Beruflich Dokumente

Kultur Dokumente

D6R Series III Track-Type Tractor Hydraulic System: Pressure Manifold

Hochgeladen von

chakrouneOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

D6R Series III Track-Type Tractor Hydraulic System: Pressure Manifold

Hochgeladen von

chakrouneCopyright:

Verfügbare Formate

RENR7956-01 FLUID POWER SYMBOLS

14 June 2006

BASIC COMPONENT SYMBOLS

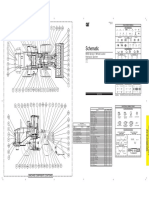

Component Locations MAIN AUX.

PUMP: VARIABLE and

Item Part Schematic 15 PUMP or MOTOR FLUID CONDITIONER SPRING CONTROL VALVES RESTRICTION LINE RESTRICTION

(FIXED)

2-SECTION PUMP PRESSURE COMPENSATED

Description

Number Number Location

1 Pump - Implement and Steering 227-0830 F-2

VARIABILITY SPRING LINE RESTRICTION PRESSURE HYDRAULIC PNEUMATIC LINE RESTRICTION ATTACHMENT

2 Steering Motor 159-7156 E-4 (ADJUSTABLE) (VARIABLE) COMPENSATION ENERGY TRIANGLES VARIABLE and PRESSURE

COMPENSATED

3 Valve Gp. - Counter Balance 227-0832 E-3 VALVES

VALVE ENVELOPES VALVE PORTS

Valve Gp. - Steering, Dozer Lift/Tilte 224-4936 E-5

4 Valve Gp. - Steering, Dozer Lift/Tilte (Ripper) 224-2937 E-5

Valve Gp. - Steering, Dozer Lift/Tilte (Winch) 239-6076 E-5 HA ONE POSITION TWO POSITION THREE POSITION TWO-WAY THREE-WAY FOUR-WAY

5 Manifold Gp. - Inlet Manifold with Relief 235-0401 E-5 CP CONTROL VALVES CHECK VALVES

6 Valve Gp. - Steering Control 235-0402 E-5 AB AB

7 Valve Gp. - Dozer Lift 235-0403 D-5

8 Valve Gp. - Dozer Tilt 235-0404 C-5 P T P T

BASIC SPRING SHUTTLE PILOT

NORMAL POSITION SHIFTED POSITION INFINITE POSITION

Valve Gp. - Ripper 235-0405 C-8 SYMBOL LOADED CONTROLLED

9

Valve Gp. - Winch 239-6074 C-5 MEASUREMENT ROTATING SHAFTS

10 Cover 235-0399 B-5, B-8

11 Valve Gp. - Ripper Pilot Valve 167-1177 B-8

12 Valve Gp. - Dozer Pilot Valve 200-0189 D-1 PRESSURE TEMPERATURE FLOW UNIDIRECTIONAL BIDIRECTIONAL

13 Valve Gp. - Shut Off 201-0950 D-8 FLUID STORAGE RESERVOIRS

D6R Series III Track-Type Tractor

14 Accumulator 200-0750 D-8

Valve Gp. - Pressure Reducing Manifold and

15 226-4751 D-8

Hydraulic System

Check Valves VENTED PRESSURIZED RETURN ABOVE FLUID LEVEL RETURN BELOW FLUID LEVEL

16 Valve Gp. - Cooler Bypass 9T-3004 A-3

COMBINATION CONTROLS

17 Cooler 169-3806 E-2

18 Valve Gp. - Breather 3G-4783 A-3 GJB1-UP DMK1-UP

19 Element - Implement and Case Drain Return 1R-0777 A-3

SOS CPG WCB1-UP LGP1-UP SOLENOID SOLENOID SOLENOID SOLENOID and SERVO THERMAL DETENT

20 Valve Gp. - Quick Drop 227-0831 F-1 or MANUAL and PILOT PILOT or MANUAL

Cylinder Gp. - Lift (STD) 227-0844 F-1

HDC1-UP JDL1-UP

MANUAL CONTROL SYMBOLS

21 RFC1-UP DLM1-UP

Cylinder Gp. - Lift (LGP) 227-0843 F-1 The pressure reducing manifold (15) is located inside the forward compartment on the

22 Cylinder Gp. - Dual Tilt (Option) 227-0841 E-1 right fender and is situated outboard from the power train oil filter. Service points identi- TBC1-UP LFM1-UP

23 Cylinder Gp. - Tilt 233-9134 E-1 fied above are: JEK1-UP EXL1-UP PUSH-PULL LEVER MANUAL SHUTOFF GENERAL MANUAL PUSH BUTTON PEDAL SPRING

24 Cylinder Gp. - Ripper Lift 227-0842 E-8

(HA) Implement pump discharge pressure test port.

