Beruflich Dokumente

Kultur Dokumente

TDS Chesterton 783 ACR en

Hochgeladen von

nghiaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TDS Chesterton 783 ACR en

Hochgeladen von

nghiaCopyright:

Verfügbare Formate

783 ACR

PRODUCT DATA SHEET

KEY FEATURES AND BENEFITS DESCRIPTION

• No toxic heavy metals Chesterton® 783 ACR represents

• Waterproof the newest generation of anti-seize

compound. A proprietary blend of

• Ultra-fine particles

ultra-fine inorganic solid lubricants,

• Broad service temperature range 783 ACR can be used under extremely

APPLICATION AREAS • Corrosion resistant severe conditions of temperature and

• For extreme pressure - up to 8928 kg/cm2 pressure to assist in assembly and

• Bolts disassembly of threaded components.

(126,983 psi)

• Screws Because the particles are ultra-fine, they

• Usable under most extreme conditions spread evenly and fill surface profiles

• Press Fits PACKAGING to prevent metal to metal contact and

insure thorough coverage. Chesterton

• Pipe Threads 250g Brush Top 783 ACR protects assembled parts

500g Brush Top against corrosion and presents a barrier

• Pump Sleeves 20L to the corrosive effects of moisture,

steam, salt water, high temperatures

DIRECTIONS and corrosive chemicals. In a standard

Treat all threaded or press-fit parts before corrosion test, ASTM B-117, 783

joining to make assembly and disassembly provides 20 times longer rust protection

easier. Surfaces should be free of dirt, oil, than conventional anti-seize products.

grease, etc. Apply liberally to mating In resistance to water wash off, 783 can

surfaces. be considered virtually waterproof. The

result is long term performance even in

difficult environments such as marine,

chemical plants, or metals refining.

TYPICAL PHYSICAL PROPERTIES

Appearance Light gray

NLGI Grade (ASTM D 217, DIN 51 518) 2

Texture Soft paste

Specific Gravity 1.33 kg/l

Average Particle Size < 11 microns

Extreme Pressure (ASTM D 2596, DIN 51 530) 8928 kg/cm2 (126,983 psi)

Dropping Point (ASTM D 566, ISO 2176) >288°C (550°F)

Operating Temperature -34°C to 900°C (-30°F to 1650°F)

Coeffecient of Friction "K" Factor (Skidmore-Wilhelm Method) 0.160

Corrosion Resistance (ASTM B 117) 5% NaCl >1200 hrs @ 100 microns

Copper Corrosion (ASTM D 130, DIN 51 811) 100°C (212°F) 2A, 24 hrs.

Water Washout (ASTM D 1265) 79C (175°F) <0.13%

Penetration (ASTM D 217, ISO 2137) 270

Weld Point (ASTM 2596, DIN 51 350) >800 kfg

Load Wear Index (ASTM 2596, DIN 51 350) 168.7

Before using this product, please refer to Safety Data Sheet (SDS).

Technical information continues on page 2

783 ACR

Maximum Bolt Service Temperatures*

General Classification "ASTM" Symbols "JIS" Symbols Max. Service Temperature

Mild Steel G3101-SS41 260°C (500°F)

Carbon Steel A307-B G4051-S250 420°C (788°F)

5Cr-1/2Mo A193-B5 G41407-SNB5 600°C (1112°F)

1Cr-1/5Mo A193-B7 G41407-SNB7 550°C (1022°F)

Cr-Mo-VA A193-B16 G41407-SNB16 600°C (1112°F)

18Cr-8Ni A196-B8 G4303-SUS304 800°C (1472°F)

18Cr-10Ni-Cb A193-B8C G4303-SUS347 800°C (1472°F)

18Cr-10Ni-Ti A193-B8T G4303-SUS321 800°C (1472°F)

18Cr-12Ni-2Mo A193-B8M G4303-SUS316 800°C (1472°F)

15Cr-25Ni-Mo-Ti-V-B A453-600 540°C (1004°F)

*Use of threaded pastes will not extend service temperature of fasteners/bolts. Consult bolting supplier for proper temperature and tension limits.

860 Salem Street, Groveland, MA 01834 USA Technical Data reflects results of laboratory tests and is intended to indicate general characteristics only. Since many actual

978-469-6888 www.chesterton.com application circumstances are beyond Chesterton's knowledge and/or control, the product user must determine the suitability

© 2018 A.W. Chesterton Company of the products it intends to use for its particular purpose and assume all risks and liabilities in connection therewith.

