Beruflich Dokumente

Kultur Dokumente

Mechanical Seals Reliability TQ-PJN

Hochgeladen von

Pete PompesCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mechanical Seals Reliability TQ-PJN

Hochgeladen von

Pete PompesCopyright:

Verfügbare Formate

Operations & Maintenance

Improving the

Reliability of

Mechanical Seals

With a better understanding of seals,

Michael Huebner

Flowserve Corp. their selection, material considerations and

operation requirements, users can greatly

improve equipment reliability and

reduce operating costs.

M

echanical seals provide an important contribution By far the most challenging aspects of seal selection are

to the operation of many different industries. due to the nature of the fluids themselves. Almost every

These ubiquitous devices are found in centrifugal fluid in a refinery is a good lubricant. Very few fluids in

pumps, reactors, mixers, blowers, compressors and some chemical plants share this property. Process fluids can

positive-displacement pumps. Despite their widespread use polymerize on the seal components or crystallize on expo-

though, they are often given little consideration. With a sure to the atmosphere. There may be wide swings in fluid

better understanding of seals, their selection, material con- properties during a batch or between processes. The seal

siderations, and operational requirements, users can greatly and system must be designed to tolerate all of these.

improve equipment reliability and reduce operating costs.

Many chemical processes require variable operating con- Pump selection and operating requirements

ditions or batch processing. Fluctuations in pressure or tem- It is impossible to define a comprehensive list of fac-

perature, the addition or creation of intermediate com- tors that could cause a mechanical seal to fail due to the

pounds, and start/stop operations are not unusual. variety of chemicals and processes. By looking across

Equipment may require cleaning, steaming or sterilization many different industries and end users, though, it is pos-

between batches. Due to these large variations, users tend to sible to see some repeating patterns that lead to success or

oversize equipment to allow for changes or future increases failure. By addressing these factors users can improve the

in capacity. This results in pumps running well away from performance and reliability of their pumps and seals.

their best efficiency point (BEP). As a result, pump reliabili- Most chemical industries rely on chemical duty pumps

ty, bearing life and seal performance are compromised. for the majority of their pumping duties. Most of these are

Material selection is also a challenge in some processes. based on established standards such as ASME B73. While

While austenitic stainless steels and fluoroelastomers are these standards have evolved over time, they have general-

used in most industries, chemical processing can push ly targeted low pressure and moderate temperature applica-

material selection to the edge of current technology. Exotic tions. They were also historically based on the use of pack-

materials, such as titanium or zirconium, may be required ing for pump sealing, although virtually all pump standards

for metallic materials. Gasket materials may include poly- now include or default to the use of mechanical seals.

tetrafluoroethylene (PTFE), perfluoroelastomers and flexi- Most chemical duty pumps are thought of as standard-

ble graphite. Seal face materials may require special chem- ized units. Their designs allow for relatively easy change-

ically resistant grades of carbon and ceramics. outs between design options and manufacturers. This

40 www.cepmagazine.org November 2005 CEP

allows users to stock a relatively small number of pumps Mechanical Seal Basics

(or just power ends) to cover a large number of installa- Mechanical seals provide a seal between a pump

tions. While this does lower inventory levels, it also can casing and a rotating shaft. While this description is sim-

encourage users to try to make one pump cover too wide of ple, it is a significant engineering challenge. Current cus-

a range of operating conditions. The majority of pumps tomer expectations and environmental regulations

chemical plants are not operated near their design or BEP. require no visible leakage for many applications. For

Dozens of studies have been performed and published that many chemicals that are toxic or hazardous, the seals

correlate pump and seal reliability to the operating point on and systems must be designed such that there is no

the pump curve (1). All of these cite a decrease in reliabili- atmospheric leakage under any conditions. One of the

ty as the operating point moves away from the BEP. fundamental concepts of a mechanical seal is to create a

The initial pump-selection phase is critical to operating very small separation between the rotating and station-

pumps at or near their BEP. Unfortunately, many engineers ary seal faces. This film must be small enough to control

apply liberal “safety factors” when establishing the pump- leakage, but not allow excessive face contact. Actual

ing requirements. One specific user in the chemical indus- fluid films are on the order of 0.5 mm (or 20 millionth of

try sizes equipment 50% larger than calculated values. an inch) on typical seal application. Any condition that

For oversized pumps that are already in use in a specific jeopardizes this film will affect seal performance.

application, measures can be taken to move them closer to The pump, piping, baseplate, mechanical seal, seal

the BEP. The most common is the use of a recirculation support systems, coupling, and driver are all integral

line. Fluid from the discharge line is routed back to the suc- parts of the pumping system. Failure of any of these

tion piping or vessel. This keeps the flowrate through the components will cause failure of the entire system. At an

pump near the BEP, although only the required flowrate is operating level, degradation or misapplication on any

passed into the discharge system. Trimming the impeller on one of these components may show up as a failure in

a pump will reduce the head generated and lower the different component. Mechanical seals often act as the

flowrate into a given system. This should only be done with barometer for systems integrity. Pipe strain, cavitation or

a full understanding of the pump and system curves and the coupling misalignment may all show up initially as a seal

required pressure in the discharge line. For pumps that must failure. Seals are often identified as the problem rather

operate over a large range of flows and pressures, consider than the symptom of another problem. This is where

using variable-speed drives that can adjust the pump output users with good equipment reliability differ from those

to more closely match the operating requirements. with poor reliability — the ability to investigate and

understand the factors that affect performance.

