Beruflich Dokumente

Kultur Dokumente

SOMC FHR 8 - Manejo de Equipamiento

Hochgeladen von

Axel CornaloOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SOMC FHR 8 - Manejo de Equipamiento

Hochgeladen von

Axel CornaloCopyright:

Verfügbare Formate

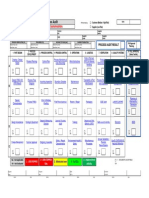

Plantilla de Implementacion del Factory Handbook de Sony para BGH Rev.

X

Se encuentra

Nombre y numero del Procedimiento Estado de la

Requerimiento R(x) Revisar/Crear un Procedimiento hecho? /

involucrado / Evidencia Acción (%)

Cuando?

8.Manejo de Equipamiento

R(x) 8.1-A1 When designing new test fixtures it is mandatory to review and Adhere the Generic Test Fixture Design Guidelines

(17/0113-LXE108688) and the Generic Test and Assembly Fixture Requirements (12/1056-LXE10880). For final assembly fixtures,

Final Assembly Design Guidelines (3/0113-LXE108724) and the Generic Test and Assembly Fixture Requirements (12/1056-

N/A

LXE10880)shall be reviewed and adhered to.

R(x) 8.1-B1 New and used equipment shall be clearly documented during the industrialization, including instructions necessary

to duplicate and maintain the equipment. All equipment specification, instructions and other documentation shall be stored in the

PLC

R(x) 8.1-C The production site shall establish a procedure that schedules and plans the usage and maintenance of equipment.

R(x) 8.1-D Each assembly- and test fixture must have a unique identifier, i.e. part number, revision and serial number. This

requirement is valid both for equipment from supplier as well as in-house made equipment.

R(x) 8.1-E The production site and the SOMC IP manager shall prior to RTL (Ready To Launch) agree on and document what is

regarded as unique equipment. In this document the site costs (investment and depreciations) for the equipment shall be

included.

R(x) 8.1-F All equipment intended to be used in factories in China as well as all generic equipment shall be marked according to

document Marking requirements on fixtures (14/1770-LXE 108 030). N/A

R(x) 8.2-A The installation and calibration, initial and continuous, of test stations must be performed according to the Test

Station Manual delivered for each test station.

R(x8.2-B The production site shall establish a procedure with defined responsibilities for maintenance of equipment which shall

be based on supplier recommendations. The maintenance activities shall be documented and illustrated.

R(x) 8.2-C Maintenance instruction must include information of what the operator is expected to do.

• Standard procedures – How to log and document results, etc

• Corrective actions – How to correct issues

• Escalation – How to handle unsolvable faults (not covered in the instruction for corrective actions)

R(x) 8.2-D Planned maintenance activities and other down time of production (i.e. holiday) shall, if affecting available capacity,

be considered in detailed production scheduling process. There shall be an implemented maintenance plan for each line,

defined on a daily, weekly and monthly basis.

R(x) 8.2-E All maintenance and repair activities shall be verified before put in high volume production. The verification shall

secure that SOMC specifications are met. This shall be included in the Production Process Verification plan.

R(x8.2- F When feasible, maintenance and calibration shall be performed by certified maintenance and calibration firms for the

specific equipment. When the supplier of equipment have certified firms that performs repairs such shall be used.

R(x) 8.2 -G All equipment that requires calibration shall have a controlled calibration process to ensure that only calibrated

equipment is used. All equipment that requires calibration shall have a controlled calibration process to ensure that only

calibrated equipment is used. Uncalibrated equipment shall be kept in such a manner that usage is hindered. Records of

calibration result, e.i. "OK" or "Not OK", and measurement values shall be saved.

R(x) 8.2-H The production site shall have a procedure for repair of equipment established, including spare parts management,

minimizing potential down time of production line.

Das könnte Ihnen auch gefallen

- A Practical Guide to Maintenance EngineeringVon EverandA Practical Guide to Maintenance EngineeringBewertung: 4 von 5 Sternen4/5 (6)

- SOMC FHR 6 - Manejo Del Proceso de ProducciónDokument4 SeitenSOMC FHR 6 - Manejo Del Proceso de ProducciónErgonomic WayNoch keine Bewertungen

- Static Analysis of Software: The Abstract InterpretationVon EverandStatic Analysis of Software: The Abstract InterpretationNoch keine Bewertungen

- SOMC FHR 10 - Soporte de InfraestructuraDokument3 SeitenSOMC FHR 10 - Soporte de InfraestructuraAxel CornaloNoch keine Bewertungen

- 737 Performance Reference Handbook - EASA EditionVon Everand737 Performance Reference Handbook - EASA EditionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- SOMC FHR 9 - Infraestructura y Desarrollo de SistemasDokument2 SeitenSOMC FHR 9 - Infraestructura y Desarrollo de SistemasAxel CornaloNoch keine Bewertungen

