Beruflich Dokumente

Kultur Dokumente

GIS 66kV Manual PDF

Hochgeladen von

EkiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

GIS 66kV Manual PDF

Hochgeladen von

EkiCopyright:

Verfügbare Formate

On-Site Test Reports SF6 Gas insulated Switchgear

Type EXK-0

ABB Calor Emag Hochspannung GmbH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 2 of 53

Table of Contents

Cover Page...............................................................................................................3

General Data ............................................................................................................4

Circuit Diagrams .......................................................................................................5

Primary Drawings .....................................................................................................6

Moisture Contents ....................................................................................................7

Gas Density Relay....................................................................................................9

WIKA Gas Density Sensor .....................................................................................14

TRAFAG Gas Density Sensor ................................................................................21

Protocol for SF6 Inventory ......................................................................................28

Gas Tightness.........................................................................................................29

High Voltage Test of the Main Circuits ...................................................................30

Voltage Drop...........................................................................................................32

Local Control Cubicle .............................................................................................33

Circuit Breaker General ..........................................................................................35

Circuit Breaker Single Pole.....................................................................................37

Disconnector...........................................................................................................43

Disconnector / Earthing Switch...............................................................................44

Earthing Switch with Short Circuit Making Capacity...............................................45

Current Transformer ...............................................................................................46

Voltage Transformer...............................................................................................47

Surge Arrester ........................................................................................................48

Earthing / Transversal Erection Module .................................................................49

Capacitive Voltage Indicator...................................................................................50

High Voltage Detection System..............................................................................51

Remarks .................................................................................................................52

Sealing of GIS Equipment ......................................................................................53

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 3 of 53

Cover Page

Customer :

Project :

Project-Nr. :

Substation :

Location :

Country :

ABB-Order No. :

ABB-Installation Supervisor :

ABB-Commissioning Supervisor :

Hand-over on :

Customer’s Representative :

Department :

Consultant’s Representative :

Remarks :

Remarks :

Remarks :

Note The commissioning protocol as part of the on-site tests is sufficiently validated by one

signature (either customer’s or consultant’s).

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 4 of 53

General Data

Customer:

Substation:

GIS type : No. of bays:

Layout diagram : Revision :

Standard : IEC VDE ANSI BS

Installation acc. to Installation Instructions :

Filling acc. to Filling Pressure Diagram :

Ratings

Voltage : kV Control Voltage : V

Frequency : Hz Auxiliary Voltage : V

Lightning Impulse Withstand Voltage: kV Auxiliary Voltage 3phase : V

Power Frequency Withstand Voltage: kV Heater Voltage : V

Breaking Current : kA Voltage Drive Motor : V

Current Busbar : A Voltage Hydraulic Pump : V

Current Feeder : A Crane? Yes No

Current Coupler : A Lifting Capacity : t

Commissioning finished on :

Hand-over to Customer on :

Energization on :

Remarks :

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 5 of 53

Circuit Diagrams

Table 1: Circuit Diagrams

Bay No. Drawing Set No. Rev. Revision on by

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 6 of 53

Primary Drawings

Table 1: Primary Drawings

Drawing No. Rev. Revision on by

Circuit Diagrams

Building Plan

GIS Plan

Earthing

Gas Schematics

Sections -Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

-Bay

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 7 of 53

Moisture Contents

Measuring Instrument Type : DP19

Inventory No. :

Conversion (Pressure) : 100 kPa = 1 bar

Table 1: Measurement of Moisture Contents

Filling Dew Point at Date of

SF6-Gas Date of Ambient Tem- Signa-

Bay Pressure Filling Pressure Measure- Remarks

Compartment Filling perature (°C) ture

kPa (°C) ment

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 8 of 53

Measurement of Moisture Contents

Maximum permissible Dewpoint (measured at rated pressure): Refer to Figure 1.

10

8

°C

6

Dewpoint Temperature

-2

-4

-6

-8

-10

0 5 10 15 20 25 30 35 40

Ambient Temperature °C

Figure 1: Dewpoint

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 9 of 53

Gas Density Relay

Measuring Instrument Type: DILO SK 509

Inventory No.:

Ambient Temperature:

SF6-Pressure (measured actual value): refer to Table 1

SF6-Filling Pressure (default value): refer to Figure 1

Table 1: SF6-Pressures

SF6-Filling Pressures

Contact / Default Actual

Bay Gas Density Relay Remarks

Signal Level

at Ambient Temperature

kPa (100 kPa = 1 bar)

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 10 of 53

Gas Density Relay

Table 2: Pressure in the Gas Compartments (default values at 20 °C)

Filling Warning Alarm

Pressures at 20°C Diagram max. kV*

Pressure Contact Contact

Circuit Breaker Figure 1 145 700 kPa 620 kPa 600 kPa

Separate Current Transformer Figure 1 145 700 kPa 620 kPa 600 kPa

Surge Arrester AZ 41 Figure 2 - 500 kPa 440 kPa 420 kPa

All other Gas Compartments Figure 3 145 600 kPa 540 kPa 520 kPa

* Rated Voltage

SF6-Filling Pressure (default value): refer to Figure 1 to Figure 3

840

820

800

F illin g P r e s s u re

780

760

Pabs [kPa]

740

720

S ig n a l C o n ta c t 1

700

680 S ig n a l C o n ta c t 2

(C B B lo c k in g )

660

640

620

600

580

560

540

520

500

480

460

440

420

400

380

360

T o le r a n c e s :

F illin g P r e s s u re : + 10 kPa

340 S w itc h in g P o in t: + 10 kPa

320

300

-3 0 -2 0 -1 0 0 10 20 30 40 50 60

T

Figure 1: SF6-Filling pressure circuit breaker and separate current transformer

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 11 of 53

840

820

800

Pabs [kPa]

780

760

740

720

700

680

660

640

620

600

580

Filling Pressure

560

540

520

500 Signal Contact 1

480 Signal Contact 2

460

440

420

400

380

Tolerances:

360

Filling Pressure: + 10 kPa

340 Switching Point: + 10 kPa

320

300

-30 -20 -10 0 10 20 30 40 50 60

T

Figure 2: SF6-Filling pressure surge arrester AZ 41

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 12 of 53

840

820

800

Pabs [kPa]

780

760

740

720

700

680 Filling Pressure

660

640

620 Signal Contact 1

600

Signal Contact 2

580

560

540

520

500

480

460

440

420

400

Tolerances:

380

Filling Pressure: + 10 kPa

360

Switching Point: + 10 kPa

340

320

300

-30 -20 -10 0 10 20 30 40 50 60

T

Figure 3: SF6-Filling pressure for all other gas compartments

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 13 of 53

Gas Density Relay

Formula for pressure calculation in relation to the temperature

Note The following formula are only valid for the gaseous state, not for partial liquification!

