Beruflich Dokumente

Kultur Dokumente

Vendor: Design Information: Gas Boot

Hochgeladen von

124swadeshi0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

190 Ansichten2 SeitenVertical Vessel

Originaltitel

Vertical Vessel (2)

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenVertical Vessel

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

190 Ansichten2 SeitenVendor: Design Information: Gas Boot

Hochgeladen von

124swadeshiVertical Vessel

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

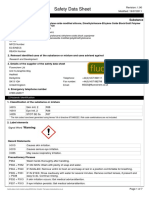

1 VENDOR: HICO DESIGN INFORMATION 1

2 NO.: TYPE: VERTICAL 2

3 CRN NO.: * DIAMETER: 3,962 ID mm SHELL LENGTH: 10,668 T/T mm 3

4 WEIGHTS (kg) SKIRT / SADDLE HEIGHT: 8700 mm 4

5 FABRICATION 46,898* EMPTY 60,233* OPERATING (INTERNAL) 400 kPag @ 120 °C 5

6 OPERATING 198,859* HYDROTEST 221,055* OPERATING (EXTERNAL) - kPag @ - °C 6

7 DESIGN (INTERNAL) 1,310 kPag @ 165 °C 7

8 DESIGN (EXTERNAL) FV kPag @ 148 °C 8

9 MINIMUM DESIGN METAL TEMPERATURE -29 °C 9

10 CORROSION ALLOWANCE 3.2 mm 10

11 HYDROTEST PER CODE kPag @ x MAWP SPECIFIC GRAVITY: 0.86 11

12 POST WELD HEAT TREATMENT: YES AS PER SOUR SERVICE 12

13 RADIOGRAPHY: 100% JOINT EFF% CIRC.: 100% LONG: 100% 13

14 WIND VELOCITY (1/50) NOTE 3 EARTHQUAKE ZONE NOTE 3 14

15 REGISTERED YES IN JURISDICTION ALBERTA WITH ABSA 15

16 CODE: ASME VIII DIV 1 ASME VIII DIV 2 16

17 CODE STAMPED REVISION IN FORCE: LATEST 17

18 TYPE: HORIZONTAL VERTICAL SPHERICAL 18

19 HEADS: 2:1 SEMI-ELL. SPHERICAL FLANGED 19

20 SERVICE GENERAL SOUR SERVICE HYDROGEN 20

21 NACE: MR0175 / ISO 15156 OTHER 21

22 MATERIALS OF CONSTRUCTION: 22

23 SHELL: SA-516-70-N HEADS: SA-516-70-N 23

24 PIPE: SA-106 Gr. B FORGINGS: SA-105-N 24

25 FITTINGS: SA-234-WPB REPADS: NOTE 10 25

26 BOLTS SA-193-B7M / SA-194-2HM GASKETS: NOTE 4 26

27 STRUCT: PER STRUCTURAL SPEC INTERNALS: SA-516-70-N 27

28 OTHER: - OTHER: - 28

29 INSULATION: MINERAL WOOL THK (mm) 64 EXTENT: ALL 29

30 CLADDING: ALUMINUM THK (mm) PER SPEC FIREPROOF: NO 30

31 TRACING: YES TYPE: EHT EXTENT: NOTE 16 31

32 SPECIFICATIONS: NOTE 18 32

33 DRAWINGS: 33

34 34

35 SELLER TO FURNISH 35

36 SKIRT & BASE RING INLET NOZZLE DISTRIB TOP DAVIT 36

37 LEGS MIST ELIMINATOR MANWAY DAVIT 37

38 SADDLES MIST ELIMINATOR SUPP. MANWAY HINGE 38

39 PLATFORM CLIPS TRAY SUPPORT RINGS SAND BLASTING 39

40 PLATFORMS DOWNCOMER SUPP. PIPE COIL 40

41 LADDER CLIPS SUPPORT GRID ANCHOR BOLT CHAIRS 41

42 LADDERS SEAL PAN SUPPORT ANC. BOLT TEMPLATE 42

43 INSULATION RINGS INTERNAL LADDER RUNGS / GRAB RUNGS 43