- 701P49624 Freeflow Accxes Service Manual Yke Yke N FRX LVX UxcDokument172 Seiten701P49624 Freeflow Accxes Service Manual Yke Yke N FRX LVX UxcdinomounarymaminaNoch keine Bewertungen

- Tender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Dokument26 SeitenTender Bulletin 05 Attachment #1 Project Deliverables & Requirements...Hamza ShujaNoch keine Bewertungen

- Manual Servicio - Controler - SM - Yke - Yke-N - FRX - LVX - Uxc - Uxc - N PDFDokument186 SeitenManual Servicio - Controler - SM - Yke - Yke-N - FRX - LVX - Uxc - Uxc - N PDFData PrintNoch keine Bewertungen

- RTEM IC Report GuidelinesDokument2 SeitenRTEM IC Report GuidelinesSyed TouqeerNoch keine Bewertungen

- 701P49624 Freeflow Accxes Service Manual Yke Yke-N FRX LVX UxcDokument172 Seiten701P49624 Freeflow Accxes Service Manual Yke Yke-N FRX LVX Uxcvladimir2426100% (1)

- PID Level Description Rev 2Dokument9 SeitenPID Level Description Rev 2smithworkNoch keine Bewertungen

- Process Flow/Control Plan WorksheetDokument4 SeitenProcess Flow/Control Plan WorksheetVu NguyenNoch keine Bewertungen

- 04 - 03 - Annex C - Maintenance Plan - Ver03Dokument2 Seiten04 - 03 - Annex C - Maintenance Plan - Ver03ELILTANoch keine Bewertungen

- Steering Gear Control System: Standard For CertificationDokument7 SeitenSteering Gear Control System: Standard For CertificationsimonNoch keine Bewertungen

- Guidelines For Control PlanDokument4 SeitenGuidelines For Control PlanArjun Rathore100% (1)

- Durat Is Well Experienced in Pre-Commissioning and Commissioning Activities and Can Provide The inDokument13 SeitenDurat Is Well Experienced in Pre-Commissioning and Commissioning Activities and Can Provide The inEduardo Papupita NúñezNoch keine Bewertungen

- ELECDokument4 SeitenELECrenjithv_4Noch keine Bewertungen

- Enable - Checklist (1) - Copy2Dokument4 SeitenEnable - Checklist (1) - Copy2iman2222Noch keine Bewertungen

- 2011 702P00466 FFA Controler SM Yke Yke-N FRX LVX Uxc Uxc N Da0 PDFDokument216 Seiten2011 702P00466 FFA Controler SM Yke Yke-N FRX LVX Uxc Uxc N Da0 PDFData PrintNoch keine Bewertungen

- Control PlanDokument6 SeitenControl PlanFahmy Khoerul HudaNoch keine Bewertungen

- URFSDI00595-Signaling Storm Solution Service Delivery Instruction-V2R3-EDokument11 SeitenURFSDI00595-Signaling Storm Solution Service Delivery Instruction-V2R3-EMohamed Abdel MonemNoch keine Bewertungen

- Commissioning PlanDokument25 SeitenCommissioning Plananjum128100% (2)

- 02 MaintInspecForm TelehandlersDokument3 Seiten02 MaintInspecForm TelehandlersLeobardo Genaro Roque NájeraNoch keine Bewertungen

- Operation Management 2007 Ed.Dokument333 SeitenOperation Management 2007 Ed.netygen1Noch keine Bewertungen

- 02 MaintInspecForm BoomsDokument5 Seiten02 MaintInspecForm BoomsImam AffandyNoch keine Bewertungen

- IATF Documented ProcessDokument2 SeitenIATF Documented ProcessRakesh JangraNoch keine Bewertungen

- To Include Services As Part of Super ESPC Detailed Energy SurveyDokument8 SeitenTo Include Services As Part of Super ESPC Detailed Energy Surveyenlightened1718Noch keine Bewertungen

- New ISA CCST Task Lists Reference Document For 2013 Exam ChangeDokument13 SeitenNew ISA CCST Task Lists Reference Document For 2013 Exam ChangeNaseer HydenNoch keine Bewertungen

- Operation and Maintenance Manual For Waste Water Treatment WorksDokument15 SeitenOperation and Maintenance Manual For Waste Water Treatment WorksAniket SharmaNoch keine Bewertungen

- 02 MaintInspecForm ScissorsDokument4 Seiten02 MaintInspecForm ScissorsWilliam RodriguezNoch keine Bewertungen

- Instrumentation A For: Process That WillDokument1 SeiteInstrumentation A For: Process That WillAnuragKumarNoch keine Bewertungen