® Registered trademark owned by A.W. Chesterton CHESTERTON DISCLAIMS ALL WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND

Company in USA and other countries, unless FITNESS FOR A PARTICULAR PURPOSE.

otherwise noted. Form No. 071603 1/18

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Con-Tech Service Manual Rev 1 - 3 Xe Bon TronDokument379 SeitenCon-Tech Service Manual Rev 1 - 3 Xe Bon Tronnghia100% (1)

- TDS - Idemitsu Transformer Oil G - ENDokument2 SeitenTDS - Idemitsu Transformer Oil G - ENnghiaNoch keine Bewertungen

- Postoperative Care in Thoracic Surgery A Comprehensive GuideDokument397 SeitenPostoperative Care in Thoracic Surgery A Comprehensive GuideΑΘΑΝΑΣΙΟΣ ΚΟΥΤΟΥΚΤΣΗΣ100% (1)

- Abccomp Corporate Brochure EnglishDokument12 SeitenAbccomp Corporate Brochure EnglishnghiaNoch keine Bewertungen

- High Pressure CompressorsDokument16 SeitenHigh Pressure CompressorsnghiaNoch keine Bewertungen

- Pet Compressors: Reliable Beyond LimitsDokument14 SeitenPet Compressors: Reliable Beyond LimitsnghiaNoch keine Bewertungen

- Art No Shell Retinax LX 2Dokument1 SeiteArt No Shell Retinax LX 2nghiaNoch keine Bewertungen

- Guidelines For Proprietary Substances and Nonfood Compounds (2004), Which Are Available atDokument1 SeiteGuidelines For Proprietary Substances and Nonfood Compounds (2004), Which Are Available atnghiaNoch keine Bewertungen

- ArChine-Food-Grade-Lubricants - eDokument53 SeitenArChine-Food-Grade-Lubricants - enghiaNoch keine Bewertungen

- Pet-High Pressure Low Pressure: ReliableDokument14 SeitenPet-High Pressure Low Pressure: ReliablenghiaNoch keine Bewertungen

- MSDS - Caltex Clarity Hydraulic Oil AW 100 - ENDokument8 SeitenMSDS - Caltex Clarity Hydraulic Oil AW 100 - ENnghiaNoch keine Bewertungen

- Brugarolas Food Industry CatalogueDokument4 SeitenBrugarolas Food Industry CataloguenghiaNoch keine Bewertungen

- Dromus BX: Water Miscible Metalworking FluidDokument1 SeiteDromus BX: Water Miscible Metalworking FluidnghiaNoch keine Bewertungen

- MSDS - Caltex Canopus 32 - ENDokument7 SeitenMSDS - Caltex Canopus 32 - ENnghiaNoch keine Bewertungen

- TDS - Motul VIS 46 - ENDokument2 SeitenTDS - Motul VIS 46 - ENnghiaNoch keine Bewertungen

- BA - Linestar - 9000 - Kanal - en - IX-2014 (0) Operating Manual Bauer OEM Recommended OilDokument113 SeitenBA - Linestar - 9000 - Kanal - en - IX-2014 (0) Operating Manual Bauer OEM Recommended OilnghiaNoch keine Bewertungen

- Wire Rope Lubrication System Dat Viet CoDokument4 SeitenWire Rope Lubrication System Dat Viet ConghiaNoch keine Bewertungen

- Lubricants Miscibility MatrixDokument1 SeiteLubricants Miscibility MatrixnghiaNoch keine Bewertungen

- Material Safety Data Sheet - Reach' 1907/2006: Cas Number Product Name Content Symbols R PhrasesDokument4 SeitenMaterial Safety Data Sheet - Reach' 1907/2006: Cas Number Product Name Content Symbols R PhrasesnghiaNoch keine Bewertungen

- Isoflex Topas Nca 52: Product InformationDokument2 SeitenIsoflex Topas Nca 52: Product InformationnghiaNoch keine Bewertungen

- MSDS - Caltex Brake and Clutch Fluid DOT 3 - ENDokument8 SeitenMSDS - Caltex Brake and Clutch Fluid DOT 3 - ENnghiaNoch keine Bewertungen

- Shell GadusRail S2 PDFDokument2 SeitenShell GadusRail S2 PDFnghiaNoch keine Bewertungen

- MSDS - Asada Threading Oiil Red - ENDokument7 SeitenMSDS - Asada Threading Oiil Red - ENnghiaNoch keine Bewertungen

- Check&your&systems&oil& Contamina2on! &200&barDokument1 SeiteCheck&your&systems&oil& Contamina2on! &200&barnghiaNoch keine Bewertungen

- Total Rubia S 10WDokument1 SeiteTotal Rubia S 10WnghiaNoch keine Bewertungen

- Okamoto Precision Surface Grinding Machine 1624n 1632n BrochureDokument12 SeitenOkamoto Precision Surface Grinding Machine 1624n 1632n BrochurenghiaNoch keine Bewertungen

- MSDS OmegaDokument10 SeitenMSDS OmeganghiaNoch keine Bewertungen

- Grease SLL 00Dokument1 SeiteGrease SLL 00nghiaNoch keine Bewertungen

- TDS - Shell Irus C - ENDokument2 SeitenTDS - Shell Irus C - ENnghiaNoch keine Bewertungen

- 2018.11.25 Grease Book FuchsDokument18 Seiten2018.11.25 Grease Book FuchsnghiaNoch keine Bewertungen

