Beruflich Dokumente

Kultur Dokumente

A Small Scale Photovoltaic Energy System Based On Lab VIEW Monitoring by Using Data Acquisition System)

Hochgeladen von

Mohd AfiqOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A Small Scale Photovoltaic Energy System Based On Lab VIEW Monitoring by Using Data Acquisition System)

Hochgeladen von

Mohd AfiqCopyright:

Verfügbare Formate

A Small Scale Photovoltaic Energy System Based on Lab

VIEW Monitoring by Using Data Acquisition System

M.A. Zakaria1, A.F. Ayob2 and W.B. Wan Nik3

1,2,3

Department of Maritime Technology, Faculty of Maritime Studies & Marine Science,

Universiti Malaysia Terengganu, 21030 Kuala Terengganu, Malaysia

Email: m_afiq84@yahoo.com.my

Abstract - This paper studied the usage of sources would increase correspondingly as

virtual monitoring system in order to monitor Malaysia was progressively moving towards an

the performance of the photovoltaic energy industrialized country [2][5]. The tropical climate in

system. It explained the development of Malaysia was favourable for the development of

automated monitoring measurement system for solar energy. This was because the average of local

small scale solar PV plant in Universiti Malaysia sunlight irradiance per year was 1643 kWh/m2 [5].

Terengganu, Malaysia. This study used the data Photovoltaic cells produced electricity when

acquisition system (DAS) whereby all the data sunlight excited electrons in the cell. The sunbeams

for the parameters were recorded and shown in Malaysia was available throughout the year and

through the software. The measurement for all this gave advantages for the development of solar

data e.g. voltage, current, temperature, humidity energy. Solar energy was the most prominent source

and power were gathered using sensor, of clean and renewable energy. Plus, it had the

microcontroller (Arduino) data acquisition greatest potential to solve the world energy

module, and LabVIEW software. The objective problems [6]. Malaysia was one of the countries

of this study was to investigate the performance that rich with solar force. The annual average of

of photovoltaic energy system in the UMT area daily solar irradiations for Malaysia had a

by using the monitoring system. The most magnitude of 4.21–5.56 kW h m-2 and the sunshine

significant advantage of this system was the duration was more than 2200 h per year [3].

performance could be monitored virtually and Meanwhile, the annual average daily solar

remotely where the data could also be retrieved irradiation for Malaysia was from 4.21 kWh m -2 to

on-line. Furthermore, this system also allowed 5.56 kWh m-2 [5]. The highest solar radiation was

the collection of data for long period of time with estimated at 6.8 kWh m-2 in August and November

no interruption by human. Lastly, this study while the lowest was 0.61 kWh m -2 in December

would be advantageous to generate more [3]. Fig. 1 showed the annual average of solar

environmental friendly energy production radiation in Malaysia.

initiatives and offer suggestions in the

prospective of building the solar system in UMT

at the larger scale as well as urging more

researches on solar beam to be carried out in the

future.

Index Terms — acquisition, labview, microcontroller,

real-time, wireless.

I. INTRODUCTION

Renewable sources of energy like solar, wind,

hydro, geothermal and biomass were essential

alternatives to fossil fuels that depleting fast. By Fig. 1: Annual average solar radiation

using these sources, it would be helpful not only in (MJ/m2/day)

reducing the emission of greenhouse gas gained

from the energy generation and consumption but

also lessened the dependency on imports of fossil Photovoltaic conversion was the direct

fuels for a country [1]. These types of energy conversion of the sunlight into electricity with no

sources had been contributing to the rapid growth inverting heat engine. Photovoltaic devices were

of Malaysia’s economy [2]. The dependency on this solid state; therefore, they were rugged and simple

in design and required very little preservation [7]. had a capability to program with modular graphical

Perhaps, the biggest advantage of solar photovoltaic programming language.

devices was they could be constructed as stand- Lab VIEW, a program by National Instruments

alone system in order to give outputs from fitted all these requirements and was widely used

microwatts to megawatts. That was the reason of among researchers and engineers [13]. It was a

why they had been used as the main power sources good option to use the mentioned software to

for calculators, watches, water pump, remote develop this monitoring system for PV-Wind

building, communications, satellites and space energy. The development could be done parallel

vehicles, and even megawatt scale power plants [8] with the generating process. Plus, the software

[9]. Photovoltaic panels could be used to form could also be easily edited. Besides that, the system

components of building features such as roof might be implemented on Microsoft Windows,

shingles and wall panels. (Goswami, 1999) which able to work through internal and external

The development of photovoltaic systems was network. Above and beyond, the data would be

accompanied by a rapid adaptation of measurement easily downloaded and in the mean time, it would

and control systems to the latest trends in digital lesser the upgrading time in the future. The good

techniques and computer-aided measurement [11]. thing gained from this was the improvement shall

