Beruflich Dokumente

Kultur Dokumente

Ops Case - Feb 2019 - Answers - Variant 2

Hochgeladen von

Jayashree JayaramCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ops Case - Feb 2019 - Answers - Variant 2

Hochgeladen von

Jayashree JayaramCopyright:

Verfügbare Formate

OPERATIONAL CASE STUDY February 2019 EXAM ANSWERS

Variant 2

SECTION 1

DECISION CRITERIA UNDER CONDITIONS OF UNCERTAINTY

The three decision criteria used under conditions of uncertainty are known as maximax,

maximin and minimax regret.

Maximax criterion

A decision maker that uses the maximax criterion is an optimist. Using this approach, the

option chosen will be the one that offers the maximum monthly return. The maximum return

here for each product range are: F$218,400 for the climbing wall, F$174,000 for the playhouse

and F$256,800 for the adventure platform.

Therefore, under this criterion we will choose the adventure platform as this gives us the

highest possible return.

Maximin criterion

A decision maker that uses the maximin criterion is a pessimist. Using this approach, the range

that maximises the minimum return achievable will be selected. The minimum returns for each

of the three ranges are: F$40,800 for the climbing wall, F$108,000 for the playhouse and

F$32,400 for the adventure platform.

Therefore, under this criterion we will choose the playhouse as this is the highest of the three

lowest returns.

Minimax regret criterion

A decision maker that uses the minimax regret criterion is often referred to as a “bad loser”.

The decision is made by firstly identifying the product range that maximises the return at each

of the three market conditions. The differential between the highest return and the other two

at each of the market conditions represents the regret of having made a bad choice.

If the market demand is low the playhouse has the best return and so the regret of choosing

the playhouse is F$0. The climbing wall has a regret of F$67,200 (= F$108,000-F$40,800)

and the adventure platform has a regret of F$75,600 (= F$108,000-F$32,400).

CIMA 2019 – no reproduction without prior consent

February 2019 Operational Case Study

1

Once we have completed the regret table we then choose the product range that minimises

the maximum regret, or to put it another way, we select the best of the worst. So, the maximum

regrets for each product range are: F$67,200 for the climbing wall, F$82,800 for the playhouse

and F$75,600 for the adventure platform.

Therefore, under this criterion we will choose the climbing wall as this has the minimum of the

maximum regrets of the three product ranges.

CIMA 2019 – no reproduction without prior consent

February 2019 Operational Case Study

2

DEVELOPMENT PROJECT EXPENDITURE

How the criteria in IAS 38: Intangible assets apply to the development project

The project to develop the new product ranges has been underway for approximately two

months. Under IAS 38 we can capitalise the costs incurred for a development project from the

date that six criteria have been met. These six criteria are as follows:

• The intangible asset must be technically feasible. As the working prototypes were

completed on 31 January we can assume that this is the date that this was achieved.

• There must be an intention to complete the intangible asset and use or sell it. As the

senior management authorised Grace to start work on the project on 1 January and

set a deadline for 28 February, this criterion has been satisfied.

• Resources to complete the development must be available. The finance and staff

resources were made available to complete this project on 1 January.

• The intangible asset will generate probable future economic benefit. The market

research consultancy firm confirmed that the market was viable on 14 January. In

addition, the demand estimates that the consultancy supplied show a positive return

even at the markets lowest demand level. Therefore, this criterion was met on 14

January.

• The costs to be capitalised can be reliably measured. The schedule of expenditure

identified for the project are proof that this criterion has been met.

• There is an ability to use or sell the intangible asset. As we have developed these

product ranges internally with the express intention to sell them in the commercial

market, this criterion was met on 1 January.

Therefore, all these criteria had been met on 31 January and this is the date that we should

consider that the intangible asset was created.

Treatment in the financial statements for the year ending 31 December 2019

As 31 January is the point at which the intangible asset was created, we can capitalise relevant

expenditure incurred from that date until 28 February, which is the date that the project was

completed. Relevant expenditure includes any expenditure which is directly attributable to

creation of the intangible asset and includes salaries and raw materials and consumables.

The advertising costs are specifically excluded under IAS 38 as this expenditure is not incurred

to generate the intangible asset.

Although the new cutting machine can be capitalised it is not an intangible asset and therefore

will not be covered under IAS 38. Instead this will be part of property, plant and equipment

and depreciated in accordance with IAS 16: Property, plant and equipment.