Calculation of gas pressures for ambient temperatures other than 20 °C:

273 + ϑ

Pϑ = P20 ·

273 + 20

Pϑ = pressure at temperature ϑ

ϑ = actual gas temperature in °C

P20 = pressure at 20°C

Example:

Circuit breaker, pressure at 40°C:

273 + 40

P40 = 700 kPa· = 748 kPa

273 + 20

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 14 of 53

WIKA Gas Density Sensor

Measuring Instrument Type:

Inventory No.:

SF6-Pressure (measured actual value): refer to Table 1

SF6-Filling Pressure (default value): refer to Table 3 and Table 4

Table 1: SF6-Pressures

SF6-Filling Pressure

Remarks

Measuring point

Measured Measured values PISA sensor (Permissible deviation

Bay Gas Density Sensor TU value with standardized to value between measured

manometer 20°C (calculate with (at 20°C) value from equation b)

at TU equation b)) and sensor

value ± 10 kPa)

°C kPa kPa kPa

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

TU = ambient temperature (indoor installation), temperature of enclosure (outdoor installation)

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 15 of 53

WIKA Gas Density Sensor

Table 2: Pressure in the Gas Compartments (default values at 20 °C)

Filling Warning Alarm

Pressures at 20°C Diagram max. kV*

Pressure Contact Contact

Circuit Breaker Figure 1 145 700 kPa 620 kPa 600 kPa

Separate Current Transformer Figure 1 145 700 kPa 620 kPa 600 kPa

Surge Arrester AZ 41 Figure 2 - 500 kPa 440 kPa 420 kPa

All other Gas Compartments Figure 3 145 600 kPa 540 kPa 520 kPa

* Rated Voltage

SF6-Filling Pressure (default value): refer to Figure 1 to Figure 3

840

820

800

F illin g P re s s u re

780

760

Pabs [kPa]

740

720

S ig n a l C o n ta c t 1

700

680 S ig n a l C o n ta c t 2

(C B B lo c k in g )

660

640

620

600

580

560

540

520

500

480

460

440

420

400

380

360

T o le r a n c e s :

F illin g P re s s u re : + 10 kP a

340 S w itc h in g P o in t: + 10 kP a

320

300

-3 0 -2 0 -1 0 0 10 20 30 40 50 60

T

Figure 1: SF6-Filling pressure circuit breaker and separate current transformer

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 16 of 53

840

820

800

Pabs [kPa]

780

760

740

720

700

680

660

640

620

600

580

Filling Pressure

560

540

520

500 Signal Contact 1

480 Signal Contact 2

460

440

420

400

380

Tolerances:

360

Filling Pressure: + 10 kPa

340 Switching Point: + 10 kPa

320

300

-30 -20 -10 0 10 20 30 40 50 60

T

Figure 2: SF6-Filling pressure surge arrester AZ 41

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 17 of 53

840

820

800

Pabs [kPa]

780

760

740

720

700

680 Filling Pressure

660

640

620 Signal Contact 1

600

Signal Contact 2

580

560

540

520

500

480

460

440

420

400

Tolerances:

380

Filling Pressure: + 10 kPa

360

Switching Point: + 10 kPa

340

320

300

-30 -20 -10 0 10 20 30 40 50 60

T

Figure 3: SF6-Filling pressure for all other gas compartments

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 18 of 53

WIKA Gas Density Sensor

Formula for pressure calculation in relation to the temperature

Note The following formula are only valid for the gaseous state, not for partial liquification!

a) Calculation of gas pressures for ambient temperatures other than 20 °C:

273 + ϑ

Pϑ = P20 ·

273 + 20

Pϑ = pressure at temperature ϑ

ϑ = actual gas temperature in °C = ambient temperature in °C

P20 = pressure at 20°C

Example:

Circuit breaker, pressure at 40°C:

273 + 40

P40 = 700 kPa· = 748 kPa

273 + 20

b) Equation for calculating the standardized gas pressure at 20 °C:

273 + 20

P20 = Pϑ ·

273 + ϑ

Pϑ = pressure at temperature ϑ

ϑ = actual gas temperature in °C

P20 = pressure at 20°C

Example:

Gas compartment with 515 kPa at 25°C:

273 + 20

P20 = 515 kPa· = 506.36 kPa

273 + 25

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 19 of 53

Note 1 kg / m3 = 1 g / l

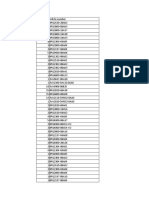

Table 3: Conversion SF6 density into SF6 pressure for entire range 0... to 60 kg / m3 at 20°C

D [kg/m3] I [mA] P [kPa] D [kg/m3] I [mA] P [kPa] D [kg/m3] I [mA] P [kPa]