44 INSULATION CLIPS SPECIAL NOZZLE BKRS: 44

45 FIREPROOFING CLIPS VORTEX BREAKERS: 45

46 PIPE SUPPORT CLIPS SYPHON DRAINS: 46

47 PIPE SUPPORTS BLIND FLANGES: 47

48 LIFTING LUG / TRUNNION EXTERNAL PAINTING 48

49 TAILING LUG EXTERNAL COATING 49

50 GROUND LUG (2 #s) INTERNAL COATING 50 0

51 NAME PLATE OTHER: 51 0

52 INTERNALS: INLET DEFLECTOR (SEE NOTES & SKETCH) 52

53 53

54 54

55 CONNECTION SCHEDULE NOTES REV DATE REVISION BY CHK PRO APP OTH 55

56 MARK NO. DESCRIPTION SIZE RATING TYPE 1. " * " INDICATES THAT VENDOR SHALL PROVIDE, CONFIRM OR MODIFY THE CONTENT. A 3/1/2012 ISSUED FOR QUOTATION NSB RL PC PP KG 56

57 N1 1 INLET 20" 150# RF 2. ALL EDGES PREPARED FOR PRESSURE BOUNDARY WELDING SHALL BE 100% MT EXAMINED. 0 6/22/2012 ISSUED FOR PURCHASE NSB RL PC PP KG 57 0

58 N2 1 VAPOR OUTLET 8" 150# RF 3. SEISMIC, WIND LOAD AND SNOW LOAD DESIGN SHALL BE IN ACCORDANCE WITH ABC 2006. 58

59 N3 1 LIQUID OUTLET / DRAIN 16" 300# RF 4. GASKETS SHALL BE 1/8" THK, 316 SS SPIRAL WOUND WITH GRAPHITE FILLER. 59

60 N4 1 TEMPERATURE GAUGE 2" 300# RFLWN 5. THE KNUCKLE AREA OF THE HEAD AFTER FORMING SHALL BE 100% MT EXAMINED. 60

61 N5 A/B 2 PRESSURE TRANSMITTER 2" 300# RFLWN 6. 100% WFMT / MT ON ALL INTERNAL AND EXTERNAL ARC STRIKE AREAS, TEMPORARY ATTACHMENT REMOVAL AREAS, AND REPAIR WELDS AFTER GRINDING. JCI PROJECT: CE4160 61

62 N6 1 PRESSURE GAUGE 2" 300# RFLWN 7. NOZZLES / MANWAYS SHALL BE INSTALLED WITH THE INSIDE GROUND FLUSH WITH THE VESSELS INSIDE SURFACE. CORNER RADIUS SHOULD BE MIN 1/8". REQ. NO.: CE4160-M-25-04-00014 62

63 N7 A/B 2 LEVEL TRANSMITTER 4" 300# RF 8. ALL INTERNAL ATTACHMENT WELDS TO THE PRESSURE BOUNDARY SHALL BE FULL PENETRATION. PROPOSAL: 63

64 N8 1 MIN FLOW BYPASS (NOTE 17) 8" 300# RF 9. THE VESSEL SHALL BE DESIGNED FOR FULL LIQUID CONDITION. CLIENT: CNRL 64

65 N9 1 TEMPERATURE TRANSMITTER 2" 300# RFLWN 10. REPADS ARE NOT PERMITTED FOR THE NOZZLE / MANWAY REINFORCEMENT. SELF-REINFORCEMENT TYPE NOZZLES SHALL BE USED LOCATION: CONKLIN, AB 65

66 N10 1 SPARE (c/w BLIND) 6" 150# RF 11. 100% RT IS REQUIRED FOR ALL BUTT WELDS AFTER PWHT. 100% UT IS REQUIRED FOR ALL CAT D JOINTS AFTER PWHT. PROJECT: KIRBY NORTH PHASE 1 66

67 N11 1 STEAM OUT 2" 150# RFLWN 12. THE VESSEL IS IN WET H2S SERVICE. MATERIALS AND FABRICATION OF COMPONENTS WHICH CONTACT PROCESS FLUID SHALL COMPLY WITH KBP-SPEC-WM-102 AND CLIENT NO.: 67

68 N12 1 RELIEF 3" 150# RF NACE MR0175 / ISO 15156-2009 AND ITS ASSOCIATED TECHNICAL CIRCULARS AND CORRIGENDA. PWHT IS REQUIRED. UNIT: 68 0

