Beruflich Dokumente

Kultur Dokumente

Answers Short Test Answers

Hochgeladen von

Malcolm Diamond0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten2 SeitenHobart short test answers

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenHobart short test answers

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten2 SeitenAnswers Short Test Answers

Hochgeladen von

Malcolm DiamondHobart short test answers

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

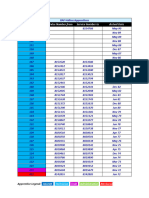

Answer Key for AWS D1.

1 Short Exams 2015

Short Exam #1 Reference

1. d Welder qualifications, production weld positions, table 4.10 pg 135

2. d Processes,3.2.1 pg 45

3. c Transitions of thickness & width, fig. 2.2, pg 37

Unequal thickness, 2.17.1.1 pg 14

4. c Temperature, ambient, 5.11.2 pg 169

5. a IIW UT reference block, 6.22.1, fig 6.13 note 3 pg 240

6. c Basemetal, table 4.9 pg 131

7. c IQI, table 6.4 pg 212

8. e Visual inspection or Acceptance criteria, visual, 4.9.1 (3) pg 111

9. b Basemetal, table 3.1 pg 49

10.c Convexity, table 5.9 pg 182

Short Exam #2 Reference

1. e Repair, of plate, 5.14.5.2, table 5.4 pg 180

2. b Electrodes, table 4.13 pg 138

3. b Position of welding, 4.3.4, fig 4.1 pg 140

4. d Prequalified joint details, fig 3.3 pg 84

5. b Backing, removal of, 5.9.1.5 pg 169

6. e NOT, personnel qualification, 6.14.6.1 pg 196

7. c Preheat, table 3.3 pg 57 see fn a

8. c Essential variables, table 4.5 (12) pg 124

9. b Prequalified joint details, fig 3.3 pg 91

10.d Dewpoint or Shielding gas, 5.3.1.3 pg 165

Short Exam #3 Reference

1. a Exposed application or Weathering steel, 3.7.3, table 3.4 pg 60

2. c WPS, qualification, table 4.2 pg 121

3. e Maximum fill pass thickness, table 3.6 pg 61

4. b Preheat, table 3.3 pg 57

5. d Qualification, responsibility, 4.2.1.1 pg 10~

6. b Guided bend test jig, 4.9.3.1, fig 4.11 pg 150

7. b Stress relief, alternate temperatures, 5.8.2, table 5.3 pg 180

8. c Fillet welds, assembly tolerances, 5.21, 5.21.1 pg 174

9. e Welder qualification, essential variables, table 4.12 pg 138

10.b Faying surfaces, 5.21.1.1 pg 174

Short Exam #4 Reference

1. d Effective weld size or Flare-groove weld, 2.4.1.4, table 2.1 pg 16

2. c Intermittent welds, 2.4.2.4 pg 7

3. d Prequalified joint details, fig 3.3 see note h pg 86

4. e Reentrant corners, 5.15 pg 172

5. b Misalignment, 5.21.3 pg 174

6. a Girders, depth, 5.22.9 pg 176

7. d Test specimens. table 4.2 pg 121

8. d Repair, of cracks, 5.25.1.4 pg 178

9. e Peening, acceptable peening, 5.26 pg 178

10.a Visual inspection or Delayed inspection, table 6.1 pg 209

Short Exam #5 Reference

1. d Lap joints, 2.4.2.9, fig 2.1 (b) pg 36

2. a Arc strikes, 5.28 pg 179

3. c Weld cleaning, completed welds, 5.29.2 pg 179

4. d Performance qualification, 4 Part C, 4.15.2.1, table 4.11 pg 136

5. e Flux,5.3.3.2 pg 167

6. c Inspection, general, 6.1, 6.1.7 pg 192

7. e UT, reports, 6.26.1 pg 203

8. e Studs, acceptance, 7.4.1 pg 246

9. d Rivets (or Bolts), 2.7.7 pg 10

10.d Base metal, filler metal combinations, 3.3, table 3.1 pg 45 (group 1)

11.b SMAW, essential variables table 4.5 pg 124

12.a Undercut, table 6.1 (7b) pg 209

13.c Girder, 5.22.5 pg 175

14.a Oxygen gouging, on quenched & tempered steels, 5.14.6 pg 171

15.c SAW, single electrodes, table 3.6 pg 61

Das könnte Ihnen auch gefallen

- RAF ApprenticeDokument6 SeitenRAF ApprenticeMalcolm DiamondNoch keine Bewertungen

