Beruflich Dokumente

Kultur Dokumente

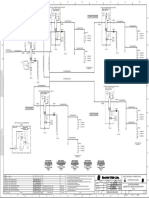

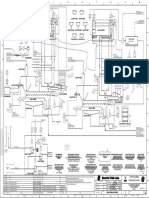

Hakiki Gamtek 2-Model

Hochgeladen von

Mohamad123 Hakiki123Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hakiki Gamtek 2-Model

Hochgeladen von

Mohamad123 Hakiki123Copyright:

Verfügbare Formate

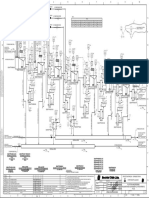

H090.8.100-2.083.

E33-1

15

compressed air from outer pipe 4 H090.8.100-2.819.E22-4

14

gas to ammonium sulfate

fresh water from water channel

2 3

M V82508

waste water

to bio-treatment

H090.8.100-2.815.E22-8

8 9

18

V82506A/B

17

residual ammonia water

from Condensing / exhaust unit

Steam

11 X82501A/B

6 6

steam condensate

H090.8.100-2.815.E22-8 V82504

10

1

12

Sulfur

7 5 7 5

T82501 T82503A T82503B

T82502A T82502B

chilled water supply V82501A V82501B

16

chilled water return

13

P82505A/B V82507

chilled water supply

V82502A/B E82501A/B

P82504

chilled water return

E82502A/B P82505A/B T82501 V82504 T82502A V82501A V82502A/B P82501A/B/C T82503A V82501B E82501A/B T82502B T82503B V82506A/B P82503A/B V82508 P82504 V82507 X82501A/B

Pre-cooling heat exchanger Pre-cooling circulation pump Pre-cooling column Catalyst storage tank Desulfurization tower Desulfurization tower seal tank Solution recirculating tank Solution circulating pump Regeneration tower Desulfurization tower seal tank Solution heat exchanger Desulfurization tower Regeneration tower Sulfur foam tank Sulfur foam pump Water seal tank Buffer tank liquid transfer pmp Solution buffer tank Sulfur melting kettle

Point for material

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

Constituents Kg/h Kg/h Kg/h Kg/h Kg/h Kg/h

Net and dry gas 27800 27800 27800 27800

NH3 8~11 8~11 8~11 7~10

H2S 6~8 6~8 0.7 0.5

HCN 1~1.5 1.50 0.75 0.3

crude benzol 30~35 30~35 30~35 30~35

Nepthalene 0.4 0.4 0.4 0.4

Tor troce troce troce troce

H2O 22.98 26.0 29.30 31.26

Sulfur 133.5

precooling cirulating liquid 771.5 180 180

fresh water 125

desulfurized liquid 485 485 485 905 This drawing is the property of SEDIN. Unauthorized disclosure to any third party or duplication is not permitted.

905

SEDIN

Sulfur foam 1550 260 Class Comprehensive A Certificate No:

Engineering Design PT. Krakatau Steel Coking Plant

A114000782

Qualification Certificate

compressed air 2440

Desulfurication and

Circulated ammonia water 30 DUTY SIGN DATE SECTION

sulfur recovery

DESN'D STAGE Basic engineering

CHK'D

process flow diagram DWG.NO. H090.8.100-2.825.E22-1 REV

45 25 27 28 29.7 29.8 30 30 30 50 50 30 80 30 30 25.18 24 80 REV'D

Pressure Mpa (G) 0.0170 0.0160 0.0145 0.0130 0.5 normal pressure normal pressure normal pressure normal pressure normal pressure normal pressure normal pressure 0.3 0.4 0.5 0.4 0.4 0.5 APP'D SCALE SPECIAL By product 1 OF 1 CHINA TAIWAN

MOHAMAD HAKIKI_3335160016_A2

Das könnte Ihnen auch gefallen

- Class Participation 9 E7-18: Last Name - First Name - IDDokument2 SeitenClass Participation 9 E7-18: Last Name - First Name - IDaj singhNoch keine Bewertungen

- Instant Assessments for Data Tracking, Grade 2: MathVon EverandInstant Assessments for Data Tracking, Grade 2: MathNoch keine Bewertungen

- Instant Assessments for Data Tracking, Grade 5: MathVon EverandInstant Assessments for Data Tracking, Grade 5: MathNoch keine Bewertungen

- Forecasting and Demand Management PDFDokument39 SeitenForecasting and Demand Management PDFKazi Ajwad AhmedNoch keine Bewertungen

- 25635-220-M6-0210-00001-R2 Chancadora 1Dokument1 Seite25635-220-M6-0210-00001-R2 Chancadora 1Victor Guzman PretellNoch keine Bewertungen