69 N13 1 BLANKET GAS 2" 150# RFLWN 13. DETAILS ON INLET BAFFLE WILL BE FINALIZED IN DETAILED ENGINEERING. AREA: OIL TREATING 69 0

70 N14 A/B 2 LEVEL TRANSMITTER 4" 300# RF 14. WFMT IS REQUIRED AFTER PWHT ON ALL INTERNAL SURFACES OF ATTACHMENT WELDS TO THE PRESSURE BOUNDARY AND PRESSURE RETAINING WELDS. NAME / SERVICE 70

71 15. 100% MT IS REQUIRED FOR THE WELDS OF LIFTING DEVICES AFTER PWHT. 100% MT IS REQUIRED FOR THE OUTSIDE OF CAT D WELDS AFTER PWHT. 71

72 M1 1 MANWAY (c/w DAVIT AND BLIND) 24" 150# RF 16. INSTALLATION OF THE ELECTRICAL HEAT TRACING IS IN VESSEL VENDOR'S SCOPE. (DESIGN, SUPPLY AND ENGINEERING WILL BE DONE BY OTHERS) GAS BOOT 72

73 - MAINTAIN PROCESS TEMPERATURE OF: 20 °C . TAG NO. 73

74 SV 1-4 4 SKIRT VENT 4" - UP TO 5500m FROM VESSEL BOTTOM TAN LINE 74

75 SA 1/2 2 SKIRT ACCESS 24" 17. NOZZLE N8 ELEVATION SHALL BE BELOW LEVEL LLL (EL +3290). 101-V-190 75

76 SO 1 SKIRT OPENING 30" DOCUMENT NO. REV. 76

77 SEE NOTES CONTINUED ON PAGE 2 77 0

78 KNP-DS-M-101-V-190 0 78

SHEET 1 OF 2

¤ IFP - REV 0 - 7/3/2012 ¤

1 1

2 2

3 3

4 4

5 NOTES CONTINUED FROM PAGE 1: 5

6 18. FOR APPLICABLE SPECIFICATIONS & STANDARDS REFER CE4160-M-25-04-00014, MR SECTION-2. 6 0

7 19. DESIGN OF ANCHOR BOLT DIAMETER SHALL BE BASED ON ASTM A 307 GRADE A / ASTM F 1554 GRADE 36 CLASS 2A RODS. 7 0

8 8 0

9 9 0

10 10 0

11 11 0

12 12 0

13 13 0

14 14 0

15 15 0

16 16 0

17 17

18 18

19 19

20 20

21 21

22 22

23 23

24 24

25 25

26 26

27 27

28 28

29 29

30 30

31 31

32 32

33 33

34 34

35 35

36 36

37 37

38 38

39 39

40 40

41 41

42 42

43 43

44 44

45 45

46 46

47 47

48 48

49 49

50 50

51 51

52 52

53 53

54 54

55 55

56 56

57 57

58 58

59 59

60 60

61 61

62 62

63 63

64 64

65 65

66 66

67 67

68 68

69 69

70 NAME / SERVICE 70

71 71

72 GAS BOOT 72

73 TAG NO. 73

74 74

75 101-V-190 75

76 DOCUMENT NO. REV. 76

77 77

78 KNP-DS-M-101-V-190 0 78

SHEET 2 OF 2

¤ IFP - REV 0 - 7/3/2012 ¤

Das könnte Ihnen auch gefallen

- Technical Specs - Rev01Dokument109 SeitenTechnical Specs - Rev01Marcos Verissimo Juca de PaulaNoch keine Bewertungen

- Valve Materials DetailsDokument15 SeitenValve Materials DetailsKasthuri Rangan KNoch keine Bewertungen

- Vessel DesignDokument14 SeitenVessel DesignElia MekdadNoch keine Bewertungen

- Design Recommendation For Screw Machine ProductsDokument23 SeitenDesign Recommendation For Screw Machine Productsashwin josephNoch keine Bewertungen

- Smith Meter VDR Vertical Deaerator SpecificationsDokument8 SeitenSmith Meter VDR Vertical Deaerator SpecificationsClarkFedele27Noch keine Bewertungen

- GH CatalogueDokument95 SeitenGH CatalogueMiroslav AleksicNoch keine Bewertungen

- Ball Valves - Metal SeatedDokument6 SeitenBall Valves - Metal Seatedmetasoniko2014Noch keine Bewertungen

