Beruflich Dokumente

Kultur Dokumente

Bombas Api VS Bombas Ansi PDF

Hochgeladen von

ABRAHAM ESTRADAOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bombas Api VS Bombas Ansi PDF

Hochgeladen von

ABRAHAM ESTRADACopyright:

Verfügbare Formate

Grupo de Ingeniería Consultoría y

Calidad Industrial SA de CV

Comparing API 610 Pumps With ANSI / ASME B73.1 Centrifugal Pumps

The comparison that is provided in this article is referenced from Heinz P. Bloch’s book “Pump

User’s Handbook Life Extension” co-authored with Allan R. Budris.

ANSI vs API:

Compared to an API pump, the typical ANSI pump has the following characteristics:

A thinner casing, i.e. less corrosion allowance

An ANSI pump has reduced permissible nozzle loads. It is even more sensitive to pipe-

induced stresses than the API pump.

An ANSI pump has a smaller stuffing box size. Unless a large bore option is chosen, an

ANSI pump may not be able to accommodate the optimum mechanical seal for a given

service.

ANSI pump impellers are designed and manufactured without wear rings. Many ANSI pump

impellers are open or semi-open whereas API pumps feature closed impellers with

replaceable wear rings.

ANSI pumps are generally foot-mounted, whereas the API pump will be centerline

mounted. Refer the attached sketch. In foot-mounted pumps casing heat tends to be

conducted into the mounting surfaces and thermal growth will be noticeable. It is generally

easier to maintain alignment of API pumps since their supports are surrounded by the

typically moderate-temperature ambient environment.

surrounded by the typically moderate-temperature ambient environment.

Progreso de Obregón, Hidalgo CP: 42730

Telefono: 738 7250527. Móvil: 5512287002

aeflores@giccisa.com

Grupo de Ingeniería Consultoría y

Calidad Industrial SA de CV

The decision on API vs ANSI construction is experience-based and is not governed by

governmental or regulatory agencies. However, experienced machinery specialists have their own

likes and dislikes based on the experience gathered by them over their long years in the machinery

field.

Many highly experienced and reliability-focused machinery engineers would prefer to use pumps

designed and constructed according to API 610 for toxic, flammable, or explosion-proof services at

on-site locations in close proximity to furnaces and boilers in some of the conditions (rules-of-

thumb) that are listed below:

Head exceeds 106.6 m (350 ft)

Temperature of pumpage exceeds 149°C (300°F) on pumps with discharge flange sizes

larger than 4 inch or 177°C (350°F) on pumps with 4 inch discharge flange size or less.

Driver horsepower exceeds 74 kW (100 hp)

Suction pressure in excess of 516 kPag (75 psig)

Rated flow exceeds flow at best efficiency point (BEP)

Pump speed in excess of 3600 rpm.

The author mentions that there have been exceptions made where deviations from the rules-of-

thumb were minor, or in situations where the pump manufacturer was able to demonstrate

considerable experience with ANSI pumps under the same, or even more adverse conditions.

Finally the author gives his opinion on choosing either API or ANSI pumps based on the following:

Conventional Wisdom: API-compliant pumps are always a better choice than ANSI or ISO pumps

Fact: Unless flammable, toxic or explosion-prone liquids are involved, many carefully selected,

properly installed, operated and maintained ANSI or ISO pumps may represent an uncompromising

and satisfactory choice.

About the Author: This article is written by Mr Ankur Srivastava, a Chemical Engineer with 32

years of process engineering experience in oil and gas, refining, polymers and petrochemical

industries. Activities include conceptual and feasibility studies, front end engineering design, detail

engineering, preparation of company standards and pre-commissioning/operation manuals,

erection, pre-commissioning and start-up assistance, PHA and HAZOP, and planning and quality

control.

Progreso de Obregón, Hidalgo CP: 42730

Telefono: 738 7250527. Móvil: 5512287002

aeflores@giccisa.com

Das könnte Ihnen auch gefallen

- All Diafragms Meters Sb3500Dokument17 SeitenAll Diafragms Meters Sb3500Ruben Romero SotoNoch keine Bewertungen

- Autoflame Emissions CalculatorDokument9 SeitenAutoflame Emissions CalculatorLuilio Esparza100% (1)

- 8C-16M B3 CatalogDokument27 Seiten8C-16M B3 CatalogBernardo Campos PereiraNoch keine Bewertungen

- Touch Screen Torque TesterDokument1 SeiteTouch Screen Torque TesterMelinda AstutiNoch keine Bewertungen