HCD1-UP DPS1-UP PILOT CONTROL SYMBOLS

25 Tank Gp. 224-4946 A-3

(14) Accumulator. HKE1-UP EXW1-UP RELEASED PRESSURE REMOTE SUPPLY PRESSURE

26 Valve Gp. - Winch Pilot Control 160-0766 A-8 (CP) Pilot supply pressure test port. WRG1-UP GMT1-UP

27 Winch Arrangement 237-5912 F-8 (S•O•S) Hydraulic oil sampling port. MTJ1-UP MRT1-UP

28 Valve Gp. - Counter Balance-Lift Circuit 239-0681 F-2 (CPG) Accumulator pressure test port. EXTERNAL RETURN INTERNAL RETURN SIMPLIFIED COMPLETE INTERNAL

SUPPLY PRESSURE

29 Valve Gp. - EH Solenoid Valves 239-5317 C-1

ACCUMULATORS CROSSING AND JOINING LINES HYDRAULIC AND PNEUMATIC CYLINDERS

30 Shuttle Valve 233-6942 C-1

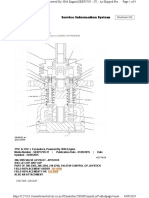

PRESSURE MANIFOLD 15

SPRING LOADED GAS CHARGED LINES CROSSING LINES JOINING SINGLE ACTING DOUBLE ACTING

Tap Locations

HYDRAULIC PUMPS HYDRAULIC MOTORS INTERNAL PASSAGEWAYS

Pressure, Sampling, and Sensor D6R SERIES III BLADE ANGLE EH PILOT MANIFOLD

FIXED

Tap Schematic VARIABLE DISPLACEMENT FIXED VARIABLE DISPLACEMENT INFINITE THREE TWO

Description DISPLACEMENT NON-COMPENSATED DISPLACEMENT NON-COMPENSATED POSITIONING POSITION POSITION

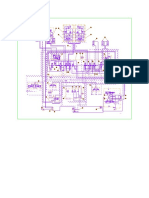

Number Location The machine will have an EH pilot manifold installed for blade angle control (29) if the machine UNIDIRECTIONAL UNIDIRECTIONAL

HB IMPLEMENT PUMP SIGNAL PRESSURE F-3 is equipped with a VPAT blade. The EH pilot manifold for blade angle control is located in the

forward compartment on the right fender, directly below the pressure reducing manifold. The PARALLEL CROSS FLOW ALLOWED IN

HA IMPLEMENT PUMP DISCHARGE PRESSURE E-8

FLOW IN ONE

BIDIRECTIONAL BIDIRECTIONAL DIRECTION FLOW FLOW EITHER DIRECTION

K UPSTREAM FILTER PRESSURE D-3 ANGLE RIGHT solenoid controlled pilot valve and the ANGLE LEFT solenoid controlled pilot

valve are identified in the picture below. Pilot Control and Accugrade Ready (HE)

CP PILOT SUPPLY PRESSURE D-8

CPG ACCUMULATOR D-8 © 2006 Caterpillar Printed in U.S.A.

EH PILOT MANIFOLD

Angle Right All Rights Reserved

MA STEERING PORT PRESSURE (A) F-4 (To Blade Angle Control Valve)

MB STEERING PORT PRESSURE (B) E-4 Angle Left

C COOLER BYPASS PRESSURE D-2

To Tank

Pilot

supply (Drain)

Electrical Symbols Table

29

(A) From Pressure

Reducing Manifold Hydraulic Symbols (Electrical)

Angle Right Angle Left

Angle Right Angle Left

E F G 1

Illustration (A) shows the EH pilot manifold when the operator has moved the thumb rocker switch

to the BLADE ANGLE RIGHT position. The Machine ECM receives the signal from the thumb

G M

8 9 10 28 rocker switch and sends a corresponding signal to the ANGLE RIGHT solenoid controlled pilot

valve and the solenoid is ENERGIZED. Pilot supply oil is then directed to the appropriate end of Transducer Transducer Generator Electric Motor

24 11 2 5 6 7 MA 3 1 HB 20 22 the blade angle control valve. (Fluid) (Gas / Air)

D6R SERIES III BLADE TILT AND LIFT EH PILOT MANIFOLD

The EH pilot manifold (28) for blade lift and tilt functions is mounted to the outboard side of the

RENR7956-01

valve stack bracket, if the machine is equipped with AccuGrade. Pressure Switch Temperature Switch Electrical Wire

Pressure Switch

(Adjustable)

Components of the AccuGrade EH pilot manifold identified above are the blade raise solenoid, the D

blade tilt right solenoid, the AccuGrade Boost solenoid, the blade tilt left solenoid, and the blade

lower solenoid.