- SeriesDokument4 SeitenSeriesteguheafNoch keine Bewertungen

- SeparatorDokument8 SeitenSeparatorIra Purnama SariNoch keine Bewertungen

- Data Sheet WB RU VDokument5 SeitenData Sheet WB RU VMaharani Putri IndrianurNoch keine Bewertungen

- Tender Specification - Sea WaterDokument12 SeitenTender Specification - Sea WaterSuhas NatuNoch keine Bewertungen

- Design Rule Asme Sec Viii Div 2Dokument2 SeitenDesign Rule Asme Sec Viii Div 2Malathy RajaNoch keine Bewertungen

- Booking Ticket For BusDokument54 SeitenBooking Ticket For BusJaga Nathan50% (2)

- QCDC - Hydraulic and Manual Quick Connect/Disconnect Couplers For Marine Loading ArmsDokument2 SeitenQCDC - Hydraulic and Manual Quick Connect/Disconnect Couplers For Marine Loading ArmsVasudev ShanmughanNoch keine Bewertungen

- Jsa For Roof Air LiftDokument2 SeitenJsa For Roof Air LiftKoshy Thankachen100% (1)

- Aesseal Capi Dual SealDokument2 SeitenAesseal Capi Dual SealSulaiman Kadher KNoch keine Bewertungen

- Tombo - Gasket - Genetal CatalogDokument117 SeitenTombo - Gasket - Genetal CatalogAnh CaoNoch keine Bewertungen

- Guideline For Technical Regulation: Design of Thermal Power Facilities Book 7/12 Liquefied Gas Handling FacilityDokument117 SeitenGuideline For Technical Regulation: Design of Thermal Power Facilities Book 7/12 Liquefied Gas Handling Facilityshahjada100% (1)

- Belzona 1831 Instruction For UseDokument2 SeitenBelzona 1831 Instruction For UseshambhoiNoch keine Bewertungen

- Lubrication, Shaft-Sealing and Control Oil Systems and Auxiliaries For Petroleum, Chemical and Gas Industry Services (Amendments/Supplements To Api 614)Dokument33 SeitenLubrication, Shaft-Sealing and Control Oil Systems and Auxiliaries For Petroleum, Chemical and Gas Industry Services (Amendments/Supplements To Api 614)fpiccoli_4Noch keine Bewertungen

- Shaft Design: Design Against Static LoadingDokument6 SeitenShaft Design: Design Against Static Loadingakshat singhNoch keine Bewertungen

- Flare Gas Recovery Using Gas EjectorDokument8 SeitenFlare Gas Recovery Using Gas Ejectoremmanuel limaNoch keine Bewertungen

- MODELS 4, 6, 8 High-Capacity Strainers and FiltersDokument6 SeitenMODELS 4, 6, 8 High-Capacity Strainers and Filterspeter2mNoch keine Bewertungen

- Renderoc TGDokument2 SeitenRenderoc TGMansoor Ali50% (2)

- Balmoral Bunded Tank InstallationDokument4 SeitenBalmoral Bunded Tank InstallationAlberto DiazNoch keine Bewertungen

- Car Washer CatalogueDokument24 SeitenCar Washer Cataloguesra electricalsNoch keine Bewertungen

- Roof Air Rising of An Ammonia Storage Tank at KPICDokument12 SeitenRoof Air Rising of An Ammonia Storage Tank at KPICHgagselim Selim100% (1)

- 2.0 Pressure TestingDokument11 Seiten2.0 Pressure TestingHATEMNoch keine Bewertungen

- Gas LiftDokument12 SeitenGas LiftLulav BarwaryNoch keine Bewertungen

- SBC (Safety Break-Away Couplings) v140630Dokument16 SeitenSBC (Safety Break-Away Couplings) v140630Robert Villavicencio0% (1)

- Pds Tial m80Dokument2 SeitenPds Tial m80Yan FerizalNoch keine Bewertungen

- Preservation by NitrogenDokument3 SeitenPreservation by NitrogenHesham badawy50% (2)

- E07 QDokument20 SeitenE07 QSoledad Fernández SantosNoch keine Bewertungen

- Pump Sizing Fire Hydrant MojoDokument2 SeitenPump Sizing Fire Hydrant MojoAnonymous 6S9tcbhNoch keine Bewertungen