The specialized photovoltaic (PV) data acquisition be done without changing any of the hardware [15].

systems (DAS) had been recognized as an In order to create a highly reliable monitoring

inevitable tool in the PV monitoring systems and system, the researchers were needed to select

the data collecting for the optimizing the proper hardware to be used with selected software.

performance of energy conversion [12]. Since years Currently, this PV energy system did not have a

ago, diverse DAS had been used in different full monitoring system. It still could be measured

equipments to evaluate: and displayed on the average value of the output

and some parameters. The system was unable to

the performance of solar cells and check other compulsory values that affected the

modules in outdoor conditions, process of the generating system. Therefore, this

long term stability and reliability of PV type of monitoring system was designed and

systems components (PV modules and created to fulfill the objectives to monitor and

arrays, charge controllers, inverters etc.), report the data from PV energy system effectively.

performance of different PV devices in

strongly chargeable conditions, II. PV SYSTEM DESIGN

theoretical assumptions and analyses.

The solar PV system was constructed on a

This PV monitoring system did not have a prototype fisheries-house in University Malaysia

fixed pattern. It depended solely on the objectives Terengganu (UMT) Kuala Terengganu, Malaysia to

and technologies used for that project. Normally, generate electricity. It operated by obtaining the

the PV system tested and evaluated the capacity of measurement of the solar panel performance.

the system by using sensors along with the proper Measurements were taken for 8 hours starting from

software [10]. Nowadays, the monitoring systems 9.00 am until 5.00 pm daily through observation on

measured and collected data in a digital form [13]. the production of power by solar panel. The system

Thus, hardware that could perform the data came with battery bank and charger controller to

acquisition with capability to do the remote regulate deficiencies in unreliable solar energy. The

monitoring was needed. A good design for this data was collected by using data acquisition system

monitoring system should have minimum impact on that implanted in PV system to monitor and record

the performance of the generating system and the the raw data. A solar cell was usually represented

monitoring system should not consume more than 5 by an equivalent one-diode model. The model

percent of the total output of that PV Generating contained a current source Iph and series resistance

System [12].This monitoring system was used to Rs, which represented the resistance inside each cell

observe whether the generating system was in and in the connection between the cells as shown in

normal circumstance or not. Fig. 2. The net current was the difference between

Generally, this monitoring system ought to the photocurrent Iph and the normal diode current

monitor the system every day and was able to ID:-

report the result daily, monthly or yearly. Thus, the

computer measurement and monitoring system I =I ph−I D (1)

played an important role because it was a highly

flexible system for installing new sensors,

measuring instruments and different types of

hardware. Moreover, the software should also be

(

¿ I ph−I 0 exp

e ( V + IR S )

m KT ab

−1)

Where:

flexible, could be used with many types of m is the idealizing factor,

hardware, easily developed or be the software that K is the Boltzmann’s constant,

Tab is the absolute temperature of the cell, In this way, all data was parallel captured and

e electronic charge, events in each channel could be compared in real

V is the cell voltage, time. Nevertheless, by using a multiplexer that

I0 is the saturation current, which depends strongly switched among the inputs of multiple channels and

on the cell temperature. drove a single ADC could substantially reduce the

cost of a system [16]. Specialized data acquisition

systems for PV installations required a study of

sample rates and optimal configuration of the

measuring chain.

This chapter provided the information

regarding the structure of data acquisition systems

used in the monitoring of photovoltaic installations.

Fig. 2. PV model It showed that the operating principles of building

blocks were performed by simulations using

2.1 System architecture LabVIEW™ - Laboratory Virtual Instrumentation

Engineering Workbench. This monitoring system

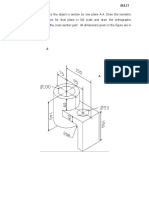

The architecture of the PV system on Fig. 3 was designed to acquire two parts. The first was the

showed the connection of Solar PV system which weather condition at the research area consisted of

connected directly to battery by using charger ambient temperature, relative humidity and PV

controller. The PV array was installed on a module surface temperature. The second was the

mounting structure of the PV system in which data from the generating process which was

consisted of 1 PV modules by facing through with connected to an existed distribution system. The

the optimum designed slope angle of latitude. The digital data was connected through inverter and

technical characteristics of the PV module based on saved on the database. Next, it would be able to

standard testing conditions were listed in Table 1. analyze and generate research information report

easily.

2.2.1 Hardware design

The designed virtual instrument represented a

relationship between the hardware equipment

(Arduino board using microcontroller Atmega 328)

and the software application (processing) which

implemented the required functions, played the

function of interface between the human operator

and measurement system. The usage of this

hardware equipment ensured the flexibility (other

Fig. 3: System architecture of Solar PV system virtual instruments could be designed) to measure

other physical measurement by using

Table 1: Specification of Solar PV sensors/transducers which were specific to the

measurement process [10]. Figure 3 showed the

flow chart of the hardware part which allowed

Maximun power(Pmax) 20WP Arduino board programming to read and write the

Power tolerance -1% to +3% data.