Electrical Symbols (Electrical)

The EH pilot manifold receives pilot supply oil from the pressure reducing manifold. The EH pilot

21 manifold contains four (proportional) solenoid controlled pilot valves that receive PWM signals

from the Machine ECM for operation of the blade lift and the blade tilt functions. When

B

24 Page

ENERGIZED, the solenoid controlled pilot valve directs pilot supply oil to the end of the C T

corresponding implement control valve, in direct proportion to the movement of the dozer control Pressure Flow

Temperature Level

lever (or as automatically commanded by the AccuGrade system). The EH pilot manifold also Symbol Symbol

Symbol Symbol

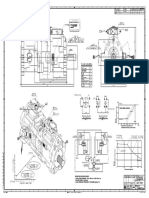

contains the AccuGrade Boost solenoid valve, which uses an ON/OFF solenoid.The AccuGrade The implement hydraulic pump (1) is mounted to the rear of the flywheel housing, at the upper

Boost strategy was discussed earlier in the Implement Hydraulics section ofthis presentation. left corner. High pressure supply oil to the implement valve stack is directed through a hose

that connects to the pump discharge port (B). High pressure supply oil to the pressure reduc-

Wire Number Identification Codes

ing manifold is directed through a hose that connects to the lower fitting (C) from the pump

26 discharge port.

Electrical Schematic Example Hydraulic Schematic Example

A pump discharge pressure sensor (D) is installed on the opposite side of the "tee" fitting from

Current Standard Current Standard

the pressure reducing manifold supply line. This pressure sensor is only present on machines

that are equipped with AccuGrade. It is a necessary component for the calibration of the four Harness identification code

16 29 30 25 18 19 13 14 15 HA CP 17 C 23 proportional solenoids on the EH pilot manifold that are used for blade control. Machines that

This example indicates

wire 135 in harness "AG". Wire

CPG SOS are not equipped with AccuGrade will have an "L" fitting at this location, connecting the pump- Circuit Number Wire Color

Identification

supply line to the pressure reducing manifold.

325-AG135 PK-14

Other components identified above are: 325-PK

CPG SOS Circuit Identification Wire Color Wire Gauge

Number

16 25 26 11 18 29 30 19 13 14 15 HA CP 20 21 E. pump pressure and flow compensator valve

F. fitting for the load sensing signal line (from the signal resolver network)

IMPLEMENT VALVE STACK EH PILOT MANIFOLD G. fitting for the case drain line Previous Standard

Wire Color

Accugrade Wire

Boost This implement pump is identical to the implement pump used in the D6R Series II machines

To Tank with differential steering.

(Drain)

Pilot 325-PK-14

supply

B A

Accugrade Boost Line

Circuit Number Wire Gauge

Identification (EXAMPLE VALVE)

Tilt

Right

Tilt

Left

IMPLEMENT PUMP 1

Blade Blade

Raise Lower

To Float Pilot

Boost Line

To Blade Tilt To Blade Tilt To Blade Tilt

Control Valve Control Valve Control Valve

(Tilt Right) (Tilt Left) (Tilt Left)

The steering and implement control E Service points on the back of the hydraulic oil

28 10 C

valve stack is mounted to a bracket tank that are identified above are:

inside the right fender, below the right

To Blade Lift Control Valve console in the operator compartment. F A. Steering implement pump suction port.

(Blade Lower/Float)

The implement valve stack consists of B. Valve stack end cover drain port.

the inlet manifold (5), the steering valve 9 C. Hydraulic oil temperature sensor.

The AccuGrade Boost solenoid valve directs pilot supply oil to an external resolver. The blade (6), the blade lift control valve (7), the D. Pilot valve drain port.

lower solenoid controlled pilot valve also directs pilot supply oil to this same external resolver, in blade tilt control valve (8), the optional A E. Case drain return port (to internal filter).

24 MA 2 5 6 7 3 1 HB 17 C 22 23 addition to the pilot supply oil that is directed to the LOWER end of the blade lift control valve. blade angle control valve (A), the ripper G F. Fitting for hose to hydraulic oil cooler

Pilot supply oil is directed (through the resolver) to the Float Pilot Boost line when either solenoid (or winch) control valve (9), and the end 8 (via bypass valve).

