Beruflich Dokumente

Kultur Dokumente

BS en 1074-4-2000, Valves For Water Supply - Fitness For Purpose Requirements and Appropriate Verification Tests - Part 4 Air Valves

Hochgeladen von

Kok WaiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BS en 1074-4-2000, Valves For Water Supply - Fitness For Purpose Requirements and Appropriate Verification Tests - Part 4 Air Valves

Hochgeladen von

Kok WaiCopyright:

Verfügbare Formate

CD/K/015-4:2009

ICS 23.060.01; 91.140.60

r d

da

an

St

an

ri c

Af

EAST AFRICAN STANDARD

st

Ea

Valves for water supply — Fitness for purpose requirements and

appropriate verification tests — Part 4: Air valves

as

ed

cit

be

t to

No

—

ly

on

ts

en

mm

co

or

ft f

EAST AFRICAN COMMUNITY

a

Dr

© EAC 2010 First Edition 2010

CD/K/015-4:2009

r d

da

Foreword

an

Development of the East African Standards has been necessitated by the need for harmonizing

requirements governing quality of products and services in East Africa. It is envisaged that through

St

harmonized standardization, trade barriers which are encountered when goods and services are

exchanged within the Community will be removed.

an

In order to meet the above objectives, the EAC Partner States have enacted an East African

Standardization, Quality Assurance, Metrology and Test Act, 2006 (EAC SQMT Act, 2006) to make

ri c

provisions for ensuring standardization, quality assurance, metrology and testing of products

produced or originating in a third country and traded in the Community in order to facilitate industrial

Af

development and trade as well as helping to protect the health and safety of society and the

environment in the Community.

st

East African Standards are formulated in accordance with the procedures established by the East

Ea

African Standards Committee. The East African Standards Committee is established under the

provisions of Article 4 of the EAC SQMT Act, 2006. The Committee is composed of representatives of

the National Standards Bodies in Partner States, together with the representatives from the private

as

sectors and consumer organizations. Draft East African Standards are circulated to stakeholders

through the National Standards Bodies in the Partner States. The comments received are discussed

and incorporated before finalization of standards, in accordance with the procedures of the

ed

Community.

Article 15(1) of the EAC SQMT Act, 2006 provides that “Within six months of the declaration of an

cit

East African Standard, the Partner States shall adopt, without deviation from the approved text of the

standard, the East African Standard as a national standard and withdraw any existing national

be

standard with similar scope and purpose”.

East African Standards are subject to review, to keep pace with technological advances. Users of the

t to

East African Standards are therefore expected to ensure that they always have the latest versions of

the standards they are implementing.

No

© East African Community 2010 — All rights reserved*

—

East African Community

P O Box 1096

ly

Arusha

on

Tanzania

Tel: 255 27 2504253/8

ts

Fax: 255-27-2504481/2504255

en

E-Mail: eac@eachq.org

Web: www.each.int

mm

co

or

ft f

*

© 2010 EAC — All rights of exploitation in any form and by any means reserved worldwide for EAC Partner States’ NSBs.

a

Dr

ii © EAC 2010 — All rights reserved

CD/K/015-4:2009

r d

da

Contents

an

1 Scope ...................................................................................................................................... 1

St

2 Normative references .............................................................................................................. 1

an

3 Terms and definitions .............................................................................................................. 1

ri c

4 Design requirements ............................................................................................................... 2

Af

5 Performance requirements ...................................................................................................... 2

5.1 Mechanical strength ................................................................................................................ 2

st

Ea

5.2 Leaktightness .......................................................................................................................... 2

5.3 Airflow characteristics .............................................................................................................. 3

as

5.4 Resistance to disinfection products ......................................................................................... 3

ed

5.5 Endurance ............................................................................................................................... 3

cit

6 Conformity assessment ........................................................................................................... 4

be

6.1 General.................................................................................................................................... 4

t to

6.2 Type tests ................................................................................................................................ 4

6.3 Control of production process and quality system.................................................................... 4

No

7 Marking.................................................................................................................................... 4

—

8 Packaging ................................................................................................................................ 4

ly

Annex A (normative) Test method for the airflow characteristics of valves with an air release function

on

(see 5.3 and 5.3.1) ............................................................................................................................... 6

Annex B (normative) Test method for the airflow characteristics of valves with an air intake function

ts

(see 5.3 and 5.3.2) ............................................................................................................................... 8

en

Annex C (normative) Test method for the endurance of valves with air intake and/or air release

functions (see 5.3 and 5.3.3) ................................................................................................................ 9

mm

co

or

ft f

a

Dr

© EAC 2010 — All rights reserved iii

CD/K/015-4:2009

d r

da

Introduction

an

In the preparation of this East African Standard, the following source was consulted extensively:

BS EN 1074-4:2000, Valves for water supply — Fitness for purpose requirements and appropriate