By using microcontroller that we had created

Open circuit voltage (Voc) 21.96V and developed, it functioned as monitoring system,

Short circuit current (Isc) 1.27A data acquisitions and controller interfaces. It

acquired data from the entire sensor in an analog

Rated voltage (Vmpp) 17.82V signal. Then it would be converted into a digital

signal which able to control the data

Rated current (Impp) 1.14A

communication through a specific computer

Maximun system voltage DC100V network via connecting module used in the

industry. The detail for this distributed I/O was

2.2 Data Acqusition System (DAS) shown below:-

Data acquisition systems measured and stored Sensor

the data collected from hundreds of channels a) Current sensor the ACS758 outputs was an

simultaneously. The majority of systems contained analog voltage output signal that varies

the data from eight to 32 channels, typically in linearly with sensed current.

multiples of eight. An ideal data acquisition system

used a single ADC for each measurement channel.

b) DHT11 Temperature and Humidity Sensor

featured a calibrated digital signal output

with the temperature and humidity sensor

complex. The measurement was 1% RH /

±20%, its stability was better than ±1%

RH / year and the humidity range is 0-

100%RH.

2.2.2 Software Interfacing

These systems were communicated through

software interface by PC which was called

LabVIEW. LabVIEW was a graphical programming

language that allowed for the instrument control,

data acquisition and pre/post processing of acquired

data. LabVIEW was designed to take input data

directly from the user through its virtual-instrument

interface or from measurements of real-world

phenomenon (Data Acquisition). Data inputted

from real-world phenomena generally required

Data Acquisition (DAQ) hardware. Interfacing was

done by developed algorithm and some

programming.

Fig. 4 showed the flow chart for LabVIEW

part, where the inputs from hardware were recorded

and displayed through the screen computer. The

measured data was presented in the front panel of

LabVIEW program in two forms: i) numbers of

measured points, voltage, current, temperature and

ii) power. The front panel of the developed

LabVIEW Program was shown in Fig. 5. The

LabVIEW Acquisition system structure in the block

diagram was presented in Fig. 5(a). The front panel

of virtual instrument was presented in Fig. 5(b).

Fig. 4: Flow chart of collected data

III. RESULTS

3.1 Experimental result

The proposed system operation was shown in

Fig. 5(a): Block Diagram Fig. 6. The system comprised of the following

components: solar cell under test, conditioning

circuit, power supply, microcontroller board and the

measuring tools multi meter and supervisory

control (Computer) with the developed LabVIEW

software program. The solar cell tests were

executed in two stages. On the first stage, the

system was used to measure the voltage, current

and temperature to figure out the characteristics of

the solar cell under test. The system measured the

performance of solar in recharging the battery

storage on the second stage. All of the

measurements used on-line monitoring system

developed with LabView GUI as showed in Fig. 7.

Fig. 5(b): Front Panel

except on the 5th, 9th and 14th day. The changes in

voltage measured were influenced by the cloudy

weather and reduction of the sun radiation rate.

However, solar panels still generated good reading

because of the solar panel efficiency.

Power measurement in every solar panel was

considerably influenced by the efficiency of the

current velocity produced. If the current produced

was high, then the generated power was also high.

The result of the experiment showed similar

average daily current rate. It showed that maximum

current that able to be generated by solar panel was

2A. The power generated by solar could be

calculated using the formula below:-

P ( power )=Voltage ( V ) ×Current ( I )

(2)

Fig. 6: PV system proposed Power generated by solar panel depended on

Data were collected for 14 days of observation the efficiency of the current strength. The result on

on the solar panel performances. Table 1 showed the 14th day showed that the solar panel managed to

the measurement analyzed in form of an average generate 80 % of its maximum power capacity.

data per day. Parameters such as voltage, current From this monitoring system, all the data obtained

and temperature were recorded using system and were recorded and saved in a data base for further

powers were calculated using formula. The raw analysis. Through the usage of LabVIEW software,

data gathered displayed a trend of daily regular the data were automatically calculated by applying

occurrence with the identical amount of voltages the formula and directly displayed on the monitor.

Fig. 7: Graphical output from LabView using DAS system proposed.