8 9 10 28 cover (10), EH pilot manifold for tilt and

A

is ENERGIZED. The Float Pilot Boost signal line enters the signal resolver network through the G. Implement return oil port (to internal filter).

end cover of the valve stack. In either situation, the pump's flow compensator valve senses the lift. The blade angle control valve and

the ripper/winch control valve may not 7

pilot supply oil as a signal and the implement pump will up stroketo maintain margin pressure

above LOW PRESSURE STANDBY pressure. (If the steering valve or another implement valve be present, depending on how the

sends a higher signal into the resolver network, the highest pressure is sensed by the compensa- machine is equipped. 6 5

tor valve.)This EH pilot manifold is only present on ARO machines.

B D

MACHINE EH PILOT MANIFOLDS STEERING and IMPLEMENT HYDRAULIC OIL TANK 25

28 29

COMPONENT LOCATIONS CONTROL VALVE

8 7 6 5 4 3 2 1

27 MA

PUMP DISCHARGE

20

F RAISE F

SIGNAL TO PUMP SIGNAL TO PUMP 21

A1 LOWER

A2

LIFT CYLINDERS

PACCAR WINCH UNIT

REXROTH MOTOR AA6VM80HA1T

HB

5

TILT RIGHT

1 TILT LEFT 22

MAIN RELIEF VALVE

B1 PUMP FLUSHING DUAL TILT OPTION

E CIRCUIT

E

24

TILT RIGHT

6 2 3 SUCTION

TILT LEFT 17

B2

MB 17

RIPPER LIFT SINGLE TILT OPTION

STEERING

HA PRESSURE LIMITER LIFT AND TILT CYLINDERS

15 PS T

C

7 1

DOZ LIFT

2 3

DOZ TILT 4

ELEC. DET.

SOS PRESSURE C1 C2

REDUCING

MANIFOLD 12 D

D

CPG K

RAISE

ACC D1

DOZER LIFT LOWER

D2 1 T S 2 3 T S 4

CPG 13 PRESSURE

LIMITER C2 C1 C3 C4

CP PILOT CONTROL

14

8

CP

C1

C2

C4

C3

C3 C4

TILT RIGHT D2

29

TILT LEFT

DOZER TILT

RENR7956-01

DOZER TILT

D1

C C

D1

30

24 Page, Color 2

D2 C5

EH SOLENOID VALVES

RIPPER WINCH

B3 B4

A1

PAY OUT CYLINDER CONTROL

RAISE HAUL IN

B1 A2

FLOAT PILOT

LOWER

B2 BOOST SIGNAL WINCH

RIPPER

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

MAIN PUMP OUTPUT

SUPPLY LINE

DRAIN / RETURN LINE

C5 C1 STEERING CIRCUIT

TILT CYLINDER CIRCUIT

LIFT CYLINDER CIRCUIT

9 FLOAT AND CTCT LS

RIPPER CYLINDER CIRCUIT

PACCAR WINCH CIRCUIT

BOOST SIGNAL SHUTTLE VALVE CONTROL CIRCUIT

10

9 B

B

RIPPER CONTROL

10 LINE PATTERNS

3 4 Pressure Line

Pilot / Load Sensing Pressure

11

Drain / Return Lines

Component Group

Attachment

PILOT SUPPLY Air Line

PILOT DRAIN

3 S 4

CALLOUTS

T

AIR RELIEF

YY Taps (Pressure, Sampling, Sensor) by letter

B4

B3 1 Components by number

18 AA Connections by letter

FREE SPOOL HAUL IN PAY OUT 16

ARROW PATTERNS

1 2 3 4 26 RETURN

RIPPER OR WINCH

ELEC. DET.

AIR VENT

A A

HOUSING DRAIN

25

19

PILOT SUPPLY

THIS SCHEMATIC IS FOR THE D6R SERIES III TRACK-TYPE TRACTOR

PILOT DRAIN

1 T S 2 3 T S 4 PART #: 223-1198 CHG 04

Components are shown installed on a fully operable machine with the key and engine off and

transmission shifter in neutral.

WINCH CONTROL Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations.