St

verification tests — Part 4: Air valves

an

Assistance derived from this source and others inadvertently not mentioned is hereby acknowledged.

ri c

Af

st

Ea

as

ed

cit

be

t to

No

—

ly

on

ts

en

mm

co

or

ft f

a

Dr

iv © EAC 2010 — All rights reserved

EAST AFRICAN STANDARD CD/K/015-4:2009

r d

da

Valves for water supply — Fitness for purpose requirements and

appropriate verification tests — Part 4: Air valves

an

St

1 Scope

This East African Standard specifies the minimum fitness for purpose requirements for valves to be

an

used in, or connected to, water supply pipe systems above or below ground (see CD-K-004-2009),

carrying water intended for human consumption.

ri c

This standard specifies the design requirements, the performance requirements, and the conformity

Af

assessment method for valves, whatever their type and materials.

This standard applies in priority to any other product or test standard: the requirements from other

st

standards apply only when this standard refers to them.

Ea

This standard deals with the requirements applicable to air valves with DN up to DN 300 and PFA 6 to

PFA 25.

as

2 Normative references

ed

This East African Standard incorporates, by dated or undated reference, provisions from other

publications. These normative references are cited at the appropriate places in the text and the

publications are listed hereafter. For dated references, subsequent amendments to or revisions of any

cit

of these publications apply to the East African Standard only when incorporated in it by amendment or

revision. For undated references the latest edition of the publication referred to applies.

be

ISO 7268, Pipe components — Definition of nominal pressure

t to

CD/K/004:2009, Water supply — Requirements for systems and components outside buildings

ISO 6708, Pipework components — Definition and selection of DN (nominal size)

No

CD/K/015-1:2009, Valves for water supply — Fitness for purpose requirements and appropriate

verification tests — Part 1: General requirements

—

CD/K/015-2:2009, Valves for water supply — Fitness for purpose requirements and appropriate

verifications tests — Part 2: Isolating valves

ly

ISO 5208:2008, Industrial valves — Pressure testing of metallic valves

on

3 Terms and definitions

ts

For the purposes of this standard, the terms and definitions given in CD/K/015-1:2009 apply together

en

with the following:

3.1

mm

float type purgers and air valves

self-operating float type valves for the evacuation of air from, or for the ingress of air into water

pipelines. Such valves may be single float or double float and may fulfil one or more of the following

co

functions: air release, air intake, air venting

3.2

or

air release function

to discharge a large air flow from a water pipeline

ft f

3.3

a

air intake function

Dr

© EAC 2010 — All rights reserved 1

CD/K/015-4:2009

d

to admit a large air flow into a water pipeline

r

da

3.4

air venting function

an

to purge entrapped air from a water pipeline in service under pressure

St

4 Design requirements

an

Self-operating float type purgers and air valves shall be designed in compliance with the requirements

given in clause 4 of CD/K/015-1:2009. In addition, these valves may be fitted with an integrated

isolating device which shall be in accordance with CD/K/015-2:2009.

ri c

5 Performance requirements

Af

5.1 Mechanical strength

st

5.1.1 Resistance to internal pressure of the shell and all pressure containing components

Ea

Requirement and test shall be in accordance with 5.1.1 of CD/K/015-1:2009. For double float valves,

the obturators may be tested simultaneously or separately.

as

5.1.2 Resistance of the obturator to differential pressure

ed

Tested within 5.1.1.

5.1.3 Resistance of valves to bending

cit

Not applicable.

be

5.1.4 Resistance of valves to operating loads

t to

Not applicable, except for any integrated isolating device which shall be in accordance with 5.1.4 of

CD/K/015-2:2009.

No

5.2 Leaktightness

5.2.1 Leaktightness of the shell and all pressure containing components

—

5.2.1.1 Leaktightness to internal pressure

ly

The requirement of leaktightness to internal pressure is fulfilled by conformance to 5.1.1.

on

5.2.1.2 Leaktightness to external pressure

ts

Not applicable, except for any integrated isolating device which shall be in accordance with 5.2.1.2 of

CD/K/015-2:2009.

en

5.2.2 Seat tightness

mm

5.2.2.1 Seat tightness at high pressure

Requirement and test shall be in accordance with 5.2.2.1 of CD/K/015-1:2009, the test fluid shall be

co

water. The leakage rate shall be the rate A. For a type test, the test duration shall be not less than 10

min. For double float valves, the obturators may be tested simultaneously or separately.

or

5.2.2.2 Seat tightness at low pressure

ft f

Requirement and test shall be in accordance with 5.2.2.2 of CD/K/015-1:2009, with test fluid, leakage

rate and test duration as given in 5.2.2.1. For double float valves, the obturators may be tested

a

simultaneously or separately.

Dr

2 © EAC 2010 — All rights reserved

CD/K/015-4:2009

r d

da

5.2.3 Maximum operating torque (MOT) for operation and tightness

Not applicable, except for any integrated isolating device which shall be in accordance with 5.2.3 of

an

CD/K/015-2:2009.