Table 2: Data collection for 14 days

Average data per Day

Day voltage (volt) Current (ampere) Power (watt) Temperature ( oC)

1 19.52 1.65 32.20 32

2 19.21 1.56 29.96 31

3 19.36 1.59 30.78 32

4 19.74 1.76 34.74 32

5 18.95 1.43 27.09 30

6 19.23 1.57 30.19 31

7 19.65 1.59 31.24 32

8 19.45 1.57 30.53 32

9 18.32 1.41 25.83 31

10 19.03 1.46 27.78 31

11 19.11 1.49 28.47 31

12 19.14 1.51 28.90 32

13 19.03 1.5 28.54 31

14 18.92 1.42 26.86 30

3.2 Observation Results

Data collected through the monitoring system Fig. 9: The output power and surface temperature by

would be analyzed to identify the features of the PV

effective solar system. Data gathered in the forms of

voltage and current velocity measurement were Fig. 10 demonstrated the total average for

shown in Fig. 8. The daily measurement of data voltage, current and power outputs for PV system in

showed no significant difference from day 1 until day fourteen days. All the data recorded were using DAS

14th due to experiment. By looking at the voltage system proposed. Data collected proved the behavior

pattern taken, it showed a reduction with less amount of solar radiation in UMT surrounding areas. It could

of radiation. Values of voltage intakes for each day be deduced that if the same experiment was to be

were compared to identify the reason of the power carried out in the whole areas of UMT, it possibly

decline. It seemed that cloudy weather condition would be able to produce enough energy to start solar

prohibited direct absorption by the solar panel which system either in small or large scale. The obtained

subsequently resulted in the declining of the power. data for the fourteen days had shown sufficient

Fig. 9 showed output power and surface energy to prove that solar rays could be recorded and

temperature of the PV system. The data illustrated the studied for more benefits in the future.

temperature changed directly proportional with the

power produced. The resulted power were recorded

by calculating the voltage and the current velocities

that generated by PV system. Meanwhile, the reading

on temperature sensor that was placed on the surface

area of the PV was also collected. The value of the

power generated was influenced by the temperature

whereby when the temperature was hot, it then will

affect the value of the power generated as shown in

Fig. 10.

The data also showed high radiation rate was

measured when the panel produced high power.

Whilst the temperature rose up to 32 oC, the solar

power also reached up to 35 watts. Whereas, when Fig. 10: Output total average voltage, current and

the temperature was below 30oC, the solar power power by PV

went below 30oC as well.

25 IV. CONCLUSIONS

vol tage current

vol ta ge (v) & current (a )

20 The PV monitoring system developed by the

research could be used to measure and correct the

15 data according to the researchers’ goals. It would be

able to generate report in order to create research

10

information from PC data-based Microsoft office. The

5

research information could give details on the

performance of the PV energy system operation. This

0 monitor might well showed the unusual operational

1 2 condition of the system. This system possibly became

day a remote monitoring system via the Internet network.

Even though the experiment was not so complicated

and easy to be conducted, a research assistant was

Fig. 8: Output voltage and current by PV

still needed to assist main researcher in monitoring

and analyzing the data. Plus, an assistant was

important to ensure the system was properly

Temperature (oC), Power(watt)

34 maintained and be able to work well throughout the

32 experiment. The operating cost might cover the

30 system maintenance when it was necessary and

28 needed. The requirement for more assistants and

26 larger operating costs were essential in order to run

24 the system in larger scale. The system was

22 administered to inform and signal a warning for

20 researchers when system errors occurred such as

1 2 3 4 5 6 7temp power

8 9 10 11 12 13 14

inverter malfunction or wind generator broke down.

Day The warning signal could be transmitted through

mobile phone network as well as email. The fast

warning and prompt responds would be able to wind-hybrid energy systems in comparison to

prevent the system from total failure and helped in single photovoltaic and wind systems. Energy

increasing the energy production. Conversion and Management 43 (18).

[9] Jallouli R. & Krichen L., 2012. Sizing, techno-

REFERENCES economic and generation management analysis

[1] Azhari A.W, Sopian K, Zaharim A & Ghoul of a stand-alone photovoltaic power unit

M.A.. A new approach for predicting solar including storage devices. Energy.

radiation in tropical environment using satellite [10] Rehman S., Bader M.A. & Al-Moallem S.A.,

images – case study of Malaysia. WSEAS 2007. Cost of solar energy generated using PV

Transactions on Environmental Development panels. Renewable & Sustainable Energy

2008;4:373–8. Reviews.

[2] Kadir M.Z.A.A. & Rafeeu Y.A., 2010. Review on [11] Ozcelik S., Prakash H. & Challo R., 2011. Two-

factors for maximizing solar fraction under wet Axis Solar Tracker Analysis and Control for

climate environment in Malaysia. Renewable & Maximum Power Generation. Computer Science.

Sustainable Energy Reviews. [12] Li Z., Liu X. & Tang R., 2011. Optical

[3] Kadir B., 2010. Models of solar radiation with performance of inclined south-north single-axis

hours of bright sunshine: A Review. Renewable tracked solar panels. Energy.

& Sustainable Energy Reviews. [13] Zhong H., Li G., Tang R. & Dong W., 2011.

