Beruflich Dokumente

Kultur Dokumente

Method Statement Form: Method Statement For Excavation / Dewatering of FGD (Chimney)

Hochgeladen von

poovazhaganOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Method Statement Form: Method Statement For Excavation / Dewatering of FGD (Chimney)

Hochgeladen von

poovazhaganCopyright:

Verfügbare Formate

METHOD STATEMENT FORM

1. Method Statement Particulars

Project: GEPIL,IGSTPP (3*500MW) MS No. 02 GEPIL/EHS/MS/BIL/02

Revision: 02 Date: 13.09.2019 Company: BYGGING INDIA COMPANY

2. Work Activity

Location of Activity (attach sketches as necessary): Excavation / Dewatering work at

FGD CHIMNEY- UNIT - 1 ,UNIT -2,

Activity Description:

Method statement For Excavation / Dewatering of FGD (Chimney)

Chimney – UNIT – 1, UNIT - 2

Commencement of Activity:

13.09.2019 Duration of Activity:

3. Responsible Supervisor(s) Present At Work Place

4. Subcontractor(S) - Where Applicable including Responsible Supervisor

5. Plant and Equipment Requiring Certification

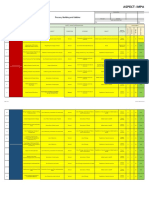

6. Special Precautions and Checklist

Equipment / Vehicle Pre- inspected.

Area should be Hard barricaded

Provide Flagman

Inspected work place to be ensure access/egress

METHOD STATEMENT FORM

Sump Systems

A Sump might be defined as, a pit in which water collects before being bailed or pumped

out. The pump suction will be dipped into a sump to remove the collected water.

By definition, a sump is at a low level in relation to surrounding ground surfaces so that

any water will flow to it due to gravity. For construction projects water is removed from

sump using suction pump.

Sump pumping is the most basic of the dewatering methods. In essence, It involves

allowing ground water to seep into the excavation, collecting it in sumps and then

pumping it away for disposal. Sumps are provided for two separate purposes, though the

form of a sump may be similar for either requirement.

To collect surface water run-off channeled to it by means of collector ditches or channels

for discharge to a disposal area.

To collect and discharge pumped water due to lowering of the groundwater for a shallow

excavation, also sump pumping may be required or gravity drainage to toe drains of

battered slopes.

The preferred method of disposal off water.

Collected in the sumps is by means of pumping. Pumps will be strategically located along

the excavation to achieve optimum system performance

METHOD STATEMENT FORM

Installation at site:

1. As mentioned in the attached plan firstly, the excavation will be started from the NGL-

224.886 to EL222.000 in slopes while maintaining 1.5m. Thereafter a bench of 1.000m

will be provided to count the collapsible condition of the sandy soil. Finally, the

excavation will be done in 1:1 slope from El-222.000 to the bed level of the PCC i.e.

EL-219.925m while maintaining the offset of clear safe working space of 950 mm.

2. First of all we have to excavate a drain around the periphery of chimney raft.

3. After excavation of drain we have to create a pit of size 2.000*2.000*1.000 m at the

south face of the plant connected through a peripheral drain of 250*250mm running

throughout the periphery of the chimney foundation with a clear offset of 200mm from

the edge of the PCC. This drain will be filled with 20 to 40mm aggregate to provide a

passage for seeping water to run through the channel and be collected in into the

collection sump.

4. This Pump will be connected to the discharge pipe connected to a suction pump

through which in turns delivers the water to nearby drain.

5. This procedure will continue till the completion of the chimney raft concreting.

6. While excavating the slopes care will be taken for the Absorber side with a safe

distance of 5.000m from the foundation edge.

METHOD STATEMENT FORM

SAFETY:

Work will be carried out in accordance with action safety documentation.

ENVIRONMENT PROTECTION:

Oil & Diesel Spillage:

Diesels and Oils shall be restricted within drip trays to prevent contamination of the sand.

Waste Oil:

Oil Disposal units to be situated on site. waste oil to be removed as and when required by an

approved contractor.

