Beruflich Dokumente

Kultur Dokumente

Methanol Fact Sheet

Hochgeladen von

Ira RamadhaniCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Methanol Fact Sheet

Hochgeladen von

Ira RamadhaniCopyright:

Verfügbare Formate

European Biofuels Biofuel Fact Sheet

T E C H N O L O G Y P L AT F O R M

Methanol from biomass

Lab scale Bench scale Pilot Plant Demonstration Production

Introduction

Methanol, also known as methyl alcohol, wood alcohol, or Molecular Formula

wood spirits, is often abbreviated as MeOH. It is the simplest

alcohol, and is a light, volatile, colourless, flammable liquid CH4O

with a distinctive odour. At room temperature it is a polar

liquid. MeOH is miscible with water, petrol and many organic Comparison of Fuel Properties

compounds. MeOH burns with an almost invisible flame

Property Methanol Petrol

and is biodegradable. Without proper conditions, methanol

attracts water while stored. Methanol is a safe fuel. The toxicity Density at 20 0.79 0.74

(mortality) is comparable to or better than gasoline. It also °C [kg/l]*

biodegrades quickly (compared to petroleum fuels) if spilled.

Lower heating 19.7 43.9

See page two for Production Process. value [MJ/kg]*

State of the Art Octane >110 92

number

MeOH has grown into one of the largest chemical synthesis

feedstocks. Key uses include production of formaldehyde, Fuel 0.48 1

MTBE/TAME (petrol additives), acetic acid, DME and olefins equivalence

and direct use as a petrol blend component. GHG [gCO2eq/ Waste wood

In 2007 the world production of MeOH amounted to 40 million MJ]** methanol: 5

tonnes with a forecast compound annual growth rate of 4.2 Farmed wood

% for the period 2008-2013 excluding captive production methanol: 7

for the methanol-to-olefins (MTO) route. Today, methanol

Source: *FNR 2012. Median values are used for simplification.

from biomass is produced through gasification of glycerine, Please refer to standards for ranges. ** Directive 2009/28/EC,

a by-product of biodiesel production, by BioMCN in the total for cultivation, processing, transport and distribution

Netherlands. The thermochemical conversion of syngas to

methanol is well known from fossil feedstocks and the basic Utilization

steps are not different for biomass. The main issue faced is Chemical feedstock, petrol blend component

the economic feasibility of gasification of biomass at elevated

pressures and conditioning of the raw synthesis gas. Relevant fuel regulations

In the past there was some small-scale production of methanol EN 228

from biomass. In 2004 the German company Choren Industries

GmbH produced methanol from wood using its Carbo-V Main feedstocks

process. In the Chemrec AB pilot plant in Piteå, Sweden Natural gas, coal, biomass

about 6 tons per day of methanol is used as an intermediate

in the production of BioDME. While the biochemical route Scale of Production

through methanothrophic bacteria is still in an early state of Industrial scale

development the conversion of biogas to methanol has been

proven at bench scale. ZSW has proven that methanol could

be produced from biogas at a decentralised level.

Projects on methanol

Applications

SUPER METHANOL - Reforming of crude glycerine in

Low-percentage methanol-gasoline blends (up to 3 % as

supercritical water to produce methanol for re-use in

per current EU standard EN228) can be effectively used

in conventional spark-ignition engines with no technical biodiesel plants (FP7-212180)

changes, the use of alcohol fuels in heavy duty applications is MTO/OCP Project - Methanol-to-olefins/olefin cracking

being investigated by motor manufacturers. process (€45m project funded by Total)

Methanol from biomass Biofuel Fact Sheet

Production process

Some major methanol stakeholders in the EU

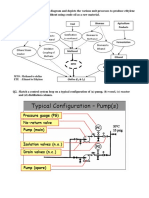

In nature MeOH is produced via anaerobic metabolism by

many bacteria. It is also formed as a by-product during the Chemrec AB, Sweden

ethanol fermentation process. MeOH also occurs naturally in VärmlandsMethanol AB, Sweden

many plants, especially in fruits. MeOH is mainly synthesized

BioMCN B.V., Netherlands

from natural gas, but also from coal, mainly in China and South

Africa. Biomass can be converted to MeOH via thermochemical B.T.G. BIOMASS TECHNOLOGY GROUP BV, Netherlands

and biotechnological pathways as shown in the following Choren Industries GmbH, Germany

diagram.