- Manual Honda CivicDokument469 SeitenManual Honda CivicshikinNoch keine Bewertungen

- Gears, Splines, and Serrations: Unit 24Dokument8 SeitenGears, Splines, and Serrations: Unit 24Satish Dhandole100% (1)

- Fendt 900 Vario Edition Electrical DiagramDokument4 SeitenFendt 900 Vario Edition Electrical Diagramjennifer100% (51)

- Iso 269-2022-014 Rotary Table NDT Cat IV - Rev1Dokument1 SeiteIso 269-2022-014 Rotary Table NDT Cat IV - Rev1Durgham Adel EscanderNoch keine Bewertungen

- 580N 580SN 580SN WT 590SN With POWERSHUTTLE ELECTRICAL SCHEMATICDokument2 Seiten580N 580SN 580SN WT 590SN With POWERSHUTTLE ELECTRICAL SCHEMATICEl Perro100% (1)

- 220 M6 0310 00032Dokument1 Seite220 M6 0310 00032nestor159357Noch keine Bewertungen

- No Requiere Aprobación Del Cliente: in WorkDokument1 SeiteNo Requiere Aprobación Del Cliente: in Worknestor159357Noch keine Bewertungen

- Questions - Mechanical Engineering Principle Lecture and Tutorial - Covering Basics On Distance, Velocity, Time, Pendulum, Hydrostatic Pressure, Fluids, Solids, EtcDokument8 SeitenQuestions - Mechanical Engineering Principle Lecture and Tutorial - Covering Basics On Distance, Velocity, Time, Pendulum, Hydrostatic Pressure, Fluids, Solids, EtcshanecarlNoch keine Bewertungen

- ACDC - Highway To HellDokument4 SeitenACDC - Highway To HellDenis RexhepiNoch keine Bewertungen

- NEBB Psych Chart Sea Level 11x17Dokument1 SeiteNEBB Psych Chart Sea Level 11x17JojolasNoch keine Bewertungen

- S-03710 P42118-Rev. 3-P18-Steam DrumDokument1 SeiteS-03710 P42118-Rev. 3-P18-Steam Drumwylie01Noch keine Bewertungen

- Np2 AnswerDokument13 SeitenNp2 AnswerMarie Jhoana100% (1)

- Sedin: Point For MaterialDokument1 SeiteSedin: Point For MaterialgilangNoch keine Bewertungen

- I I I I: No Requiere Aprobación Del ClienteDokument1 SeiteI I I I: No Requiere Aprobación Del Clientenestor159357Noch keine Bewertungen

- Ae304 - Wall Section 1&2Dokument1 SeiteAe304 - Wall Section 1&2Omar ZakiNoch keine Bewertungen

- Corrosion Loops Example 4 - Separator Template1Dokument1 SeiteCorrosion Loops Example 4 - Separator Template1Christian JoseNoch keine Bewertungen

- AC Instalado Cliente 7147700596Dokument1 SeiteAC Instalado Cliente 7147700596bernardo valenzuelaNoch keine Bewertungen

- ESP: 03301.T025/26 2 A 1: Key PlanDokument1 SeiteESP: 03301.T025/26 2 A 1: Key PlanJorgeNoch keine Bewertungen

- SI G NE D: SlopeDokument1 SeiteSI G NE D: SlopeCristhian Alexander Aguilar ChavezNoch keine Bewertungen

- GCP 1001 01 CS 0138 0391 M Pid 00002Dokument1 SeiteGCP 1001 01 CS 0138 0391 M Pid 00002Leonel Gamero CardenasNoch keine Bewertungen

- I WI I 5: GR AT NG Plat Form DTH NSI DER ADI US NDokument1 SeiteI WI I 5: GR AT NG Plat Form DTH NSI DER ADI US NAbid AyubNoch keine Bewertungen

- Pci202h - Pci Pre 2 - Mp3000Dokument1 SeitePci202h - Pci Pre 2 - Mp3000AdeniltonNoch keine Bewertungen

- Ig N e D: Ags Ral WMV Cle WMV Ral VSM AcpDokument1 SeiteIg N e D: Ags Ral WMV Cle WMV Ral VSM Acpnestor159357Noch keine Bewertungen

- 220 M6 0330 00030 - Rev3Dokument1 Seite220 M6 0330 00030 - Rev3Cristhian Alexander Aguilar ChavezNoch keine Bewertungen

- L&T Construction: B D F K N Q S CDokument1 SeiteL&T Construction: B D F K N Q S CPowerhouse ShaftNoch keine Bewertungen