Small-bore stuffing boxes vs.

large-bore seal chambers around the seal are very restricted, which can prevent ade-

The term “stuffing box” has historically been used to quate cooling. Higher temperatures and shear may drive

describe the cavity where the pump shaft enters the pump some fluids into polymerization. To address these concerns

casing. Packing was “stuffed” into the cavity and mechan- and allow for better seal designs, pump manufacturer can

ically compressed to limit leakage out of the pump. While provide larger-bore seal chambers.

modern mechanical packing and packing flush configura- Seal chambers are appropriately named. They are

tions have evolved to become relatively sophisticated, the designed to accommodate mechanical seals. The most

principle remains the same. striking difference between stuffing boxes and seal cham-

Due to the requirements for packing, stuffing boxes are bers is the size of the radial cross-section. Seal chambers

designed with a small radial cross-section or clearance range from approximately 3/4 in. (19.09 mm) to 1.0 in.

between the shaft and stuffing box bore. For most chemical (25.4 mm). This allows for the installation of more robust

duty pumps, this ranges from approximately 5/16 in. (7.94 seals that can tolerate a wider range of operating condi-

mm) to 7/16 in. (11.11 mm) to accommodate the square tions. The added clearance also provides better circulation

cross-section packing. Mechanical seals can be applied into of process fluids around the seal chamber. To maximize the

these stuffing boxes. In fact, every mechanical seal manu- effect of the clearance, pump manufacturers provide sever-

facturer has designed seal models specifically to fit into al options for seal chambers. A standard large-bore seal

standard-bore stuffing boxes. This should not be interpreted chamber is designed to accommodate a throat bushing

as an endorsement from the seal industry. In doing so, there when seal chamber isolation is required. An open-bore seal

are design compromises that can affect seal performance. chamber allows for better interchange of the seal chamber

Parts and clearances must be very small. Fluid flow paths and pump process fluids. Tapered-bore seal chambers pro-

CEP www.cepmagazine.org November 2005 41

Operations & Maintenance

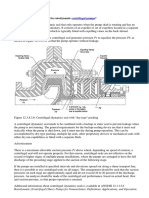

Standard Stuffing Box Big Bore Seal Chamber Tapered Bore Seal Chamber

Seal Face Temperature Seal Face Temperature Chamber Temperature Seal Face Temperature Chamber Temperature

Chamber Temperature

Temperature Plot Temperature Plot Temperature Plot

70 70 70

60 Seal Face Chamber 60 Seal Face Chamber 60 Seal Face Chamber

∆T ∆T 50 ∆T ∆T 50 ∆T ∆T

°F 50 °F °F

40 40 40

30 30 30

20 20 20

10 10 10

6 12 18 24 30 36 42 48 6 12 18 24 30 36 42 48 6 12 18 24 30 36 42 48

Time, h Time, h Time, h

■ Figure 1. Tests show that seal chambers had significant decreases in the temperatures around the seal and at the seal faces when

compared to a standard stuffing box (2).

vide for even better fluid interchange and solids rejection. Some chemical processes operate in a continuous man-

Finally, tapered-bore seal chambers with flow modifiers ner where the operating conditions for a piece of equipment

provide maximum circulation in the seal chamber. are relatively constant over time. In these cases, it is easy to

The user may ask if these seal chambers really do provide document the application conditions and make equipment

better operating conditions than stuffing boxes. The simple selections. Other processes may require variable conditions

answer is yes. A series of tests were run to evaluate the or batch operations, including starts and stops, or changes in

effects on temperatures in the pump, seal chamber and seal pressures or temperatures. It may involve changes in the

faces with different seal chambers and stuffing boxes (2). composition of the fluid stream over time. A subtle, but

The operating conditions (speed, pressure, test fluid) and potentially important, factor related to this is the formation

seal design were constant over the tests. The results showed of intermediate chemicals that are not listed as either inputs

that seal chambers had significant decreases in the tempera- or products of a process. These can affect fluid properties

tures around the seal and at the seal faces when compared to and have implications on material selection.

a standard stuffing box (Figure 1). It is also important to Many batch operations will run in a reactor or vessel that

notice the stability of the temperature under steady-state is filled, processed and drained during one cycle. In the drain-

operation. The restricted flow around the seal in a stuffing ing operation, pumps and seals may be run dry in an attempt

box allows for spikes in temperature between the seal faces, to fully evacuate the vessel. The system may then be cleaned

which can cause flashing or degradation of the process fluid. and purged with chemicals, steam or nitrogen prior to begin-

Since these results and many more studies have been ning the next batch. Other systems are designed to be flexible

published to illustrate the benefits of seal chambers (3), it is depending upon the needs of the plant. To the extent possible,

surprising that all pumps with mechanical seals are not the variability and duty cycle of these processes must be con-

equipped with seal chambers. Unfortunately, in many plants sidered during equipment and material selection.

over half the pumps may still use stuffing boxes. By chang- Oil refineries can provide the ideal environment for seal

ing from stuffing boxes to seal chambers, the user has a applications, since many of their primary products are clean

greater selection of seals options, benefits of improved seal lubricants. Chemical processes can be far more challenging.

cooling, and potential for greater seal reliability. Many solvents, such as acetone, have no lubricating proper-

ties. Some fluids must be processed at higher viscosities,

Nature of chemical process and fluids which makes it difficult to form a fluid film between the seal