Karlruhe Institute for Technology (KIT), Germany

ZSW, Germany

DECHEMA, Germany

Dry Biomass Wet Biomass Technical University of Vienna, Austria

Technical University of Graz, Austria

Synthesis Gas Anaerobic

Production Digestion Biochemical pathways

One biochemical route is via methane formation by anaerobic

digestion. This process is well developed due to the rise of

biogas production from municipal waste or landfill sites. The

ethane Methanthropic biogas has to be cleaned to obtain a gas with high methane

Methane

Bacteria content and MeOH is then produced from the methane as

described above.

Recently a genuine biochemical route using methanothrophic

bacteria has been investigated. For example, bacteria such as

Methanol Methylococcus capsulatus will convert methane to MeOH if

methane is the only available resource.

Thermochemical pathways Further information

Up-to-date information on methanol from biomass R&D&D

The thermochemical conversion paths to MeOH are basically

is available on the Euorpean Biofuels Technology Platform

the same as for fossil feedstocks, such as coal or natural gas.

website www.biofuelstp.eu.

The biomass is gasified and the resulting synthesis gas,

a mixture of CO, H2 and CO2, is adapted to the quality

requirements of MeOH synthesis.

During synthesis the following reactions occur:

CO + 2H2 CH3OH

CO2 + 3H2 CH3OH + H20

CO2 + H2 CO + H20

The formation of MeOH is exothermic and is favoured by

high pressures and low temperatures. For reasons of process

simplification, investment cost reduction and energy

consumption reduction, alternatives are under development,

which could also be used for MeOH from biomass

Direct oxidation of Methane: 2CH4 + O2 2CH3OH

Liquid-phase oxidation of Methane

Conversion through monohalogenated methanes

All trademarks, registered designs, copyrights and other proprietary rights of the organisations mentioned within this document are acknowledged. While the

information in this fact sheet is believed to be accurate, neither EBTP members nor the European Commission, accept any responsibility or liability whatsoever

for any errors or omissions herein nor any use to which this information is put. The Secretariat of the EBTP is partly supported under FP7 Grant Agreement

241269. However, the information expressed on this fact sheet should not under any circumstances be regarded as stating an official position of the European

Commission. Design and content of this fact sheet are copyright © European Biofuels Technology Platform 2011.

Das könnte Ihnen auch gefallen

- Dirty Dozen List of Endocrine DisruptorsDokument4 SeitenDirty Dozen List of Endocrine DisruptorsMariuszNoch keine Bewertungen

- Methanol Synthesis From SyngasDokument38 SeitenMethanol Synthesis From SyngasShahabuddin Khan NiaziNoch keine Bewertungen

- PNFDokument51 SeitenPNFMuhamad Hakimi67% (3)

- Your Marathon Training PlanDokument16 SeitenYour Marathon Training PlanAndrew Richard ThompsonNoch keine Bewertungen

- FS011 Audit Plan Stage 2Dokument2 SeitenFS011 Audit Plan Stage 2Ledo Houssien0% (1)

- Continuous Microbiological Environmental Monitoring For Process Understanding and Reduced Interventions in Aseptic ManufacturingDokument44 SeitenContinuous Microbiological Environmental Monitoring For Process Understanding and Reduced Interventions in Aseptic ManufacturingTorres Xia100% (1)

- RoadToBio Action PlanDokument32 SeitenRoadToBio Action PlanArunNoch keine Bewertungen

- (Jill E. Thistlethwaite) Values-Based Interprofess (B-Ok - CC)Dokument192 Seiten(Jill E. Thistlethwaite) Values-Based Interprofess (B-Ok - CC)Ria Qadariah AriefNoch keine Bewertungen

- Ems 01 Iso 14001 ManualDokument26 SeitenEms 01 Iso 14001 ManualG BelcherNoch keine Bewertungen

- Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerVon EverandThermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerNoch keine Bewertungen

- Production of Methanol From GlycerolDokument64 SeitenProduction of Methanol From GlycerolHafizuddin AdzharNoch keine Bewertungen

- Methanol DistillationDokument6 SeitenMethanol DistillationNaseeb AliNoch keine Bewertungen

- Isobutylene by MTBE Decomposition-CD TECHDokument2 SeitenIsobutylene by MTBE Decomposition-CD TECHDrVedprakash Mishra100% (1)

- Bioenergy: Biomass to Biofuels and Waste to EnergyVon EverandBioenergy: Biomass to Biofuels and Waste to EnergyAnju DahiyaNoch keine Bewertungen

- Topsoe MethanolDokument14 SeitenTopsoe Methanolk_selv321100% (2)

- Propylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIIDokument12 SeitenPropylene, Propylene Oxide and Isopropanol: Course: Chemical Technology (Organic) Module VIImaheshNoch keine Bewertungen

- Production of Paper From Pineapple LeavesDokument9 SeitenProduction of Paper From Pineapple LeavesIra RamadhaniNoch keine Bewertungen

- Biology Lab ReportDokument5 SeitenBiology Lab Reportapi-2576094460% (1)

- New MTBE Production DesignDokument13 SeitenNew MTBE Production DesignImad Sami100% (2)

- Production of MTBEDokument47 SeitenProduction of MTBERonald Manyama100% (5)

- Technician's Instructions Estetica E30Dokument142 SeitenTechnician's Instructions Estetica E30виктор100% (1)

- Direct Methane to Methanol: Foundations and Prospects of the ProcessVon EverandDirect Methane to Methanol: Foundations and Prospects of the ProcessNoch keine Bewertungen

- Design and Simulation of A Methanol Production Plant From CO2 HydrogenationDokument8 SeitenDesign and Simulation of A Methanol Production Plant From CO2 HydrogenationJJNoch keine Bewertungen

- Process Integration Study of A Biorefinery Producing Ethylene From Lignocellulosic Feedstock For A Chemical ClusterDokument23 SeitenProcess Integration Study of A Biorefinery Producing Ethylene From Lignocellulosic Feedstock For A Chemical ClusterMiguel PardoNoch keine Bewertungen

- MI Combined Slide Deck MDC Slides Revised PDFDokument30 SeitenMI Combined Slide Deck MDC Slides Revised PDFdinaNoch keine Bewertungen

- BIomass Syngas Production Technology by Gasification For Liquid Fuel and Other ChemicalsDokument5 SeitenBIomass Syngas Production Technology by Gasification For Liquid Fuel and Other ChemicalsgujunjssNoch keine Bewertungen

- ETIP Bioenergy Biomethanol Production and Use As FuelDokument15 SeitenETIP Bioenergy Biomethanol Production and Use As FuelmanojNoch keine Bewertungen

- Methanol Production Using Carbon Capture Technology: An OverviewDokument6 SeitenMethanol Production Using Carbon Capture Technology: An OverviewmohdaizadahmadNoch keine Bewertungen

- Production of Ethylene and Propylene From Methanol: I. Over ViewDokument10 SeitenProduction of Ethylene and Propylene From Methanol: I. Over ViewPhạm Ngọc ThạchNoch keine Bewertungen

- Biomethanol Production From Organic Waste Materials: Energy Sources, Part ADokument9 SeitenBiomethanol Production From Organic Waste Materials: Energy Sources, Part AahmadNoch keine Bewertungen

- Evaluasi EkonomiDokument9 SeitenEvaluasi EkonomiSilvia Widi YantiNoch keine Bewertungen

- Wilson2018 Article Bio-productionOfGaseousAlkenesDokument11 SeitenWilson2018 Article Bio-productionOfGaseousAlkenesJPBCNoch keine Bewertungen

- ETIP B Factsheet BiomethaneDokument4 SeitenETIP B Factsheet BiomethaneLove EpiphanyNoch keine Bewertungen