- Safe Shooting MapDokument2 SeitenSafe Shooting MapMalcolm DiamondNoch keine Bewertungen

- Welding Abreviation and SymbolsDokument1 SeiteWelding Abreviation and SymbolsMalcolm DiamondNoch keine Bewertungen

- Decinal To Metric ConversionDokument1 SeiteDecinal To Metric ConversionMalcolm DiamondNoch keine Bewertungen

- Project Libre TutorialDokument34 SeitenProject Libre TutorialMalcolm Diamond100% (1)

- Cisco Router WRT160N v2Dokument38 SeitenCisco Router WRT160N v2SDaroosterNoch keine Bewertungen

- SS SinksDokument8 SeitenSS SinksMalcolm DiamondNoch keine Bewertungen

- Metric and Pressure Conversion ChartDokument1 SeiteMetric and Pressure Conversion ChartMalcolm DiamondNoch keine Bewertungen

- US and Metric Standard UnitsDokument2 SeitenUS and Metric Standard UnitsMalcolm DiamondNoch keine Bewertungen

- Things Every Press Brake Operator Should KnowDokument4 SeitenThings Every Press Brake Operator Should KnowMalcolm DiamondNoch keine Bewertungen

- AWS D1.1 Skewed T-Joint Exam QuestionsDokument3 SeitenAWS D1.1 Skewed T-Joint Exam QuestionsMalcolm DiamondNoch keine Bewertungen

- AWS D1.1 Table 5.8 & 5.9 Exam QuestionsDokument2 SeitenAWS D1.1 Table 5.8 & 5.9 Exam QuestionsMalcolm DiamondNoch keine Bewertungen

- Corona Checklist Teaching OnlineDokument10 SeitenCorona Checklist Teaching OnlineMalcolm DiamondNoch keine Bewertungen

- Project Libre TutorialDokument36 SeitenProject Libre TutorialMalcolm DiamondNoch keine Bewertungen

- 4140 HandoutDokument5 Seiten4140 HandoutMalcolm DiamondNoch keine Bewertungen

- Rigid Bobber Frame Assembly GuideDokument15 SeitenRigid Bobber Frame Assembly GuideMalcolm Diamond100% (1)

- DIY Bench Top Tubing BenderDokument17 SeitenDIY Bench Top Tubing BenderMalcolm DiamondNoch keine Bewertungen

- Rigid Sportster Frame Assembly GuideDokument14 SeitenRigid Sportster Frame Assembly GuideMalcolm DiamondNoch keine Bewertungen

- Frame Jig Assembly GuideDokument12 SeitenFrame Jig Assembly GuideMalcolm DiamondNoch keine Bewertungen

- Chapter 1 - SelectionDokument1 SeiteChapter 1 - SelectionMalcolm DiamondNoch keine Bewertungen

- Chapter 1 - Welding DefinedDokument2 SeitenChapter 1 - Welding DefinedAnonymous dh6DITNoch keine Bewertungen

- Bike Lift Assembly GuideDokument15 SeitenBike Lift Assembly GuideMalcolm DiamondNoch keine Bewertungen

- The History of WeldingDokument18 SeitenThe History of WeldingMalcolm DiamondNoch keine Bewertungen

- Chapter 1 - ProcessesDokument6 SeitenChapter 1 - ProcessesAnonymous dh6DITNoch keine Bewertungen

- AWS D1.1 Short Code Tests #4Dokument3 SeitenAWS D1.1 Short Code Tests #4Malcolm DiamondNoch keine Bewertungen

- Calculating Development ErrorDokument6 SeitenCalculating Development ErrorMalcolm DiamondNoch keine Bewertungen

- Welding Inspection and CertificationDokument30 SeitenWelding Inspection and CertificationtuvuNoch keine Bewertungen

- AWS D1.1 Structural Welding Code - SteelDokument8 SeitenAWS D1.1 Structural Welding Code - SteelMalcolm DiamondNoch keine Bewertungen

- AWS D1.1 Short Code Tests #3Dokument4 SeitenAWS D1.1 Short Code Tests #3Malcolm DiamondNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5782)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Week 7Dokument3 SeitenWeek 7ABEGRACE LIG-ANGNoch keine Bewertungen

- Taining Materials 2021, HobartDokument28 SeitenTaining Materials 2021, HobartVijo JoseNoch keine Bewertungen