8 7 6 5 4 3 2 1

Das könnte Ihnen auch gefallen

- Tractor d8 TDokument2 SeitenTractor d8 TAkira TamashiroNoch keine Bewertungen

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokument13 SeitenInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Rajan Mullappilly100% (1)

- PC278 PA110VS D9R Diff Steer Parts PDFDokument24 SeitenPC278 PA110VS D9R Diff Steer Parts PDFعمار العماريNoch keine Bewertungen

- 374F L TRG PDFDokument52 Seiten374F L TRG PDFDAnielNoch keine Bewertungen

- The Basic Principles of HydraulicsDokument8 SeitenThe Basic Principles of Hydraulicsyakarim100% (3)

- d9r Hydraulic SystemDokument2 Seitend9r Hydraulic Systemwtn2013Noch keine Bewertungen

- m00979800001 Plano ElectricoDokument4 Seitenm00979800001 Plano ElectricoJuan Carlos Inga VasquezNoch keine Bewertungen

- Machine Component Locations: 793D Off-Highway Truck Hydraulic SystemDokument2 SeitenMachine Component Locations: 793D Off-Highway Truck Hydraulic SystemИгорь Иванов0% (1)

- Cosechadora 522B Plano HYD 2016 SISDokument8 SeitenCosechadora 522B Plano HYD 2016 SISFabrizio Jesús100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokument11 SeitenInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768falahNoch keine Bewertungen

- Esquema Hidráulico (793D)Dokument2 SeitenEsquema Hidráulico (793D)Oswaldo Ayma VisaNoch keine Bewertungen

- 432d Signal Resolver Network - CheckDokument6 Seiten432d Signal Resolver Network - CheckDiego CatariNoch keine Bewertungen

- Bombas y Controles Serv7107 - V05N01 - SLD3Dokument23 SeitenBombas y Controles Serv7107 - V05N01 - SLD3jorge william ramirezNoch keine Bewertungen

- Diagrama Hidraulico 777FDokument4 SeitenDiagrama Hidraulico 777Ffabioalbor100% (1)

- Drum and Blade Attachment Under Platform: CS56B, CP56B, CS68B, and CP68B Hydraulic System Vibratory Soil CompactorsDokument2 SeitenDrum and Blade Attachment Under Platform: CS56B, CP56B, CS68B, and CP68B Hydraulic System Vibratory Soil CompactorsAndresCorreaNoch keine Bewertungen

- Specification 320CDokument7 SeitenSpecification 320CSteven ManuputtyNoch keine Bewertungen

- Uenr0213uenr0213-01 Sis PDFDokument2 SeitenUenr0213uenr0213-01 Sis PDFRaphael Ruiz Ramos100% (2)

- RENR8305-02 Esquematico Hidraulico 777FDokument4 SeitenRENR8305-02 Esquematico Hidraulico 777FEIDER LEYESNoch keine Bewertungen

- 994K Wheel Loader Brake SystemDokument2 Seiten994K Wheel Loader Brake SystemHéctorHernándezDíaz100% (1)

- Uenr8357uenr8357 SisDokument8 SeitenUenr8357uenr8357 Sisjhonas del marNoch keine Bewertungen

- Serv 2739Dokument42 SeitenServ 2739Said Touhami100% (1)

- SENR2452: 14G & 16G Motor Graders Hydraulic SystemDokument2 SeitenSENR2452: 14G & 16G Motor Graders Hydraulic SystemMohamed HarbNoch keine Bewertungen

- D7H Electrico PDFDokument2 SeitenD7H Electrico PDFAnonymous KOtSfT6qNoch keine Bewertungen

- Caterpillar 350 Excavator SpecsDokument4 SeitenCaterpillar 350 Excavator SpecsAgus Budiluhur100% (1)

- Hydraulic System 966G and 972G Series II Wheel Loader: Fluid Power SymbolsDokument4 SeitenHydraulic System 966G and 972G Series II Wheel Loader: Fluid Power SymbolsFernando QSNoch keine Bewertungen

- Excavadora Doosan Dx300lcaDokument5 SeitenExcavadora Doosan Dx300lcaXiomara Muñoz Mendoza100% (2)

- COMPUTER AIDED ANALYSIS AND MODELLING LecturesDokument41 SeitenCOMPUTER AIDED ANALYSIS AND MODELLING LecturesBen Anim100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokument11 SeitenInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Yancarlos Quispe AmayaNoch keine Bewertungen

- Piston Pump MetarisDokument44 SeitenPiston Pump Metarissml2001100% (3)

- Groupon Vale CatDokument4 SeitenGroupon Vale CatLuis Carlos RamosNoch keine Bewertungen

- ELECTRICAL SCHEMATIC INDEXDokument47 SeitenELECTRICAL SCHEMATIC INDEXLeopoldo Del Campo75% (4)

- Cat Loader980G Hyd Steering CircuitDokument2 SeitenCat Loader980G Hyd Steering CircuitveereshNoch keine Bewertungen

- Plano Hidráulico Cargador 988GDokument13 SeitenPlano Hidráulico Cargador 988Ggerardo100% (1)

- Pump parts assembly diagram and listDokument4 SeitenPump parts assembly diagram and listLenin GullapalliNoch keine Bewertungen

- Cat 950GDokument5 SeitenCat 950GAhmed Ragab100% (2)