- Bridgwater PDFDokument19 SeitenBridgwater PDFABDO Moh.Noch keine Bewertungen

- Tert 1634-04-4 M: 2 Methyl Tert-Butyl EtherDokument20 SeitenTert 1634-04-4 M: 2 Methyl Tert-Butyl EtherMahmood Al-hashime0% (1)

- APE - Group 1 Methanol ProductionDokument5 SeitenAPE - Group 1 Methanol ProductionNeeravNoch keine Bewertungen

- Name of Report: Production of Mythel Tertiary Butyl Ether (MTBE) From Methanol & ButyleneDokument12 SeitenName of Report: Production of Mythel Tertiary Butyl Ether (MTBE) From Methanol & Butyleneمصطفى سعدNoch keine Bewertungen

- Producción de Metanol en Aspen PlusDokument8 SeitenProducción de Metanol en Aspen PlusAna Buelvas HernándezNoch keine Bewertungen

- Methanol Production From Bio-SyngasDokument14 SeitenMethanol Production From Bio-SyngasVinicius dos Santos MirandaNoch keine Bewertungen

- CPT PresentationDokument15 SeitenCPT PresentationNavket JhaNoch keine Bewertungen

- Method of Biofuel ProductionDokument6 SeitenMethod of Biofuel ProductionJuan ParisNoch keine Bewertungen

- Biomasa PDFDokument102 SeitenBiomasa PDFAriLo Ariel CastilloNoch keine Bewertungen

- Monetisation of Gas Through MethanolDokument42 SeitenMonetisation of Gas Through MethanolchavedaculturaNoch keine Bewertungen

- PMC Tech: Department of EeeDokument6 SeitenPMC Tech: Department of EeeEbin PeterNoch keine Bewertungen

- Plug Electrolyzers Key To Creating Low-Carbon Methanol: Green Hydrogen at Work™Dokument6 SeitenPlug Electrolyzers Key To Creating Low-Carbon Methanol: Green Hydrogen at Work™Anita SinagaNoch keine Bewertungen

- Produccion de MetanolDokument13 SeitenProduccion de MetanolJosué Genaro García DuqueNoch keine Bewertungen

- Biofuel and Energy Conversion From BioresourcesDokument49 SeitenBiofuel and Energy Conversion From BioresourcesYoong KitNoch keine Bewertungen

- Michael J. Waites, Neil L. Morgan, John S. Rockey, Gary Higton-Industrial Microbiology - An Introduction-Wiley-Blackwell (2001) - DikonversiDokument29 SeitenMichael J. Waites, Neil L. Morgan, John S. Rockey, Gary Higton-Industrial Microbiology - An Introduction-Wiley-Blackwell (2001) - Dikonversiegi maulanaNoch keine Bewertungen

- All Biofuel Fact Sheets 2016Dokument11 SeitenAll Biofuel Fact Sheets 2016Ömer LaçinNoch keine Bewertungen

- Coal Natural Gas Agriculture Products Gasification To Methanol Biomass To Ethanol BiomassDokument2 SeitenCoal Natural Gas Agriculture Products Gasification To Methanol Biomass To Ethanol BiomassJega YuvanNoch keine Bewertungen

- 2تقرير بتروكمياوياتDokument7 Seiten2تقرير بتروكمياوياتljjbNoch keine Bewertungen

- Article 1Dokument9 SeitenArticle 1Abderrahim Najah ElidrissiNoch keine Bewertungen

- DME To Olefins PDFDokument1 SeiteDME To Olefins PDFChristianNoch keine Bewertungen

- 1 s2.0 S0360544223005960 MainDokument14 Seiten1 s2.0 S0360544223005960 MainFrank Joel Herrera ApaesteguiNoch keine Bewertungen

- Pro IiDokument52 SeitenPro IiMedranoIvanNoch keine Bewertungen

- Meat Technology Update: Covered Anaerobic PondsDokument4 SeitenMeat Technology Update: Covered Anaerobic Pondsrajareski ekaputraNoch keine Bewertungen

- Methanol and HydrogenDokument2 SeitenMethanol and Hydrogenibrahim kokashNoch keine Bewertungen