As stated earlier, mechanical seals operate on a very faces. Some fluids can be driven into polymerization based

thin fluid film. This fluid film hydrostatically separates on the added heat and fluid shear between the faces. Process

and provides lubrication between the faces. The seal fluids can also solidify upon exposure to atmosphere or cre-

designer has many options for face materials and face ate deposits due to vaporization of the solvent. Consideration

loading conditions to accommodate most fluids. It does for these effects on seals cannot be obtained by merely look-

require that the user understand and communicate exactly ing at a pump datasheet. These effects can only be known by

what the process conditions are and how they can change having experience with a given fluid and chemical process.

during the operation of the equipment. Fortunately, seal manufacturers have a large database of

42 www.cepmagazine.org November 2005 CEP

installed seals that provides excellent guidance to what has between components.

worked successfully in the same or similar processes. This In most seal applications this requires a resilient, elas-

will include not only seal selection, but also seal configura- tomer-based gasket. Generic names such as ethylene propy-

tions and piping plan requirements. lene rubber (EPR), nitrile and fluoroelastomer are commonly

used to describe elastomer materials. This can be very decep-

Material selection tive since compounding and curing processes have a large

Mechanical seals are manufactured from a variety of effect on physical properties and chemical resistance of elas-

components that have very different material requirements tomers. Perfluoroelastomer selection is even more demanding

based on their function. Metal parts form the structure of the since these are used in the most aggressive applications and

seal and must be capable of supporting the pressures and compounds selection can be very application-specific.

loads of the application. Gaskets provide sealing between Some of the most common gasket materials are:

other components and must allow for motions and variation • Ethylene propylene — copolymer of ethylene and

in tolerances and thermal growth. Seal faces must provide a propylene with good resistance in some ketones, alcohols

good tribological pair to allow for low wear and low friction and hot water but not compatible with hydrocarbons

in operation. All of the components must be rated for the • Nitrile — a copolymer of acrylonitrile and butadiene

operating temperature and the chemical environment of the with good general compatibilities and excellent low tem-

application. All of these materials must also work together to perature properties

allow the seal to function properly. Fortunately, all seal man- • Fluoroelastomers — best standard-duty elastomer with

ufacturers have done extensive research into materials and excellent overall chemical capability

narrowed the selection down to a finite number of options • Perfluoroelastomers — a wide range of specific elas-

that can meet most application needs. tomer compounds with superior chemical compatibility and

Metallic materials. Metals are used throughout most high-temperature properties

chemical processes. Piping, valves and pump components • Polytetrafluoroethylene (PTFE) — near universal

are generally made from metals, and careful consideration chemical compatibility, but no resiliency

goes into their selection. • Flexible graphite — near universal chemical compati-

In most cases, relatively common materials such as bility and high-temperature capability, but no resiliency.

austenitic stainless steels (e.g., AISI 316) can be used. In Seal faces. In most seal applications, the face materials

extreme cases, exotic materials, such as zirconium and tanta- consist of a hard face and a soft face. This combination has

lum, must be used. When material costs become very high, proven to provide a low coefficient of friction and best tol-

users will often consider service life against initial cost. erance of face contact. The soft face can also wear to

While there are some up-front cost savings with this match the profile of the hard face, resulting in a thin fluid

approach, the service life is defined with the initial purchase. film and low leakage. The hard faces in modern mechani-

Common seal metallic materials are listed below: cal seals are almost exclusively ceramic materials. The soft

• AISI 316 (UNS S31600) — general-duty chromium face is a blend of amorphous carbon, carbon graphite,

alloy with a wide range of chemical resistance impurities, and impregnants. In the most aggressive servic-

• Alloy C-276 (UNS N10276) — nickel-molybdenum- es, some seals will use the two hard faces for the maximum

chromium alloy with good resistance in many strong acids chemical resistance and tolerance of impurities.

and chlorides The most common hard-face materials are:

• Alloy 20 (UNS N08020) — nickel-chromium-molybde- • Tungsten carbide with cobalt binder — low-duty WC

num alloy with especially good resistance in hot sulfuric acid with cobalt metal phase having poor chemical resistance

• Alloy 400 (UNS N04400) — copper-nickel alloy with • Tungsten carbide with nickel binder — general-duty

excellent resistance in hydrofluoric acid applications WC where compatibility is limited by nickel metal phase

• Inconel 718 (UNS N07718) — excellent corrosive • Reaction-bonded silicon carbide — general-duty SiC

properties and strength at high temperatures with free silicon, which limits its use in caustics and

• Titanium — excellent resistance in oxidizing acids and salts strong acids

• Zirconium — excellent chemical resistance in strong • Alumina oxide — homogenous ceramic materials

acids such as nitric and sulfuric acids. with excellent chemical resistance, but poor thermal shock

Gaskets. Gaskets form a seal between the various com- characteristics

ponents in the mechanical seal and with the pump. These • Direct-sintered silicon carbide (also referred to as

materials must be not only provide a seal, but also allow for alpha-sintered SiC or direct-sintered SiC) — homogeneous

some movement, thermal expansion, and tolerances ceramic SiC material with excellent chemical resistance.

CEP www.cepmagazine.org November 2005 43

Operations & Maintenance

The most common soft-face materials are:

• Metalized carbon — carbon grade with metal phase,

which improves strength, but limits chemical compatibility

• Resin-impregnated carbon — general-duty carbon

with excellent chemical resistance

• Acid-grade carbon — carbon-grade with low impregnant

and ash content to provide superior chemical compatibility.