0.0 4.00 000 20.0 9.33 321 40.0 14.67 616

0.5 4.13 008 20.5 9.47 328 40.5 14.80 623

1.0 4.27 017 21.0 9.60 336 41.0 14.93 630

1.5 4.40 025 21.5 9.73 344 41.5 15.07 637

2.0 4.53 033 22.0 9.87 351 42.0 15.20 644

2.5 4.67 042 22.5 10.00 359 42.5 15.33 651

3.0 4.80 050 23.0 10.13 367 43.0 15.47 658

3.5 4.93 058 23.5 10.27 374 43.5 15.60 665

4.0 5.07 066 24.0 10.40 382 44.0 15.73 672

4.5 5.20 074 24.5 10.53 389 44.5 15.87 679

5.0 5.33 083 25.0 10.67 397 45.0 16.00 686

5.5 5.47 091 25.5 10.80 404 45.5 16.13 693

6.0 5.60 099 26.0 10.93 412 46.0 16.27 700

6.5 5.73 107 26.5 11.07 419 46.5 16.40 707

7.0 5.87 115 27.0 11.20 427 47.0 16.53 713

7.5 6.00 123 27.5 11.33 434 47.5 16.67 720

8.0 6.13 131 28.0 11.47 442 48.0 16.80 727

8.5 6.27 139 28.5 11.60 449 48.5 16.93 734

9.0 6.40 148 29.0 11.73 457 49.0 17.07 741

9.5 6.53 156 29.5 11.87 464 49.5 17.20 748

10.0 6.67 164 30.0 12.00 472 50.0 17.33 754

10.5 6.80 172 30.5 12.13 479 50.5 17.47 761

11.0 6.93 180 31.0 12.27 486 51.0 17.60 768

11.5 7.07 188 31.5 12.40 494 51.5 17.73 775

12.0 7.20 196 32.0 12.53 501 52.0 17.87 781

12.5 7.33 203 32.5 12.67 508 52.5 18.00 788

13.0 7.47 211 33.0 12.80 516 53.0 18.13 795

13.5 7.60 219 33.5 12.93 523 53.5 18.27 801

14.0 7.73 227 34.0 13.07 530 54.0 18.40 808

14.5 7.87 235 34.5 13.20 537 54.5 18.53 815

15.0 8.00 243 35.0 13.33 545 55.0 18.67 821

15.5 8.13 251 35.5 13.47 552 55.5 18.80 828

16.0 8.27 259 36.0 13.60 559 56.0 18.93 834

16.5 8.40 266 36.5 13.73 566 56.5 19.07 841

17.0 8.53 274 37.0 13.87 573 57.0 19.20 848

17.5 8.67 282 37.5 14.00 580 57.5 19.33 854

18.0 8.80 290 38.0 14.13 588 58.0 19.47 861

18.5 8.93 298 38.5 14.27 595 58.5 19.60 867

19.0 9.07 305 39.0 14.40 602 59.0 19.73 874

19.5 9.20 313 39.5 14.53 609 59.5 19.87 880

60.0 20.00 887

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 20 of 53

Note

1 kg / m3 = 1 g / l

Table 4: Conversion SF6 density into SF6 pressure for partial range 25... to 48.8 kg / m3 at 20°C

D [kg/m3] I [mA] P [kPa] D [kg/m3] I [mA] P [kPa] D [kg/m3] I [mA] P [kPa]

25.0 10.67 397 33.0 12.80 516 41.0 14.93 630

25.2 10.72 400 33.2 12.85 518 41.2 14.99 633

25.4 10.77 403 33.4 12.91 521 41.4 15.04 636

25.6 10.83 406 33.6 12.96 524 41.6 15.09 639

25.8 10.88 409 33.8 13.01 527 41.8 15.15 641

26.0 10.93 412 34.0 13.07 530 42.0 15.20 644

26.2 10.99 415 34.2 13.12 533 42.2 15.25 647

26.4 11.04 418 34.4 13.17 536 42.4 15.31 650

26.6 11.09 421 34.6 13.23 539 42.6 15.36 653

26.8 11.15 424 34.8 13.28 542 42.8 15.41 655

27.0 11.20 427 35.0 13.33 545 43.0 15.47 658

27.2 11.25 430 35.2 13.39 547 43.2 15.52 661

27.4 11.31 433 35.4 13.44 550 43.4 15.57 664

27.6 11.36 436 35.6 13.49 553 43.6 15.63 667

27.8 11.41 439 35.8 13.55 556 43.8 15.68 669

28.0 11.47 442 36.0 13.60 559 44.0 15.73 672

28.2 11.52 445 36.2 13.65 562 44.2 15.79 675

28.4 11.57 448 36.4 13.71 565 44.4 15.84 678

28.6 11.63 451 36.6 13.76 568 44.6 15.89 680

28.8 11.68 454 36.8 13.81 570 44.8 15.95 683

29.0 11.73 457 37.0 13.87 573 45.0 16.00 686

29.2 11.79 460 37.2 13.92 576 45.2 16.05 689

29.4 11.84 463 37.4 13.97 579 45.4 16.11 691

29.6 11.89 466 37.6 14.03 582 45.6 16.16 694

29.8 11.95 469 37.8 14.08 585 45.8 16.21 697

30.0 12.00 472 38.0 14.13 588 46.0 16.27 700

30.2 12.05 474 38.2 14.19 590 46.2 16.32 703

30.4 12.11 477 38.4 14.24 593 46.4 16.37 705

30.6 12.16 480 38.6 14.29 596 46.6 16.43 708

30.8 12.21 483 38.8 14.35 599 46.8 16.48 711

31.0 12.27 486 39.0 14.40 602 47.0 16.53 713

31.2 12.32 489 39.2 14.45 605 47.2 16.59 716

31.4 12.37 492 39.4 14.51 608 47.4 16.64 719

31.6 12.43 495 39.6 14.56 610 47.6 16.69 722

31.8 12.48 498 39.8 14.61 613 47.8 16.75 724

32.0 12.53 501 40.0 14.67 616 48.0 16.80 727

32.2 12.59 504 40.2 14.72 619 48.2 16.85 730

32.4 12.64 507 40.4 14.77 622 48.4 16.91 733

32.6 12.69 510 40.6 14.83 625 48.6 16.96 735

32.8 12.75 513 40.8 14.88 627 48.8 17.01 738

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 21 of 53

TRAFAG Gas Density Sensor

Measuring Instrument Type:

Inventory No.:

SF6-Pressure (measured actual value): refer to Table 1

SF6-Filling Pressure (default value): refer to Table 3 and Table 4

Table 1: SF6-Pressures

SF6-Filling Pressure

Remarks

Measuring point

Measured Measured values Sensor value (Permissible deviation

Bay Gas Density Sensor TU value with standardized to (at 20°C) between measured

manometer 20°C (calculate with value from equation b)

at TU equation b)) and sensor

value ± 10 kPa)

°C kPa kPa kPa

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

TU = ambient temperature (indoor installation), temperature of enclosure (outdoor installation)

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 22 of 53

TRAFAG Gas Density Sensor

Table 2: Pressure in the Gas Compartments (default values at 20 °C)