St

5.3 Airflow characteristics

Requirement shall be in accordance with 5.3 of CD/K/015-1:2009.

an

The characteristics given by the manufacturer shall be the air flow as a function of pressure. When it

ri c

is measured according to the conditions defined in the relevant hereafter subclauses, the flow shall be

not less than 90 % of the value indicated by the manufacturer, at two points of the curve, these two

Af

points being indicative of the range and functions of the valve.

5.3.1 Air release function

st

Ea

The type test shall be in accordance with Annex A. Testing is not required for air valves larger than

DN 100.

5.3.2 Air intake function

as

The type test shall be in accordance with Annex B. Testing is not required for air valves larger than

ed

DN 100.

5.3.3 Air venting function

cit

The air venting function shall be verified by measuring the section of the small orifice of the valve,

be

calculating the flow through it under sonic conditions and comparing the result with the value given in

the manufacturer's catalogues.

t to

The difference shall be no greater than ±10 %.

5.4 Resistance to disinfection products

No

Requirement and test shall be in accordance with 5.4 of CD/K/015-1:2009.

—

5.5 Endurance

5.5.1 Endurance of valves with air intake and/or air release functions

ly

The endurance of a valve with air intake and/or air release functions shall be evaluated by subjecting

on

the valve to 250 consecutive cycles of filling and draining in accordance with Annex C, the pressure

varying from atmospheric to PFA; the valve shall open and close fully during the test and shall pass

the leaktightness tests in accordance with 5.2.1 and 5.2.2 after the 250 cycles.

ts

en

5.5.2 Endurance of valves with an air venting function

The endurance of a valve with air venting function shall be evaluated by subjecting the valve to 2 500

mm

consecutive cycles of air venting. This may be achieved by continuous injection of air into the system

allowing the valve to cycle automatically, or by cyclic injection of air. The valve shall open and close

fully at each cycle of the test and shall pass the leaktightness tests in accordance with 5.2.1 and 5.2.2

co

after the 2 500 cycles.

5.5.3 Long term unseating test

or

This is an accelerated test to ensure that the obturator will release after being under pressure for a

ft f

long time.

a

Dr

© EAC 2010 — All rights reserved 3

CD/K/015-4:2009

d

The test shall be carried out on a valve in its delivery condition, mounted vertically, at a temperature

r

da

of ( 50 0−5 ) °C, kept under hydraulic pressure of at least PFA during five days.

an

Then release the pressure and check that the valve opens normally.

The valve shall pass the leaktightness tests in accordance with 5.2.1 and 5.2.2.

St

Valves with several functions shall be tested without isolating the parts ensuring the different

an

functions.

6 Conformity assessment

ri c

6.1 General

Af

Requirement shall be in accordance with 6.1 of CD/K/015-1:2009.

st

6.2 Type tests

Ea

Requirement shall be in accordance with 6.2 of CD/K/015-1:2009; the type tests to be performed shall

be those given in Table 1.

as

6.3 Control of production process and quality system

ed

Requirement shall be in accordance with 6.3 of CD/K/015-1:2009; the production tests given in Table

1 are informative.

cit

7 Marking

be

Requirement shall be in accordance with clause 7 of CD/K/015-1:2009.

t to

8 Packaging

Requirement shall be in accordance with clause 8 of CD/K/015-1:2009.

No

—

ly

on

ts

en

mm

co

or

ft f

a

Dr

4 © EAC 2010 — All rights reserved

CD/K/015-4:2009

r d

da

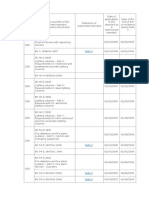

Table 1 — Requirements and tests

Subclause Requirement a Type tests Production tests

an

(informative)

4.1 a Materials See drawing and parts lists —

St

4.2 a DN See drawings —

a

4.3 Pressures See technical —

an

documentation

4.4 a Temperatures See materials —

4.5 a Design of the shell and obturator See test or calculation —

ri c

report

4.6 a End types and interchangeability See drawings and marking —

Af

a

4.7 Operating direction See drawings —

4.8 a Maximum water velocity See clause 4 —

st

4.9 a All materials, including lubricants, in See test reports in —

contact with water intended for accordance with national

Ea

human consumption regulations

4.10 a Internal corrosion and ageing See drawings, parts lists Visual inspection of

resistance and technical coatings

as

documentation

4.11 a External corrosion and ageing See drawings, parts lists Visual inspection of

