Beruflich Dokumente

Kultur Dokumente

Op 7

Hochgeladen von

Jeffrey C. De VeroOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Op 7

Hochgeladen von

Jeffrey C. De VeroCopyright:

Verfügbare Formate

PLD2009, December 02-04, 2009, IIT Madras, Chennai

OP7

Material transfer dynamics of infrared (1064 nm) Nd:YAG pulsed laser deposition

of yttrium doped Bi2 Sr2 CaCu2 O8+d thin films

Jeffrey C. de Vero*, Glaiza Rose S. Blanca†, Jaziel R. Vitug, Wilson O Garcia, and Roland V. Sarmago.

National Institute of Physics, University of the Philippines, Diliman, Quezon City, Philippines 1101

*Email: jcdevero@up.edu.ph

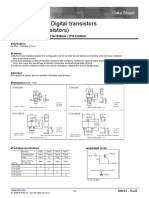

Yttrium doped BSCCO (Bi-22Y2) films on MgO (100) were fabricated by infrared (1064 nm) Nd: YAG

pulsed laser deposition with ex-situ post heat treatments. The technique comprised of pulsed laser ablation of

Bi2 Sr2 Ca1-x Yx Cu 2 O8+δ target with x = 0.01, 0.02, 0.03, and 0.05 for 180 minutes at 5.5 J/cm2 energy fluence and 10-2

mbar chamber pressure. After the deposition, the as - deposited film is partially melted 930°C for 15 minutes and

subsequently annealed at 8500 C for 5 hours in air. Molten stoichiometric blocks of Bi-22Y2 form clusters of

immobile spheroids on the substrate surface. Figure 1a shows the SEM image of film at different yttrium doping

concentration. EDX measurement on these films shows that stoichiometry for both target and film is the same as

shown in figure 1.b. Figure 1.c. shows that the intensity of the optical emission lines yttrium is linear with the

amount of the yttrium in the target. We take this to indicate that the material transfer is block-by-block and hence

preserving the stoichiometry of the target to the deposited films. To promote growth on MgO substrate, films were

subjected to partial melting and annealing in ambient air. Heat treatment exposed the crystal facets of Bi-22Y2 and

facilitates on reconfiguration and eventually re-orientation of the Bi-22Y2 on the substrate axis . Superconducting

property of the film was confirmed by the temperature dependence of its resistance. Figure 1.d. shows the resistance

curve as a function of temperature for the representative Bi-22Y2 with Tc-onset of 90 K, 93 K, 91 K, and 83 K for x =

0, 0.01, 0.02, 0.03, and 0.05, respectively. Partial substitution of yttrium on Bi-2212 films exhibits the expected

increase in the superconducting critical temperature due to reduction of doping level. This property of the film is

due to fact that the material transfer using infrared (1064 nm) Nd: YAG pulsed laser is block-by-block and not

atomized.

1% 2%

3% 5%

(a) (b)

1.0 )

Normalized Resistance

0.8

0.6

0.4 1%

2%

3%

0.2 5%

0.0

0 20 40 60 80 100 120 140 160

Temperature (K)

(d)

(c)

)

Figure 1: (a) SEM images of as-deposited y-doped films grown by infrared (1064 nm) Nd:YAG laser with post- deposition heat treatment,

(b)EDX measurement of the as-deposited film; (c) Relative intensity of yttrium emission at 485.25 nm at varying doping concentration ; and

(d) Superconducting transition temperature.