- SIMS2021 Article Ecp21185444Dokument6 SeitenSIMS2021 Article Ecp21185444العنود راشدNoch keine Bewertungen

- Group 4 - EH2206M - A2Dokument50 SeitenGroup 4 - EH2206M - A2NNNoch keine Bewertungen

- Production of Biogas From BiomassDokument11 SeitenProduction of Biogas From BiomassEphrem GizachewNoch keine Bewertungen

- Sia Partners Benchmark Europe BiomethaneDokument32 SeitenSia Partners Benchmark Europe BiomethaneDavoud ShalforoushanNoch keine Bewertungen

- Biotechnological Conversion of Methane To MethanolDokument38 SeitenBiotechnological Conversion of Methane To Methanolpadam0088Noch keine Bewertungen

- Technoeconomic Assessment of Ethanol ProductionDokument12 SeitenTechnoeconomic Assessment of Ethanol ProductionsumitrochakrabortiNoch keine Bewertungen

- IAFT Presentation Ethanol & MethanolDokument24 SeitenIAFT Presentation Ethanol & MethanolTech RulerNoch keine Bewertungen

- CO2 To Methanol-Single StepDokument2 SeitenCO2 To Methanol-Single StepUmesh DeshNoch keine Bewertungen

- 1 s2.0 S2212982020300688 MainDokument13 Seiten1 s2.0 S2212982020300688 MainRafi AkbarNoch keine Bewertungen

- Synthesis of Methanol Using Steam Reforming of Biomass FeedstockDokument17 SeitenSynthesis of Methanol Using Steam Reforming of Biomass FeedstockAdi AbyogaNoch keine Bewertungen

- MTBE Cracking Full Compile v2Dokument26 SeitenMTBE Cracking Full Compile v2Teck Huai100% (1)

- Advances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsVon EverandAdvances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsLalit Kumar SinghNoch keine Bewertungen

- Prod11322045433376.r1107, EFP06 (Report) RISØ April 2011 PDFDokument261 SeitenProd11322045433376.r1107, EFP06 (Report) RISØ April 2011 PDFIra RamadhaniNoch keine Bewertungen

- 3153 15619 1 PBDokument12 Seiten3153 15619 1 PBIra RamadhaniNoch keine Bewertungen

- 18 November PFD FixDokument2 Seiten18 November PFD FixIra RamadhaniNoch keine Bewertungen

- 043 PDFDokument6 Seiten043 PDFIra RamadhaniNoch keine Bewertungen

- 3153 15619 1 PBDokument12 Seiten3153 15619 1 PBIra RamadhaniNoch keine Bewertungen

- Implementation of bio-CCS in Biofuels Production - Final - Isbn PDFDokument60 SeitenImplementation of bio-CCS in Biofuels Production - Final - Isbn PDFIra RamadhaniNoch keine Bewertungen

- Pulp and Paper-Making Potential of CornDokument4 SeitenPulp and Paper-Making Potential of CornIra Ramadhani100% (1)

- PatentDokument6 SeitenPatentIra RamadhaniNoch keine Bewertungen

- Pulp and Paper-Making Potential of CornDokument4 SeitenPulp and Paper-Making Potential of CornIra Ramadhani100% (1)

- Optimization of Ethanol-Alkali Delignification of False BananaDokument8 SeitenOptimization of Ethanol-Alkali Delignification of False BananaIra RamadhaniNoch keine Bewertungen

- BAB II OleoDokument6 SeitenBAB II OleoIra RamadhaniNoch keine Bewertungen

- International Journal of FermentationDokument14 SeitenInternational Journal of FermentationIra RamadhaniNoch keine Bewertungen

- MK PDFDokument1 SeiteMK PDFIra RamadhaniNoch keine Bewertungen

- Bahan Presentasi OpdDokument2 SeitenBahan Presentasi OpdIra RamadhaniNoch keine Bewertungen

- 26.WJNF A 874962 O11 PDFDokument14 Seiten26.WJNF A 874962 O11 PDFKate Andrea LacsonNoch keine Bewertungen