- (Chemical Injection System) - Operation and Maintenance ManualDokument19 Seiten(Chemical Injection System) - Operation and Maintenance Manualasri elektronikNoch keine Bewertungen

- Classes and Comparisons Between CompressorsDokument48 SeitenClasses and Comparisons Between CompressorsVijay MeenaNoch keine Bewertungen

- Astm B 163-08Dokument12 SeitenAstm B 163-08Ramsi AnkziNoch keine Bewertungen

- Digital Pipeline Leak Detection: Remote MonitoringDokument3 SeitenDigital Pipeline Leak Detection: Remote MonitoringSARFRAZ ALINoch keine Bewertungen

- Konveyor RantaiDokument91 SeitenKonveyor Rantaiabdulloh_99Noch keine Bewertungen

- PolykenDokument7 SeitenPolykenJanllo83Noch keine Bewertungen

- S.V Reg. in Asme TDP 1, Asme Sec 1, b31.1Dokument9 SeitenS.V Reg. in Asme TDP 1, Asme Sec 1, b31.1K.S.MAYILVAGHANANNoch keine Bewertungen

- Bi-Di PigDokument1 SeiteBi-Di PigrobyharyudhaNoch keine Bewertungen

- 1.0 J1415 QF200-2 PSA DatasheetDokument2 Seiten1.0 J1415 QF200-2 PSA DatasheetCarlos MagNoch keine Bewertungen

- Stiffening Rings EvaluationDokument4 SeitenStiffening Rings EvaluationHomer SilvaNoch keine Bewertungen

- Distillation Column Tray Selection & Sizing - 1 - Separation TechnologiesDokument18 SeitenDistillation Column Tray Selection & Sizing - 1 - Separation TechnologiesOmesh Borole100% (1)

- Datasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDokument4 SeitenDatasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDylan RamasamyNoch keine Bewertungen

- Actuator Maintenance ServicesDokument7 SeitenActuator Maintenance ServicesKevin MuhalingNoch keine Bewertungen

- 03 Metal Packing Support PlatesDokument3 Seiten03 Metal Packing Support PlatesypatelsNoch keine Bewertungen

- Storage Tank Data SheetDokument2 SeitenStorage Tank Data SheetsandyaNoch keine Bewertungen

- CPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingDokument18 SeitenCPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingAdil Ijaz100% (1)

- Steam Separator and Steam Trap Are Almost Same in FunctionDokument7 SeitenSteam Separator and Steam Trap Are Almost Same in FunctionTHEOPHILUS ATO FLETCHERNoch keine Bewertungen

- ES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Dokument10 SeitenES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Nikki RobertsNoch keine Bewertungen

- Topic API 676 Pump Nozzle LoadsDokument2 SeitenTopic API 676 Pump Nozzle LoadsAshok KumarNoch keine Bewertungen

- Atbq1714 Measurement I: Piling WorksDokument24 SeitenAtbq1714 Measurement I: Piling WorksJIE YI CHENNoch keine Bewertungen

- Dry Bulk Storage Tank SpecificationDokument7 SeitenDry Bulk Storage Tank SpecificationMohamed Mostafa IbrahimNoch keine Bewertungen

- Bourdon Sensing Pressure GaugeDokument2 SeitenBourdon Sensing Pressure GaugeJitendra BhosaleNoch keine Bewertungen

- Spark Gaps: Dehn (Uk) LTDDokument8 SeitenSpark Gaps: Dehn (Uk) LTDElectromacnetist ElectrodNoch keine Bewertungen

- Screening Reactor For Water HammerDokument49 SeitenScreening Reactor For Water HammerYu GanNoch keine Bewertungen

- Sample Seal Pot DWGDokument1 SeiteSample Seal Pot DWGsandesh sadvilkarNoch keine Bewertungen

- Sample Seal Pot DWGDokument1 SeiteSample Seal Pot DWGsandesh sadvilkarNoch keine Bewertungen

- 12 PDMS PML Manual 1 PDFDokument2 Seiten12 PDMS PML Manual 1 PDF124swadeshiNoch keine Bewertungen

- Covid-19 Q&ADokument10 SeitenCovid-19 Q&AAjay_mane22Noch keine Bewertungen

- Utensils Stainless Steel: Profile No.: 133 NIC Code:25994Dokument10 SeitenUtensils Stainless Steel: Profile No.: 133 NIC Code:25994124swadeshiNoch keine Bewertungen