resistance and technical coatings

ed

documentation

5.1.1a Resistance to internal pressure of See 5.1.1 See 5.1.1

cit

the shell and of all pressure

containing components

5.1.23 Resistance of the obturator to See 5.1.2 —

be

differential pressure

5.1.4 a Resistance of valves to operating See 5.1.4 —

t to

loads

a

5.2.1.1 Leaktightness of the shell and all See 5.2.1.1 See 5.2.1.1

pressure containing components to

No

internal pressure

5.2.1.23 Leaktightness of the shell and all See 5.2. 1.2 —

pressure containing components to

external pressure

—

5.2.2.1 a Seat tightness at high pressure See 5.2.2.1 See 5.2.2.1

5.2.2.2 a Seat tightness at low pressure See 5.2.2.2 —

ly

5.2.3 a Maximum operating torque (MOT) See 5.2.3 See 5.2.3

5.3.1 Airflow characteristics for air release See 5.3.1 —

on

function

5.3.2 Airflow characteristics for air intake See 5.3.2 —

ts

function

5.3.3 Airflow characteristics for air venting See 5.3.3 —

en

function

5.4 a Resistance to disinfection products See 5.4 —

mm

5.5.1 Endurance for air intake and/or air See 5. 5.1 —

release function

5.5.2 Endurance for air venting function See 5.5.2 —

5.5.3 Long term unseating test See 5.5.3 —

co

a

The sub-clauses and requirements shown above are those given in CD/K/015-1:2009.

or

ft f

a

Dr

© EAC 2010 — All rights reserved 5

CD/K/015-4:2009

r d

da

Annex A

(normative)

an

Test method for the airflow characteristics of valves with an air release

St

function (see 5.3 and 5.3.1)

A.1 General

an

Test medium shall be air; air pressure testing shall be in accordance with all related safety

ri c

regulations; additional safety measures shall be taken when necessary.

Af

The test shall be carried out on a valve in its delivery conditions, mounted vertically. The test shall

begin with the valve and the air at ambient temperature.

st

At the point where the air flow is measured, the air temperature shall remain between 5 °C and 45 °C

Ea

throughout the test.

Valves with several functions (air release, air intake and air venting) shall be tested without isolating

the parts ensuring the different functions.

as

A.2 Test installation

ed

Figure A.1 is given as an example. cit

A.3 Test procedure

Open the isolating valve to reach the flow of the first point of measurement.

be

The value of the flow shall be within the range of ±4 % for all the test duration.

t to

The value of the pressure shall be within the range of ±5 % for all the test duration.

No

The value of the temperature shall be within the range of ±2 °C for all the test duration.

Calculate the average flow and express it in m3/h (at standard temperature and pressure).

—

Record the test conditions and test results (average pressure, average temperature, average flow).

ly

Repeat the procedure by opening the isolating valve to reach the flow of the second point of

measurement.

on

ts

en

mm

co

or

ft f

a

Dr

6 © EAC 2010 — All rights reserved

CD/K/015-4:2009

r d

da

an

St

an

ri c

Af

st

Ea

as

Key

1 Pressure source

ed

2 Air valve

3 Pressure and temperature measurement devices

cit

4 Flow stabilizer

5 Flowmeter

be

Figure A.1 — Test installation

t to

No

—

ly

on

ts

en

mm

co

or

ft f

a

Dr

© EAC 2010 — All rights reserved 7

CD/K/015-4:2009

r d

da

Annex B

(normative)

an

Test method for the airflow characteristics of valves with an air intake function

St

(see 5.3 and 5.3.2)

an

B.1 General

ri c

See A.1.

Af

B.2 Test installation

The test installation shall be capable of creating an air flow in the air intake direction, either by

st

negative pressure below the valve or by positive pressure around or into the valve. Drawings in Figure

Ea

B.1 are given as examples.

The test installation shall be equipped with devices allowing the measurement of air flow, pressure

and temperature.

as

B.3 Test procedure

ed

Open the isolating valve to reach the flow of the first point of measurement.

cit

The value of the flow shall be within the range of ±4 % for all the test duration.

The value of the pressure shall be within the range of ±5 % for all the test duration.

be

The value of the temperature shall be within the range of ±2 °C for all the test duration.

t to

Calculate the average flow and express it in m3/h (at standard temperature and pressure), converting

it to normal outside atmospheric conditions.

No

Record the test conditions and test results (average pressure, average temperature, average flow).

Repeat the procedure by opening the isolating valve to reach the flow of the second point of

measurement.

—

ly

on

ts

en

mm

co

Figure B.1 — Test installation examples

or

ft f

a

Dr

8 © EAC 2010 — All rights reserved

CD/K/015-4:2009

r d

da

Annex C

(normative)

an

Test method for the endurance of valves with air intake and/or air release

St

functions (see 5.3 and 5.3.3)

an

C.1 General

ri c

Test medium shall be water: however, some air may get trapped and compressed; air pressure

testing shall therefore be in accordance with the related safety regulations.

Af

The test shall be carried out on a valve in its delivery condition at ambient temperature, mounted

vertically.

st

Ea

Valves with several functions (air release, air intake and air venting) shall be tested without isolating

the parts ensuring the different functions.