The options listed above are generally arranged in order

from the least chemically resistant to the most chemically

resistant. This ordering is highly dependent on the actual

chemical, concentration, temperature and exposure condi-

tions. Different corrosion mechanisms can also be present

depending upon the application and contact with other

materials in the seal and pump.

Seal selection

Mechanical seal designs can be divided into two main

categories — pusher seals and bellows seals. Pusher seals

are designed so that the flexible seal face is sealed against

another seal component with a dynamic gasket. This allows

the seal face to move axially to compensate for shaft ■ Figure 2. Inside (top) vs. outside (bottom) mounted configurations.

motion, thermal growth, misalignment or seal face wear.

The flexible gasket in most pusher seals is a standard cross- of the metal parts out of the process and designing the seal in

section O-ring. This allows easy availability of the gasket in an outside mounted configuration (Figure 2). While these

a large number of elastomer compounds. Because the face options can provide benefits in terms of corrosion, there will

must remain free to move, any swelling or degradation of always be some exposure of the components to the process,

the gasket may cause excessive leakage or seal failure. so the most compatible materials must be selected.

Bellows seals, on the other hand, do not rely on a For seal selection, there are design options to handle most

dynamic gasket to allow for motion of the flexible face. applications. Clean products with minimal gasket compatibili-

This design uses a bellows element to provide sealing and ty issues can successfully use almost any design. As products

motion for the seal face. The most common bellows seal become more contaminated, change physical properties (crys-

design involves a welded metal bellows. Thin metal tallize or polymerize), or suffer from elastomer compatibility

diaphragms are welded at the outer and inner diameters to issues, bellows seals become the preferred selection. For serv-

form a continuous barrier between the process fluid and ices where the chemical compatibility of metal parts is chal-

atmosphere. The primary advantage to this design is that lenging, outside mounted seals may provide the best service.

there are no dynamic gaskets. Larger amounts of swelling

are allowed on the static gaskets without adversely affecting Seal support systems

seal performance. In some designs, other static gasket mate- In some cases, pumps contain a single seal operating on

rials, such as PTFE or flexible graphite, are used to provide the process fluid in the pump. In other cases, multiple seals

near universal chemical compatibility for a seal. Bellows may be used where leakage of the process fluid must be

seals are also less likely to have the flexible element hang- avoided. There may be still other cases where the process

up due to debris, polymerization or crystallization. fluid cannot be successfully sealed and a barrier fluid or

Seal designs can also be categorized according to their external fluid must be provided to the seals. Process fluids

exposure to the pump process fluid. In a standard rotating in the seal chamber may also require cleaning or cooling to

flexible element configuration, many of the seal’s metal com- improve seal performance. All of these situations are

ponents are exposed to process conditions. This can create defined and documented in the seal piping plans.

areas where debris may collect or where there will be corro- Piping plans are standardized definitions of the piping,

sion of thin metal components, such as springs. To minimize control, monitoring and conditioning of the fluid around

exposure of the metal components, a stationary spring design the mechanical seals. The most common definitions are

can be used to remove these components from the process documented in ASME B73 and API 682. At the simplest

environment. The most extreme option involves removing all end, a seal may run dead-ended in a seal chamber (Plan

44 www.cepmagazine.org November 2005 CEP

02). At the more complex end, a dual pressurized seal will with a written procedure. To help make the procedure rele-

require a barrier fluid and external reservoir (Plan 53). The vant to the operators, it should be documented onto a check-

success of the pump and seal depends upon the correct list that the operators can carry with them during the com-

selection and maintenance of the support system. missioning and operation of a pump and seal.

One of the most commonly overlooked areas in system

maintenance involves dual-seal support systems. Barrier or Think outside of the box

buffer fluids are used in these systems to provide the envi- Knowledge is only effective if it is put into action. The

ronment between the two seals. When a reservoir is first author was involved in a troubleshooting exercise at a major

installed and filled with fresh barrier fluid, the environment chemical plant. Documentation was prepared to conclusively

is known. After long periods of operation, the barrier fluid describe the cause of the problems and copies of previously

may become contaminated by process fluid or break down published studies were provided for the users’ review. After

under high temperatures. Most users continue to operate a few minutes, they looked up and stated that they already

with the same barrier fluid until the seal fails. In many knew all of this. This is the way they operated their pumps

cases, the seal failure is actually hastened due to the poor and they wanted to know what could be done to improve the

condition of the barrier fluid. After a seal fails, a surprising pumps’ performance. Although the meeting went on for

number of users simply refill the reservoir and restart the some time, it effectively ended when they stated that they

pump. Any contamination or debris in the reservoir or con- were unwilling to correct conditions that were causing their

necting piping is left to re-contaminate the barrier fluid. problems. If you change nothing, nothing will change.