- Handok Hydraulic - Co: Flow Rate ControlDokument1 SeiteHandok Hydraulic - Co: Flow Rate Controlanon_485665212Noch keine Bewertungen

- 785d HydraulicDokument2 Seiten785d HydraulicSainbayr SainaaNoch keine Bewertungen

- Hydrostatic drive system components and functionsDokument27 SeitenHydrostatic drive system components and functionsGiancarlo Olivera Bejar100% (3)

- CS 563 Hydraulic PDFDokument2 SeitenCS 563 Hydraulic PDFanggieNoch keine Bewertungen

- Compresor Mobil Atlas Copco XAS97Dokument1 SeiteCompresor Mobil Atlas Copco XAS97dicon100% (1)

- Material Schematic Hydraulic System Motor Grader 16h CaterpillarDokument2 SeitenMaterial Schematic Hydraulic System Motor Grader 16h CaterpillarMuhammadRidhoHidayatNoch keine Bewertungen

- Performance Test D8R (9EM)Dokument6 SeitenPerformance Test D8R (9EM)ahmad ruyaniNoch keine Bewertungen

- 777D 3PR Senr6910Dokument2 Seiten777D 3PR Senr6910Putra Jawa100% (1)

- Plano 2 Hidra.374fDokument2 SeitenPlano 2 Hidra.374fIlder NavizNoch keine Bewertungen

- Diagrama Electrico 966dDokument2 SeitenDiagrama Electrico 966dpedro melendez100% (1)

- 320D FMDokument20 Seiten320D FMlesantiago67% (3)

- Cat Rope ShowelDokument2 SeitenCat Rope ShowelGanapati HegdeNoch keine Bewertungen

- Curso PDFDokument185 SeitenCurso PDFJose VidalNoch keine Bewertungen

- D9T Schematic TransmissionDokument2 SeitenD9T Schematic Transmissionjulio peña lima100% (1)

- View All Callouts: Function Isolation ToolsDokument11 SeitenView All Callouts: Function Isolation ToolsEdwin GamarraNoch keine Bewertungen

- 938HDokument24 Seiten938HJusto César Ruidias Juárez100% (1)

- CAT 930D Excavator C620823Dokument28 SeitenCAT 930D Excavator C620823Dutchie169Noch keine Bewertungen

- Hydraulic Schematic IT38G Series II Wheel LoaderDokument2 SeitenHydraulic Schematic IT38G Series II Wheel LoaderDennis OlayaNoch keine Bewertungen

- Schéma Hy 227B 01Dokument2 SeitenSchéma Hy 227B 01Juju100% (1)

- Edoc - Pub 938giihydraulicsystemDokument2 SeitenEdoc - Pub 938giihydraulicsystemGeobel HernandezNoch keine Bewertungen

- 966M and 972M Wheel Loader 966mDokument2 Seiten966M and 972M Wheel Loader 966mF Labio AlexNoch keine Bewertungen

- Hydraulic GramDokument2 SeitenHydraulic Gramerln LimaNoch keine Bewertungen

- Up and Away Classroom Labels and OrganizersVon EverandUp and Away Classroom Labels and OrganizersNoch keine Bewertungen

- Instant Assessments for Data Tracking, Grade 1: Language ArtsVon EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNoch keine Bewertungen

- Instant Assessments for Data Tracking, Grade 1: MathVon EverandInstant Assessments for Data Tracking, Grade 1: MathBewertung: 4 von 5 Sternen4/5 (1)

- Jjkgfhkijdeghsxgfjuhfgyy 4Dokument1 SeiteJjkgfhkijdeghsxgfjuhfgyy 4chakrouneNoch keine Bewertungen

- Prise Rapid Cat - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPDokument2 SeitenPrise Rapid Cat - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPchakrouneNoch keine Bewertungen

- GROUP 3 ELECTRICAL COMPONENT SPECIFICATIONSDokument8 SeitenGROUP 3 ELECTRICAL COMPONENT SPECIFICATIONSRoussel Florez ZuloagaNoch keine Bewertungen

- 1hhhhhhjkkjhh Sisweb Sisweb Techdoc Techdoc Print Page - JSPDokument9 Seiten1hhhhhhjkkjhh Sisweb Sisweb Techdoc Techdoc Print Page - JSPchakrouneNoch keine Bewertungen

- 127.0.0.1 432E Sisweb Techdoc Techdoc Print Page - JSPDokument15 Seiten127.0.0.1 432E Sisweb Techdoc Techdoc Print Page - JSPchakrouneNoch keine Bewertungen