- United States Patent (19) : Lightner Oct. 17, 2000Dokument6 SeitenUnited States Patent (19) : Lightner Oct. 17, 2000Ira RamadhaniNoch keine Bewertungen

- Abstract Design Circle Bubble PowerPoint Templates StandardDokument3 SeitenAbstract Design Circle Bubble PowerPoint Templates StandardIra RamadhaniNoch keine Bewertungen

- Baasel W.D.-preliminary Chemical Engineering Plant Design (1976)Dokument8 SeitenBaasel W.D.-preliminary Chemical Engineering Plant Design (1976)Ira RamadhaniNoch keine Bewertungen

- Work Environment Act (1977:1160) : Chapter 1 Purpose and Scope of The ActDokument26 SeitenWork Environment Act (1977:1160) : Chapter 1 Purpose and Scope of The ActNatalie BlackmoreNoch keine Bewertungen

- Canfield FairDokument3 SeitenCanfield Fairapi-546463844Noch keine Bewertungen

- Kmart PDFDokument105 SeitenKmart PDFkaranbhayaNoch keine Bewertungen

- Seachem Laboratories, Inc. Safety Data SheetDokument10 SeitenSeachem Laboratories, Inc. Safety Data SheetJorge Restrepo HernandezNoch keine Bewertungen

- UNIT 3 Polymer and Fuel ChemistryDokument10 SeitenUNIT 3 Polymer and Fuel Chemistryld6225166Noch keine Bewertungen

- Full Download Small Animal Care and Management 4th Edition Warren Test BankDokument35 SeitenFull Download Small Animal Care and Management 4th Edition Warren Test Bankkrzyszhugvik6100% (20)

- BATES CH 6 The Thorax and LungsDokument2 SeitenBATES CH 6 The Thorax and LungsAngelica Mae Dela CruzNoch keine Bewertungen

- ResDokument21 SeitenResMarian EvangelioNoch keine Bewertungen

- Contact Point ContoursDokument69 SeitenContact Point ContourstarekrabiNoch keine Bewertungen

- Bleeding in A NeonateDokument36 SeitenBleeding in A NeonateDrBibek AgarwalNoch keine Bewertungen

- Economics Half Yearly Question PaperDokument6 SeitenEconomics Half Yearly Question PaperBhumika MiglaniNoch keine Bewertungen

- Differential Partitioning of Betacyanins and Betaxanthins Employing Aqueous Two Phase ExtractionDokument8 SeitenDifferential Partitioning of Betacyanins and Betaxanthins Employing Aqueous Two Phase ExtractionPaul Jefferson Flores HurtadoNoch keine Bewertungen

- Chapter 3.2 Futures HedgingDokument19 SeitenChapter 3.2 Futures HedginglelouchNoch keine Bewertungen

- VedasUktimAlA Sanskrit Hindi EnglishDokument47 SeitenVedasUktimAlA Sanskrit Hindi EnglishAnantha Krishna K SNoch keine Bewertungen

- Thai Book Lesson From Genius SchoolDokument85 SeitenThai Book Lesson From Genius SchoolAlexis L.D (Riker94)Noch keine Bewertungen

- Death Obituary Cause of Death Ookht PDFDokument4 SeitenDeath Obituary Cause of Death Ookht PDFMayerRhodes8Noch keine Bewertungen

- Strict and Absolute LiabilityDokument29 SeitenStrict and Absolute LiabilityShejal SharmaNoch keine Bewertungen

- Quotation: Kentex CargoDokument2 SeitenQuotation: Kentex CargoMalueth AnguiNoch keine Bewertungen

- Design and Fabrication of Floor Cleaning Machine - A ReviewDokument4 SeitenDesign and Fabrication of Floor Cleaning Machine - A ReviewIJIERT-International Journal of Innovations in Engineering Research and Technology100% (1)

- WP DeltaV Software Update Deployment PDFDokument8 SeitenWP DeltaV Software Update Deployment PDFevbaruNoch keine Bewertungen

- ReclosersDokument28 SeitenReclosersSteven BeharryNoch keine Bewertungen