Sound Pollution:

All Diesel generators shall be silent pack units.

Das könnte Ihnen auch gefallen

- Jha For Batching Plant OprationDokument7 SeitenJha For Batching Plant Oprationpoovazhagan80% (5)

- RCC CHIMNEY METHOD STATEMENTDokument17 SeitenRCC CHIMNEY METHOD STATEMENTpoovazhagan100% (3)

- Excavation Permit FormDokument2 SeitenExcavation Permit FormKarim KachourNoch keine Bewertungen

- QPV-CV-PRM-PMP-016 - VB Transportation Management Plan During ConstructionDokument22 SeitenQPV-CV-PRM-PMP-016 - VB Transportation Management Plan During ConstructionMehwish Rehman Alvi100% (1)

- 013100.1 - CSI Form 1.5A Subcontractors and Major Material Suppliers ListDokument1 Seite013100.1 - CSI Form 1.5A Subcontractors and Major Material Suppliers ListWestmere Fire DistrictNoch keine Bewertungen

- DSTI Supervisors Daily Safet Task Instruction PDFDokument1 SeiteDSTI Supervisors Daily Safet Task Instruction PDFRicoNoch keine Bewertungen

- Catgt1501 PDFDokument432 SeitenCatgt1501 PDFrenatoeliegeNoch keine Bewertungen

- Method Statement For Cable Terminaton (CP3)Dokument20 SeitenMethod Statement For Cable Terminaton (CP3)Jacky TamNoch keine Bewertungen

- JHA Crosscut Saw Use & Maintenance - ROMODokument5 SeitenJHA Crosscut Saw Use & Maintenance - ROMORandy100% (1)

- Undergrad Practicum ProposalDokument4 SeitenUndergrad Practicum ProposalSimone aNoch keine Bewertungen

- MDLZ-RBIPL-MS-01-SITE MOBILIZATION WORK - UptdDokument21 SeitenMDLZ-RBIPL-MS-01-SITE MOBILIZATION WORK - Uptdshamshad ahamedNoch keine Bewertungen

- Role of Safety OfficerDokument12 SeitenRole of Safety OfficerJerry ConsorteNoch keine Bewertungen

- EHS 2-F8 PTW LiftingDokument2 SeitenEHS 2-F8 PTW LiftingLee Xiao YuNoch keine Bewertungen

- 08 Hirarc Form (r02)Dokument2 Seiten08 Hirarc Form (r02)Aizat Sera SuwandiNoch keine Bewertungen

- Method Statement for Hot WorkDokument5 SeitenMethod Statement for Hot WorkJeffersonDeGuiaNoch keine Bewertungen

- SCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift ProcedureDokument10 SeitenSCOPE:: Sacyr Medgulf Hse Management Systems Manual Crane Lift Procedureloveson709100% (1)

- Specification - Topographic and Plant Surveys SpecificationDokument4 SeitenSpecification - Topographic and Plant Surveys SpecificationAzhar AliNoch keine Bewertungen

- Environment Impact Assessment ReportDokument259 SeitenEnvironment Impact Assessment ReportPranav WalkhadeNoch keine Bewertungen

- Name: SignDokument1 SeiteName: SignAdel AlKhedawyNoch keine Bewertungen

- Learn SMAW Welding SafetyDokument49 SeitenLearn SMAW Welding SafetyEgghead YTCNoch keine Bewertungen

- NEOM-NPR-SOP-26 FRM001 Scaffolding Inspection ChecklistDokument3 SeitenNEOM-NPR-SOP-26 FRM001 Scaffolding Inspection Checklistmohamed.elsawaf100% (1)

- 43 Equipment Erection (Static and Rotary)Dokument5 Seiten43 Equipment Erection (Static and Rotary)Hamza DhariwalNoch keine Bewertungen

- Risk AssessmentDokument8 SeitenRisk Assessmentm.umarNoch keine Bewertungen

- Hazard Identification FormDokument1 SeiteHazard Identification Formabdulrazzaq hatem100% (1)