- Audit Checklist Master-HEMSA - June2010Dokument6 SeitenAudit Checklist Master-HEMSA - June2010jkhgvdj mnhsnjkhgNoch keine Bewertungen

- Factory Acceptance Test (FAT) GuideDokument6 SeitenFactory Acceptance Test (FAT) GuideOmar Angulo100% (1)

- Template Seat Heat Peeland Stick Heater Control PlanpostedDokument6 SeitenTemplate Seat Heat Peeland Stick Heater Control PlanpostedvfuntanillaNoch keine Bewertungen

- Device Master RecordsDokument57 SeitenDevice Master RecordsRobertoNoch keine Bewertungen

- Device Master RecordsDokument70 SeitenDevice Master Recordsmogluk100% (3)

- Commissioning Definition and Activities: Technical Data BaseDokument1 SeiteCommissioning Definition and Activities: Technical Data BaseInfoNoch keine Bewertungen

- Device Master RecordsDokument15 SeitenDevice Master Recordstrungthanhnguyen_83Noch keine Bewertungen

- 02 - MaintInspecForm - Booms HartDokument5 Seiten02 - MaintInspecForm - Booms HartOtto PlataformasNoch keine Bewertungen

- 7 Setting Up and Commissioning 7.5 Installation DocumentationDokument6 Seiten7 Setting Up and Commissioning 7.5 Installation DocumentationLouis ChewNoch keine Bewertungen

- Exhibit D3 Inspection and Test Plan (ITP)Dokument12 SeitenExhibit D3 Inspection and Test Plan (ITP)Muhammad Ali AkbarNoch keine Bewertungen

- GMP ChecklistDokument11 SeitenGMP ChecklistWerner Schrammel100% (1)

- Factory Acceptance Test: Appendix HDokument6 SeitenFactory Acceptance Test: Appendix HArif ShakeelNoch keine Bewertungen

- 2.6.1.1 AHU - Construction.checklistDokument5 Seiten2.6.1.1 AHU - Construction.checklistHiếu Nguyễn100% (1)

- Turnover Package ChecklistDokument3 SeitenTurnover Package Checklistacrisiu2005100% (2)

- 701P37410 Synergix Scanner Service ManualDokument218 Seiten701P37410 Synergix Scanner Service Manualjovan5510% (1)

- Iso Work InstructionsDokument115 SeitenIso Work InstructionsEkondroNoch keine Bewertungen

- BN-S-UC001 Standard Checklist For Plant CompletionDokument3 SeitenBN-S-UC001 Standard Checklist For Plant Completionwisnu_bayusaktiNoch keine Bewertungen

- JLR PSF-010 Capacity Analysis ReportDokument7 SeitenJLR PSF-010 Capacity Analysis ReporttruongngvNoch keine Bewertungen

- Anexo 06 - PA - Process Audit v1.1Dokument19 SeitenAnexo 06 - PA - Process Audit v1.1BalajiNoch keine Bewertungen

- API RP 2A Platform Inspection Procedure REV 0Dokument21 SeitenAPI RP 2A Platform Inspection Procedure REV 0Putu Yusna Armita100% (3)

- OQ RawMaterialsSampleTentDokument38 SeitenOQ RawMaterialsSampleTentNishad PathakNoch keine Bewertungen

- 6.E Installation Qualification (IQ) : Here You Will Find Answers To The Following QuestionsDokument10 Seiten6.E Installation Qualification (IQ) : Here You Will Find Answers To The Following QuestionsFilipNoch keine Bewertungen

- Ppap, R&R, MsaDokument8 SeitenPpap, R&R, MsaArun SaigalNoch keine Bewertungen

- Technical File GuideDokument2 SeitenTechnical File GuideGeroldo 'Rollie' L. QuerijeroNoch keine Bewertungen

- AA RD 20211 - Equipment Performance MetricsDokument15 SeitenAA RD 20211 - Equipment Performance Metricsjonodo89Noch keine Bewertungen

- Handling and Transportation of EquipmentDokument2 SeitenHandling and Transportation of EquipmentGajaNand MallickNoch keine Bewertungen

- PPAP Checklist GenericDokument9 SeitenPPAP Checklist Genericamr ahmedNoch keine Bewertungen

- Process AuditDokument15 SeitenProcess Auditdesurkarb100% (2)

- Part IV Civil ProcedureDokument3 SeitenPart IV Civil Procedurexeileen08Noch keine Bewertungen

- Export-Import Documentation Aditya Kapoor PDFDokument8 SeitenExport-Import Documentation Aditya Kapoor PDFPradeepNoch keine Bewertungen

- Deed of Donation CabiaoDokument3 SeitenDeed of Donation CabiaoJholo AlvaradoNoch keine Bewertungen