The intangible asset will be shown in the statement of financial position and will be amortised

once production begins. Given the project is to develop three new products and only one will

be launched on 1 May, then one third of the asset can be amortised from 1 May (the rest will

start to be amortised once the other two products are launched). Therefore, in the statement

of profit or loss there will be an eight-month charge for the year. The amortisation period should

reflect the useful economic life of the asset, which will be the anticipated life of the new product

range.

CIMA 2019 – no reproduction without prior consent

February 2019 Operational Case Study

3

SECTION 2

SALES FORECASTING

How the information has been used to forecast sales demand for our climbing walls

The trend formula has been assumed to apply to our climbing walls because it has been taken

from actual sales of similar products. The trend is the long-term direction or underlying

movement in values in a set of data. The trend formula, Y = 188 + 12 M is the formula for a

straight line and shows an upward demand. We can expect to sell (188+12) 200 climbing walls

in the first month following launch and 12 more for every month after this: this is the basis on

which the trend for sales of our new climbing wall has been calculated.

Once we had the forecast trend figures for each month’s sales for the first year, we adjusted

the trend for seasonal variations. Seasonal variations are short–term, predictable variations in

the trend. For example, sales of climbing walls may increase during periods when demand for

our customers’ services is low. These periods would be the most practical time for customers

to renew equipment. Our domestic outdoor play equipment is also subject to seasonal

variations as we experience higher demand during the summer than we do in the winter.

As the seasonal variation for climbing walls is based on the multiplicative model, this means

that the seasonal variation for each month is a proportion of the trend. For example, in January

the forecast sales will be 50% below the trend forecast, while in October the seasonal variation

will be 50% higher than the trend forecast. We can adjust all the monthly trend figures by the

relevant month’s seasonal variation and aggregate them to arrive at a demand forecast for the

first year’s sales.

How the sales forecast has then been used to set the raw material purchase budget

Sales demand is our principal budget factor. This means that sales demand is the element

which limits output and therefore our performance and profits in this new sector. Therefore, all

our functional budgets flow from the principal budget factor, which is why budget preparation

starts with the sales forecast. To calculate our raw material purchase budget, we must follow

the budget setting process in a set, logical order.

Once we know how many climbing walls we are forecast to sell each month, we can produce

the sales budget. The sales budget will detail the number of climbing walls and the revenue

that we expect to achieve from them. Following this we calculate how many climbing walls we

need to produce to satisfy the sales budget: this is the production budget. The production

budget will differ from the sales budget because, in the early months of production, when sales

are below the trend we will be producing climbing walls and placing them in inventory. This

inventory will reduce once sales demand increases from October onwards. From the

production budget we calculate the material usage, that it the amount of raw materials that we

will use in order to satisfy the production budget. We have standard cost cards that detail all

the material requirements and we can use these to calculate how much of each of the different

categories of raw materials we will need. At this point we can adjust for any fluctuations in raw

material inventory levels and any normal loss to ascertain how much raw material we need to

purchase.

CIMA 2019 – no reproduction without prior consent

February 2019 Operational Case Study

4

THE DECISION-MAKING UNIT (DMU)

A DMU is a term used to describe all the individuals that play a part in their businesses’ buying

decision-making process. These are:

Users: These are the members of an organisation that will use our climbing walls, in the case

of the nurseries and play centres these will be the children and the carers or supervisors of

the children. It is important that the sales team understands the needs of the users in order to

match the correct product from the range with the organisation.

Influencers: These are the people that can steer the buying decision in a particular direction.

For example, the local government will have a Health and Safety Officer and this person could

decide that climbing walls are too high a risk for children in the play centre. Although

influencers are often formal and internal to the organisation they can also be informal and

external. For example, we sent prototypes to specialist children’s magazines for review and

when the results are published, they may influence the buying decision.

Gatekeepers: These are the people who control the flow of information to others. Even if we

produce the best product in Fawland we will not be able to sell it unless we are known by the

key roles in the buying decision. A good example of gatekeepers are the receptionists who

prevent the members of the sales team from accessing the people in these key buying roles.

Buyers: The buyer is the professional purchasing role. This person will have a criteria for

selecting the products and will be responsible for sourcing goods and negotiating the terms.

In most cases this is the person that members of our team need to persuade that our products

are the most fitting for their organisation’s needs.

Decider: This is the person that will make the final decision about placing an order, usually a

senior manager. For example, most organisations will operate within budgetary constraints

and even if our products are the most suitable for the users, the Finance Director could still

veto the deal.

Initiator: The initiator is the person that recognises that there is a need to be satisfied. This

role could be as simple as replacing a worn out version of the product. In the case of the

climbing walls this is unlikely to be a direct replacement as the climbing walls are novel and

innovative. The fact that the Government has warned that children in Fawland are not fit

enough may mean that organisations recognise the need for play equipment that means more

physical exertion.