- Nitrate Fertilisers: Rupp Industrial SolutionsDokument20 SeitenNitrate Fertilisers: Rupp Industrial SolutionsCarlos Manuel Castillo SalasNoch keine Bewertungen

- Asaddff: Pumps vs. Agitators For Tank Mixing, Classic Case of CAPEX Vs OPEX: White PaperaDokument5 SeitenAsaddff: Pumps vs. Agitators For Tank Mixing, Classic Case of CAPEX Vs OPEX: White PaperaMARK LESTER REALNoch keine Bewertungen

- F. Huang - Engineering ThermodynamicsDokument52 SeitenF. Huang - Engineering ThermodynamicsHectorCabz100% (1)

- Flexible PVC Pipe and Fittings Price ListDokument172 SeitenFlexible PVC Pipe and Fittings Price ListAmparitoNoch keine Bewertungen

- Content AccessHatchBrochure 2012 LR 10-30-12 PDFDokument24 SeitenContent AccessHatchBrochure 2012 LR 10-30-12 PDFJizelle JumaquioNoch keine Bewertungen

- Performance Evaluation of Absorption Refrigeration SystemsDokument10 SeitenPerformance Evaluation of Absorption Refrigeration SystemsalmadhagiNoch keine Bewertungen

- Catalogue Air Handling Unit DDW Without Frame PDFDokument27 SeitenCatalogue Air Handling Unit DDW Without Frame PDFFirman AnriNoch keine Bewertungen

- Up Down Pumping Vs AgitationDokument24 SeitenUp Down Pumping Vs AgitationSubrata BanerjeeNoch keine Bewertungen

- Biocleaner - Manual de Operacion y MantenimientoDokument9 SeitenBiocleaner - Manual de Operacion y MantenimientoFabian Ignacio Marquez OsorioNoch keine Bewertungen

- Odin Elastopipe Eng Oct 2019 PDFDokument2 SeitenOdin Elastopipe Eng Oct 2019 PDFHafidzManaf100% (1)

- LWN Operating Manual of FanDokument20 SeitenLWN Operating Manual of FanYogesh Badhe100% (1)

- Tracerase: Operating and Instruction ManualDokument16 SeitenTracerase: Operating and Instruction ManualKrishnaNoch keine Bewertungen

- DOC011Dokument4 SeitenDOC011InggitNoch keine Bewertungen

- Analizadores de Presion de Vapor Analizador RVPDokument6 SeitenAnalizadores de Presion de Vapor Analizador RVPLuis OsorioNoch keine Bewertungen

- Assembly-Install STD Control Dryer PDFDokument106 SeitenAssembly-Install STD Control Dryer PDFdonyaNoch keine Bewertungen

- Pulsa Series BrochureDokument8 SeitenPulsa Series Brochurewhatdidijustwatch manNoch keine Bewertungen

- Sound Speed & Pipe Size Data: (For Ultrasonic Flowmeters)Dokument50 SeitenSound Speed & Pipe Size Data: (For Ultrasonic Flowmeters)sherio amrousyNoch keine Bewertungen

- 07-01 MafDokument5 Seiten07-01 MafJuan Roberto López BetanzosNoch keine Bewertungen

- Manual Algor TuberiasDokument0 SeitenManual Algor TuberiascaletonesNoch keine Bewertungen

- Pipe Flow Expert Quick Start GuideDokument12 SeitenPipe Flow Expert Quick Start Guidemetasoniko2014Noch keine Bewertungen

- SPE 38866 Analysis of Commingled Gas Reservoirs With Variable Bottom-Hole Flowing Pressure and Non-Darcy FlowDokument13 SeitenSPE 38866 Analysis of Commingled Gas Reservoirs With Variable Bottom-Hole Flowing Pressure and Non-Darcy Flowjuan jose100% (1)

- Gascalc: Demonstration GuideDokument32 SeitenGascalc: Demonstration GuideJesusNoch keine Bewertungen

- Calentador Catalitico de TuberíasDokument2 SeitenCalentador Catalitico de TuberíasDavid RomeroNoch keine Bewertungen

- Tanque Esferico Con Boquillas-ModelDokument1 SeiteTanque Esferico Con Boquillas-ModelAle JaimeNoch keine Bewertungen

- VI Rotary CompressorDokument16 SeitenVI Rotary CompressorJayNoch keine Bewertungen

- Mecánica de FluidosDokument11 SeitenMecánica de FluidosmaialenNoch keine Bewertungen

- Plate Heat Exchangers-Method of Calculation, Charts and Guidelines For Selecting Plate Heat Exchanger ConfigurationsDokument8 SeitenPlate Heat Exchangers-Method of Calculation, Charts and Guidelines For Selecting Plate Heat Exchanger ConfigurationsFrandhoni UtomoNoch keine Bewertungen