- What Is A Welding CertificationDokument12 SeitenWhat Is A Welding Certificationmjinspector100% (1)

- Pocket Welding Guide PDFDokument186 SeitenPocket Welding Guide PDFJairo Contreras100% (2)

- Rwac - Lssti - LNHS - KNHS - Smaw - January 17 - 20 - Elmer Cigara AbloDokument52 SeitenRwac - Lssti - LNHS - KNHS - Smaw - January 17 - 20 - Elmer Cigara AbloKira RajadaNoch keine Bewertungen

- Chapter - 3 Development of Agglomerated FluxesDokument36 SeitenChapter - 3 Development of Agglomerated Fluxesvikram singhNoch keine Bewertungen

- WPS-43 - Gtaw & Smaw Tig + SmawDokument19 SeitenWPS-43 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNoch keine Bewertungen

- 42 M Bow String Girder-10408-R PDFDokument1 Seite42 M Bow String Girder-10408-R PDFPhanindra MajetiNoch keine Bewertungen

- Trainees Record Book NCIIDokument3 SeitenTrainees Record Book NCIIlara joey datoyNoch keine Bewertungen

- Welding Processes and TechniqueDokument49 SeitenWelding Processes and TechniqueRanendraNoch keine Bewertungen

- Join Metal Parts with Gas Welding, Brazing & SolderingDokument105 SeitenJoin Metal Parts with Gas Welding, Brazing & SolderingAnuj Verma100% (1)

- Quality Management ServicesDokument112 SeitenQuality Management ServicesTech 5Noch keine Bewertungen

- Tm1 PresentationDokument27 SeitenTm1 PresentationSam Louis LepitenNoch keine Bewertungen

- Las Smaw 9 - Q2 W3-4Dokument20 SeitenLas Smaw 9 - Q2 W3-4Daryl TesoroNoch keine Bewertungen

- Welding QuestionsDokument40 SeitenWelding Questionssaba100% (1)

- Arc Welding PPT FinishDokument50 SeitenArc Welding PPT FinishmahendraNoch keine Bewertungen

- CBT WELDING QUESTION ANSWERSDokument57 SeitenCBT WELDING QUESTION ANSWERSRishiNoch keine Bewertungen

- Arc Welding ElectrodeDokument36 SeitenArc Welding ElectrodeAinul Yaqien80% (5)

- CBC SMAW NCII Feb. 9 2018Dokument76 SeitenCBC SMAW NCII Feb. 9 2018jayson platino100% (1)

- Correct Arc Length, Correct Travel Speed and Correct Electrode AngleDokument6 SeitenCorrect Arc Length, Correct Travel Speed and Correct Electrode AngleFelix MilanNoch keine Bewertungen

- En Iso 21952 - 2012 (E)Dokument20 SeitenEn Iso 21952 - 2012 (E)getatodicaNoch keine Bewertungen

- Smaw 12 DLLDokument3 SeitenSmaw 12 DLLSally Java Senayo100% (5)

- Development of The Matching Filler Metal For MARBN - New Advanced Creep Resisting Alloys For Thermal Power PlanDokument10 SeitenDevelopment of The Matching Filler Metal For MARBN - New Advanced Creep Resisting Alloys For Thermal Power PlanBurag HamparyanNoch keine Bewertungen

- Summary Note For CSWIP 3.1Dokument9 SeitenSummary Note For CSWIP 3.1Muhamad ShakyreenNoch keine Bewertungen

- Structural Welding ManualDokument76 SeitenStructural Welding ManualThomasman43Noch keine Bewertungen

- INDUSTRIAL SKILLS FRAMEWORK OGE 1st EDITION NEW PDFDokument124 SeitenINDUSTRIAL SKILLS FRAMEWORK OGE 1st EDITION NEW PDFandyNoch keine Bewertungen

- CTS Welder (Pipe) NSQFDokument33 SeitenCTS Welder (Pipe) NSQFzaki amNoch keine Bewertungen

- Standar Elektroda PDFDokument182 SeitenStandar Elektroda PDFFakhar WindratamaNoch keine Bewertungen

- Welding SymbolsDokument5 SeitenWelding Symbolsjojo_323100% (3)

- Weld Defects and How To Avoid Them: ContinuedDokument5 SeitenWeld Defects and How To Avoid Them: ContinuedFaizPuadNoch keine Bewertungen