Whenever a seal is replaced, the seal support system Improving pump and seal reliability starts with a change

should be inspected and cleaned prior to operation of the of focus away from initial cost and speed of repair. This

equipment. For all dual-seal systems, the old barrier fluid requires a recognition of total cost of ownership from a man-

should be drained and properly discarded. If the barrier agement level. It also requires a dedication to making

system was contaminated with process fluid, the system improvements in existing equipment and systems that are

should be flushed with a compatible fluid. This is also true not providing acceptable reliability. Finally, it requires a con-

if there is evidence that debris from the seal failure circu- sistent reliability program to put these concepts into proce-

lated through the barrier system. dures. Although initial efforts may seem high, the results

provide excellent medium- and long-term savings. CEP

Operator training

Some of the most common causes of seal failures can be Literature Cited

traced to operator training. From an operator’s perspective, 1. Adams, W., et. al., “The Role of Off-Design Pump Operation on

an installed pump and seal should be ready to run whenever Mechanical Seal Performance,” Proceedings of the Sixth

International Pump Users Symposium, Turbomachinery

required. In reality, many steps need to be taken to ensure a Laboratory, Department of Mechanical Engineering, Texas

successful start-up. This can include priming the pump, A&M University, College Station, TX (1994).

venting the seal, filling the seal support systems, or turning 2. Davidson, M., “The Effects of Seal Chamber Design on Seal

on cooling water, depending upon the application. Many of Performance,” Proceedings of the Sixth International Pump

Users Symposium, Turbomachinery Laboratory, Department

these requirements may be ignored at a time when there are of Mechanical Engineering, Texas A&M University, College

many other activities requiring the operator’s attention. This Station, TX (1989).

is especially true when an operator does not fully under- 3. Adams, W., et. al., “Enhanced Mechanical Seal Performance

stand how a pump and seal really work at a detailed level. It Through Proper Selection and Application of Enlarged-Bore

Seal Chambers,” Proceedings of the Tenth International Pump

is unlikely that operators will become seal experts, but they Users Symposium, Turbomachinery Laboratory, Department

should be given the knowledge necessary to operate the of Mechanical Engineering, Texas A&M University, College

equipment correctly. This includes training on pump and Station, Texas (1993).

seal basics. Whenever there is a change in seal or system

design, they should be given training on the new require-

MICHAEL HUEBNER is a staff engineer for Flowserve Corp. (906 W. 13th Street,

ments or changes in the procedures. Deer Park, TX 77536; Phone: 281 479 7325; Fax: 281 479 0250). He has over 22

Even after years of training and experience, aircraft pilots years of experience in centrifugal pump and mechanical seal design and

go through a checklist before every flight. This ensures that application. He has been responsible for seal design, qualification, application,

and testing at Flowserve in both the U.S. and Europe. Huebner received his BS

no step will be forgotten or taken for granted. Operating a degree in Engineering Technology at Texas A&M University. He is member of

pump and seal in many processes can be just as dangerous the API 682 Task Force and ISO 21049 Committee on seal standards. He is also

and deserves an equal focus on following established proce- a member of the ASME B73 Committee and the on the advisory committee for

the International Pump User Symposium at Texas A&M University.

dures. Whenever possible, training should be documented

CEP www.cepmagazine.org November 2005 45

Das könnte Ihnen auch gefallen

- Machinery Reliability Chapter 1 M Seal Secrets Alkhowaiter Final 4 Expanded 5Dokument25 SeitenMachinery Reliability Chapter 1 M Seal Secrets Alkhowaiter Final 4 Expanded 5Abdulrahman AlkhowaiterNoch keine Bewertungen

- 7secrets Pump RelyDokument2 Seiten7secrets Pump RelyRichard S. BabanNoch keine Bewertungen

- Sealing Sense - Mech Seal StorageDokument4 SeitenSealing Sense - Mech Seal StoragesurawutwijarnNoch keine Bewertungen

- Next generation materials for pumps and mechanical sealsDokument3 SeitenNext generation materials for pumps and mechanical sealsmadairkifNoch keine Bewertungen

- The Case For Double Mechanical Seal PDFDokument4 SeitenThe Case For Double Mechanical Seal PDFgirlycaptainNoch keine Bewertungen

- Mechanical Seal Selection For VSDs PDFDokument3 SeitenMechanical Seal Selection For VSDs PDFAnonymous 1XHScfCINoch keine Bewertungen

- JC Seal Leakage CausesDokument1 SeiteJC Seal Leakage CausesasrikalyanNoch keine Bewertungen

- Sealing Concept-RwDokument20 SeitenSealing Concept-RwnuradiadnanNoch keine Bewertungen

- Shaft Sealing Mechanical Seals 1662138716Dokument195 SeitenShaft Sealing Mechanical Seals 1662138716eslam zainNoch keine Bewertungen

- SUBJECT: A Quick Reference Guide For Mechanical Seal Failure 4-11Dokument5 SeitenSUBJECT: A Quick Reference Guide For Mechanical Seal Failure 4-11Liz Lynn LimNoch keine Bewertungen

- API PLAN 23 COOLINGDokument3 SeitenAPI PLAN 23 COOLINGsapu11jagat5855Noch keine Bewertungen

- Mechanical Seals Vs Gland Packing - Mechanical Engineering SiteDokument5 SeitenMechanical Seals Vs Gland Packing - Mechanical Engineering SiteRajKumarNoch keine Bewertungen

- 53C - FsaDokument5 Seiten53C - FsaSulaiman Kadher KNoch keine Bewertungen

- What Determines Seal Leakage?Dokument3 SeitenWhat Determines Seal Leakage?Pradeep MotaparthyNoch keine Bewertungen

- Pitfalls of Pump PipingDokument3 SeitenPitfalls of Pump PipingChris PeramunugamaNoch keine Bewertungen

- Mechanical Seal Repair PDFDokument4 SeitenMechanical Seal Repair PDFVictor Flores ResendizNoch keine Bewertungen