- All FormsDokument18 SeitenAll FormsSuhendraNoch keine Bewertungen

- Health, Safty & Environment SheduleDokument21 SeitenHealth, Safty & Environment SheduleEmmanuel ThomasNoch keine Bewertungen

- 1 45Dokument3 Seiten1 45nsadnan0% (1)

- Safety and Health ProgramsDokument21 SeitenSafety and Health ProgramsJason SunnyNoch keine Bewertungen

- GGC-HSEF 037 Site Daily ObservationDokument1 SeiteGGC-HSEF 037 Site Daily ObservationAmjadNoch keine Bewertungen

- JHA ANALYSIS SCALE REMOVAL VESSELDokument2 SeitenJHA ANALYSIS SCALE REMOVAL VESSELRiyadh SalehNoch keine Bewertungen

- P6022MAB.000.51S.001a01 - FDH JV Site HSE Organization ChartDokument1 SeiteP6022MAB.000.51S.001a01 - FDH JV Site HSE Organization ChartbabjihanumanthuNoch keine Bewertungen

- Safety, Health & EnvironmentDokument60 SeitenSafety, Health & EnvironmentGopalakrishnanNoch keine Bewertungen

- Weekly Equipment ChecklistDokument6 SeitenWeekly Equipment Checklistdickson abujaNoch keine Bewertungen

- COVID-19 Prevention PlanDokument12 SeitenCOVID-19 Prevention PlanZubair KhanNoch keine Bewertungen

- SOP 4 - Coal Bed Leveling in PGPDokument18 SeitenSOP 4 - Coal Bed Leveling in PGPfaraz ahmedNoch keine Bewertungen

- Climate Change Impact On Occupational Health and SafetyDokument31 SeitenClimate Change Impact On Occupational Health and Safetyarslan MaqboolNoch keine Bewertungen

- TCF 1 - Daily Safety Report 21-Aprl-2021Dokument4 SeitenTCF 1 - Daily Safety Report 21-Aprl-2021Muhammad TariqNoch keine Bewertungen

- Vaultex CatelogDokument218 SeitenVaultex Catelogprabu prasad0% (1)

- Glenbrook Rd. Demolition and Disposal PlanDokument56 SeitenGlenbrook Rd. Demolition and Disposal PlanBruno CarvalheiroNoch keine Bewertungen

- 012 Piling WorkDokument17 Seiten012 Piling WorkSarah HaiderNoch keine Bewertungen

- Construction Daily Report 03-10-2018Dokument3 SeitenConstruction Daily Report 03-10-2018Saddem HadfiNoch keine Bewertungen

- SWP Fire PumpDokument6 SeitenSWP Fire PumpbsynnottNoch keine Bewertungen

- Close-Out Report: A.I.S.E. Laundry Sustainability Project # 1 For Heavy Duty Low Suds Laundry Powder Detergents (LSP-1)Dokument8 SeitenClose-Out Report: A.I.S.E. Laundry Sustainability Project # 1 For Heavy Duty Low Suds Laundry Powder Detergents (LSP-1)Rutu PatelNoch keine Bewertungen

- CONST-PK-HSE FRM-38 Environmental Risk Assessment and Control FormDokument6 SeitenCONST-PK-HSE FRM-38 Environmental Risk Assessment and Control FormPerwez21Noch keine Bewertungen

- P2S Hse Audit: Form 000.653.F0272 Date 17jul2009 Page 1 of 11Dokument11 SeitenP2S Hse Audit: Form 000.653.F0272 Date 17jul2009 Page 1 of 11Wahyu RizalNoch keine Bewertungen

- Sample JHADokument5 SeitenSample JHAKen100% (1)

- Dibia Ifeanyichukwu Peter Updated CV (Resume)Dokument7 SeitenDibia Ifeanyichukwu Peter Updated CV (Resume)wizzy basseyNoch keine Bewertungen

- MS Working at HeightsDokument15 SeitenMS Working at HeightsNauval FadliNoch keine Bewertungen

- Excavation Method StatementDokument4 SeitenExcavation Method StatementAnonymous 3eHGEDbxNoch keine Bewertungen