[4] Ahmad G.E., Hussein H.M.S. & El-Ghetany H.H., Optical performance of inclined south-north axis

2003. Theoritical analysis and experimental three-positions tracked solar panels. Energy.

verification of PV modules. Renewable Energy. [14] Ian H.R., Briana P.K. & Ian B.M., 2011. Optimal

[5] Muzathik, A.M., Wan Nik, W.B., Samo, K.B. & solar-PV tilt angle and azimuth: An Ontario

Ibrahim, M.Z., 2010. Reference solar radiation (Canada) case-study. Energy Policy.

year and some climatology aspects of East Coast [15] Weinstock D. & Appelbaum J., September 2004.

of West Malaysia. American Journal of Shadow variation on photovoltaic collectors in a

Engineering and Applied Sciences 3, 293–299. solar field. In: IEEE Convention of Electrical and

[6] Viorel B., 2001. Dynamic model of a complex Electronics Engineers. Proceedings; p. 354e7.

system including PV cells, electric battery, [16] Remi C. & Andreas K.A., 2006. Optimization of

electrical motor and water pump. Energy. the performance of double-facades with

[7] Kellog, W.D., Nehir, M.H., Venkataramanan, G. & integrated photovoltaic panels and motorized

Gerez, V., 1998. Generation unit sizing and cost blinds. Solar Energy.

analysis for stand-alone wind, photovoltaic, and

hybrid wind/PV systems. IEEE Transactions on

Energy Conversion 13 (1).

[8] Celik, A.N., 2002. Optimization and techno-

economic analysis of autonomous photovoltaic–

Das könnte Ihnen auch gefallen

- Project Execution PlanDokument69 SeitenProject Execution PlanGraco Calle100% (6)

- Performance Analysis of 5 MWP Grid-Connected Solar PV Power Plant Using IEC 61724Dokument5 SeitenPerformance Analysis of 5 MWP Grid-Connected Solar PV Power Plant Using IEC 61724Anonymous kw8Yrp0R5r0% (1)

- Leadership and FollowershipDokument43 SeitenLeadership and FollowershipNishant AgarwalNoch keine Bewertungen

- Natural Law and The Theory of Society 1500 To 1800 (Scan Perso) PDFDokument508 SeitenNatural Law and The Theory of Society 1500 To 1800 (Scan Perso) PDFjcfichte100% (1)

- Effective Problem Solving and Decision MakingDokument46 SeitenEffective Problem Solving and Decision MakingAndreeaMare1984100% (2)

- Dual Axis Solar Tracking System With Weather SensorDokument6 SeitenDual Axis Solar Tracking System With Weather SensorIJRASETPublicationsNoch keine Bewertungen

- Automated Deep CNN-LSTM Architecture Design For Solar Irradiance ForecastingDokument12 SeitenAutomated Deep CNN-LSTM Architecture Design For Solar Irradiance Forecastingoctober87Noch keine Bewertungen

- Sun Tracker Full ReportDokument23 SeitenSun Tracker Full ReportGiridhar SinghNoch keine Bewertungen

- Work Immersion Plan For Psychology Students in PsychologyDokument2 SeitenWork Immersion Plan For Psychology Students in PsychologyJune DelaPaz Baunillo100% (1)

- A Practical Guide To Geostatistical - HenglDokument165 SeitenA Practical Guide To Geostatistical - HenglJorge D. MarquesNoch keine Bewertungen

- The Mooladhara ChakraDokument13 SeitenThe Mooladhara Chakraimamith100% (1)

- Solar Power Panel Monitoring and Data Acquisition SystemDokument6 SeitenSolar Power Panel Monitoring and Data Acquisition SystemIJRASETPublicationsNoch keine Bewertungen

- Zamudio - 2023 - J. - Phys. - Conf. - Ser. - 2538 - 012004Dokument9 SeitenZamudio - 2023 - J. - Phys. - Conf. - Ser. - 2538 - 012004nopaNoch keine Bewertungen

- Opera - DL: Deep Learning Modelling For Photovoltaic System MonitoringDokument10 SeitenOpera - DL: Deep Learning Modelling For Photovoltaic System MonitoringAlexandru FloricicaNoch keine Bewertungen

- Measurement: Massimo Lazzaroni, Stefano Ferrari, Vincenzo Piuri, Aysße Salman, Loredana Cristaldi, Marco FaiferDokument18 SeitenMeasurement: Massimo Lazzaroni, Stefano Ferrari, Vincenzo Piuri, Aysße Salman, Loredana Cristaldi, Marco FaiferYatheesh KaggereNoch keine Bewertungen

- Intelligent Monitoring and Maintenance of Solar Plants Using Real-Time Data AnalysisDokument6 SeitenIntelligent Monitoring and Maintenance of Solar Plants Using Real-Time Data AnalysisSardar MuzammilNoch keine Bewertungen