- A Bi - Directional Gas Thrust BearingDokument9 SeitenA Bi - Directional Gas Thrust Bearingshahir93Noch keine Bewertungen

- Thermal Engineering ME 5103Dokument3 SeitenThermal Engineering ME 5103ahmadskhanNoch keine Bewertungen

- Señor de Los Cielos Pemex Yuum - K - Ak - Naab - Imo7708302Dokument3 SeitenSeñor de Los Cielos Pemex Yuum - K - Ak - Naab - Imo7708302Adrian Angulo100% (1)

- Owner & Operator's Manual: ModelsDokument16 SeitenOwner & Operator's Manual: ModelskmpoulosNoch keine Bewertungen

- Manual Medidor Turbina RMG TRZ 03Dokument8 SeitenManual Medidor Turbina RMG TRZ 03Cleverson BorghezanNoch keine Bewertungen

- Sopladores RegenerativosDokument52 SeitenSopladores RegenerativosErick Reyna Chirinos100% (1)

- Temperatura de Bulbo Seco, Bulbo Húmedo Y de RocíoDokument5 SeitenTemperatura de Bulbo Seco, Bulbo Húmedo Y de RocíoYtzZel Sponge GrrNoch keine Bewertungen

- Ipc2022-87060 - Estimating Measurement Performance With Truncated Data SetsDokument8 SeitenIpc2022-87060 - Estimating Measurement Performance With Truncated Data SetsOswaldo MontenegroNoch keine Bewertungen

- CATALYTIC HEATERS OVERVIEWDokument4 SeitenCATALYTIC HEATERS OVERVIEWmauricio_rrNoch keine Bewertungen

- Abb El 3060Dokument20 SeitenAbb El 3060రామకృష్ణ పాశలNoch keine Bewertungen

- Temspec Hi-Rise BookDokument35 SeitenTemspec Hi-Rise Bookvn8480Noch keine Bewertungen

- CatCo Catalytic Heater Enclosures for Fisher RegulatorsDokument2 SeitenCatCo Catalytic Heater Enclosures for Fisher Regulatorsinstrumentacion.hsrNoch keine Bewertungen

- E06-017 Rev 1 EIV Manual PDFDokument29 SeitenE06-017 Rev 1 EIV Manual PDFPalomino VergaraNoch keine Bewertungen

- 0000 Experimental Confirmation On The Theoritical Model For The Velocity Profile in A Rectangular Wind TunnelDokument8 Seiten0000 Experimental Confirmation On The Theoritical Model For The Velocity Profile in A Rectangular Wind TunnelArnalt StalinNoch keine Bewertungen

- User Instructions: Limitorque MX Electronic Actuator Installation Operation MaintenanceDokument104 SeitenUser Instructions: Limitorque MX Electronic Actuator Installation Operation MaintenanceFernando FerradaNoch keine Bewertungen

- Beginner's Guide To Differential Pressure Level TransmittersDokument3 SeitenBeginner's Guide To Differential Pressure Level Transmittersswatkool100% (1)

- 200912515224111903Dokument5 Seiten200912515224111903GBHJRNoch keine Bewertungen

- Fisher Specification Manager SoftwareDokument4 SeitenFisher Specification Manager SoftwarehrtoroNoch keine Bewertungen

- Medidores BK g4Dokument2 SeitenMedidores BK g4Daniel MaldonadoNoch keine Bewertungen

- KSB Ball Valve 2 inDokument8 SeitenKSB Ball Valve 2 inrusli bahtiarNoch keine Bewertungen

- Teoria y Principios Eyectores TermocompresoresDokument4 SeitenTeoria y Principios Eyectores TermocompresoresJohn Kennedy FernandesNoch keine Bewertungen

- CVS pressure controllers instruction manualDokument12 SeitenCVS pressure controllers instruction manualsalmo83:18Noch keine Bewertungen

- Parmiability and SeepageDokument26 SeitenParmiability and SeepageFardous Rababah100% (1)

- Regulador Eska ValveDokument5 SeitenRegulador Eska ValveFercho Mariscal100% (1)

- IM200-20 (LC Mag Insertion) PDFDokument8 SeitenIM200-20 (LC Mag Insertion) PDFLazzarus Az GunawanNoch keine Bewertungen

- 03 Dew Point Measurements Andy Benton Michell EngezerDokument64 Seiten03 Dew Point Measurements Andy Benton Michell EngezerccdumitraNoch keine Bewertungen