C.2 Test procedure

as

Fill the test installation with water up to the lowest point of the valve to be tested.

ed

Begin the first test cycle by filling the valve with water, purging the air, in a time not exceeding 10s.

cit

Increase the water pressure inside the valve up to PFA ±10 % and maintain it for at least 2 min.

Release the pressure to allow the full displacement of the obturator, the air coming into the valve

be

through the orifice in case of a valve with air intake function.

t to

Repeat the same procedure for 250 cycles.

Proceed to the leaktightness tests in accordance with 5.2.1 and 5.2.2.

No

Record the test conditions and test results.

—

ly

on

ts

en

mm

co

or

ft f

a

Dr

© EAC 2010 — All rights reserved 9

Dr

aft f

or

co

mm

en

ts

on

ly

—

No

t to

be

cit

ed

as

Ea

st

Af

ri c

an

St

an

da

r d

Dr

aft f

or

co

mm

en

ts

on

© EAC 2010 — All rights reserved

ly

—

No

t to

be

cit

ed

as

Ea

st

Af

ri c

an

St

CD/K/015-4:2009

an

da

r d

Das könnte Ihnen auch gefallen

- Masterspec Copper SpecificationDokument10 SeitenMasterspec Copper SpecificationNabil RamehNoch keine Bewertungen

- Article - The Good Ventilation of Switchgear and Transformer Rooms 18dec2015 PDFDokument8 SeitenArticle - The Good Ventilation of Switchgear and Transformer Rooms 18dec2015 PDFphilipyongNoch keine Bewertungen

- DG251 14 Electrical ServicesDokument3 SeitenDG251 14 Electrical Servicesnirmalb21Noch keine Bewertungen

- PalDuct Phenolic Datasheet MEDokument2 SeitenPalDuct Phenolic Datasheet MERamadan RashadNoch keine Bewertungen

- 2023 Training ProgrammeDokument11 Seiten2023 Training ProgrammeFernando CabreraNoch keine Bewertungen

- LPCB Sprinkler Plastic Pipe RequirementsDokument20 SeitenLPCB Sprinkler Plastic Pipe RequirementsAkmal Hazuan SulaimanNoch keine Bewertungen

- Pre-Contract AdministrationDokument16 SeitenPre-Contract AdministrationhurulNoch keine Bewertungen

- Commissioning Training Manual TemplateDokument12 SeitenCommissioning Training Manual TemplateHuseyin Sengul100% (1)

- Romold TrapDokument2 SeitenRomold Traprajkumar_chinniah100% (1)

- 0983 03 Method Statement For Installation Testing of Fire Fighting PipesDokument3 Seiten0983 03 Method Statement For Installation Testing of Fire Fighting PipesAnkit KumarNoch keine Bewertungen

- Hvca Revises Dw144Dokument1 SeiteHvca Revises Dw144Laxminarayan JhaNoch keine Bewertungen

- SPE-5102-Performance CRAC and Downflow Unit Particular Speci PDFDokument57 SeitenSPE-5102-Performance CRAC and Downflow Unit Particular Speci PDFSwamy Dhas DhasNoch keine Bewertungen

- CommissioningDokument14 SeitenCommissioninghuguer1Noch keine Bewertungen

- HVAC Understanding Basics TOCDokument12 SeitenHVAC Understanding Basics TOCexperthvachomeNoch keine Bewertungen

- VictaulicDokument52 SeitenVictaulicadventure11111Noch keine Bewertungen

- YDFC CatalogueDokument24 SeitenYDFC CatalogueMichael FutolNoch keine Bewertungen

- BS en 12502-3Dokument18 SeitenBS en 12502-3laboratorium logamNoch keine Bewertungen

- Hotel Fire SafetyDokument9 SeitenHotel Fire SafetyShashankNoch keine Bewertungen

- Under Floor Trunking CatalogueDokument60 SeitenUnder Floor Trunking CatalogueARUNDAS572Noch keine Bewertungen

- L190129 PartBMech ADokument22 SeitenL190129 PartBMech Atboltdesignsltd100% (1)

- Note 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Blue or GreenDokument9 SeitenNote 1: in These Programs, Required Input Values Are in Yellow Cells. Output Values Are in Blue or GreenrakamechNoch keine Bewertungen

- Vaillant FlexoTHERM Tech Brochure 2.6 Web March 2018Dokument42 SeitenVaillant FlexoTHERM Tech Brochure 2.6 Web March 2018Duncan StevenNoch keine Bewertungen

- COP 101 Version 9.1 Document (Text) Jan 2006Dokument41 SeitenCOP 101 Version 9.1 Document (Text) Jan 2006MarcusNoch keine Bewertungen

- LightPro For IES VEDokument23 SeitenLightPro For IES VEraminabkNoch keine Bewertungen

- Legislation Statutory Inspection ChecklistDokument2 SeitenLegislation Statutory Inspection Checklistforevertay2000Noch keine Bewertungen