- Master 2Dokument34 SeitenMaster 2aliNoch keine Bewertungen

- Low-Cost Dual-Axis System For Solar Tracking: Dimitrija Angelkov Natasa Koceska Saso KoceskiDokument4 SeitenLow-Cost Dual-Axis System For Solar Tracking: Dimitrija Angelkov Natasa Koceska Saso KoceskiRegard AlestairNoch keine Bewertungen

- 449 E1173 PDFDokument5 Seiten449 E1173 PDFsaraNoch keine Bewertungen

- THESIS Proposal SampleDokument4 SeitenTHESIS Proposal SampleAnonymous 7aTnmVShUNoch keine Bewertungen

- Simulation Tool For Energy Management ofDokument11 SeitenSimulation Tool For Energy Management ofMohd Lutfi MahaliNoch keine Bewertungen

- Sensors 16 00770 PDFDokument25 SeitenSensors 16 00770 PDFFaycelNoch keine Bewertungen

- A Comparison of Fuzzy Logic and PID Controller For A Single-Axis Solar Tracking SystemDokument14 SeitenA Comparison of Fuzzy Logic and PID Controller For A Single-Axis Solar Tracking SystemSenthil KumarNoch keine Bewertungen

- Solar Tracking Full DocumentDokument38 SeitenSolar Tracking Full DocumentPraveen KumarNoch keine Bewertungen

- Wei Chang 2022 J. Phys. Conf. Ser. 2319 012002Dokument11 SeitenWei Chang 2022 J. Phys. Conf. Ser. 2319 012002hsdeys_551122303Noch keine Bewertungen

- Irjmets JournalDokument10 SeitenIrjmets JournalIRJMETS JOURNALNoch keine Bewertungen

- Day Ahead ForecastDokument10 SeitenDay Ahead ForecastVISHNU KARTHIK S 18BEE1089Noch keine Bewertungen

- Dual Axis Solar Tracker With IoT Monitoring SystemDokument8 SeitenDual Axis Solar Tracker With IoT Monitoring SystemDARSHANI WAGHMARENoch keine Bewertungen

- IOT Based Dual Axis Solar Module Tracking Using Cloud ComputingDokument5 SeitenIOT Based Dual Axis Solar Module Tracking Using Cloud ComputingIJRASETPublicationsNoch keine Bewertungen

- Processes: Inverter E Power Estimation Using Solar RadiationDokument19 SeitenProcesses: Inverter E Power Estimation Using Solar RadiationSujeet KumarNoch keine Bewertungen

- Day-Ahead Hourly Forecasting of Power Generation From Photovoltaic PlantsDokument14 SeitenDay-Ahead Hourly Forecasting of Power Generation From Photovoltaic PlantsRazvan MaresNoch keine Bewertungen

- Design and Implementation of An Off-Grid Solar Tracker Control System Using Proteus 8.1Dokument9 SeitenDesign and Implementation of An Off-Grid Solar Tracker Control System Using Proteus 8.1Hachimenum AmadiNoch keine Bewertungen

- Sustainability 12 09227 v2 PDFDokument16 SeitenSustainability 12 09227 v2 PDFمصطفى عثمانNoch keine Bewertungen

- 6342-Article Text-18708-1-10-20240125Dokument16 Seiten6342-Article Text-18708-1-10-20240125Abusabah I. A. AhmedNoch keine Bewertungen

- Adaptive Power System (Simulation)Dokument6 SeitenAdaptive Power System (Simulation)Yenny BeltranNoch keine Bewertungen

- Paper 6Dokument10 SeitenPaper 6Raja MohamedNoch keine Bewertungen

- Energies: Outdoor PV System Monitoring-Input Data Quality, Data Imputation and Filtering ApproachesDokument18 SeitenEnergies: Outdoor PV System Monitoring-Input Data Quality, Data Imputation and Filtering Approachesiot03 HalconDataNoch keine Bewertungen

- Comparative Analysis of FLC and ANN Techniques For Efficient MPPT in Changing Conditions in JordanDokument20 SeitenComparative Analysis of FLC and ANN Techniques For Efficient MPPT in Changing Conditions in JordanInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Performance Analysis of Solar PV Modules With Dust Accumulation For Indian ScenarioDokument6 SeitenPerformance Analysis of Solar PV Modules With Dust Accumulation For Indian ScenarioKomal SinghNoch keine Bewertungen

- Ijetae Ncetet 2018 03Dokument3 SeitenIjetae Ncetet 2018 03Ajaysinh SolankiNoch keine Bewertungen

- Inverter Efficiency Analysis Model Based On Solar Power Estimation Using Solar RadiationDokument19 SeitenInverter Efficiency Analysis Model Based On Solar Power Estimation Using Solar RadiationAzeddine AISSAOUINoch keine Bewertungen

- 139 Paper-M SrbinovskaDokument4 Seiten139 Paper-M SrbinovskaAbdullahNoch keine Bewertungen