- Comparación Entre Bombas API y ASMEDokument2 SeitenComparación Entre Bombas API y ASMEFranklin Santiago Suclla Podesta100% (1)

- Ansi Vs API PumpsDokument4 SeitenAnsi Vs API PumpsarcanicrahulNoch keine Bewertungen

- API Vs Ansi PumpsDokument6 SeitenAPI Vs Ansi PumpsMarcos Martínez SánchezNoch keine Bewertungen

- Considerations For Pumping Produced Water in Upstream Oil & Gas Applications - Empowering Pumps and EquipmentDokument3 SeitenConsiderations For Pumping Produced Water in Upstream Oil & Gas Applications - Empowering Pumps and EquipmentABRAHAM ESTRADANoch keine Bewertungen

- Axial Flow Check ValvesDokument10 SeitenAxial Flow Check ValvesABRAHAM ESTRADANoch keine Bewertungen

- Improve The Reliability of Safety Instrumented SystemsDokument12 SeitenImprove The Reliability of Safety Instrumented SystemsABRAHAM ESTRADANoch keine Bewertungen

- A Step-by-Step Approach To Pump Selection Pumps & SystemsDokument6 SeitenA Step-by-Step Approach To Pump Selection Pumps & SystemsABRAHAM ESTRADANoch keine Bewertungen

- Keep Pumps Running with Condition MonitoringDokument14 SeitenKeep Pumps Running with Condition MonitoringABRAHAM ESTRADANoch keine Bewertungen

- 5 Common Pump and System Design Mistakes Flow ControlDokument7 Seiten5 Common Pump and System Design Mistakes Flow ControlABRAHAM ESTRADANoch keine Bewertungen

- Modification of Pump Curves by Installing Restrictive Orifices at Pump Discharge (Part 2) - LinkedInDokument3 SeitenModification of Pump Curves by Installing Restrictive Orifices at Pump Discharge (Part 2) - LinkedInABRAHAM ESTRADANoch keine Bewertungen

- Class V Wells For Injection of Non-Hazardous Fluids Into or Above Underground Sources of Drinking WaterDokument2 SeitenClass V Wells For Injection of Non-Hazardous Fluids Into or Above Underground Sources of Drinking WaterABRAHAM ESTRADANoch keine Bewertungen

- Grundfos Pressure Boosting Investment PDFDokument6 SeitenGrundfos Pressure Boosting Investment PDFABRAHAM ESTRADANoch keine Bewertungen

- Class III Injection Wells For Solution Mining - Protecting Underground Sources of Drinking Water From Underground Injection (UIC) - US EPA PDFDokument4 SeitenClass III Injection Wells For Solution Mining - Protecting Underground Sources of Drinking Water From Underground Injection (UIC) - US EPA PDFABRAHAM ESTRADANoch keine Bewertungen

- Class IV Shallow Hazardous and Radioactive Injection WellsDokument3 SeitenClass IV Shallow Hazardous and Radioactive Injection WellsABRAHAM ESTRADANoch keine Bewertungen

- Grundfos Pressure Boosting Investment PDFDokument6 SeitenGrundfos Pressure Boosting Investment PDFABRAHAM ESTRADANoch keine Bewertungen

- Class II Oil and Gas Related Injection Wells - Protecting Underground Sources of Drinking Water From Underground Injection (UIC) - US EPA PDFDokument6 SeitenClass II Oil and Gas Related Injection Wells - Protecting Underground Sources of Drinking Water From Underground Injection (UIC) - US EPA PDFABRAHAM ESTRADANoch keine Bewertungen

- Utilizing Produced Water As A New Water ResourceDokument1 SeiteUtilizing Produced Water As A New Water ResourceABRAHAM ESTRADANoch keine Bewertungen

- Commissioning of Pipe and Flare Stack PDFDokument13 SeitenCommissioning of Pipe and Flare Stack PDFABRAHAM ESTRADANoch keine Bewertungen

- Concrete Pavers Roof Decks - Tech Spec 14 PDFDokument12 SeitenConcrete Pavers Roof Decks - Tech Spec 14 PDFbatteekhNoch keine Bewertungen

- 计量泵metering pump PDFDokument43 Seiten计量泵metering pump PDFAnonymous Tj3ApePIrNoch keine Bewertungen

- 5-1-14 Recueil Methodes Vol 1 en 2012Dokument488 Seiten5-1-14 Recueil Methodes Vol 1 en 2012James Quynh NguyenNoch keine Bewertungen

- RC Corbel Design (ACI318-05)Dokument2 SeitenRC Corbel Design (ACI318-05)Mohammed Z. AlSaqqa100% (1)