Filling Warning Alarm

Pressures at 20°C Diagram max. kV*

Pressure Contact Contact

Circuit Breaker Figure 1 145 700 kPa 620 kPa 600 kPa

Separate Current Transformer Figure 1 145 700 kPa 620 kPa 600 kPa

Surge Arrester AZ 41 Figure 2 - 500 kPa 440 kPa 420 kPa

All other Gas Compartments Figure 3 145 600 kPa 540 kPa 520 kPa

* Rated Voltage

SF6-Filling Pressure (default value): refer to Figure 1 to Figure 3

840

820

800

F illin g P re s s u re

780

760

Pabs [kPa]

740

720

S ig n a l C o n ta c t 1

700

680 S ig n a l C o n ta c t 2

(C B B lo c k in g )

660

640

620

600

580

560

540

520

500

480

460

440

420

400

380

360

T o le r a n c e s :

F illin g P re s s u re : + 10 kP a

340 S w itc h in g P o in t: + 10 kP a

320

300

-3 0 -2 0 -1 0 0 10 20 30 40 50 60

T

Figure 1: SF6-Filling pressure circuit breaker and separate current transformer

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 23 of 53

840

820

800

Pabs [kPa]

780

760

740

720

700

680

660

640

620

600

580

Filling Pressure

560

540

520

500 Signal Contact 1

480 Signal Contact 2

460

440

420

400

380

Tolerances:

360 Filling Pressure: + 10 kPa

340 Switching Point: + 10 kPa

320

300

-30 -20 -10 0 10 20 30 40 50 60

T

Figure 2: SF6-Filling pressure surge arrester AZ 41

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 24 of 53

840

820

800

Pabs [kPa]

780

760

740

720

700

680 Filling Pressure

660

640

620 Signal Contact 1

600

Signal Contact 2

580

560

540

520

500

480

460

440

420

400

Tolerances:

380

Filling Pressure: + 10 kPa

360

Switching Point: + 10 kPa

340

320

300

-30 -20 -10 0 10 20 30 40 50 60

T

Figure 3: SF6-Filling pressure for all other gas compartments

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 25 of 53

TRAFAG Gas Density Sensor

Formula for pressure calculation in relation to the temperature

Note The following formula are only valid for the gaseous state, not for partial liquification!

a) Calculation of gas pressures for ambient temperatures other than 20 °C:

273 + ϑ

Pϑ = P20 ·

273 + 20

Pϑ = pressure at temperature ϑ

ϑ = actual gas temperature in °C = ambient temperature in °C

P20 = pressure at 20°C

Example:

Circuit breaker, pressure at 40°C:

273 + 40

P40 = 700 kPa· = 748 kPa

273 + 20

b) Equation for calculating the standardized gas pressure at 20 °C:

273 + 20

P20 = Pϑ ·

273 + ϑ

Pϑ = pressure at temperature ϑ

ϑ = actual gas temperature in °C

P20 = pressure at 20°C

Example:

Gas compartment with 515 kPa at 25°C:

273 + 20

P20 = 515 kPa· = 506.36 kPa

273 + 25

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 26 of 53

Note 1 kg / m3 = 1 g / l

Table 3: Conversion SF6 density into SF6 pressure for entire range 0... to 60 kg / m3 at 20°C

D [kg/m3] f [Hz] P [kPa] D [kg/m3] f [Hz] P [kPa] D [kg/m3] f [Hz] P [kPa]

0.0 10.00 000 20.0 113.23 321 40.0 206.71 616

0.5 14.80 008 20.5 115.60 328 40.5 209.02 623

1.0 18.06 017 21.0 117.97 336 41.0 211.33 630

1.5 21.06 025 21.5 120.34 344 41.5 213.64 637

2.0 23.93 033 22.0 122.70 351 42.0 215.95 644

2.5 26.71 042 22.5 125.07 359 42.5 218.26 651

3.0 29.44 050 23.0 127.43 367 43.0 220.56 658

3.5 32.12 058 23.5 129.78 374 43.5 222.87 665

4.0 34.77 066 24.0 132.14 382 44.0 225.18 672

4.5 37.38 074 24.5 134.49 389 44.5 227.48 679

5.0 39.97 083 25.0 136.84 397 45.0 229.78 686

5.5 42.54 091 25.5 139.19 404 45.5 232.09 693

6.0 45.10 099 26.0 141.54 412 46.0 234.39 700

6.5 47.63 107 26.5 143.89 419 46.5 236.69 707

7.0 50.16 115 27.0 146.23 427 47.0 238.99 713

7.5 52.67 123 27.5 148.57 434 47.5 241.29 720

8.0 55.17 131 28.0 150.92 442 48.0 243.59 727

8.5 57.65 139 28.5 153.26 449 48.5 245.89 734

9.0 60.13 148 29.0 155.59 457 49.0 248.19 741

9.5 62.60 156 29.5 157.93 464 49.5 250.48 748

10.0 65.07 164 30.0 160.27 472 50.0 252.78 754

10.5 67.52 172 30.5 162.60 479 50.5 255.08 761

11.0 69.97 180 31.0 164.93 486 51.0 257.37 768

11.5 72.41 188 31.5 167.26 494 51.5 259.66 775

12.0 74.85 196 32.0 169.59 501 52.0 261.96 781

12.5 77.28 203 32.5 171.92 508 52.5 264.25 788

13.0 79.70 211 33.0 174.25 516 53.0 266.54 795

13.5 82.12 219 33.5 176.57 523 53.5 268.84 801

14.0 84.54 227 34.0 178.90 530 54.0 271.13 808

14.5 86.95 235 34.5 181.22 537 54.5 273.42 815

15.0 89.36 243 35.0 183.54 545 55.0 275.71 821

15.5 91.76 251 35.5 185.87 552 55.5 278.00 828

16.0 94.16 259 36.0 188.19 559 56.0 280.29 834

16.5 96.56 266 36.5 190.50 566 56.5 282.58 841

17.0 98.95 274 37.0 192.82 573 57.0 284.86 848

17.5 101.34 282 37.5 195.14 580 57.5 287.15 854

18.0 103.72 290 38.0 197.46 588 58.0 289.44 861

18.5 106.10 298 38.5 199.77 595 58.5 291.73 867

19.0 108.48 305 39.0 202.08 602 59.0 294.01 874

19.5 110.86 313 39.5 204.40 609 59.5 296.30 880

60.0 887

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 27 of 53

Note

1 kg / m3 = 1 g / l

Table 4: Conversion SF6 density into SF6 pressure for partial range 25... to 48.8 kg / m3 at 20°C