It is important to understand that the six roles in a DMU are not mutually exclusive. For

example the carers of the children in the play centres or nurseries could also take the role of

influencer. If a carer viewed the equipment as too advanced or dangerous for the children, as

experts, they could influence the buyer not to buy.

CIMA 2019 – no reproduction without prior consent

February 2019 Operational Case Study

5

SECTION 3

BONUS SCHEME CRITERIA

Motivational

A good bonus scheme should encourage the sales team to be effective and productive. They

should want to work harder as a result of the scheme. The climbing wall bonus scheme does

achieve this as more walls have been sold in total than budgeted.

Consistent and fair

A good bonus scheme should be applied equally to all sales and be within the control of the

sales team. This bonus scheme is fair as it rewards employees for sales, which should be

within their control. It is also consistent in as much as each climbing wall sold earns the

employee F$10. However, this is not consistent with the bonus paid for the other products sold

by Trigg Adventure.

Reward good performance

Good performance for the sales team must be defined in terms of the amount of sales made.

The bonus scheme awards F$10 for each unit sold and so would appear to meet this criterion

in terms of sales volume. However, to achieve this sales volume, it appears that the sales

team have discounted the selling price of the entire range to the maximum limit. Therefore,

the bonus scheme is rewarding actual units sold regardless of the price and does not achieve

this criterion.

In line with organisational goals

A good bonus scheme should encourage goal congruence; it should align personal and

organisational goals. The bonus scheme does not meet this criterion as although it motivates

the team to sell more units in total the sales are skewed towards selling the small climbing

wall. The target was to sell 30 large climbing walls, but the sales team only sold five. This has

implications for the contribution earned during June (see below): in effect the bonus scheme

is encouraging the sales team to act in self-interest at the expense of Trigg Adventure.

Affordability

Clearly any bonus scheme that Trigg Adventure adopts must be affordable. All bonus schemes

have a dual aspect, an inherent conflict, as the higher the bonus earned by the sales team,

the higher the cost to Trigg Adventure. There is no evidence to suggest that Trigg Adventure

cannot afford this new bonus scheme, but it is more expensive than the scheme it replaces

and has contributed to a lower contribution than budgeted.

Suggestions for improving the bonus scheme

A better bonus scheme would need to ensure goal congruence and reward good performance.

The scheme could be set as a percentage of sales revenue rather than a flat rate.

CIMA 2019 – no reproduction without prior consent

February 2019 Operational Case Study

6

SALES VARIANCES

Sales price variance F$11,850 adverse

This variance shows that the actual selling price achieved was less than the budgeted selling

price for all three products in the range. The sales team were given the discretion to offer

customers a discount in order to secure a sale and the difference between the actual and

budgeted selling price indicates that this discount was offered freely. The motivation for the

sales staff offering the discount is probably due to the fact that their bonus was based on units

sold and not on achieving the budgeted selling price.

Sales mix variance F$14,000 adverse

The sales mix variance indicates the increase or decrease in profit due to the actual total

volume of products being sold in a different proportion to the budgeted mix. We must have

sold proportionately more of the lower contribution products and less of the higher contribution

products to achieve this adverse variance.

As can be seen from the data we have sold significantly more of the small climbing walls than

the actual quantity in the budgeted mix and these products have the lowest standard

contribution of all the items sold. Similarly, we can see that we sold significantly less than the

actual quantity in budgeted mix of the large climbing walls and these items are the items with

the highest standard contribution. It is probable that these differences in product sales have

been influenced by the bonus scheme. As the bonus is paid at a flat rate per item, regardless

of the type of item, it is likely that the sales team have focused on selling the smaller climbing

walls because they are easier to sell. This could be because they are less of a financial outlay.

Sales quantity variance F$6,000 favourable

The sales quantity variance quantifies the effect on our contribution of selling a higher quantity

in standard mix than budgeted. We sold 105 climbing walls which is more than the 90 budgeted

and when this difference is multiplied by the standard contribution it indicates that we have

earned F$6,000 more contribution than budgeted.

The reasons for this variance are not altogether clear. However, as the sales team are paid a

bonus for each item sold, it is possible that the bonus has motivated them. Another reason for

the variance could be because this is the first month of sales of the climbing walls and that the

forecasts could have been inaccurate, so it follows that our sales budgets are inaccurate.