- IOS Base APP DevelopmentDokument9 SeitenIOS Base APP Development124swadeshiNoch keine Bewertungen

- Covid-19 Q&ADokument10 SeitenCovid-19 Q&AAjay_mane22Noch keine Bewertungen

- PD107 - Piperack For P&CDokument50 SeitenPD107 - Piperack For P&C124swadeshiNoch keine Bewertungen

- Hot Air Dry VegetablesDokument12 SeitenHot Air Dry Vegetables124swadeshiNoch keine Bewertungen

- Papaya Proteinase EnzymeDokument7 SeitenPapaya Proteinase Enzyme124swadeshiNoch keine Bewertungen

- Ginger, Garlic & Onion PastesDokument13 SeitenGinger, Garlic & Onion Pastes124swadeshiNoch keine Bewertungen

- Solar Items: Profile No.: 230 NIC Code:26105Dokument11 SeitenSolar Items: Profile No.: 230 NIC Code:26105124swadeshiNoch keine Bewertungen

- Mini Rice MillDokument14 SeitenMini Rice Mill124swadeshiNoch keine Bewertungen

- Cyber Cafe and Back Office ServicesDokument11 SeitenCyber Cafe and Back Office Services124swadeshi0% (1)

- Hot Air Dry VegetablesDokument12 SeitenHot Air Dry Vegetables124swadeshiNoch keine Bewertungen

- Public E-Learning PortalDokument11 SeitenPublic E-Learning Portal124swadeshiNoch keine Bewertungen

- Cryogenic Grining of SpicesDokument12 SeitenCryogenic Grining of Spices124swadeshiNoch keine Bewertungen

- Ready-To Serve Drinks & Soft Drinks With CO2Dokument12 SeitenReady-To Serve Drinks & Soft Drinks With CO2124swadeshiNoch keine Bewertungen

- National Institute of Micro, Small and Medium Enterprises (Ni-Msme) (An Organisation of Ministry of MSME, Govt. of India)Dokument18 SeitenNational Institute of Micro, Small and Medium Enterprises (Ni-Msme) (An Organisation of Ministry of MSME, Govt. of India)124swadeshiNoch keine Bewertungen

- Papaya Proteinase EnzymeDokument7 SeitenPapaya Proteinase Enzyme124swadeshiNoch keine Bewertungen

- Seasonings For Snacks: Profile No.: 203 NIC Code:10614Dokument13 SeitenSeasonings For Snacks: Profile No.: 203 NIC Code:10614124swadeshiNoch keine Bewertungen

- Ready-To Serve Drinks & Soft Drinks With CO2Dokument12 SeitenReady-To Serve Drinks & Soft Drinks With CO2124swadeshiNoch keine Bewertungen

- PCB & MountingsDokument11 SeitenPCB & Mountings124swadeshiNoch keine Bewertungen

- Confectionery High Boiled ToffeesDokument7 SeitenConfectionery High Boiled Toffees124swadeshiNoch keine Bewertungen

- Portable Water FiltersDokument10 SeitenPortable Water Filters124swadeshiNoch keine Bewertungen

- Service & Support For IT or AutomationDokument12 SeitenService & Support For IT or Automation124swadeshiNoch keine Bewertungen

- Extruded Pellets From Maida For FryingDokument14 SeitenExtruded Pellets From Maida For Frying124swadeshiNoch keine Bewertungen

- E Retail Outlet For GarmentsDokument11 SeitenE Retail Outlet For GarmentsAEBEE SIMONNoch keine Bewertungen

- Full PVC FootwearDokument13 SeitenFull PVC Footwear124swadeshiNoch keine Bewertungen

- Ladies Gowns & NightyDokument8 SeitenLadies Gowns & Nighty124swadeshiNoch keine Bewertungen

- Confectionery High Boiled ToffeesDokument7 SeitenConfectionery High Boiled Toffees124swadeshiNoch keine Bewertungen

- Effect of W/C Ratio On Self Compacting Concrete of M70 Grade With Fly Ash and Micro Silica As Filler MaterialDokument76 SeitenEffect of W/C Ratio On Self Compacting Concrete of M70 Grade With Fly Ash and Micro Silica As Filler MaterialbenhasidNoch keine Bewertungen