D [kg/m3] f [Hz] P [kPa] D [kg/m3] f [Hz] P [kPa] D [kg/m3] f [Hz] P [kPa]

25.0 136.84 397 33.0 174.25 516 41.0 211.33 630

25.2 137.78 400 33.2 175.18 518 41.2 212.26 633

25.4 138.72 403 33.4 176.11 521 41.4 213.18 636

25.6 139.66 406 33.6 177.04 524 41.6 214.10 639

25.8 140.60 409 33.8 177.97 527 41.8 215.03 641

26.0 141.54 412 34.0 178.90 530 42.0 215.95 644

26.2 142.48 415 34.2 179.83 533 42.2 216.87 647

26.4 143.42 418 34.4 180.76 536 42.4 217.80 650

26.6 144.36 421 34.6 181.69 539 42.6 218.72 653

26.8 145.29 424 34.8 182.62 542 42.8 219.64 655

27.0 146.23 427 35.0 183.54 545 43.0 220.56 658

27.2 147.17 430 35.2 184.47 547 43.2 221.49 661

27.4 148.11 433 35.4 185.40 550 43.4 222.41 664

27.6 149.04 436 35.6 186.33 553 43.6 223.33 667

27.8 149.98 439 35.8 187.26 556 43.8 224.25 669

28.0 150.92 442 36.0 188.19 559 44.0 225.18 672

28.2 151.85 445 36.2 189.11 562 44.2 226.10 675

28.4 152.79 448 36.4 190.04 565 44.4 227.02 678

28.6 153.72 451 36.6 190.97 568 44.6 227.94 680

28.8 154.66 454 36.8 191.90 570 44.8 228.86 683

29.0 155.59 457 37.0 192.82 573 45.0 229.78 686

29.2 156.53 460 37.2 193.75 576 45.2 230.70 689

29.4 157.46 463 37.4 194.68 579 45.4 231.63 691

29.6 158.40 466 37.6 195.60 582 45.6 232.55 694

29.8 159.33 469 37.8 196.53 585 45.8 233.47 697

30.0 160.27 472 38.0 197.46 588 46.0 234.39 700

30.2 161.20 474 38.2 198.38 590 46.2 235.31 703

30.4 162.13 477 38.4 199.31 593 46.4 236.23 705

30.6 163.07 480 38.6 200.23 596 46.6 237.15 708

30.8 164.00 483 38.8 201.16 599 46.8 238.07 711

31.0 164.93 486 39.0 202.08 602 47.0 238.99 713

31.2 165.86 489 39.2 203.01 605 47.2 239.91 716

31.4 166.80 492 39.4 203.94 608 47.4 240.83 719

31.6 167.73 495 39.6 204.86 610 47.6 241.75 722

31.8 168.66 498 39.8 205.79 613 47.8 242.67 724

32.0 169.59 501 40.0 206.71 616 48.0 243.59 727

32.2 170.52 504 40.2 207.63 619 48.2 244.51 730

32.4 171.46 507 40.4 208.56 622 48.4 245.43 733

32.6 172.39 510 40.6 209.48 625 48.6 246.35 735

32.8 173.32 513 40.8 210.41 627 48.8 247.27 738

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 28 of 53

Protocol for SF6 Inventory

Customer:

Designation of substation:

No. of bays:

Delivery amount of SF6

Amount of SF6 in bay gas compartments: kg

Amount of SF6 in gas bottles: Pieces à kg

Total delivered amount of SF6: kg

Mounting of the GIS

Amount of SF6 filled in substation: kg

Remaining SF6 in gas bottles: Pieces à kg

Amount of remaining rest of SF6

Amount of SF6 bottles delivered to customer: Pieces

Total amount of SF6 delivered to customer: kg

Recipient at customer site:

Name:

Department:

Amount of SF6 bottles returning to WGA: Pieces

Total amount of SF6 returning to WGA: kg

Recipient in WGA:

Name:

Department:

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 29 of 53

Gas Tightness

Measurement Instrument Type: L-780 a

Inventory No.:

Table 1: Test for Gas Tightness

Gas Compartment-Identification through:

Electrical Designation of o.k. Remarks

Bay

Gas Density Relay

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 30 of 53

High Voltage Test of the Main Circuits

Resonance Test Set :

Step Transformator No. :

Test Transformator No. :

Peak Voltage Test Device No. :

Test Adapter No. :

Power of Test Transformer : kVA

Test Voltages Up : refer to Table 1

Table 1: Test Voltages

Rated Voltage BIL Test Duration Test Voltage Up

kV kV min kV

72.5 325 1 120

123 550 1 200

145 650 1 235

Gas Pressure for High Voltage Test of the Main Circuits

Table 2: Pressure in the Gas Compartment (default values at 20 °C)

Pressures at 20° / 293 Kelvin Max. Rated Voltage [kV] Filling Pressure

Circuit Breaker 145 700 kPa

Separate Current Transformer 145 700 kPa

Surge Arrester AZ 41 145 500 kPa

All other Gas Compartments 145 600 kPa

Note All the procedures associated with carrying out the high voltage test of the main circuits

are described in detail in the product manual in chapter “Commissioning” in document

1HDG 918 742 “High Voltage Test of the Main Circuits”.

Note The filling pressures for other ambient temperatures are listed in this document in section

“Gas Density Relay”.

Note All works associated with the handling of SF6 are described in detail in the product

manual in chapter “Gas Insulated Switchgear” in document 1HDG 518 012 “Sulphur

Hexafluoride”.

For the test values please refer to Table 3

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 31 of 53

High Voltage Test of the Main Circuits

Test Unit mounted on :

Circuit Diagram No. : Revision :

Test Voltage Up (default value) : kV

I1 (A) ⋅ U1 (V )

Calculation formula : I2 (mA ) =

U p (kV )

Table 3: Test Values

Primary Voltage U1 Primary Current I1 Test Voltage Up

Bay Device Designation Phase

V A kV

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 32 of 53

Voltage Drop

Measuring Instrument Type : Micro Ohmmeter 600 A

Inventory No.: :

I ( A)xR( µOhm )

Conversion Formula : U (mV ) =

1000

(adjusted current range: 200 A DC)

Note The procedures associated with the measurement of the voltage drop and the related

default values for the individual components are listed in the product manual in chapter

“Commissioning” in document 1HDG 918 740 “Tests Prior to Commissioning”.