Sales volume contribution variance F$8,000 adverse

The sales volume variance is the sum of the sales mix and sales quantity variances. It

quantifies the effect on our contribution due to selling 105 units rather than the budgeted 90

units. This variance is adverse overall because the positive effect on contribution gained from

the quantity does not overcome the negative effect on contribution caused by the sales mix

variance.

CIMA 2019 – no reproduction without prior consent

February 2019 Operational Case Study

7

SECTION 4

PRODUCTION SCHEDULE

The optimal production decision

The production schedule should be prioritised according to the products that maximise total

contribution. As we have enough hangers in inventory to meet the maximum demand for all

sizes of climbing wall, these specialist components are not a production constraint. However,

we only have 5,000 pegs in inventory and need 7,560 to satisfy the maximum demand for all

products. This means that we are over 2,500 pegs short of meeting maximum demand and

are only just able to cover our contractual obligation and meet the minimum demand.

Therefore, pegs are a production constraint.

As we have identified a single production constraint we should prioritise production in order to

maximise contribution per unit of limiting factor. This will maximise overall contribution and

therefore profit.

Before we prioritise the order that we make the climbing we must meet our contractual

obligations and make the minimum demand of each size. The 5,000 pegs that we hold in

inventory will allow us to satisfy this minimum demand. The remaining pegs (5,000-4,600)

would then be allocated to the product earning the largest contribution per peg. This would be

the small climbing wall. This is because we want to earn the largest contribution and a peg will

generate F$10.00 contribution when we make a small climbing wall, F$8.70 when we make a

medium climbing wall and F$8.57 when we make a large climbing wall.

Should we pay F$2,500 for 1,000 additional pegs?

If we had 1,000 additional pegs, we would continue to make the products in the order

suggested above to maximise contribution. We would buy the 1,000 additional pegs if the

contribution earned from them exceeded the cost of buying them. As the additional 1,000 pegs

will still leave us short of the 7,560 needed to meet maximum demand, the minimum

contribution we can earn from a peg is F$8.57. As the additional cost is F$2.50 a peg, it will

be worthwhile to place the special order for the 1,000 pegs.

CIMA 2019 – no reproduction without prior consent

February 2019 Operational Case Study

8

EOQ

The purpose of the EOQ and the nature of holding and ordering costs

The EOQ model works on the principle that the optimal order size for inventory is the order

quantity which minimises the total of inventory holding costs and ordering costs. Therefore, its

purpose is to establish an optimal order level for each component of inventory.

Holding costs consist of the incremental cost of holding inventory. The holding costs at Trigg

Adventure are the incremental cost of insurance (our premiums are charged on the value of

the inventory), the opportunity cost of the capital that is invested in the inventory (money used

to finance inventory holding cannot be used to expand our product range further), the

incremental warehouse costs (if we extend our product lines further we may have to increase

the number of stores staff or increase the space needed), and so on. It is assumed that the

relevant holding cost will increase as the quantity of inventory held increases.

Ordering costs are the fixed cost of placing an order. These costs are usually the clerical costs

of preparing the purchase order, receiving deliveries and paying invoices. This includes

Richard Herrick’s salary for the time taken to complete the order form, postage costs,

transportation costs, and so on. These costs are assumed to remain constant regardless of

the number of components ordered therefore the fewer orders, the lower the cost.

Assumptions that mean that it is inappropriate for purchase of the climbing wall

components

The EOQ is a useful model but it is based on a number of assumptions that may not apply to

our new products.

One assumption is that the holding cost per unit will remain constant. As most of our raw

material inventory is bulky in nature, this may not always be the case as costs of storage are

likely to be stepped (more store room labour or space will be needed as inventory levels

increase).

Another assumption made when calculating the total holding cost is that the average holding

is half of the order quantity. This would be the case where demand for the product is evenly

distributed throughout the year. However, we have a business that is seasonal and therefore

demand varies throughout the year for all our products. In addition, the demand for our

climbing walls is currently expanding in an unpredictable pattern which is not conducive to

using the EOQ.

A further assumption is that the lead time is known with certainty. The lead time is the time

taken from placing the order to receiving the goods. When this is known with certainty the

EOQ can be used to determine at what point the order should be raised to obtain additional

inventory. However, our peg and hanger supplier has not been consistent as they have taken

between two and four weeks to deliver a standard order.

The EOQ ignores shortage costs which may be quite significant, given our current shortage

problems with the pegs and hangers. If we are short of these components we lose sales and

customer goodwill.