- JSA PRE-TEST UploadDokument2 SeitenJSA PRE-TEST UploadDenny Kurniawan PrawiraNoch keine Bewertungen

- Work Method Statement For Structure ErectionDokument12 SeitenWork Method Statement For Structure ErectionMuhammad TeguhNoch keine Bewertungen

- Imb SH Hse 0009 01Dokument64 SeitenImb SH Hse 0009 0101095902062ahmedNoch keine Bewertungen

- Oshcim Report Guideline MalaysiaDokument1 SeiteOshcim Report Guideline MalaysiareedzaNoch keine Bewertungen

- Decommissioning Plan for Eight Point Wind Energy CenterDokument16 SeitenDecommissioning Plan for Eight Point Wind Energy CenteradiNoch keine Bewertungen

- Emergency Response and Contingency PlanDokument21 SeitenEmergency Response and Contingency PlanKarimo KilaniNoch keine Bewertungen

- SCOPE OF WORK For Cooling Tower Sump CLEANINGDokument10 SeitenSCOPE OF WORK For Cooling Tower Sump CLEANINGAbhinav PradhanNoch keine Bewertungen

- Aspect-Impact Rating Sheet (Airs) : Department/ Section/ Unit: Process, Building and UtilitiesDokument4 SeitenAspect-Impact Rating Sheet (Airs) : Department/ Section/ Unit: Process, Building and UtilitiesSir ZenNoch keine Bewertungen

- Method For Installation of Protection Panels, Control Cable Pulling & Termination - GOSP 10Dokument6 SeitenMethod For Installation of Protection Panels, Control Cable Pulling & Termination - GOSP 10Subhash Chekka SEC 115KV ProjectNoch keine Bewertungen

- Installation & Testing of OPGW & UGNMFOC at Uthmaniyah GOSP-10Dokument10 SeitenInstallation & Testing of OPGW & UGNMFOC at Uthmaniyah GOSP-10Subhash Chekka SEC 115KV ProjectNoch keine Bewertungen

- Dust Control Report 032006 PDFDokument63 SeitenDust Control Report 032006 PDFFrancisco ChavezNoch keine Bewertungen

- Method of Statement for Piling WorksDokument15 SeitenMethod of Statement for Piling Worksahmad100% (1)

- Longwall Mining at Shallow Depth of Cover in IndiaVon EverandLongwall Mining at Shallow Depth of Cover in IndiaNoch keine Bewertungen

- Introduction to Petroleum Process SafetyVon EverandIntroduction to Petroleum Process SafetyBewertung: 3 von 5 Sternen3/5 (2)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Dokument6 SeitenJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNoch keine Bewertungen

- Method Statement For PCC & RCC WorksDokument11 SeitenMethod Statement For PCC & RCC WorkspoovazhaganNoch keine Bewertungen

- Jsa of ExcavationonDokument5 SeitenJsa of ExcavationonpoovazhaganNoch keine Bewertungen

- Method Statement For PCC & RCC WorksDokument11 SeitenMethod Statement For PCC & RCC WorkspoovazhaganNoch keine Bewertungen

- Jsa of ExcavationonDokument5 SeitenJsa of ExcavationonpoovazhaganNoch keine Bewertungen

- RA For ExcavationDokument7 SeitenRA For ExcavationpoovazhaganNoch keine Bewertungen

- Jsa of ExcavationonDokument5 SeitenJsa of ExcavationonpoovazhaganNoch keine Bewertungen

- Jsa of ExcavationonDokument5 SeitenJsa of ExcavationonpoovazhaganNoch keine Bewertungen

- RA For ExcavationDokument7 SeitenRA For ExcavationpoovazhaganNoch keine Bewertungen

- Cameron CCDokument6 SeitenCameron CCYogesh Badhe100% (1)

- Caterpillar 3412cDokument123 SeitenCaterpillar 3412cmarceloieee88% (8)

- Methanol From GlycerinDokument5 SeitenMethanol From GlycerinaudreysosoNoch keine Bewertungen