- Ensuring reliability of API Piping Plan 53BDokument4 SeitenEnsuring reliability of API Piping Plan 53Bkalam2k2Noch keine Bewertungen

- Presentación DuPont Agrícolas 2015Dokument19 SeitenPresentación DuPont Agrícolas 2015GambeatNoch keine Bewertungen

- JHON CRANE 2152037 Barrier FluidsDokument19 SeitenJHON CRANE 2152037 Barrier Fluidstotalquality100% (2)

- 6 Reasons Why Mechanical Seals FailDokument3 Seiten6 Reasons Why Mechanical Seals Failgustavo rivaroliNoch keine Bewertungen

- API Seal Plans 52 and 53 A/BDokument21 SeitenAPI Seal Plans 52 and 53 A/BvenkeekuNoch keine Bewertungen

- Double Mechanical Seals, Tandem ArrangementDokument10 SeitenDouble Mechanical Seals, Tandem ArrangementViwek MertiyaNoch keine Bewertungen

- Construction Maintenance Department: Mechanical Technician Qualification ModuleDokument109 SeitenConstruction Maintenance Department: Mechanical Technician Qualification ModuleAndinata Sitepu100% (1)

- Mechanical seal failure analysisDokument2 SeitenMechanical seal failure analysisrizki akhadiNoch keine Bewertungen

- Double Mechanical Seal For PumpsDokument7 SeitenDouble Mechanical Seal For PumpsNikeshNoch keine Bewertungen

- Explosive DecompressionDokument11 SeitenExplosive DecompressionAndrey EkkertNoch keine Bewertungen

- Mechanical Seal and Support System Considerations For Negative Temperature Hydrocarbon Services: NGL Processing and Ethylene Production FocusDokument21 SeitenMechanical Seal and Support System Considerations For Negative Temperature Hydrocarbon Services: NGL Processing and Ethylene Production FocuspratapNoch keine Bewertungen

- 100 Mechanical SealsDokument20 Seiten100 Mechanical SealsDeepa VpNoch keine Bewertungen

- Key to Selection Pages Fluid DataDokument42 SeitenKey to Selection Pages Fluid DataPete PompesNoch keine Bewertungen

- 4 Ways To Prevent Seal FailureDokument5 Seiten4 Ways To Prevent Seal FailureGlobe Star Engineers Pvt LtdNoch keine Bewertungen

- Case Study: Root Cause Analysis of Seal Failures in Refinery PumpsDokument8 SeitenCase Study: Root Cause Analysis of Seal Failures in Refinery PumpsVaibhav SinghNoch keine Bewertungen

- Calgary Pump Symposium Seal Specification PresentationDokument36 SeitenCalgary Pump Symposium Seal Specification PresentationReyes SanchezNoch keine Bewertungen

- Troubleshooting of Mechanical Seals PDFDokument5 SeitenTroubleshooting of Mechanical Seals PDFNasser KhattabNoch keine Bewertungen

- TD 5610V 5610VQ 5620VP 2PG BW Oct2015Dokument2 SeitenTD 5610V 5610VQ 5620VP 2PG BW Oct2015Pham Thien TruongNoch keine Bewertungen

- Mechanical Seal Principles Chesterton)Dokument6 SeitenMechanical Seal Principles Chesterton)Joon EeoNoch keine Bewertungen

- API Plan 32 Flush Systems. Avoiding Seal FailuresDokument1 SeiteAPI Plan 32 Flush Systems. Avoiding Seal Failuresdk4monjureNoch keine Bewertungen

- JC 2648 Seal IOM Manual PDFDokument4 SeitenJC 2648 Seal IOM Manual PDFRené Mora-CasalNoch keine Bewertungen

- What Is The Best Silicon Carbide Wear Face Material For My Mechanical SealDokument3 SeitenWhat Is The Best Silicon Carbide Wear Face Material For My Mechanical SealMahmoud Al HomranNoch keine Bewertungen

- The Dual Seal ArrangementDokument17 SeitenThe Dual Seal Arrangementnyuvaraj1981Noch keine Bewertungen

- Fitting InstructionDokument6 SeitenFitting InstructionAan Sarkasi AmdNoch keine Bewertungen

- Choose the Right Piping Plan: 53A, 53B or 53CDokument3 SeitenChoose the Right Piping Plan: 53A, 53B or 53CAmol PatkiNoch keine Bewertungen

- Aes Api682 01Dokument9 SeitenAes Api682 01meghanahariNoch keine Bewertungen

- Dual Gas-Lubricated Seals Provide Energy Efficient SolutionsDokument2 SeitenDual Gas-Lubricated Seals Provide Energy Efficient Solutionssudhindra_tiwariNoch keine Bewertungen

- 1648 ManualDokument29 Seiten1648 ManualSherif Adel100% (2)

- Mechanical Seal InstructionsDokument25 SeitenMechanical Seal Instructionsjack-bcNoch keine Bewertungen

- Seal Reliability and Failure AnalysisDokument41 SeitenSeal Reliability and Failure Analysiskarioke mohaNoch keine Bewertungen

- Sealing Extreme Cold Application - FSADokument3 SeitenSealing Extreme Cold Application - FSASulaiman Kadher KNoch keine Bewertungen

- b5860 For Slurry ApplicationDokument6 Seitenb5860 For Slurry Applicationpeach5Noch keine Bewertungen