A. Phasing checked acc. to primary drawings

B. Values of voltage drop measured (s. Table 1)

Table 1: Measurement of Voltage Drop

Designation of Measuring Point Phase Actual Value (measured) Remarks

in accordance with the Circuit

Diagram mV µOhm

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 33 of 53

Local Control Cubicle

Bay :

Customer Designation :

O.K. at Commissioning

A. Visual Check for external Damages

B. Bay Interlocking

C. Station Interlocking

D. Antipumping Circuit Breaker

E. All Messages checked acc. to Signal List

F. Circuit Breaker Blocking (Operating Mechanism)

AR

CLOSE

OPEN I

OPEN II

G. Protection Trip on Relay or Terminal Block

H. Electrical Plug-Connections (Plugs) secured with Screws

I. Check of Position Indicators

Circuit Breaker

Disconnector / Earthing Switch

Disconnector

Earthing Switch

Earthing Switch with Short Circuit Making Capacity

J. Check of Control Circuits acc. to Function Chart

K. Functional Check of Anti-Condensation Heaters

L. Adjustment of Timing Relays acc. to Operating Schematics

For Test Values please refer to Table 1

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 34 of 53

Local Control Cubicle

Table 1: Test Values

Default Value Actual Value (measured)

Device Designation

s s

Timing Relay K210 60 s

Timing Relay K301 20 s

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 35 of 53

Circuit Breaker General

Bay :

Customer Designation :

Device Designation :

Component No. :

CB-Chamber Type :

Measuring Instrument Type : TM 1600

TM 16______

CAUTION The Circuit Breaker may only be operated when filled with SF6 (min. 600 kPa)!

O.K. at Commissioning

A. Visual Inspection for external Damages

B. Check Counter for Operating Hours

C. Check that the locking varnish on the throttle screw for setting

the operating mechanism speed is undamaged

D. Functional Check of Anti-Condensation Heater (if provided)

E. Check the carbon brushes (minimum height 11 mm)

F. Check if the stored operating sequence is enabled from control cubicle without blocking

G. Visual Check of Operating Mechanism Elements: Rotary Bushing on the Operating Mechanism

H. Visual Check of Operating Mechanism Elements: Auxiliary Switches, Position Indicator

I. Check of the Electrical Plug-Connections for secure Contacting

J. Check the Numbers of Operations and Pump Starts

Operations: _________ Date:_______________

Pump Starts: _________ Date:_______________

K. Functional Test acc. to Circuit Diagram (Engineering Document)

L. Charging Time of Hydraulic Operating Mechanism from 0 to Operating Pressure _______________s

M. Setting time relays:

k_________________ Actual value: ____________________ Specified value: ___________________

k_________________ Actual value: ____________________ Specified value: ___________________

k_________________ Actual value: ____________________ Specified value: ___________________

k_________________ Actual value: ____________________ Specified value: ___________________

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 36 of 53

Circuit Breaker General

O.K. at Commissioning

N. Check for simultaneity of contact separation: ≤ 3 ms

O. Functional check of circuit breaker (Table 1)

Table 1: Functional check of circuit breaker

OPEN I * OPEN II * OPEN III * OPEN IV * CLOSE I * CLOSE II *

Functional Check

tOPEN = From opening impulse until contact separation,

tCLOSE = From closing impulse until contact touch,

The measured values shall not exceed a deviation of ± 3 ms compared with

the factory routine-tests.**

Phase L1 (ms)

factory / on site

Phase L2 (ms)

factory / on site

Phase L3 (ms)

factory / on site

∆t (ms) O.K.

[YES/NO]

* Measurements to be performed with fully charged operating mechanism and 100% supply voltage.

** The switching cycle times are described in detail in the product documentation in chapter

“Equipment and Functional Descriptions” in document 1HDG 918 750 “Circuit Breaker”.

Protocol strips of time measurement -> please refer to the following page(s)

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 37 of 53

Circuit Breaker Single Pole

Additional tests required for circuit breaker with single pole operating mechanism

(Table 2):

O.K. at Commissioning

P. Check for simultaneity of contact making: ≤ 3 ms

Q. Check for simultaneity of contact separation during CO switching: ≤ 5 ms

Table 2: Additional tests required for Circuit Breaker with single pole operating mechanism

CLOSE I – OPEN II * CLOSE I – OPEN II *

Functional Check

Test of switching time for CO operation with shortest close-open time:

From closing impulse to contact separation at CO switching = 60 ms - 100 ms

Phase L1 (ms)

factory / on site

Phase L2 (ms)

factory / on site

Phase L3 (ms)

factory / on site

∆t (ms) O.K.

[YES/NO]

* Measurements to be performed with fully charged operating mechanism and 100% supply voltage.

Protocol strips of time measurement -> please refer to the following page(s)

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 38 of 53

Circuit Breaker

Protocol Strip of Time Measurement: OPEN I (Figure 1)

Figure 1: Protocol Strip of Time Measurement: OPEN I

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 39 of 53

Circuit Breaker

Protocol Strip of Time Measurement: OPEN II (Figure 2)

Figure 2: Protocol Strip of Time Measurement: OPEN II

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 40 of 53

Circuit Breaker

Protocol Strip of Time Measurement: CLOSE I (Figure 3)

Figure 3: Protocol Strip of Time Measurement: CLOSE I

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 41 of 53

Circuit Breaker

Protocol Strip of Time Measurement: OPEN I – CLOSE I (Figure 4)

Figure 4: Protocol Strip of Time Measurement: OPEN I – CLOSE I

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 42 of 53

Circuit Breaker

Protocol Strip of Time Measurement: OPEN II – CLOSE I (Figure 5)

Figure 5: Protocol Strip of Time Measurement: OPEN II – CLOSE I

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 43 of 53

Disconnector

Bay :

Customer Designation :

Device Designation :

Component No. :

Type :

Location : BB1 BB2 BB3 Feeder

O.K. at Commissioning

A. Visual Inspection for external Damages

B. Visual Inspection of Operating Mechanism Elements

C. Functional Check of Operating Mechanism mechanical (with Handcrank) CLOSE / OPEN

D. Functional Check of Signalling Devices:

Limit Switch, Interlocking Switch (Hand crank), Position Indicator, Auxiliary Switches

E. Check Interlocking of Handcrank

F. Check Key-Interlocking

G. Functional Check of Operating Mechanism electrical CLOSE / OPEN

H. Performance Check:

Measurement of Motor Current at Auxiliary Voltage: __________ V

Motor Current: CLOSE: __________ A OPEN: __________ A

I. Electrical Plug-Connections (Plugs) secured with Screws

J. Functional Check of Anti-Condensation Heater (if applicable)

K. Visual Inspection of electrical Connections

L. Functional Check acc. to Circuit Diagrams (planning standard)

Note All default values for the disconnector are listed in chapter “Equipment Descriptions” in

document “Disconnector / Earthing Switch” 1HDG 918 754.