- WPS (AsmeDokument8 SeitenWPS (AsmeMohammad Elhedaby100% (6)

- How To Process and Print Black-and-White FilmDokument6 SeitenHow To Process and Print Black-and-White FilmPepParamosNoch keine Bewertungen

- Lisa Bennie Honours Thesis ReducedDokument67 SeitenLisa Bennie Honours Thesis ReducedNur NadiahNoch keine Bewertungen

- P Block Short NotesDokument22 SeitenP Block Short Notesthapliyaldivyanshu274Noch keine Bewertungen

- MZ2000W PDS EnglishDokument3 SeitenMZ2000W PDS EnglishLeandroNoch keine Bewertungen

- VWR® Symphony® Analysis PackagesDokument3 SeitenVWR® Symphony® Analysis Packageslusoegyi 1919Noch keine Bewertungen

- Belaria+twin+ Technical+ INM-en+ 2017 PDFDokument38 SeitenBelaria+twin+ Technical+ INM-en+ 2017 PDFAnonymous 4MLEo9TVQNoch keine Bewertungen

- A Snapshot of The Drilling and Completio N Practices in High Temperature Geothermal Wells - SarmientoDokument13 SeitenA Snapshot of The Drilling and Completio N Practices in High Temperature Geothermal Wells - SarmientoAdil AytekinNoch keine Bewertungen

- Drugs of Hindustan PDFDokument382 SeitenDrugs of Hindustan PDFdr madan mohan gundu100% (1)

- Filter Bag SystemsDokument52 SeitenFilter Bag SystemskategordNoch keine Bewertungen

- Corrosol VE GP - TDS - Rev 4 - Feb 19Dokument2 SeitenCorrosol VE GP - TDS - Rev 4 - Feb 19mkash028Noch keine Bewertungen

- Flowserve Lined Flush BottomDokument32 SeitenFlowserve Lined Flush BottomDevdatt WaghuleNoch keine Bewertungen

- Invalon: FL Equipment Cleaning AgentDokument5 SeitenInvalon: FL Equipment Cleaning Agentsasko100% (1)

- Republic Act No 6969Dokument7 SeitenRepublic Act No 6969Alelie BatinoNoch keine Bewertungen

- Airfoil Lift Procedures PDFDokument12 SeitenAirfoil Lift Procedures PDFmatthias.s.sommer3656Noch keine Bewertungen

- Check Maf Kia Carnival DieselDokument7 SeitenCheck Maf Kia Carnival Dieseljulio797Noch keine Bewertungen

- Organic Pigments - The Basics - SII - Dec 2008Dokument298 SeitenOrganic Pigments - The Basics - SII - Dec 2008Prince Jannisari100% (1)

- Application Letter Elvera MarlianiDokument3 SeitenApplication Letter Elvera MarlianiElvera MarlianiNoch keine Bewertungen

- BMW Fault Codes OBDDokument15 SeitenBMW Fault Codes OBDtitibacsiNoch keine Bewertungen

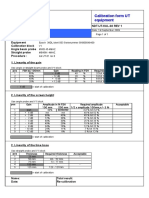

- Calibration Sheet Ultrasonic Test EquipmentDokument1 SeiteCalibration Sheet Ultrasonic Test EquipmentjohnNoch keine Bewertungen

- Hendricks, David W-Fundamentals of Water Treatment Unit Processes - Physical, Chemical, and biological-CRC Press (2011) PDFDokument930 SeitenHendricks, David W-Fundamentals of Water Treatment Unit Processes - Physical, Chemical, and biological-CRC Press (2011) PDFÂn HồngNoch keine Bewertungen

- Megtron 6Dokument3 SeitenMegtron 6rfduh100% (1)

- Feasibility of Using Lightweight Eps Based Partitions For Washrooms of ApartmentsDokument6 SeitenFeasibility of Using Lightweight Eps Based Partitions For Washrooms of ApartmentsVishnuNoch keine Bewertungen

- APPLIED MECHANICAL ENGINEERING PROBLEM SOLVINGDokument4 SeitenAPPLIED MECHANICAL ENGINEERING PROBLEM SOLVINGKyle LoveNoch keine Bewertungen

- DAO 2016-08 Features and CAPDokument64 SeitenDAO 2016-08 Features and CAPDianne Kristine Avila100% (4)

- Dwnload Full Visual Anatomy and Physiology 2nd Edition Martini Solutions Manual PDFDokument36 SeitenDwnload Full Visual Anatomy and Physiology 2nd Edition Martini Solutions Manual PDFalluviumopuntialjvoh100% (9)