- Api 52Dokument3 SeitenApi 52Sofiane HalimiNoch keine Bewertungen

- Failure Analysis John CraneDokument83 SeitenFailure Analysis John CraneIulian Luncan96% (23)

- Non-Asbestos Sealing Products CatalogueDokument44 SeitenNon-Asbestos Sealing Products CataloguezatenneNoch keine Bewertungen

- Rotating Face Mechanical SealsDokument3 SeitenRotating Face Mechanical SealsSufi Lord NewNoch keine Bewertungen

- Flowserve Seal InstructionDokument4 SeitenFlowserve Seal InstructionhafizudinNoch keine Bewertungen

- Flowserve Pusher Seal ManualDokument16 SeitenFlowserve Pusher Seal ManualNikhil Princeton AndradeNoch keine Bewertungen

- Asset Integrity Management A Complete Guide - 2020 EditionVon EverandAsset Integrity Management A Complete Guide - 2020 EditionNoch keine Bewertungen

- Optimizing Vertical Suspended Pump Performance A10360Dokument6 SeitenOptimizing Vertical Suspended Pump Performance A10360Hidroterm Plantas Electricas-Bombas De Agua-Maquinaria PesadaNoch keine Bewertungen

- Aug08 PDFDokument3 SeitenAug08 PDFammar kkNoch keine Bewertungen

- Literature Review Centrifugal PumpDokument5 SeitenLiterature Review Centrifugal Pumpea44a6t7100% (1)

- Pump SealsDokument10 SeitenPump Sealspaul_brightNoch keine Bewertungen

- Mechanical Seals Often Fail As A Consequence of Prior Bearing DistressDokument4 SeitenMechanical Seals Often Fail As A Consequence of Prior Bearing DistressMagical RiyaNoch keine Bewertungen

- Water Well SeriesDokument1 SeiteWater Well SeriesPete PompesNoch keine Bewertungen

- Why Choose Short Term?: To Exit: To EnterDokument1 SeiteWhy Choose Short Term?: To Exit: To EnterPete PompesNoch keine Bewertungen

- Impellers SelectionDokument0 SeitenImpellers Selectionpeach5Noch keine Bewertungen

- Edwards EDC Dry Claw Pumps Brochure PDFDokument8 SeitenEdwards EDC Dry Claw Pumps Brochure PDFPete PompesNoch keine Bewertungen

- ABEL Positive Displacement Pumps for Sludge, Slurry and Solids HandlingDokument6 SeitenABEL Positive Displacement Pumps for Sludge, Slurry and Solids HandlingPete PompesNoch keine Bewertungen

- Submersible Engineering DatasheetDokument2 SeitenSubmersible Engineering DatasheetTunas WibowoNoch keine Bewertungen

- Abel EM SeriesDokument6 SeitenAbel EM SeriesPete PompesNoch keine Bewertungen

- Pump WearDokument6 SeitenPump WearSumeet SawantNoch keine Bewertungen

- What Is A Mechanical Seal PDFDokument2 SeitenWhat Is A Mechanical Seal PDFIrma Tri Puspita SariNoch keine Bewertungen

- Laser Tip of The Month: Norm VoelzowDokument2 SeitenLaser Tip of The Month: Norm VoelzowPete PompesNoch keine Bewertungen

- Wear Rings: Contributed by Zoeller Engineering DepartmentDokument2 SeitenWear Rings: Contributed by Zoeller Engineering DepartmentAjay VishwakarmaNoch keine Bewertungen

- What Is A Mechanical Seal PDFDokument2 SeitenWhat Is A Mechanical Seal PDFIrma Tri Puspita SariNoch keine Bewertungen

- How To Perform A Precision Alignment When Nearby Machines Are Vibrating.Dokument2 SeitenHow To Perform A Precision Alignment When Nearby Machines Are Vibrating.Pete PompesNoch keine Bewertungen

- Pump WearDokument6 SeitenPump WearSumeet SawantNoch keine Bewertungen

- Types of mechanical seals for wastewater pumpsDokument2 SeitenTypes of mechanical seals for wastewater pumpsPete PompesNoch keine Bewertungen

- 7977 8cd2Dokument2 Seiten7977 8cd2Pete Pompes0% (1)

- Types of mechanical seals for wastewater pumpsDokument2 SeitenTypes of mechanical seals for wastewater pumpsPete PompesNoch keine Bewertungen

- Mechanical Seal Principles Chesterton)Dokument6 SeitenMechanical Seal Principles Chesterton)Joon EeoNoch keine Bewertungen

- NPSHDokument3 SeitenNPSHHarsimran Singh ੴNoch keine Bewertungen

- Durco Mark III Seal SentryDokument1 SeiteDurco Mark III Seal SentryPete PompesNoch keine Bewertungen

- Shaft TolerancesDokument1 SeiteShaft TolerancesPete PompesNoch keine Bewertungen

- Pumps and System CurvesDokument22 SeitenPumps and System CurvesgusgifNoch keine Bewertungen

- What Is A Centrifugal Seal in Rotodynamic Centrifugal PumpsDokument1 SeiteWhat Is A Centrifugal Seal in Rotodynamic Centrifugal PumpsPete PompesNoch keine Bewertungen

- Durco-Reverse Vane Vs Front VaneDokument1 SeiteDurco-Reverse Vane Vs Front VanePete PompesNoch keine Bewertungen

- Key to Selection Pages Fluid DataDokument42 SeitenKey to Selection Pages Fluid DataPete PompesNoch keine Bewertungen