- DampersDokument72 SeitenDampersSMBEAUTY100% (1)

- List of BS Standards No. Codes BS Description ValidityDokument1 SeiteList of BS Standards No. Codes BS Description ValidityGilbert LimNoch keine Bewertungen

- ASHRAE Guideline 36-2018: High-Performance Sequences of Operation For HVAC SystemsDokument66 SeitenASHRAE Guideline 36-2018: High-Performance Sequences of Operation For HVAC SystemsAouina Chokri100% (1)

- Section 23 82 19 - Fan Coil UnitsDokument5 SeitenSection 23 82 19 - Fan Coil UnitsSaber ElkassasNoch keine Bewertungen

- BS en 1716Dokument11 SeitenBS en 1716OmerfAtaNoch keine Bewertungen

- HTM 2025 - Ventilation in Healthcare Premises - Design Consideration PDFDokument121 SeitenHTM 2025 - Ventilation in Healthcare Premises - Design Consideration PDFAnnahuynhNoch keine Bewertungen

- Climaver Ductwork System BrochureDokument12 SeitenClimaver Ductwork System BrochureFredoMari LCNoch keine Bewertungen

- External & Internal Design Conditions: Project: 22 Tower Street, Bedford Row & Jockeys Field & 49-51 FARRINGDONDokument2 SeitenExternal & Internal Design Conditions: Project: 22 Tower Street, Bedford Row & Jockeys Field & 49-51 FARRINGDONrahul anandNoch keine Bewertungen

- 01 02 10 Reference StandardsDokument49 Seiten01 02 10 Reference StandardsKiran D AnvekarNoch keine Bewertungen

- En Standards For Construction MaterialsDokument50 SeitenEn Standards For Construction MaterialsAnonymous xqokgZ3GNoch keine Bewertungen

- Comptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseDokument5 SeitenComptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseFcma0903100% (1)

- BS 7346-6-2005 Specifications For Cable SystemsDokument26 SeitenBS 7346-6-2005 Specifications For Cable SystemsFathyNoch keine Bewertungen

- Development of Vietnamese Codes and Standards in Construction - Ws2006-Nbnguyen-PDokument20 SeitenDevelopment of Vietnamese Codes and Standards in Construction - Ws2006-Nbnguyen-PSen HuNoch keine Bewertungen

- Tabb PDFDokument7 SeitenTabb PDFFsNoch keine Bewertungen

- BS 5258 PART 8 (Specifications For Safety of Domestic Gas Appliances-Combined Appliances-Gas, FireDokument36 SeitenBS 5258 PART 8 (Specifications For Safety of Domestic Gas Appliances-Combined Appliances-Gas, Fireminsara madtNoch keine Bewertungen

- Heat Pipes Write Up With ExampleDokument9 SeitenHeat Pipes Write Up With Examplesyed mustafa aliNoch keine Bewertungen

- BS en 60728-1-2-2009Dokument38 SeitenBS en 60728-1-2-2009Rachid MounirNoch keine Bewertungen

- MCERTs Self Monitoring of Effluent Flow Audit 2013Dokument6 SeitenMCERTs Self Monitoring of Effluent Flow Audit 2013ServosteelNoch keine Bewertungen

- RF Fire Department Connection in Let Flow AssessmentDokument68 SeitenRF Fire Department Connection in Let Flow AssessmentAdam ThimmigNoch keine Bewertungen

- IecDokument13 SeitenIecLaxman NaiduNoch keine Bewertungen

- CFPA E Guideline No 26 2010 FDokument30 SeitenCFPA E Guideline No 26 2010 Fdvs99Noch keine Bewertungen

- Feedwater LCA Statement of ComplianceDokument5 SeitenFeedwater LCA Statement of ComplianceTarundeep Singh100% (1)

- BS 13410-2001 Ventilation For Commercial Overhead Radiant HeatersDokument12 SeitenBS 13410-2001 Ventilation For Commercial Overhead Radiant HeatersMartin CherryNoch keine Bewertungen

- Booster Pumps Technical Submittal-Hatta Hydro Power PlantDokument57 SeitenBooster Pumps Technical Submittal-Hatta Hydro Power PlantSamra MuzaferovicNoch keine Bewertungen

- Fan and Coil YGFCDokument22 SeitenFan and Coil YGFCWakko20IPNNoch keine Bewertungen

- IEC - 61892 6 2019 en FR stGnH9WUUvDokument101 SeitenIEC - 61892 6 2019 en FR stGnH9WUUvElia MadyNoch keine Bewertungen

- Mechanical, Electrical and PLubmbing SOW PDFDokument25 SeitenMechanical, Electrical and PLubmbing SOW PDFchoclate2012Noch keine Bewertungen

- Standards: Velocity Traverse of Air DuctsDokument2 SeitenStandards: Velocity Traverse of Air DuctssimonliaNoch keine Bewertungen

