAhmed OusamaNoch keine Bewertungen

- Operation Procedure for VR-ToolDokument17 SeitenOperation Procedure for VR-ToolAhmed Ousama100% (1)

- VR Plugs Ind-SectionsDokument1 SeiteVR Plugs Ind-SectionsAhmed OusamaNoch keine Bewertungen

- Gate Valve AssemblyDokument5 SeitenGate Valve AssemblyAhmed OusamaNoch keine Bewertungen

- TURBINE & AUX MAL FUNCTIONSDokument29 SeitenTURBINE & AUX MAL FUNCTIONSdurga praveenNoch keine Bewertungen

- Pre-Commissioning Check ListDokument1 SeitePre-Commissioning Check Listjay royNoch keine Bewertungen

- CDS 31Dokument2 SeitenCDS 31MarleyNoch keine Bewertungen

- Pipe SizingDokument16 SeitenPipe SizingnagarajhebbarNoch keine Bewertungen

- Pneumatic Connections: Figure 1: Tru-Balance Box-Type 300/400 Series Sifter Pneumatic SchematicDokument2 SeitenPneumatic Connections: Figure 1: Tru-Balance Box-Type 300/400 Series Sifter Pneumatic SchematicmiguelNoch keine Bewertungen

- Sulzer SMN SBRDokument8 SeitenSulzer SMN SBRMarsinta PurbaNoch keine Bewertungen

- PA (M) - Reciprocating CompressorsDokument35 SeitenPA (M) - Reciprocating CompressorsHiral HiraniNoch keine Bewertungen

- PMC Projects (India) Pvt. LTD.: Adani Mormugao Port Terminal (P) LTDDokument31 SeitenPMC Projects (India) Pvt. LTD.: Adani Mormugao Port Terminal (P) LTDrenger20150303Noch keine Bewertungen

- Wasser PumpDokument2 SeitenWasser Pump266870idNoch keine Bewertungen

- Survey Equipment ListDokument4 SeitenSurvey Equipment ListIrfan MunirNoch keine Bewertungen

- Centrifugal Pump: Notes, Application, Methods, Principle and DiagramDokument15 SeitenCentrifugal Pump: Notes, Application, Methods, Principle and DiagramRenNoch keine Bewertungen

- 928G Wheel Loader Hydraulic System IT28G Integrated ToolcarrierDokument2 Seiten928G Wheel Loader Hydraulic System IT28G Integrated ToolcarrierOecox Cah DjadoelNoch keine Bewertungen

- Chapter 7. Measurement of Level and FlowDokument26 SeitenChapter 7. Measurement of Level and FlowNguyen NguyenNoch keine Bewertungen

- Curva Sobrerevolucionada Bomba Principal VasconiaDokument1 SeiteCurva Sobrerevolucionada Bomba Principal VasconiaHenry Garavito RamirezNoch keine Bewertungen

- TDH Calculation Models Compared 1667648114Dokument4 SeitenTDH Calculation Models Compared 1667648114Saeed AbdNoch keine Bewertungen

- GRDU-EG-PRC-04-001-A1 CommentsDokument14 SeitenGRDU-EG-PRC-04-001-A1 CommentsHermenegildo ZolaNoch keine Bewertungen

- Sheet Comp and Turb1Dokument21 SeitenSheet Comp and Turb1المهندسخانة Almohandes KhanaNoch keine Bewertungen

- Elautomation Pumps PricelistDokument7 SeitenElautomation Pumps Pricelistsolo7651Noch keine Bewertungen

- Hello How Are You DoingDokument10 SeitenHello How Are You DoingaRTNoch keine Bewertungen

- Course Contents For 5 Days GT, HRSG, ST & GenDokument2 SeitenCourse Contents For 5 Days GT, HRSG, ST & GenFazalur Rehman BabarNoch keine Bewertungen

- Typ 06217 1 enDokument2 SeitenTyp 06217 1 enВова НазаровNoch keine Bewertungen

- 6 HP Pump Technical SpecificationsDokument25 Seiten6 HP Pump Technical SpecificationsShahid AbbasNoch keine Bewertungen

- Module 3 - Pump Configuration Specific Speed and Affinity Laws - No AnsDokument17 SeitenModule 3 - Pump Configuration Specific Speed and Affinity Laws - No AnsRoi Vincent AnitNoch keine Bewertungen

- Proposed apartment complex cold water booster pump sizingDokument2 SeitenProposed apartment complex cold water booster pump sizingMaxmore KarumamupiyoNoch keine Bewertungen

- Problems ؤا 5Dokument4 SeitenProblems ؤا 5Abdalla MemeNoch keine Bewertungen

- ELGI Air Compressors 12 PDFDokument45 SeitenELGI Air Compressors 12 PDFSuresh NathNoch keine Bewertungen

- GascompcDokument14 SeitenGascompcchicken studiosNoch keine Bewertungen

- rv20 Variable Displacement Vane Pump PDFDokument3 Seitenrv20 Variable Displacement Vane Pump PDFMadhukar PadipallyNoch keine Bewertungen

- Lecture Title-3Dokument33 SeitenLecture Title-3Adel AshrafNoch keine Bewertungen