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 44 of 53

Disconnector / Earthing Switch

Bay :

Customer Designation :

Device Designation :

Device No. :

Type :

Location : BB1 BB2 BB3 Feeder

O.K. at Commissioning

A. Visual Inspection for external Damages

B. Visual Inspection of Operating Mechanism Elements

C. Functional Check of Operating Mechanism mechanical (Handcrank) CLOSE / OPEN

D. Functional Check of Signalling Devices:

Limit Switches, Interlocking Switch (Hand crank), Position Indicators, Auxiliary Switches

E. Check the Handcrank Interlocking

F. Check the Key-Interlocking

G. Functional Check of the Operating Mechanism electrical CLOSE / OPEN

H. Performance Check:

Measurement of Motor Current at Auxiliary Voltage:

Disconnector: Motor Current CLOSE: _________ A OPEN: _________ A

Earthing Switch: Motor Current CLOSE: _________ A OPEN: _________ A

I. Electrical Plug-Connections (Plugs) secured with Screws

J. Functional Check of Anti-Condensation Heater (if applicable)

K. Visual Inspection of electrical Connections

L. Functional Check acc. to Circuit Diagrams (planning standard)

Note All default values for the disconnector / earthing switch are listed in the product manual

in chapter “Equipment and Functional Descriptions” in document “Disconnector /

Earthing Switch” 1HDG 918 754.

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 45 of 53

Earthing Switch with Short Circuit Making Capacity

Bay :

Customer Designation :

Device Designation :

Device No. :

Type :

Location : BB1 BB2 BB3 Feeder

Note The default values for the earthing switch with short circuit making capacity are listed in

the product manual in chapter “Equipment and Functional Descriptions” in document

“Earthing Switch with Short Circuit Making Capacity” 1HDG 918 756.

O.K. at Commissioning

A. Visual Inspection for external Damages

B. Visual Inspection of Operating Mechanism Elements

C. Functional Check of Operating Mechanism mechanical (Handcrank) CLOSE / OPEN

D. Functional Check of Signalling Devices:

Limit Switches, Interlocking Switch (Hand crank), Position Indicator, Auxiliary Switches

E. Check of Handcrank Interlocking

F. Check of Key-Interlocking

G. Functional Check of the Operating Mechanism electrical CLOSE / OPEN

H. Performance Check:

Measurement of Motor Current at Auxiliary Voltage: __________ V

Motor Current: CLOSE: __________ A OPEN: __________ A

I. Electrical Plug-Connections (Plugs) secured with Screws

J. Functional Check of Anti-Condensation Heaters (if applicable)

K. Visual Inspection of electrical Connections

L. Inspection of Contact Bands: Phase - Enclosure

Phase L1

Phase L2

Phase L3

M. Functional Check acc. to Circuit Diagrams (planning standard)

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 46 of 53

Current Transformer

Bay :

Customer Designation :

Current Transformer Type :

Location :

Manufacturer :

Manufacturer Type :

Fabrication No. :

Current Transformer Ratings: please refer to Table 1

Table 1: Current Transformer Ratings

Core I Core II Core III Core IV Core V

Ratio

Burden

Accuracy

O.K. at Commissioning

A. Inspection of Connections and Earthing through ABB

B. Inspection of Connections and Earthing through:_________________________

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 47 of 53

Voltage Transformer

Bay :

Customer Designation :

Voltage Transformer Type :

Location :

Manufacturer :

Manufacturer Type :

Fabrication No. :

Voltage Transformer Ratings: please refer to Table 1

Table 1: Voltage Transformer Ratings

Winding I Winding II Winding III Winding IV

Ratio

Burden

Accuracy

O.K. at Commissioning

A. Visual Inspection for external Damages

B. Visual Inspection of the Shock Indicators

C. Inspection of Connections and Earthing through ABB

D. Inspection of Connections and Earthing through:

E. Inspection of Fuses

F

F

F

F

F

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 48 of 53

Surge Arrester

Bay :

Customer Designation :

Type :

Location :

Manufacturer :

Manufacturer Type :

Fabrication No. :

Max. perm. cont. Operating Voltage : kV [RMS]

O.K. at Commissioning

A. Visual Inspection for external Damages

B. Visual Inspection of Shock Indicator

C. Inspection of Connections

D. Earthing

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 49 of 53

Earthing / Transversal Erection Module

Bay :

Customer Designation :

Earthing acc. to Drawing No. : Revision :

O.K. at Commissioning

A. Inspection of bolted and pressed Connections

B. Cable Trays earthed

C. SF6-Air Bushings earthed

D. Surge Arrestors earthed

E. Local Control Cabinets earthed

F. Base Frame earthed (if applicable)

G. HV Cables earthed (Arrestor or Spark Gap)

H. Circuit Breaker earthed

I. Transversal Erection Module: Bolts of Compensation Unit loosened and secured

J. Transversal Erection Module: Bolts of Shorting Bridge tightened

K. Outdoor Flange Connections greased

L. REC 580 earthed (SMART-GIS only)

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 50 of 53

Capacitive Voltage Indicator

Bay :

Customer Designation :

Equipment Designation :

Component No. :

Type :

O.K. at Commissioning

A. Visual Inspection for external and internal Damages

B. Electrical Plug and Socket Connections (plug) screwed-in

C. System-Check

D. Electrical functional check

Voltage at MP1~0,65 V RMS

by earthing switchgear → green LED

by current voltage → red LED

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 51 of 53

High Voltage Detection System

Bay :

Customer Designation :

Equipment Designation :

Component No. :

Type :

O.K. at Commissioning

A. Visual Inspection for external Damages

B. Electrical Plug and Socket Connections (plug) screwed-in

C. Function check at earthed arrangement

Lightning symbols not indicated

LED indication as shown in Figure 1

D. Function check at rated voltage

Lightning symbols completely displayed

LED indication as shown in Figure 2

n

ff

er

O

w

ro

V

Po

Er

H

Figure 1: LED display at earthed arrangement

n

ff

er

O

w

ro

V

Po

Er

H

Figure 2: LED display at rated voltage

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 52 of 53

Remarks

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Product Documentation GIS Type EXK-0

On-Site Test

Commissioning Protocol Page 53 of 53

Sealing of GIS Equipment

Customer :

Project :

Project No. :

DECES Commission Supervisor :

Date of sealing :

Equipment and Seal No. : refer to Table 1

Table 1: Equipment and Seal No.