- EN 10255 (BS 1387) Steel TubeDokument1 SeiteEN 10255 (BS 1387) Steel TubeChandraAKTNoch keine Bewertungen

- (BS en 15239-2007) - Ventilation For Buildings. Energy Performance of Buildings. Guidelines For Inspection of Ventilation Systems.Dokument48 Seiten(BS en 15239-2007) - Ventilation For Buildings. Energy Performance of Buildings. Guidelines For Inspection of Ventilation Systems.january1969Noch keine Bewertungen

- Air BalancingDokument4 SeitenAir BalancingMohammed Javid HassanNoch keine Bewertungen

- IsolationBase CatalogDokument8 SeitenIsolationBase CatalogarturslaveNoch keine Bewertungen

- VV PPM C AaaaaaaaaaDokument32 SeitenVV PPM C AaaaaaaaaaAlessio DeOsimoNoch keine Bewertungen

- 848 - 2017 Decree of The Ministry of The Environment On Fire Safety of BuildingsDokument25 Seiten848 - 2017 Decree of The Ministry of The Environment On Fire Safety of BuildingsPatrik AlfredssonNoch keine Bewertungen

- ISO 1444 Meat - and - Meat - Products - Free - FatDokument12 SeitenISO 1444 Meat - and - Meat - Products - Free - FatanyeNoch keine Bewertungen

- NL 80 - 315 (440 USGPM at 100 FT) - 1Dokument4 SeitenNL 80 - 315 (440 USGPM at 100 FT) - 1Kok WaiNoch keine Bewertungen

- Fire Fighting Hose - 12 Bar - EN 694 Typ A1: Application: Temperature RangeDokument1 SeiteFire Fighting Hose - 12 Bar - EN 694 Typ A1: Application: Temperature RangeKok WaiNoch keine Bewertungen

- PumpDokument2 SeitenPumpNino Gabriel EsguerraNoch keine Bewertungen

- Kruger - Propeller FanDokument2 SeitenKruger - Propeller FanKok WaiNoch keine Bewertungen

- Connecting Cities TO: Let S Be SmartDokument15 SeitenConnecting Cities TO: Let S Be SmartKok WaiNoch keine Bewertungen

- FKA-EU DE BE enDokument24 SeitenFKA-EU DE BE enKok WaiNoch keine Bewertungen

- 16 284-294 PVC FA - Indd PDFDokument11 Seiten16 284-294 PVC FA - Indd PDFKok WaiNoch keine Bewertungen

- SS213 SS272 uPVCDokument1 SeiteSS213 SS272 uPVCKok WaiNoch keine Bewertungen

- Threaded End Ball Valves: Full and Reduced PortDokument4 SeitenThreaded End Ball Valves: Full and Reduced PortKok WaiNoch keine Bewertungen

- Testing of Rubber Gaskets For Use As Elastomeric Seals For Joints in Potable Water Pipework and Pipeline - CleanedDokument5 SeitenTesting of Rubber Gaskets For Use As Elastomeric Seals For Joints in Potable Water Pipework and Pipeline - CleanedKok WaiNoch keine Bewertungen

- Econnect Payment GuideDokument29 SeitenEconnect Payment GuideKok WaiNoch keine Bewertungen

- I. Products A. Earthquake Resistant Ductile Iron Pipe (ERDIP), Fittings and AccessoriesDokument6 SeitenI. Products A. Earthquake Resistant Ductile Iron Pipe (ERDIP), Fittings and AccessoriesKok WaiNoch keine Bewertungen

- Design Handbook For Calculating: Fillet Weld SizesDokument4 SeitenDesign Handbook For Calculating: Fillet Weld SizesKok WaiNoch keine Bewertungen

- Shell Diesel ULS: Safety Data SheetDokument19 SeitenShell Diesel ULS: Safety Data SheetKok WaiNoch keine Bewertungen

- A Study On Earthquake-Resistant Design For Buried Pipeline Using Lightweight BackfillDokument9 SeitenA Study On Earthquake-Resistant Design For Buried Pipeline Using Lightweight BackfillKok WaiNoch keine Bewertungen

- A Paradigm in Chilled Water Systems: ShiftDokument8 SeitenA Paradigm in Chilled Water Systems: ShiftKok WaiNoch keine Bewertungen

- 4121 PDFDokument462 Seiten4121 PDFKok WaiNoch keine Bewertungen

- 29 Japan 5 WaterSupply Code 2009.cleanedDokument13 Seiten29 Japan 5 WaterSupply Code 2009.cleanedKok WaiNoch keine Bewertungen

- Fact Sheet - Mission Hills ERDIP - 5.17.19.cleanedDokument1 SeiteFact Sheet - Mission Hills ERDIP - 5.17.19.cleanedKok WaiNoch keine Bewertungen