- Iot Based Solar Monitoring and Tracking SystemDokument12 SeitenIot Based Solar Monitoring and Tracking SystemGowri ManognaNoch keine Bewertungen

- Design Optimization of Solar Power System With Respect To Temperature and Sun TrackingDokument5 SeitenDesign Optimization of Solar Power System With Respect To Temperature and Sun TrackingSurangaGNoch keine Bewertungen

- Solar Tracking System Thesis PDFDokument5 SeitenSolar Tracking System Thesis PDFtarahardinhuntsville100% (2)

- Parada Con PanelDokument4 SeitenParada Con PanelTomas JosephNoch keine Bewertungen

- Manu PDFDokument4 SeitenManu PDFVipin palNoch keine Bewertungen

- Synopsis: Riphah International University IslamabadDokument11 SeitenSynopsis: Riphah International University IslamabadQ SohailNoch keine Bewertungen

- Implementation of A Real Time Monitoring System For A Grid-Connected PV ParkDokument7 SeitenImplementation of A Real Time Monitoring System For A Grid-Connected PV Parkprabhu rachutiNoch keine Bewertungen

- PV IotDokument9 SeitenPV IotYOUNESS ATIFINoch keine Bewertungen

- March 18Dokument6 SeitenMarch 18Jason Jay ManlangitNoch keine Bewertungen

- Deep Learning Based Models For Solar EneDokument7 SeitenDeep Learning Based Models For Solar Enehải BùiNoch keine Bewertungen

- Energies 12 01826 PDFDokument6 SeitenEnergies 12 01826 PDFTrần Quang TuyênNoch keine Bewertungen

- Microprocessor System For Controlling The Operation of Renewable Energy SourcesDokument4 SeitenMicroprocessor System For Controlling The Operation of Renewable Energy SourcesRhogy CentenoNoch keine Bewertungen

- Energies: Machine Learning Based Photovoltaics (PV) Power Prediction Using Di Parameters of QatarDokument19 SeitenEnergies: Machine Learning Based Photovoltaics (PV) Power Prediction Using Di Parameters of QatarhouriaNoch keine Bewertungen

- Design and Implementation of Solar Tracking SystemDokument5 SeitenDesign and Implementation of Solar Tracking SystemerpublicationNoch keine Bewertungen

- Error Assessment of Solar Irradiance Forecasts and AC Power From Energy Conversion Model in Grid-Connected Photovoltaic SystemsDokument27 SeitenError Assessment of Solar Irradiance Forecasts and AC Power From Energy Conversion Model in Grid-Connected Photovoltaic Systemsmohd hazimNoch keine Bewertungen

- Measurement of Meteorological Data Based On Wireless Data Acquisition System MonitoringDokument10 SeitenMeasurement of Meteorological Data Based On Wireless Data Acquisition System MonitoringGustavo OkanoNoch keine Bewertungen

- An Unmanned Inspection System For Multiple Defects Detection in Photovoltaic PlantsDokument9 SeitenAn Unmanned Inspection System For Multiple Defects Detection in Photovoltaic PlantsRodrigoNoch keine Bewertungen

- A Predictive Model For Solar Photovoltaic Power Using The Levenberg-Marquardt and Bayesian Regularization Algorithms and Real-Time Weather DataDokument7 SeitenA Predictive Model For Solar Photovoltaic Power Using The Levenberg-Marquardt and Bayesian Regularization Algorithms and Real-Time Weather DataAbi KhanNoch keine Bewertungen

- Juan Jose Milon Guzman - Juan Carlos Zuñiga Torres - Herbert Jesus Del Carpio Melgar - Articulo - E3S Web of Conferences - en - 2020Dokument7 SeitenJuan Jose Milon Guzman - Juan Carlos Zuñiga Torres - Herbert Jesus Del Carpio Melgar - Articulo - E3S Web of Conferences - en - 2020Luis Alberto Valverde SánchezNoch keine Bewertungen

- Solar Irradiation On The Rear Surface of Bifacial Solar Modules A Modeling Approach2020scientific ReportsOpen AccessDokument10 SeitenSolar Irradiation On The Rear Surface of Bifacial Solar Modules A Modeling Approach2020scientific ReportsOpen Accessjack bladesNoch keine Bewertungen

- Bergonzi Ni 2009Dokument6 SeitenBergonzi Ni 2009Chaima MedhioubNoch keine Bewertungen

- Dual Axis Solar Tracking System With Weather SensorDokument5 SeitenDual Axis Solar Tracking System With Weather SensorEditor IJTSRDNoch keine Bewertungen

- International Journal of Pure and Applied Mathematics No. 18 2017, 313-318Dokument6 SeitenInternational Journal of Pure and Applied Mathematics No. 18 2017, 313-318Hanane LmzianNoch keine Bewertungen