7

† on- leave from FEATI University, College of Arts, Sciences, and Education, Sta. Cruz Manila, Philippines

Das könnte Ihnen auch gefallen

- Column Design ChartDokument5 SeitenColumn Design ChartGabriel100% (2)

- Lumenis Versapulse Powersuite 100w Service ManualDokument178 SeitenLumenis Versapulse Powersuite 100w Service ManualRenato CastroNoch keine Bewertungen

- Organic Chem Diels-Alder Reaction LabDokument9 SeitenOrganic Chem Diels-Alder Reaction LabPryanka BalleyNoch keine Bewertungen

- Nortel Networks Co. Angstrom Sun Technologies Inc.: Ping Hou Richard SunDokument14 SeitenNortel Networks Co. Angstrom Sun Technologies Inc.: Ping Hou Richard SunNassar Al-EssawiNoch keine Bewertungen

- Poster Solar Cell ProjectDokument1 SeitePoster Solar Cell ProjectWanichanokNoch keine Bewertungen

- 10 1016@j Ijmecsci 2020 105846Dokument34 Seiten10 1016@j Ijmecsci 2020 105846venkatadriKNoch keine Bewertungen

- TMP FD52Dokument4 SeitenTMP FD52FrontiersNoch keine Bewertungen

- 1 s2.0 S1877705815030623 MainDokument5 Seiten1 s2.0 S1877705815030623 MainJOAM MANUEL RINCÓN ZULUAGANoch keine Bewertungen

- Optimization of Process Parameters For The High-Power Laser Diode Bar Array PackagingDokument4 SeitenOptimization of Process Parameters For The High-Power Laser Diode Bar Array PackagingcjpanchalNoch keine Bewertungen

- Soft Chemical Routes For Synthesis of Nanomaterials: A. K. TyagiDokument51 SeitenSoft Chemical Routes For Synthesis of Nanomaterials: A. K. Tyagibalachandar r kNoch keine Bewertungen

- All Figures For SlidesDokument7 SeitenAll Figures For SlidesUdoy PaulNoch keine Bewertungen

- Green-Cap (Electric Double Layer Capacitors) : Snap-In Terminal Type, Standard SeriesDokument1 SeiteGreen-Cap (Electric Double Layer Capacitors) : Snap-In Terminal Type, Standard SeriesGrey ParrotNoch keine Bewertungen

- 4nanoDokument45 Seiten4nanotura emanaNoch keine Bewertungen

- Group Delay DispersionDokument38 SeitenGroup Delay DispersionJack MassaadNoch keine Bewertungen

- Wavelet Signal PsDokument5 SeitenWavelet Signal PsAli SuleNoch keine Bewertungen

- 100ma / - 50V Digital Transistors (With Built-In Resistors) : DTA123EM / DTA123EE / DTA123EUA / DTA123EKADokument3 Seiten100ma / - 50V Digital Transistors (With Built-In Resistors) : DTA123EM / DTA123EE / DTA123EUA / DTA123EKAahmad sulaimanNoch keine Bewertungen

- Nazakat Ali P20 May 2016Dokument8 SeitenNazakat Ali P20 May 2016Nazakat Ali KhosoNoch keine Bewertungen

- MPFN252010H 4R7MDokument8 SeitenMPFN252010H 4R7MjasterNoch keine Bewertungen

- BT 301 Biophysics Tutorial Sheet-IVDokument2 SeitenBT 301 Biophysics Tutorial Sheet-IVShivaani EswaranNoch keine Bewertungen

- Ross Hydrogen Storage 20041216Dokument18 SeitenRoss Hydrogen Storage 20041216Tuhin DuttaNoch keine Bewertungen

- Telcordia Qualification and Beyond Reliability ofDokument12 SeitenTelcordia Qualification and Beyond Reliability ofmwuestNoch keine Bewertungen

- 2022-Vitasynol C & Synoxyl AZ BrochureDokument8 Seiten2022-Vitasynol C & Synoxyl AZ BrochureMihaela Simona IsacNoch keine Bewertungen

- Technical Data: 02014W104KATDokument9 SeitenTechnical Data: 02014W104KATndfgdfs oishdfNoch keine Bewertungen

- 2X2.5 Cable PDFDokument1 Seite2X2.5 Cable PDFNguyen Thai ThuyNoch keine Bewertungen

- Optimizing RF Properties of Injection Molded Plastic PartsDokument26 SeitenOptimizing RF Properties of Injection Molded Plastic PartsclanonNoch keine Bewertungen