- Dynamic Seals Lower Life Cycle - Spring - 2004Dokument2 SeitenDynamic Seals Lower Life Cycle - Spring - 2004Pete PompesNoch keine Bewertungen

- D Summary of HI Stds Relating To Energy EfficencyDokument2 SeitenD Summary of HI Stds Relating To Energy EfficencyPete PompesNoch keine Bewertungen

- Pump Cheat SheetsDokument5 SeitenPump Cheat Sheetsmirakel000Noch keine Bewertungen

- Viscosity Conversion ChartDokument1 SeiteViscosity Conversion ChartOmar Teny Cigueñas OlanoNoch keine Bewertungen

- Canary TreatmentDokument117 SeitenCanary TreatmentRam KLNoch keine Bewertungen

- Food Sub Inspector Question PaperDokument12 SeitenFood Sub Inspector Question PaperGoutam shitNoch keine Bewertungen

- 4mb1 02r Que 20220608Dokument32 Seiten4mb1 02r Que 20220608M.A. HassanNoch keine Bewertungen

- MRI Week3 - Signal - Processing - TheoryDokument43 SeitenMRI Week3 - Signal - Processing - TheoryaboladeNoch keine Bewertungen

- Method Statement Pressure TestingDokument15 SeitenMethod Statement Pressure TestingAkmaldeen AhamedNoch keine Bewertungen

- Fees Structure For Government Sponsored (KUCCPS) Students: University of Eastern Africa, BaratonDokument3 SeitenFees Structure For Government Sponsored (KUCCPS) Students: University of Eastern Africa, BaratonGiddy LerionkaNoch keine Bewertungen

- Ajwin Handbuch enDokument84 SeitenAjwin Handbuch enEnzo AguilarNoch keine Bewertungen

- Affidavit of 2 Disinterested Persons (Haidee Gullodo)Dokument1 SeiteAffidavit of 2 Disinterested Persons (Haidee Gullodo)GersonGamasNoch keine Bewertungen

- 10 Compactness in Function Spaces: Ascoli-Arzel A TheoremDokument5 Seiten10 Compactness in Function Spaces: Ascoli-Arzel A TheoremronalduckNoch keine Bewertungen

- FloridaSharkman ProtocolsDokument14 SeitenFloridaSharkman ProtocolsgurwaziNoch keine Bewertungen

- Communication in Application: WhatsappDokument18 SeitenCommunication in Application: WhatsappNurul SuhanaNoch keine Bewertungen

- DMGT403 Accounting For Managers PDFDokument305 SeitenDMGT403 Accounting For Managers PDFpooja100% (1)

- 8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features DescriptionDokument3 Seiten8510C - 15, - 50, - 100 Piezoresistive Pressure Transducer: Features Descriptionedward3600Noch keine Bewertungen

- JE Creation Using F0911MBFDokument10 SeitenJE Creation Using F0911MBFShekar RoyalNoch keine Bewertungen

- Biometric SecurityDokument495 SeitenBiometric SecurityPlay100% (1)

- Wicks Angela, Roethlein Christopher - A Satisfaction - Based Definition of QualityDokument1 SeiteWicks Angela, Roethlein Christopher - A Satisfaction - Based Definition of Qualityalfdjole0% (1)

- User Manual - Rev3Dokument31 SeitenUser Manual - Rev3SyahdiNoch keine Bewertungen

- Asset Valuation: Debt Investments: Analysis and Valuation: 1 2 N M 1 2 N MDokument23 SeitenAsset Valuation: Debt Investments: Analysis and Valuation: 1 2 N M 1 2 N MSirSmirkNoch keine Bewertungen

- Barker-Choucalas, Vida PDFDokument176 SeitenBarker-Choucalas, Vida PDFAnn GarbinNoch keine Bewertungen

- ReadingDokument6 SeitenReadingakhyar sanchiaNoch keine Bewertungen

- Subtracting-Fractions-Unlike DenominatorsDokument2 SeitenSubtracting-Fractions-Unlike Denominatorsapi-3953531900% (1)

- Construction Internship ReportDokument8 SeitenConstruction Internship ReportDreaminnNoch keine Bewertungen

- Naruto Vol 4Dokument171 SeitenNaruto Vol 4Andrew WongNoch keine Bewertungen

- PWC Annual ReportDokument46 SeitenPWC Annual ReportAigulNoch keine Bewertungen

- 01 Lab ManualDokument5 Seiten01 Lab ManualM Waqar ZahidNoch keine Bewertungen

- Smartrac - Iolineug - r5Dokument66 SeitenSmartrac - Iolineug - r5Darwin Elvis Giron HurtadoNoch keine Bewertungen

- BS en 1044-1999 - Brazing Filler MetalsDokument26 SeitenBS en 1044-1999 - Brazing Filler MetalsBorn ToSinNoch keine Bewertungen

- Future War in Cities Alice Hills PDFDokument5 SeitenFuture War in Cities Alice Hills PDFazardarioNoch keine Bewertungen

- Liebert PEX+: High Efficiency. Modular-Type Precision Air Conditioning UnitDokument19 SeitenLiebert PEX+: High Efficiency. Modular-Type Precision Air Conditioning Unitjuan guerreroNoch keine Bewertungen

- Securifire 1000-ExtractedDokument2 SeitenSecurifire 1000-ExtractedWilkeey EstrellanesNoch keine Bewertungen