- 12g Meknase - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSP - PDFDokument5 Seiten12g Meknase - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSP - PDFchakrouneNoch keine Bewertungen

- Komatsu Fault Codes List PDFDokument2 SeitenKomatsu Fault Codes List PDFchakrouneNoch keine Bewertungen

- TTTTTTTDokument12 SeitenTTTTTTTchakroune100% (1)

- Jjkgfhkijdeghsxgfjuhfgyy 4Dokument1 SeiteJjkgfhkijdeghsxgfjuhfgyy 4chakrouneNoch keine Bewertungen

- Jjkgfhkijdeghsxgfjuhfgyy 4Dokument1 SeiteJjkgfhkijdeghsxgfjuhfgyy 4chakrouneNoch keine Bewertungen

- HKKGHGJHT Sisweb Sisweb Techdoc Techdoc Print Page - JSPDokument11 SeitenHKKGHGJHT Sisweb Sisweb Techdoc Techdoc Print Page - JSPchakrouneNoch keine Bewertungen

- Gfjjhgilyomplttooygjkoioyy1 PDFDokument1 SeiteGfjjhgilyomplttooygjkoioyy1 PDFchakrouneNoch keine Bewertungen

- HHHHHHHKKKLPPLRGFGFR 5Dokument1 SeiteHHHHHHHKKKLPPLRGFGFR 5chakrouneNoch keine Bewertungen

- Cat 214b Schema Hydraulic1Dokument2 SeitenCat 214b Schema Hydraulic1chakrouneNoch keine Bewertungen

- Gfjjhgilyomplttooygjkoioyy1 PDFDokument1 SeiteGfjjhgilyomplttooygjkoioyy1 PDFchakrouneNoch keine Bewertungen

- Cat 12g Fes - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSP - PDFDokument2 SeitenCat 12g Fes - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSP - PDFchakrouneNoch keine Bewertungen

- Nllkol950g Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPDokument9 SeitenNllkol950g Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPchakrouneNoch keine Bewertungen

- Cat 950g 2 Jhjkhrgfetesisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPDokument1 SeiteCat 950g 2 Jhjkhrgfetesisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPchakrouneNoch keine Bewertungen

- Caterpillar 12g Meknase - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPDokument11 SeitenCaterpillar 12g Meknase - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPchakrouneNoch keine Bewertungen

- How To Connect To An Electronic Engine PDFDokument9 SeitenHow To Connect To An Electronic Engine PDFchakrouneNoch keine Bewertungen

- BDX 00889 CatDokument16 SeitenBDX 00889 Catiprahim202066100% (2)

- 325, 325 L & 325 LN Excavators Electrical System: Area ADokument2 Seiten325, 325 L & 325 LN Excavators Electrical System: Area ARoussel Florez ZuloagaNoch keine Bewertungen

- 127.950g .1 - Sisweb - Servlet - Cat - Cis.sis - PController.CSSISCDokument3 Seiten127.950g .1 - Sisweb - Servlet - Cat - Cis.sis - PController.CSSISCchakrouneNoch keine Bewertungen

- Cat 12g Fes - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSP - PDFDokument2 SeitenCat 12g Fes - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSP - PDFchakrouneNoch keine Bewertungen

- Senr6285senr6285 01Dokument2 SeitenSenr6285senr6285 01chakrouneNoch keine Bewertungen

- Cat 950g 2 Jhjkhrgfetesisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSP - PDFDokument1 SeiteCat 950g 2 Jhjkhrgfetesisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSP - PDFchakrouneNoch keine Bewertungen

- Jjgjjthjtgfrhysisweb Sisweb Techdoc Techdoc Print Page - JSPDokument3 SeitenJjgjjthjtgfrhysisweb Sisweb Techdoc Techdoc Print Page - JSPchakrouneNoch keine Bewertungen

- Nllkol950g Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPDokument9 SeitenNllkol950g Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPchakrouneNoch keine Bewertungen

- 127jkhbggff Sisweb Sisweb Techdoc Techdoc Print Page - JSP PDFDokument2 Seiten127jkhbggff Sisweb Sisweb Techdoc Techdoc Print Page - JSP PDFchakrouneNoch keine Bewertungen

- 127jkhbggff Sisweb Sisweb Techdoc Techdoc Print Page - JSPDokument2 Seiten127jkhbggff Sisweb Sisweb Techdoc Techdoc Print Page - JSPchakrouneNoch keine Bewertungen

- Sprinkler System: NFPA 25 ITM Quick Reference Guide Sprinklers Systems & Fire Pumps - Inspection, Testing, MaintenanceDokument2 SeitenSprinkler System: NFPA 25 ITM Quick Reference Guide Sprinklers Systems & Fire Pumps - Inspection, Testing, MaintenanceMouad BoumazzoughNoch keine Bewertungen