- Optical Functions of Chalcopyrite Cuga in Se Alloys: Applied Physics ADokument6 SeitenOptical Functions of Chalcopyrite Cuga in Se Alloys: Applied Physics ARächernach 's AdventuresNoch keine Bewertungen

- Measurement and Instrumentation Principles - (Appendix 4. Solutions To Self-Test Questions)Dokument5 SeitenMeasurement and Instrumentation Principles - (Appendix 4. Solutions To Self-Test Questions)bmyertekinNoch keine Bewertungen

- Any Title: A. Partner, B. Partner, and C. Partner August 20, 2021Dokument4 SeitenAny Title: A. Partner, B. Partner, and C. Partner August 20, 2021Pratiksha SinghNoch keine Bewertungen

- Electrical Transport Properties of Some of Glass NanocompositesDokument36 SeitenElectrical Transport Properties of Some of Glass NanocompositesAbey ThomasNoch keine Bewertungen

- Corrosion and Surface Chemistry of Metals - Iran-Mavad - Com-205-409Dokument205 SeitenCorrosion and Surface Chemistry of Metals - Iran-Mavad - Com-205-409Julio CastañedaNoch keine Bewertungen

- 1Dokument1 Seite1Anees RehamnNoch keine Bewertungen

- 1D Cerium Oxide Nanorods Synthesis, Characterization and Their Humidity Sensing ApplicationDokument8 Seiten1D Cerium Oxide Nanorods Synthesis, Characterization and Their Humidity Sensing ApplicationIJRASETPublicationsNoch keine Bewertungen

- Synkiewicz-Musialska2020 LI2ODokument6 SeitenSynkiewicz-Musialska2020 LI2ORAJARAM KUMAR GUPTANoch keine Bewertungen

- EE311 BJTDokument7 SeitenEE311 BJTمحمود القويريNoch keine Bewertungen

- Acon (Radial Thru-Hole) SS SeriesDokument1 SeiteAcon (Radial Thru-Hole) SS Seriesser4595Noch keine Bewertungen

- Voids Ratio Vs Pressure: General InformationDokument6 SeitenVoids Ratio Vs Pressure: General InformationMaruda8382Noch keine Bewertungen

- RADIOGRAPHIC TEST PROCEDURE (RT Procedure)Dokument17 SeitenRADIOGRAPHIC TEST PROCEDURE (RT Procedure)Senthil Kumaran100% (1)

- Acon (Radial Thru-Hole) NKS SeriesDokument1 SeiteAcon (Radial Thru-Hole) NKS Seriesser4595Noch keine Bewertungen

- Ba2M-Ddt: Small Size, Long Distance Diffuse Reflective TypeDokument2 SeitenBa2M-Ddt: Small Size, Long Distance Diffuse Reflective TypeMin ZayarNoch keine Bewertungen

- Printable Ink Lenses, Diffusers, and 2D Gratings: Supporting InformationDokument6 SeitenPrintable Ink Lenses, Diffusers, and 2D Gratings: Supporting InformationMainul HossainNoch keine Bewertungen

- JASCO UV VIS NIR ApplBookDokument41 SeitenJASCO UV VIS NIR ApplBookJACKSONNoch keine Bewertungen

- Design of Dual-Polarized Broadband Dipole Antenna For Base Station ApplicationsDokument3 SeitenDesign of Dual-Polarized Broadband Dipole Antenna For Base Station ApplicationsmikeNoch keine Bewertungen

- Corrosion Resistant CoatingsDokument21 SeitenCorrosion Resistant CoatingsSteve SandersNoch keine Bewertungen

- Critical Load On StrutDokument5 SeitenCritical Load On StrutelhammeNoch keine Bewertungen

- PHYS 194 Report2Dokument5 SeitenPHYS 194 Report2AbdulNoch keine Bewertungen

- XRD 001 ReportDokument4 SeitenXRD 001 Reportmuhammad akbarNoch keine Bewertungen