- Well Test Ref GuideDokument2 SeitenWell Test Ref Guideleonelz6aNoch keine Bewertungen

- Standard Abbreviation List by Siemens 28Dokument1 SeiteStandard Abbreviation List by Siemens 28Pendl PendlNoch keine Bewertungen

- Fuel from plastic waste: Converting waste plastics into liquid fuelsDokument56 SeitenFuel from plastic waste: Converting waste plastics into liquid fuelssumit potdarNoch keine Bewertungen

- Welding Duplex Stainless Steel Piping SpecDokument44 SeitenWelding Duplex Stainless Steel Piping SpecAlaa100% (1)

- HKCEE Paper I running answer text 2000 Chemistry Section ADokument11 SeitenHKCEE Paper I running answer text 2000 Chemistry Section AKathy WongNoch keine Bewertungen

- Divinol Industrial Oils: Gear Oils and Hydraulic Fluids - Guide and Slideway OilsDokument12 SeitenDivinol Industrial Oils: Gear Oils and Hydraulic Fluids - Guide and Slideway OilsJorge Iván CarbajalNoch keine Bewertungen

- A-1a - CV Resume of BB.SDokument8 SeitenA-1a - CV Resume of BB.SRandy YantoNoch keine Bewertungen

- InternshipDokument1 SeiteInternshipSyazwani PuteriNoch keine Bewertungen

- Powder Processing Equipment RangeDokument36 SeitenPowder Processing Equipment RangeGRAINANNA100% (1)

- Kipor IG1000Dokument54 SeitenKipor IG1000Brandon PhelpsNoch keine Bewertungen

- The Yellow Pages of Sofc TechnologyDokument51 SeitenThe Yellow Pages of Sofc TechnologyDrew MurrayNoch keine Bewertungen

- Be 200 Pilot's Training Manual JLPDokument372 SeitenBe 200 Pilot's Training Manual JLPAviacion Jlp100% (1)

- Is 1448 70 1968Dokument9 SeitenIs 1448 70 1968Pinjala AnoopNoch keine Bewertungen

- AaxpDokument8 SeitenAaxpboergleNoch keine Bewertungen

- Universal Fire BrochureDokument12 SeitenUniversal Fire BrochureRaveenaNoch keine Bewertungen

- Airstream 2008Dokument5 SeitenAirstream 2008jomix78-1Noch keine Bewertungen

- Tecumseh OV195EA - OV195XA Engine ManualDokument32 SeitenTecumseh OV195EA - OV195XA Engine Manual"Rufus"0% (1)

- Prelim 2 p3 2011 (For Sharing)Dokument14 SeitenPrelim 2 p3 2011 (For Sharing)Yee Kai TanNoch keine Bewertungen

- Artificial Lift in Unconventional ReservoirDokument34 SeitenArtificial Lift in Unconventional ReservoirMaria IndiraNoch keine Bewertungen

- IADC/SPE 87212 New Expandable Cladding Technique Enables Extended Length Casing RepairDokument4 SeitenIADC/SPE 87212 New Expandable Cladding Technique Enables Extended Length Casing RepairmsmsoftNoch keine Bewertungen

- Air Intake System: Click HereDokument2 SeitenAir Intake System: Click HereErlangga Yudha PratamaNoch keine Bewertungen

- Reliable Power for Construction and IndustryDokument4 SeitenReliable Power for Construction and IndustryokkaNoch keine Bewertungen

- Lombardini CHD Motor - Radioničko Uputstvo (Eng)Dokument90 SeitenLombardini CHD Motor - Radioničko Uputstvo (Eng)vladaukiNoch keine Bewertungen

- Reference Cable Schedule - JGS 320 - Non-Grid SynchronizationDokument2 SeitenReference Cable Schedule - JGS 320 - Non-Grid SynchronizationfaisalnadimNoch keine Bewertungen

- ASTM (AsociacionDokument14 SeitenASTM (Asociacionjesusito07Noch keine Bewertungen

- KgaDokument4 SeitenKgam_925Noch keine Bewertungen