- Sec C Ió N: Vicepresidenciadeproyectos Minachuquicamatasubterránea IngenieríadedetalleDokument1 SeiteSec C Ió N: Vicepresidenciadeproyectos Minachuquicamatasubterránea IngenieríadedetalleCR ConductorNoch keine Bewertungen

- Hisense Rsag7.820.5536 Psu SCH Lhd32k20dweuDokument1 SeiteHisense Rsag7.820.5536 Psu SCH Lhd32k20dweuDIAGRAMAS CICAPNoch keine Bewertungen

- Hisense LED42K20D - RSAG7.820.5338 - H162 PSU SchematicDokument1 SeiteHisense LED42K20D - RSAG7.820.5338 - H162 PSU SchematicRene G Orama100% (1)

- 01 B276e5 MaaDokument1 Seite01 B276e5 MaaRenxio KahuaNoch keine Bewertungen

- President Lincoln II Version 3 SchematicDokument13 SeitenPresident Lincoln II Version 3 Schematicalf100% (1)

- PcbdigDokument1 SeitePcbdigConstantin StratulescuNoch keine Bewertungen

- IG N E D: WMV CLE AGS RAL F. Ceron WMV RAL VSM ACPDokument1 SeiteIG N E D: WMV CLE AGS RAL F. Ceron WMV RAL VSM ACPnestor159357Noch keine Bewertungen

- No Requiere Aprobación Del Cliente: Responsabilidad Exclusiva Del Autor U Originador, Según ContratoDokument1 SeiteNo Requiere Aprobación Del Cliente: Responsabilidad Exclusiva Del Autor U Originador, Según Contratonestor159357Noch keine Bewertungen

- TochiDokument1 SeiteTochiRommeoNoch keine Bewertungen

- Немецкий Танец Моцарт (Редукция1)Dokument1 SeiteНемецкий Танец Моцарт (Редукция1)kroshkaenot1Noch keine Bewertungen

- Caterpillar 3500B and 3500C. SchematicDokument2 SeitenCaterpillar 3500B and 3500C. SchematicАлексейNoch keine Bewertungen

- Plano 01Dokument1 SeitePlano 01Erick VeraNoch keine Bewertungen

- Issued For Construction: Level 0 FFL 0.022Dokument1 SeiteIssued For Construction: Level 0 FFL 0.022Sadique PkNoch keine Bewertungen

- Spa Iii - E1b121052 - Wa Ode Sitti Aisyah-DenahDokument1 SeiteSpa Iii - E1b121052 - Wa Ode Sitti Aisyah-DenahWA ODE SITTI AISYAH ANoch keine Bewertungen

- Inverter Master Philips PDFDokument1 SeiteInverter Master Philips PDFJan DettlaffNoch keine Bewertungen

- Master PDFDokument1 SeiteMaster PDFHamedKoneNoch keine Bewertungen

- Beeper Circuits I DCV ACV ACA Insu Ohm V-VDokument2 SeitenBeeper Circuits I DCV ACV ACA Insu Ohm V-VOsmar Pereira Dos SantosNoch keine Bewertungen

- BT2M1 ToribioSMS v2Dokument4 SeitenBT2M1 ToribioSMS v2Shaira Micah ToribioNoch keine Bewertungen

- X0231 PDW Eut DG 20007 AaDokument1 SeiteX0231 PDW Eut DG 20007 AajianranrenNoch keine Bewertungen

- 3400 El17Dokument1 Seite3400 El17carloscruz16Noch keine Bewertungen

- WTC SQ EeDokument3 SeitenWTC SQ EeThi ChauNoch keine Bewertungen

- Power Supply TP.MT5510I.PB801 схемаDokument1 SeitePower Supply TP.MT5510I.PB801 схемаАнатолий АнатоличNoch keine Bewertungen

- PcbdigitDokument1 SeitePcbdigitLuis Remigio Torres AcevedoNoch keine Bewertungen

- Spa Iii - E1b121052 - Wa Ode Sitti Aisyah-Denah2-3Dokument1 SeiteSpa Iii - E1b121052 - Wa Ode Sitti Aisyah-Denah2-3WA ODE SITTI AISYAH ANoch keine Bewertungen

- 220 M6 0310 00001r001Dokument1 Seite220 M6 0310 00001r001Luis BernedoNoch keine Bewertungen

- No Requiere Aprobación Del Cliente: IG N E DDokument1 SeiteNo Requiere Aprobación Del Cliente: IG N E Dnestor159357Noch keine Bewertungen

- N OR TH: Key PlanDokument1 SeiteN OR TH: Key PlanArnold Ochochoque ArcosNoch keine Bewertungen

- Hydraulic Diagram J104-0142: Pcui BDokument3 SeitenHydraulic Diagram J104-0142: Pcui BTarik FekraneNoch keine Bewertungen