- Result Analysis Report: Um D (0.9) : 22.692 131.667 D (0.1) : Um Um 2.038 D (0.5)Dokument1 SeiteResult Analysis Report: Um D (0.9) : 22.692 131.667 D (0.1) : Um Um 2.038 D (0.5)Baher SaidNoch keine Bewertungen

- Supporting InformationDokument4 SeitenSupporting InformationDanila SaraninNoch keine Bewertungen

- Poster Presentation 30-31 JanDokument9 SeitenPoster Presentation 30-31 JantraptiNoch keine Bewertungen

- Agarose Gel ElectrophoresisDokument3 SeitenAgarose Gel ElectrophoresisAarsh DabhiNoch keine Bewertungen

- Ecgr 4122 Test 2 Take Home Part v2Dokument2 SeitenEcgr 4122 Test 2 Take Home Part v2rhill55_911701980Noch keine Bewertungen

- CDE (SMD) AVE SeriesDokument4 SeitenCDE (SMD) AVE Seriesjghjkhgkh87Noch keine Bewertungen

- Highly Reversible Open Framework Electrodes For Divalent Ion BatteriesDokument3 SeitenHighly Reversible Open Framework Electrodes For Divalent Ion Batterieshilzone_Noch keine Bewertungen

- Design of CMOS Circuit Based On NAND Function at 150nm Channel Length For Low-Power and High-Speed IC FabricationDokument6 SeitenDesign of CMOS Circuit Based On NAND Function at 150nm Channel Length For Low-Power and High-Speed IC FabricationIJRASETPublicationsNoch keine Bewertungen

- CD: Cadmium: 1. Analytical ConditionsDokument2 SeitenCD: Cadmium: 1. Analytical ConditionsVương AnhNoch keine Bewertungen

- SCB 142Dokument1 SeiteSCB 142Abhijith UrumiseNoch keine Bewertungen

- Temperature Effect On The Binder-Free Nickel Copper Oxide Nanowires With Superior Supercapacitor PerformanceDokument5 SeitenTemperature Effect On The Binder-Free Nickel Copper Oxide Nanowires With Superior Supercapacitor PerformanceAbril GaarNoch keine Bewertungen

- Repair Notes, Densi MisalignmentDokument4 SeitenRepair Notes, Densi MisalignmentSteve DanielsonNoch keine Bewertungen

- Determination of The Sample IdentityDokument3 SeitenDetermination of The Sample IdentityTipa LaoNoch keine Bewertungen

- Photonic CrystalsDokument28 SeitenPhotonic CrystalsLIAKMANNoch keine Bewertungen

- Government Publications: Key PapersVon EverandGovernment Publications: Key PapersBernard M. FryNoch keine Bewertungen

- Equipment Replacement Intervals PDFDokument6 SeitenEquipment Replacement Intervals PDFKevin MicoltaNoch keine Bewertungen

- DarkDokument18 SeitenDarkana picoliniNoch keine Bewertungen

- Current Concepts On Caries RemovalDokument16 SeitenCurrent Concepts On Caries RemovalgarciadeluisaNoch keine Bewertungen

- Pump Laser With Halogen LampDokument81 SeitenPump Laser With Halogen LampmeatonNoch keine Bewertungen

- Short-Term Clinical Outcomes and Safety Associated With Percutaneous Radiofrequency Treatment For Excessive SweatingDokument10 SeitenShort-Term Clinical Outcomes and Safety Associated With Percutaneous Radiofrequency Treatment For Excessive SweatingsadraNoch keine Bewertungen

- Laser in Prosthodontics HistoryDokument30 SeitenLaser in Prosthodontics Historyyabhatia50% (2)

- Radio Electronics 1992 06Dokument92 SeitenRadio Electronics 1992 06Enéas BaroneNoch keine Bewertungen