- ACTI-PLUS® 2818: Safety Data SheetDokument12 SeitenACTI-PLUS® 2818: Safety Data SheetCharbel WannesNoch keine Bewertungen

- J.ultsonch.2014.08.022 InglesDokument48 SeitenJ.ultsonch.2014.08.022 InglesBrayan LuisNoch keine Bewertungen

- MasterCast 140Dokument4 SeitenMasterCast 140robin rezkNoch keine Bewertungen

- REPORTDokument31 SeitenREPORTUnique Boss50% (2)

- Valves SpecificationDokument13 SeitenValves Specificationkselvan_1Noch keine Bewertungen

- Air Conditioning EquipmentsDokument31 SeitenAir Conditioning EquipmentsamarparimiNoch keine Bewertungen

- Antinociceptive Activity of Buddleja Globosa (Matico)Dokument6 SeitenAntinociceptive Activity of Buddleja Globosa (Matico)alinumlNoch keine Bewertungen

- Type of Chemical ReactionsDokument13 SeitenType of Chemical ReactionsSAHARAN ANANDNoch keine Bewertungen

- 12345Dokument1 Seite12345Praveen KumarNoch keine Bewertungen

- Nafees Nastaleeq v1.02Dokument2 SeitenNafees Nastaleeq v1.02latifshaikh20Noch keine Bewertungen

- Thermo Scientific Taq Dna Polymerase With KCL Buffer: DescriptionDokument3 SeitenThermo Scientific Taq Dna Polymerase With KCL Buffer: DescriptionCHIRANJEEVINoch keine Bewertungen

- 6.0 Biology Lab ManualDokument49 Seiten6.0 Biology Lab ManualJacob SmithNoch keine Bewertungen

- Electrozincados en 10152 (2009)Dokument18 SeitenElectrozincados en 10152 (2009)joaopedrosousaNoch keine Bewertungen

- Specification For General Requirements For Steel Plates For Pressure VesselsDokument34 SeitenSpecification For General Requirements For Steel Plates For Pressure Vesselsedisson_barreraNoch keine Bewertungen

- Masel Catalog - WiresDokument30 SeitenMasel Catalog - WiresOrtho OrganizersNoch keine Bewertungen

- Filtration of AluminiumDokument218 SeitenFiltration of AluminiumNico Agung NugrahaNoch keine Bewertungen

- Chromatography PharmacyDokument41 SeitenChromatography PharmacyfarisaNoch keine Bewertungen

- Valuable CattleDokument2 SeitenValuable CattleGurmeet BrarNoch keine Bewertungen

- Netting Analysis of Composite Pressure VesselsDokument3 SeitenNetting Analysis of Composite Pressure VesselsPratyu Ch100% (1)

- Biocomposites Guide PDFDokument40 SeitenBiocomposites Guide PDFShirah CoolNoch keine Bewertungen

- Work Instructions (W.I.)Dokument18 SeitenWork Instructions (W.I.)Shamsul Azhar MohdNoch keine Bewertungen

- Handbook of Carbon Nanotubes Polymer NanDokument182 SeitenHandbook of Carbon Nanotubes Polymer NanMario Allesina JuniorNoch keine Bewertungen

- Ammonia Shift Engineer Logbook: Front End Staff: BackDokument2 SeitenAmmonia Shift Engineer Logbook: Front End Staff: BackjolymolyNoch keine Bewertungen

- 160 81-Nom2 PDFDokument76 Seiten160 81-Nom2 PDFAlexander Ruiz PerezNoch keine Bewertungen

- Airopac - Camfill Pre FilterDokument1 SeiteAiropac - Camfill Pre Filtersinu waskithoNoch keine Bewertungen

- (En GB) DBE 821 - 1.00Dokument7 Seiten(En GB) DBE 821 - 1.00Enio Miguel Cano LimaNoch keine Bewertungen

- Paradip Refinery Project Write UpDokument25 SeitenParadip Refinery Project Write UpHarsha Jayaram100% (3)

- Plumbing Notes 1 PDFDokument57 SeitenPlumbing Notes 1 PDFhoneyvie53% (15)

- Lecture 3 GlycosidesDokument18 SeitenLecture 3 Glycosidessami ullahNoch keine Bewertungen