- BS EN 1154: 1997 Controlled Door Closing Devices: Digit 1: Category of Use ExampleDokument1 SeiteBS EN 1154: 1997 Controlled Door Closing Devices: Digit 1: Category of Use ExampleKok WaiNoch keine Bewertungen

- Iowa Storm Water Management Manual: Design Standards Chapter 14-Design of CulvertsDokument31 SeitenIowa Storm Water Management Manual: Design Standards Chapter 14-Design of CulvertsKok WaiNoch keine Bewertungen

- Shallow Foundations For Colder ClimatesDokument27 SeitenShallow Foundations For Colder ClimatesFernando Pages100% (1)

- E1935-97 Cal & Measure CT DensityDokument5 SeitenE1935-97 Cal & Measure CT DensitysanthakumarNoch keine Bewertungen

- Lab ReportDokument2 SeitenLab ReportLindsey AlexanderNoch keine Bewertungen

- Extended SurfacesDokument13 SeitenExtended SurfacesDirkMyburghNoch keine Bewertungen

- AllenDokument40 SeitenAllenDhanpat RaiNoch keine Bewertungen

- ASTM D341 Viscosity ChartDokument21 SeitenASTM D341 Viscosity Chartscribdickhead100% (3)

- BiodataDokument13 SeitenBiodatasoumyamukherjeeNoch keine Bewertungen

- Wave C11Dokument8 SeitenWave C11Wajira Sanjaya PereraNoch keine Bewertungen

- Lecture-23 (Shear Force Diagram & Bending Moment Diagram)Dokument55 SeitenLecture-23 (Shear Force Diagram & Bending Moment Diagram)Anil MandariaNoch keine Bewertungen

- Analysis of GoldDokument6 SeitenAnalysis of GoldBhupesh MulikNoch keine Bewertungen

- FERA-Check List Rev.0Dokument8 SeitenFERA-Check List Rev.0Yaser AhmadNoch keine Bewertungen

- Ketonic Resin 5851Dokument1 SeiteKetonic Resin 5851hatemNoch keine Bewertungen

- Installation Manual - Brazed Heat Exchangers - UK PDFDokument2 SeitenInstallation Manual - Brazed Heat Exchangers - UK PDFesteban vasquezNoch keine Bewertungen

- BAKER Drilling - Products Fluid End Expandable Parts PDFDokument56 SeitenBAKER Drilling - Products Fluid End Expandable Parts PDFAnonymous GjCOVlgNoch keine Bewertungen

- PCARE Calculation NotesDokument10 SeitenPCARE Calculation NotesToni Sy EncinaresNoch keine Bewertungen

- 9-Agitation Aeration PDFDokument47 Seiten9-Agitation Aeration PDFCinthiaLugoNoch keine Bewertungen

- Nasa Passivation TestDokument134 SeitenNasa Passivation Testlmayhew100% (1)

- EN8000 Aqwa Tutorial: Aqwa-Line Aqwa-Fer Aqwa-Librium Aqwa-Drift Aqwa-NautDokument13 SeitenEN8000 Aqwa Tutorial: Aqwa-Line Aqwa-Fer Aqwa-Librium Aqwa-Drift Aqwa-NautDani GarciaNoch keine Bewertungen

- CL31Dokument8 SeitenCL31Juan JuanNoch keine Bewertungen

- CPD Floors Part 2ADokument19 SeitenCPD Floors Part 2AChristo BoschNoch keine Bewertungen

- Suspension ExamplesDokument6 SeitenSuspension ExamplesDivaan Raj KarunakaranNoch keine Bewertungen

- WPSAmerica Shielding Gases and Mechanical PropertiesDokument44 SeitenWPSAmerica Shielding Gases and Mechanical PropertiesRameshBaskaranNoch keine Bewertungen

- Hopping Technology On Lager Beer Flavor and Flavor StabilityDokument249 SeitenHopping Technology On Lager Beer Flavor and Flavor StabilityKrishna ChaudhariNoch keine Bewertungen

- Sulfidic Corrosion in Refineries - A ReviewDokument13 SeitenSulfidic Corrosion in Refineries - A Reviewrogerh44Noch keine Bewertungen

- Ial WCH05 01 Nov19 PDFDokument28 SeitenIal WCH05 01 Nov19 PDFsammam mahdi samiNoch keine Bewertungen

- Mathlinks8 CH 10textbookDokument30 SeitenMathlinks8 CH 10textbookapi-171445363Noch keine Bewertungen

- cfm56-7 CAPDokument12 Seitencfm56-7 CAPgarsi2346Noch keine Bewertungen

- MetallurgyDokument2 SeitenMetallurgygjabyNoch keine Bewertungen

- Jee-Mains Test Paper - 02Dokument21 SeitenJee-Mains Test Paper - 02Apex InstituteNoch keine Bewertungen

- 9701 w03 QP 3Dokument8 Seiten9701 w03 QP 3Hubbak KhanNoch keine Bewertungen