- Surface Cleaning With Laser TechnologyDokument8 SeitenSurface Cleaning With Laser TechnologyDade MurphyNoch keine Bewertungen

- Quiz/ Short Questions: Complete The Following Lines With Words/ SentencesDokument3 SeitenQuiz/ Short Questions: Complete The Following Lines With Words/ SentencesBalu phoenixNoch keine Bewertungen

- 2.types of LasersDokument12 Seiten2.types of LasersDiptiranjan SahooNoch keine Bewertungen

- L&P 14 Laser TypesDokument47 SeitenL&P 14 Laser TypesramjoceNoch keine Bewertungen

- Picocare 450 BrochureDokument2 SeitenPicocare 450 Brochureammar hamzehNoch keine Bewertungen

- Keyence Metal Printing Process Instruction ManualDokument12 SeitenKeyence Metal Printing Process Instruction ManualAlexandre GarciaNoch keine Bewertungen

- Fundamentals of Laser MarkingDokument16 SeitenFundamentals of Laser MarkingRakeshNoch keine Bewertungen

- Diode-Pumped Solid-State Laser Kit: LASKIT®-500Dokument2 SeitenDiode-Pumped Solid-State Laser Kit: LASKIT®-500lusoegyi 1919Noch keine Bewertungen

- Lecture 18 - Laser Materials ProcessingDokument22 SeitenLecture 18 - Laser Materials ProcessingGaurav GodseNoch keine Bewertungen

- Fix - Full Paper Jurnal - Inayah Mumpuni Budiati - Undip PDFDokument6 SeitenFix - Full Paper Jurnal - Inayah Mumpuni Budiati - Undip PDFinayah mumpuni budiatiNoch keine Bewertungen

- New Skin Treatment Possibilities With PIANO Mode On An Nd:YAG LaserDokument11 SeitenNew Skin Treatment Possibilities With PIANO Mode On An Nd:YAG LaserPhúc LâmNoch keine Bewertungen

- StriaeDokument7 SeitenStriaemaureenNoch keine Bewertungen

- Instrumentation Seminar: Atomic and Molecular PhysicsDokument31 SeitenInstrumentation Seminar: Atomic and Molecular PhysicsRussel SirotNoch keine Bewertungen

- Pulp Hyperthermia During Tooth Preparation The Effect of Rotary Instruments, Lasers, Ultrasonic Devices, and Airborne Particle AbrasionDokument12 SeitenPulp Hyperthermia During Tooth Preparation The Effect of Rotary Instruments, Lasers, Ultrasonic Devices, and Airborne Particle AbrasionRehabilitacion OralNoch keine Bewertungen

- Ampacet Extends Clarifier and Antistat Ranges PDFDokument2 SeitenAmpacet Extends Clarifier and Antistat Ranges PDFXuân Giang NguyễnNoch keine Bewertungen

- Ceramic-Applications Transparentkeramik 2016 WernerDokument6 SeitenCeramic-Applications Transparentkeramik 2016 WernerSyiera MujibNoch keine Bewertungen

- Lasers in Maxillofacial Surgery and Dentistry - ClaymanDokument168 SeitenLasers in Maxillofacial Surgery and Dentistry - ClaymanAnonymous LnWIBo1G100% (3)

- Laser's PowerpointDokument9 SeitenLaser's PowerpointTiffanie MortonNoch keine Bewertungen

- Lasers in Conservative DentistryDokument5 SeitenLasers in Conservative DentistryArgjend Ajvazi100% (1)

- LaserPhysics Notes LMRDokument24 SeitenLaserPhysics Notes LMRMrunal KhutemateNoch keine Bewertungen

- Laser Warner 10 12Dokument2 SeitenLaser Warner 10 12Zoran StamenkovicNoch keine Bewertungen

- United States Patent (10) Patent No.: US 8,529,561 B2Dokument20 SeitenUnited States Patent (10) Patent No.: US 8,529,561 B2rhkolte8881Noch keine Bewertungen