Feeder Equipment Seal No.

Note Seals are not allowed to be removed by unauthorised personnel, any broken seal must

be reported immediately to DECES.

Tested: Approved:

________________________________ _______________________________ _____________________________

Date, ABB Date, Customer Date, Consultant

1HDG 918 790 C en 01.06.2005 EXTMEHA 01.06.2005 CHSVOTH

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Electrical Distribution System Protection CooperDokument272 SeitenElectrical Distribution System Protection CooperPrachal Jadeja100% (1)

- ABB-Q-N-Z-J-004 Rev B - Motor Control Center - Inspection and Test PlanDokument3 SeitenABB-Q-N-Z-J-004 Rev B - Motor Control Center - Inspection and Test Planmaycol29492Noch keine Bewertungen

- FT N°364 Separable (Asymmetric) Compact Tee Connector MSCEA-EC-630A Up To 36 KV - 0Dokument4 SeitenFT N°364 Separable (Asymmetric) Compact Tee Connector MSCEA-EC-630A Up To 36 KV - 0Deni DendenNoch keine Bewertungen

- Factory Acceptance TestDokument2 SeitenFactory Acceptance TestSalem GarrabNoch keine Bewertungen

- Perform Characteristic of Directional Relay: Prepared By: B.R.PrajapatiDokument3 SeitenPerform Characteristic of Directional Relay: Prepared By: B.R.PrajapatiBhavik PrajapatiNoch keine Bewertungen

- Operation Manual For Electrical EquipmentDokument86 SeitenOperation Manual For Electrical EquipmentGunawan sitinjakNoch keine Bewertungen

- MNS-R System GuideDokument17 SeitenMNS-R System Guidesrmohapatra5086Noch keine Bewertungen

- % Z of TransformerDokument2 Seiten% Z of TransformerNevil ModiNoch keine Bewertungen

- Lecture 6 Differential ProtectionDokument39 SeitenLecture 6 Differential ProtectionIhtisham uddinNoch keine Bewertungen

- NPTEL Power System ProtectionDokument324 SeitenNPTEL Power System ProtectionCarib100% (4)

- Electrical Load ScheduleDokument110 SeitenElectrical Load ScheduleLucky MalihanNoch keine Bewertungen

- 26148-220-V1B-EVC0-00156 (007) - Unilineal MTDokument3 Seiten26148-220-V1B-EVC0-00156 (007) - Unilineal MTDomingo esteban perez ceballoNoch keine Bewertungen

- IEC Asea Siemens Sprecher MeidenDokument9 SeitenIEC Asea Siemens Sprecher MeidenEspidan68Noch keine Bewertungen

- VFD Cable Reference GuideDokument2 SeitenVFD Cable Reference GuiderodrurenNoch keine Bewertungen

- A Generalized Multilevel Inverter TopologyDokument8 SeitenA Generalized Multilevel Inverter TopologyHamid KhaleghiNoch keine Bewertungen

- Protecting Transmission Lines Terminated Into Transformers: Elmo Price and Roger Hedding, ABB IncDokument12 SeitenProtecting Transmission Lines Terminated Into Transformers: Elmo Price and Roger Hedding, ABB IncproteccionesNoch keine Bewertungen

- 7SJ66 CatalougeDokument28 Seiten7SJ66 CatalougeKripalu Commercial100% (2)

- ALR 20/A Ex Relay: Installation and Operating InstructionsDokument16 SeitenALR 20/A Ex Relay: Installation and Operating InstructionsVictor ESPÌNAQUENoch keine Bewertungen

- Ak731 606 00 0 2PLC1Dokument138 SeitenAk731 606 00 0 2PLC1Francisco MunguíaNoch keine Bewertungen

- Substation Design Guideliness PDFDokument40 SeitenSubstation Design Guideliness PDFLimuel EspirituNoch keine Bewertungen

- Soft StarterDokument13 SeitenSoft StarterThanigai VelNoch keine Bewertungen

- VT23-7002-50 Electrical Equipment ListDokument2 SeitenVT23-7002-50 Electrical Equipment ListTamNoch keine Bewertungen

- 20-0 679 8254GCP Ashtart Revamping Project Rev Customer Specification No: Generator RatingDokument10 Seiten20-0 679 8254GCP Ashtart Revamping Project Rev Customer Specification No: Generator RatingKechaouNoch keine Bewertungen

- BomDokument107 SeitenBomAhmed SultanNoch keine Bewertungen

- Basic Electronics - Junction DiodesDokument5 SeitenBasic Electronics - Junction DiodesMansour MashaeiNoch keine Bewertungen

- Current Transformer Iosk 1Dokument8 SeitenCurrent Transformer Iosk 1Dumitru Tănase0% (1)

- SE1500BF Series IIDokument13 SeitenSE1500BF Series IIMohamedNoch keine Bewertungen

- PNGRB - Electrical Safety Audit ChecklistDokument4 SeitenPNGRB - Electrical Safety Audit ChecklistKritarth SrivastavNoch keine Bewertungen

- Reyrolle Solkor R RF - Catalogue PDFDokument26 SeitenReyrolle Solkor R RF - Catalogue PDFSunil G ParakkalNoch keine Bewertungen

- Calculate IDMT Over Current Relay Setting (50 - 51)Dokument7 SeitenCalculate IDMT Over Current Relay Setting (50 - 51)Woei Song OoiNoch keine Bewertungen