- 8120 PTPDokument108 Seiten8120 PTPLuis GomezNoch keine Bewertungen

- Esquema Eletrico Nobreak MICROSOL STAY700 AUTO 115VDokument1 SeiteEsquema Eletrico Nobreak MICROSOL STAY700 AUTO 115Vwalter souza100% (6)

- Pump Room & Hot and Cold Water Sump Codination Dwg.01.08.23-A1Dokument1 SeitePump Room & Hot and Cold Water Sump Codination Dwg.01.08.23-A1Tanzil HassanNoch keine Bewertungen

- Sho001 Nap Ifc M2 06 RCM DR SS 3002 03 0aDokument1 SeiteSho001 Nap Ifc M2 06 RCM DR SS 3002 03 0aMohanad EldarerNoch keine Bewertungen

- JM 2985 w6753 - 307Dokument1 SeiteJM 2985 w6753 - 307Yosephander100% (2)

- Arr: ST. Telles: 2° Trompete BB Caetano VelosoDokument1 SeiteArr: ST. Telles: 2° Trompete BB Caetano VelosoKleber limaNoch keine Bewertungen

- Road "A": PC PCDokument1 SeiteRoad "A": PC PCRachane NuanyaiNoch keine Bewertungen

- CS 252: Computer Organization and Architecture II: Lecture 5 - The Memory SystemDokument29 SeitenCS 252: Computer Organization and Architecture II: Lecture 5 - The Memory SystemJonnahNoch keine Bewertungen

- X25Dokument10 SeitenX25RajNoch keine Bewertungen

- Assignment of Killamsetty Rasmita Scam 1992Dokument8 SeitenAssignment of Killamsetty Rasmita Scam 1992rkillamsettyNoch keine Bewertungen

- Covid ReportDokument89 SeitenCovid ReportBrynne ConnollyNoch keine Bewertungen

- Electric Baseboard StelproDokument4 SeitenElectric Baseboard StelprojrodNoch keine Bewertungen

- Governance of Cyber Security Research ProposalDokument1 SeiteGovernance of Cyber Security Research ProposalAleksandar MaričićNoch keine Bewertungen

- Paper - 1: Principles & Practice of Accounting Questions True and FalseDokument29 SeitenPaper - 1: Principles & Practice of Accounting Questions True and FalsePiyush GoyalNoch keine Bewertungen

- ScriptDokument7 SeitenScriptAllen Delacruz100% (1)

- State of The Art Synthesis Literature ReviewDokument7 SeitenState of The Art Synthesis Literature Reviewfvdddmxt100% (2)

- Fixed Plug-In Motor A2Fe: Series 6Dokument24 SeitenFixed Plug-In Motor A2Fe: Series 6Michail ArmitageNoch keine Bewertungen

- ANSYS 14.0 Fluid Dynamics Update - Dipankar ChoudhuryDokument87 SeitenANSYS 14.0 Fluid Dynamics Update - Dipankar Choudhuryj_c_garcia_d100% (1)

- Natures CandyDokument19 SeitenNatures CandyFanejegNoch keine Bewertungen

- DoctorTecar Brochure MECTRONIC2016 EngDokument16 SeitenDoctorTecar Brochure MECTRONIC2016 EngSergio OlivaNoch keine Bewertungen

- AMM Company ProfileDokument12 SeitenAMM Company ProfileValery PrihartonoNoch keine Bewertungen

- 2017 Directory WO Member PagesDokument112 Seiten2017 Directory WO Member PagessberkowitzNoch keine Bewertungen

- Katalog Bonnier BooksDokument45 SeitenKatalog Bonnier BooksghitahirataNoch keine Bewertungen

- MBA-CM - ME - Lecture 16 Market Structure AnalysisDokument11 SeitenMBA-CM - ME - Lecture 16 Market Structure Analysisrohan_solomonNoch keine Bewertungen

- OD426741449627129100Dokument1 SeiteOD426741449627129100SethuNoch keine Bewertungen

- MEC 400 CHAPTER 4 (Engineering Solution)Dokument21 SeitenMEC 400 CHAPTER 4 (Engineering Solution)hidayatullahNoch keine Bewertungen

- Termsconditions of JionetDokument3 SeitenTermsconditions of JionetskNoch keine Bewertungen

- S No. Store Type Parent ID Partner IDDokument8 SeitenS No. Store Type Parent ID Partner IDabhishek palNoch keine Bewertungen

- Fund For Local Cooperation (FLC) : Application FormDokument9 SeitenFund For Local Cooperation (FLC) : Application FormsimbiroNoch keine Bewertungen