CIMA 2019 – no reproduction without prior consent

February 2019 Operational Case Study

9

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Safety Data Sheet: Fumaric AcidDokument9 SeitenSafety Data Sheet: Fumaric AcidStephen StantonNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- SC-Rape-Sole Testimony of Prosecutrix If Reliable, Is Sufficient For Conviction. 12.08.2021Dokument5 SeitenSC-Rape-Sole Testimony of Prosecutrix If Reliable, Is Sufficient For Conviction. 12.08.2021Sanjeev kumarNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- 6 AsianregionalismDokument32 Seiten6 AsianregionalismChandria Ford100% (1)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Quantity DiscountDokument22 SeitenQuantity Discountkevin royNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Heat TreatmentsDokument14 SeitenHeat Treatmentsravishankar100% (1)

- Dr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Dokument2 SeitenDr. Najeebuddin Ahmed: 969 Canterbury Road, Lakemba, Sydney, NSW, Australia, 2195Najeebuddin AhmedNoch keine Bewertungen

- Switch CondenserDokument14 SeitenSwitch CondenserKader GüngörNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Presentation - Prof. Yuan-Shing PerngDokument92 SeitenPresentation - Prof. Yuan-Shing PerngPhuongLoanNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Question Paper: Hygiene, Health and SafetyDokument2 SeitenQuestion Paper: Hygiene, Health and Safetywf4sr4rNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- In Partial Fulfillment of The Requirements For The Award of The Degree ofDokument66 SeitenIn Partial Fulfillment of The Requirements For The Award of The Degree ofcicil josyNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- MWG Installation 7.6.2 IG INSTALLATION 0516 en - PDDokument64 SeitenMWG Installation 7.6.2 IG INSTALLATION 0516 en - PDjbondsrNoch keine Bewertungen

- Certification and LettersDokument6 SeitenCertification and LettersReimar FerrarenNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Acevac Catalogue VCD - R3Dokument6 SeitenAcevac Catalogue VCD - R3Santhosh KumarNoch keine Bewertungen

- 1980WB58Dokument167 Seiten1980WB58AKSNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- CPE Cisco LTE Datasheet - c78-732744Dokument17 SeitenCPE Cisco LTE Datasheet - c78-732744abds7Noch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Awais Inspector-PaintingDokument6 SeitenAwais Inspector-PaintingMohammed GaniNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Belimo Fire & Smoke Damper ActuatorsDokument16 SeitenBelimo Fire & Smoke Damper ActuatorsSrikanth TagoreNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- GATE General Aptitude GA Syllabus Common To AllDokument2 SeitenGATE General Aptitude GA Syllabus Common To AllAbiramiAbiNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Bea Form 7 - Natg6 PMDokument2 SeitenBea Form 7 - Natg6 PMgoeb72100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Syed Hamid Kazmi - CVDokument2 SeitenSyed Hamid Kazmi - CVHamid KazmiNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Bank Statement SampleDokument6 SeitenBank Statement SampleRovern Keith Oro CuencaNoch keine Bewertungen

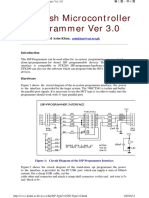

- ISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanDokument4 SeitenISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanSrđan PavićNoch keine Bewertungen

- Interest Rates and Bond Valuation: All Rights ReservedDokument22 SeitenInterest Rates and Bond Valuation: All Rights ReservedAnonymous f7wV1lQKRNoch keine Bewertungen

- Mpi Model QuestionsDokument4 SeitenMpi Model QuestionshemanthnagNoch keine Bewertungen

- Portfolio Report Zarin Tasnim Tazin 1920143 8Dokument6 SeitenPortfolio Report Zarin Tasnim Tazin 1920143 8Fahad AlfiNoch keine Bewertungen

- Icom IC F5021 F6021 ManualDokument24 SeitenIcom IC F5021 F6021 ManualAyam ZebossNoch keine Bewertungen

- A Survey On Multicarrier Communications Prototype PDFDokument28 SeitenA Survey On Multicarrier Communications Prototype PDFDrAbdallah NasserNoch keine Bewertungen

- Kicks: This Brochure Reflects The Product Information For The 2020 Kicks. 2021 Kicks Brochure Coming SoonDokument8 SeitenKicks: This Brochure Reflects The Product Information For The 2020 Kicks. 2021 Kicks Brochure Coming SoonYudyChenNoch keine Bewertungen

- QCM Part 145 en Rev17 310818 PDFDokument164 SeitenQCM Part 145 en Rev17 310818 PDFsotiris100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Shopnil Tower 45KVA EicherDokument4 SeitenShopnil Tower 45KVA EicherBrown builderNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)