- 03 Xmas Tree Test - XDokument5 Seiten03 Xmas Tree Test - XElinton SarmientoNoch keine Bewertungen

- Piston Pump (Main) - Test: SMCS - 5070-081Dokument16 SeitenPiston Pump (Main) - Test: SMCS - 5070-081Muriel Remberto100% (2)

- 4 Measurement of AirspeedDokument23 Seiten4 Measurement of AirspeedNagamani ArumugamNoch keine Bewertungen

- Wet Chemical Dataran KG BaruDokument3 SeitenWet Chemical Dataran KG BaruJeghiNoch keine Bewertungen

- School of Maritime Studies Vels University ThalamburDokument3 SeitenSchool of Maritime Studies Vels University ThalamburAayush AgrawalNoch keine Bewertungen

- Vapor Compression Refrigeration Cycle ExplainedDokument16 SeitenVapor Compression Refrigeration Cycle ExplainedDiether RigorNoch keine Bewertungen

- List WPS Piping New 2023Dokument1 SeiteList WPS Piping New 2023YUDI IRMAWANTONoch keine Bewertungen

- KPM K3VL B Series Marketing KitDokument167 SeitenKPM K3VL B Series Marketing KitClaudiu MorarNoch keine Bewertungen

- Ateliers Francois (40 Bar - PET) CompressorDokument4 SeitenAteliers Francois (40 Bar - PET) CompressorAbu Bakar KhanNoch keine Bewertungen

- Surface Well Control Exercise No. 10 - Equipment - Revised January 2012 - Welltrain Logo PDFDokument14 SeitenSurface Well Control Exercise No. 10 - Equipment - Revised January 2012 - Welltrain Logo PDFKaleem UllahNoch keine Bewertungen

- ISO 9001 Gas Turbine Test Rig QuotationDokument6 SeitenISO 9001 Gas Turbine Test Rig QuotationVekateshwaralu KNoch keine Bewertungen

- Heatexchanger 141216095212 ConversionDokument23 SeitenHeatexchanger 141216095212 Conversionraj2417705Noch keine Bewertungen

- Press Control Brio2000Dokument16 SeitenPress Control Brio2000MatiFernandezNoch keine Bewertungen

- Hydraulis All BVKDokument149 SeitenHydraulis All BVKgotu123Noch keine Bewertungen

- Design Features of The Boge Air Compressor S-SeriesDokument9 SeitenDesign Features of The Boge Air Compressor S-SeriesAir Repair, LLC100% (1)

- Diaphragm ValvesDokument24 SeitenDiaphragm ValvesJimmy Leonardo Albornoz MontenegroNoch keine Bewertungen

- New Trends in AcDokument11 SeitenNew Trends in AcNallathambiNoch keine Bewertungen

- High Pressure High Temperature Filter Press ReportDokument16 SeitenHigh Pressure High Temperature Filter Press ReportMJ LagradaNoch keine Bewertungen

- Input To NC-3658.3 Flange Evaluation MethodDokument7 SeitenInput To NC-3658.3 Flange Evaluation MethodVishal KandNoch keine Bewertungen

- MV Introduction LetterDokument1 SeiteMV Introduction LetterSoriSori2008Noch keine Bewertungen

- Ibr FormsDokument117 SeitenIbr FormsAkhilesh KumarNoch keine Bewertungen

- 004 Mud Pump PerformanceDokument33 Seiten004 Mud Pump PerformanceJuan GómezNoch keine Bewertungen

- Packing List 23-45Dokument1 SeitePacking List 23-45BTB GroupNoch keine Bewertungen

- Standart Container Kube DispensingDokument4 SeitenStandart Container Kube DispensingYuszra SabillaNoch keine Bewertungen

- Rexroth Z2S 6 - Check Valve Pilot OperatedDokument4 SeitenRexroth Z2S 6 - Check Valve Pilot OperatedEBNoch keine Bewertungen

- Smb4 Moa, Manila: Method StatementDokument4 SeitenSmb4 Moa, Manila: Method StatementJansen AnoyoNoch keine Bewertungen

- Flow Induced NoiseDokument40 SeitenFlow Induced NoiseManouel Cem CebiogluNoch keine Bewertungen

- Vane Pumps: VickersDokument4 SeitenVane Pumps: VickersLeo LeiNoch keine Bewertungen

- Pumps Pumping Systems GeneralDokument349 SeitenPumps Pumping Systems GeneralGokula Krishnan CNoch keine Bewertungen