- Idx Monthly August 2021Dokument139 SeitenIdx Monthly August 2021ElinNoch keine Bewertungen

- 20 Rules of Closing A Deal PDFDokument21 Seiten20 Rules of Closing A Deal PDFbioarquitectura100% (9)

- Catu Vs Atty. RellosaDokument5 SeitenCatu Vs Atty. RellosaUnknown userNoch keine Bewertungen

- APHYD00136810000170072 NewDokument3 SeitenAPHYD00136810000170072 NewNithin Sunny ChackoNoch keine Bewertungen

- Na Fianna Tune BookDokument41 SeitenNa Fianna Tune BookDavid LairsonNoch keine Bewertungen

- Applied PhysicsDokument5 SeitenApplied Physicsahmad irtisamNoch keine Bewertungen

- GSTR1 Excel Workbook Template V1.7Dokument63 SeitenGSTR1 Excel Workbook Template V1.7Nagaraj SettyNoch keine Bewertungen

- Class Action Lawsuit Against Johnson & JohnsonDokument49 SeitenClass Action Lawsuit Against Johnson & JohnsonAnonymous GF8PPILW575% (4)

- Executive Case Digest - CompleteDokument15 SeitenExecutive Case Digest - CompleteKatherine Aquino100% (1)

- AND9201/D The Effect of Pan Material in An Induction Cooker: Application NoteDokument9 SeitenAND9201/D The Effect of Pan Material in An Induction Cooker: Application NoteRajesh RoyNoch keine Bewertungen

- Financial Accounting Module 2Dokument85 SeitenFinancial Accounting Module 2paul ndhlovuNoch keine Bewertungen

- Gyms & Health Clubs - ERCDokument1 SeiteGyms & Health Clubs - ERCCraig Pisaris-HendersonNoch keine Bewertungen

- PNR V BruntyDokument21 SeitenPNR V BruntyyousirneighmNoch keine Bewertungen

- Shay Eshel - The Concept of The Elect Nation in Byzantium (2018, Brill) PDFDokument234 SeitenShay Eshel - The Concept of The Elect Nation in Byzantium (2018, Brill) PDFMarko DabicNoch keine Bewertungen

- Shah Abdul Latif University, Khairpur: ST NDDokument9 SeitenShah Abdul Latif University, Khairpur: ST NDsaqib maharNoch keine Bewertungen

- Annual Income Tax ReturnDokument2 SeitenAnnual Income Tax ReturnRAS ConsultancyNoch keine Bewertungen

- Republic of The Philippines Province of Laguna Barangay - Office of The Barangay CaptainDokument3 SeitenRepublic of The Philippines Province of Laguna Barangay - Office of The Barangay CaptainNehru Valdenarro ValeraNoch keine Bewertungen

- Letter of Recommendation SchelieDokument1 SeiteLetter of Recommendation Schelieapi-237542168Noch keine Bewertungen

- Strategic Litigation Impacts, Insight From Global ExperienceDokument144 SeitenStrategic Litigation Impacts, Insight From Global ExperienceDhanil Al-GhifaryNoch keine Bewertungen

- Philippine Health Care Providers, Inc. Vs CIR Case DigestDokument2 SeitenPhilippine Health Care Providers, Inc. Vs CIR Case DigestJet jet NuevaNoch keine Bewertungen

- Heirs of William Sevilla vs. Sevilla G.R. No. 150179 April 30, 2003Dokument40 SeitenHeirs of William Sevilla vs. Sevilla G.R. No. 150179 April 30, 2003misseixihNoch keine Bewertungen

- Mathematical Solutions - Part ADokument363 SeitenMathematical Solutions - Part ABikash ThapaNoch keine Bewertungen

- Facebook Expose Part 1 of WitnessesDokument5 SeitenFacebook Expose Part 1 of WitnessesByronHubbardNoch keine Bewertungen

- Vasquez Vs CADokument8 SeitenVasquez Vs CABerNoch keine Bewertungen

- Sample of Notarial WillDokument3 SeitenSample of Notarial WillJF Dan100% (1)

- Acts Punishable: Elements of Illegal Sale (ID)Dokument5 SeitenActs Punishable: Elements of Illegal Sale (ID)Jenny wicasNoch keine Bewertungen

- Dokumenti/ Këshilli I Europës Tregon Pse U Refuzuan Kandidatët e Qeverisë Shqiptare Për Gjyqtar Në StrasburgDokument4 SeitenDokumenti/ Këshilli I Europës Tregon Pse U Refuzuan Kandidatët e Qeverisë Shqiptare Për Gjyqtar Në StrasburgAnonymous pPe9isQYcSNoch keine Bewertungen