- A V N 2 0 0 0 9 Airspace Management and Air Traffic Services Assignment 1Dokument2 SeitenA V N 2 0 0 0 9 Airspace Management and Air Traffic Services Assignment 1Tanzim Islam KhanNoch keine Bewertungen

- Careerride Com Electrical Engineering Interview Questions AsDokument21 SeitenCareerride Com Electrical Engineering Interview Questions AsAbhayRajSinghNoch keine Bewertungen

- CFPB Discount Points Guidence PDFDokument3 SeitenCFPB Discount Points Guidence PDFdzabranNoch keine Bewertungen

- Tetra Pak Training CatalogueDokument342 SeitenTetra Pak Training CatalogueElif UsluNoch keine Bewertungen

- Astm B633Dokument5 SeitenAstm B633nisha_khan100% (1)

- What To Do Following A Workplace AccidentDokument5 SeitenWhat To Do Following A Workplace AccidentMona DeldarNoch keine Bewertungen

- Hodgkin LymphomaDokument44 SeitenHodgkin LymphomaisnineNoch keine Bewertungen

- Energy Optimization of A Large Central Plant Chilled Water SystemDokument24 SeitenEnergy Optimization of A Large Central Plant Chilled Water Systemmuoi2002Noch keine Bewertungen

- Reverse Osmosis Desalination: Our Global Expertise To Address Water ScarcityDokument16 SeitenReverse Osmosis Desalination: Our Global Expertise To Address Water Scarcitynice guyNoch keine Bewertungen

- Proposed Child Right's Policy FrameworkDokument2 SeitenProposed Child Right's Policy FrameworkCrisDBNoch keine Bewertungen

- Tractor Price and Speci Cations: Tractors in IndiaDokument4 SeitenTractor Price and Speci Cations: Tractors in Indiatrupti kadamNoch keine Bewertungen

- OM Hospital NEFTDokument1 SeiteOM Hospital NEFTMahendra DahiyaNoch keine Bewertungen

- BKM 10e Ch07 Two Security ModelDokument2 SeitenBKM 10e Ch07 Two Security ModelJoe IammarinoNoch keine Bewertungen

- Removing Eyelid LesionsDokument4 SeitenRemoving Eyelid LesionsMohammad Abdullah BawtagNoch keine Bewertungen

- Tackling Food Inflation: Ashwinkumar Kokku - 67 Malcolm Pinto - 89 Samir Vele - Nitin JadhavDokument9 SeitenTackling Food Inflation: Ashwinkumar Kokku - 67 Malcolm Pinto - 89 Samir Vele - Nitin JadhavMalcolm PintoNoch keine Bewertungen

- Tuyet W3 Unit 2 Tenses Adverbial Clause of Time Zalo HSDokument16 SeitenTuyet W3 Unit 2 Tenses Adverbial Clause of Time Zalo HSVũ Thanh GiangNoch keine Bewertungen

- Metabolism of Carbohydrates and LipidsDokument7 SeitenMetabolism of Carbohydrates and LipidsKhazel CasimiroNoch keine Bewertungen

- Flores V PinedaDokument10 SeitenFlores V Pinedacha chaNoch keine Bewertungen

- RMP ContractDokument181 SeitenRMP ContractHillary AmistosoNoch keine Bewertungen

- Ventura 4 DLX ManualDokument36 SeitenVentura 4 DLX ManualRoland ErdőhegyiNoch keine Bewertungen

- Dissertation Topics Forensic BiologyDokument7 SeitenDissertation Topics Forensic BiologyHelpMeWriteMyPaperPortSaintLucie100% (1)

- ANATOMY 1 NILEM and Cat FISHDokument19 SeitenANATOMY 1 NILEM and Cat FISHAnisatul Khabibah ZaenNoch keine Bewertungen

- Sol. Mock Test CBSE BiologyDokument3 SeitenSol. Mock Test CBSE BiologysbarathiNoch keine Bewertungen

- Composite Restorations: Dr. Dina NouriDokument38 SeitenComposite Restorations: Dr. Dina NouriCatherine LoyolaNoch keine Bewertungen

- Fundamental Molecular Biology: GenomesDokument45 SeitenFundamental Molecular Biology: GenomesMoonHoLeeNoch keine Bewertungen

- List of Government Circuit Bungalow Nuwara EliyaDokument4 SeitenList of Government Circuit Bungalow Nuwara EliyaAsitha Kulasekera78% (9)

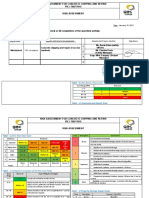

- Ra Concrete Chipping 7514Dokument5 SeitenRa Concrete Chipping 7514Charles DoriaNoch keine Bewertungen

- NURTURE Module-V 11 1 en PDFDokument4 SeitenNURTURE Module-V 11 1 en PDFJorge SingNoch keine Bewertungen

- Tcu Module Pe1 Lesson 1Dokument7 SeitenTcu Module Pe1 Lesson 1Remerata, ArcelynNoch keine Bewertungen