- Design and Implementation of A Meteorological Station With A Wireless Data Acquisition System (Wdas)Dokument10 SeitenDesign and Implementation of A Meteorological Station With A Wireless Data Acquisition System (Wdas)JORGE LUIS AROCA TRUJILLONoch keine Bewertungen

- Isr EvaluationDokument3 SeitenIsr EvaluationMohd AfiqNoch keine Bewertungen

- Manual SeaporchDokument21 SeitenManual SeaporchMohd AfiqNoch keine Bewertungen

- Proposal Master 2012Dokument4 SeitenProposal Master 2012Mohd AfiqNoch keine Bewertungen

- Manual Book DIY ROVDokument3 SeitenManual Book DIY ROVMohd AfiqNoch keine Bewertungen

- Test 2 AUTOCADDokument2 SeitenTest 2 AUTOCADMohd AfiqNoch keine Bewertungen

- Test 2 AUTOCAD (Part2)Dokument1 SeiteTest 2 AUTOCAD (Part2)Mohd AfiqNoch keine Bewertungen

- Proposal Master 2012Dokument4 SeitenProposal Master 2012Mohd AfiqNoch keine Bewertungen

- Full Paper MARTEC .Docx (Afiq)Dokument6 SeitenFull Paper MARTEC .Docx (Afiq)Mohd AfiqNoch keine Bewertungen

- Farm TechDokument1 SeiteFarm TechMohd AfiqNoch keine Bewertungen

- فص یروئت Queuining TheoryDokument47 Seitenفص یروئت Queuining Theorycampal123Noch keine Bewertungen

- T3904-390-02 SG-Ins Exc EN PDFDokument89 SeitenT3904-390-02 SG-Ins Exc EN PDFBrunoPanutoNoch keine Bewertungen

- Youtube Poop: Subverting Art OnlineDokument14 SeitenYoutube Poop: Subverting Art OnlineWill KurlinkusNoch keine Bewertungen

- Things To Remember When Writing Your Conference Proposal AbstractDokument2 SeitenThings To Remember When Writing Your Conference Proposal AbstractBalizkoa BadaezpadakoaNoch keine Bewertungen

- Chapter I - Logic and Proofs: PropositionsDokument18 SeitenChapter I - Logic and Proofs: PropositionsNênđặttênngắnTêndàiAimàmuốnđọcNoch keine Bewertungen

- Ervina Ramadhanti 069 Ptn17aDokument12 SeitenErvina Ramadhanti 069 Ptn17aMac ManiacNoch keine Bewertungen

- Quotient Tool An Holistic Assessment Tool For An Individual's Fit To A Specific Organizational RoleDokument1 SeiteQuotient Tool An Holistic Assessment Tool For An Individual's Fit To A Specific Organizational RoleCarina CovaNoch keine Bewertungen

- 23 Encoding PDFDokument5 Seiten23 Encoding PDFBharghav RoyNoch keine Bewertungen

- Pacific Plate Movement WorksheetDokument3 SeitenPacific Plate Movement WorksheetJohn OsborneNoch keine Bewertungen

- Probability Form 4Dokument10 SeitenProbability Form 4Deen ZakariaNoch keine Bewertungen

- Taylor Linker ResumeDokument2 SeitenTaylor Linker ResumeTaylor LinkerNoch keine Bewertungen

- Advanced Java SlidesDokument134 SeitenAdvanced Java SlidesDeepa SubramanyamNoch keine Bewertungen

- Earth Pressure At-Rest PDFDokument7 SeitenEarth Pressure At-Rest PDFvpb literaturaNoch keine Bewertungen

- Peranan Dan Tanggungjawab PPPDokument19 SeitenPeranan Dan Tanggungjawab PPPAcillz M. HaizanNoch keine Bewertungen

- NSF Science and Engineering Indicators 2014Dokument600 SeitenNSF Science and Engineering Indicators 2014Adrian ArizmendiNoch keine Bewertungen

- Ba101 Engineering Mathematics 1Dokument21 SeitenBa101 Engineering Mathematics 1nurhaiziinovasiNoch keine Bewertungen

- Sample Intern PropDokument7 SeitenSample Intern PropmaxshawonNoch keine Bewertungen

- TGC 121 505558shubham AggarwalDokument4 SeitenTGC 121 505558shubham Aggarwalshubham.aggarwalNoch keine Bewertungen

- A New Approach To Economic Development in NunavutDokument26 SeitenA New Approach To Economic Development in NunavutNunatsiaqNewsNoch keine Bewertungen

- VMD-412 9 April 2014Dokument8 SeitenVMD-412 9 April 2014ashish kumarNoch keine Bewertungen

- Research Methods SESSIONS STUDENTS Abeeku PDFDokument287 SeitenResearch Methods SESSIONS STUDENTS Abeeku PDFdomaina2008100% (3)