Beruflich Dokumente

Kultur Dokumente

ARES Escalator 6

Hochgeladen von

GutmonarchCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ARES Escalator 6

Hochgeladen von

GutmonarchCopyright:

Verfügbare Formate

SIGMA Date : 2007.04.

25

FIELD INDUSTRIAL

ENGINEERING

ARES Maintenance Manual Page :D - 1 / 7

FIM D Terminal gear device

Index

D. Terminal gear device................................................................................1~7

1.Drive examination........................................................................................ 2

2.Check terminal gear Chain and oiling……………………………..………...3

3.Upper Terminal Gear examination................................................................4

4.Lower R-Guide examination .......................................................................5

5.Traction Machine examination and maintenance……………..…………..6

6.Examine oil state..........................................................................................7

Unpublished Work Copyright © SIGMA Elevator Company

SIGMA Date : 2007.04.25

FIELD INDUSTRIAL

ENGINEERING

ARES Maintenance Manual Page :D - 2 / 7

FIM D Terminal gear device

D. Terminal gear device

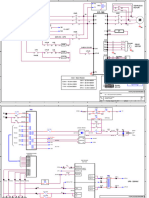

1. Drive examination

1.1 Drive examine

1.1.1 Mark in step with chalk.

1.1.2 Drive ES by using key switch.

1.1.3 After drive Step about 2 loops,affirm if the following part have abnormal

noise and quiver .

-. All Rail System

-. Step

-. Top Terminal Gear

-. Handrail drive device

-. Driving Machine

1.1.4 After drive in the opposite direction, check above approach.

1.1.5 After examine, cover the Floor.

Handrail

drive device

Rail System Top terminal

gear

Unpublished Work Copyright © SIGMA Elevator Company

SIGMA Date : 2007.04.25

FIELD INDUSTRIAL

ENGINEERING

ARES Maintenance Manual Page :D - 3 / 7

FIM D Terminal gear device

2. Check terminal gear Chain and oiling

2.1 Precondition work

Refer to precondition and finishing work.

2.2Check terminal gear Chain

2.2.1 Clean terminal gear Chain.

2.2.2Run ES down by using MSB,tension in the bottom of chain.

2.2.3Affirm sag distance of drive chain (top)

Keep 12~15mm tension by pushing and pulling chain by 8kgf

2.2.4 Check if Link of Chain is in the center of Sprocket (If position is right).

2.2.5 Oiling to all Link of main chain.

2.2.6 Handle of MCCB is On.

2.2.7 Make escalator run with MSB, and make terminal gear Chain rotate.

( 2~3 loops)

2.2.8 Remove MSB, and carry Controller into machine room.

8kgf

12~15mm

3.2.2 Tension part

Unpublished Work Copyright © SIGMA Elevator Company

SIGMA Date : 2007.04.25

FIELD INDUSTRIAL

ENGINEERING

ARES Maintenance Manual Page :D - 4 / 7

FIM D Terminal gear device

3. Upper Terminal Gear examination

3.1 Clean bearing of upper Terminal Gear

3.2 Smear Grease with oiling Nipper.

3.3 Eliminate redundant Grease and Oil.

[Take environment factor into account,should put them away]

Oiling Nipple

Unpublished Work Copyright © SIGMA Elevator Company

SIGMA Date : 2007.04.25

FIELD INDUSTRIAL

ENGINEERING

ARES Maintenance Manual Page :D - 5 / 7

FIM D Terminal gear device

4.Lower R-Guide examination

4.1 Affirm dimension difference of spring(Both sides of tension device).

4.2 Examine rod that fix slideway and constringent spring.

4.3 Affirm if Spring is in the right position, adjust it to the normal position with nut .

Tension Spring free length = 100 -1mm

Tension Spring constringent Set dimension = 80 -1mm

4.4 Clean the surface of slideway.[Deal with scrap oil]

4.5 Smear Grease on slideway.

80mm

Grease

Unpublished Work Copyright © SIGMA Elevator Company

SIGMA Date : 2007.04.25

FIELD INDUSTRIAL

ENGINEERING

ARES Maintenance Manual Page :D - 6 / 7

FIM D Terminal gear device

5. Traction Machine examination and maintenance

5.1 Traction machine examination

5.1.1 Measure Oil quantity of reducer, when needed, supply Oil.

5.1.2 Examine if reducer leaks oil.

5.1.3 Examine Brake action state

-. Fix spring and nut of Brake Rod.

-. Examine motion state of arm that belongs to Brake.

-. Examine if partition pin of Brake Lever Bolt is fixed rightly.

5.1.4 Smear a spot of oil in the both side of Brake Lever Bolt.

5.1.5 Clean traction.

5.1.6 Handle of MCCB should be On, run Escalator.

5.1.7 Examine if traction machine has abnormally noise.

5.1.8 Handle of MCCB should be Off.

Unpublished Work Copyright © SIGMA Elevator Company

SIGMA Date : 2007.04.25

FIELD INDUSTRIAL

ENGINEERING

ARES Maintenance Manual Page :D - 7 / 7

FIM D Terminal gear device

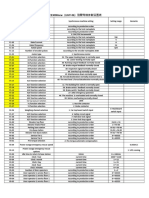

6. Examine Oil state

First examination: After ES. run 240 hours, change oil

After the first examination: Change oil one tiem every 2,000 hours.

6.1 Handle of MCCB should be On.

6.2 Spot moving ES. with MSB.

6.3 Handle of MCCB should be Off.

6.4 Compare colour of Oil.

6.5 Affirm content of Oil examination List.

Color 1 = Color is blue

-. Can continue using

-. Shorten examination cycle and affirm oil state

Color 2 = Smalt –gray-brown

-. Shorten examination cycle or change Oil.

Color 3 = Puce-Black

-. Change Oil.

Color 1

Color 2

Color 3

Unpublished Work Copyright © SIGMA Elevator Company

Das könnte Ihnen auch gefallen

- ARES Escalator BDokument2 SeitenARES Escalator BGutmonarchNoch keine Bewertungen

- 05 Muse Acd3 T&C AdjustmentDokument10 Seiten05 Muse Acd3 T&C AdjustmentRaz Marendra RamanandaNoch keine Bewertungen

- ARES Escalator 5Dokument3 SeitenARES Escalator 5GutmonarchNoch keine Bewertungen

- VVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelDokument13 SeitenVVVF Control (Variable Voltage and Variable Feriquency) : 1-LX Operator PanelKen LeeNoch keine Bewertungen

- Dokumen Dari Jon@Th@n Verrell-2-1Dokument101 SeitenDokumen Dari Jon@Th@n Verrell-2-1omotu79Noch keine Bewertungen

- Hyundai Elevator Preventive Maintenance ProcedureDokument19 SeitenHyundai Elevator Preventive Maintenance ProcedureTrebor Santos100% (2)

- GLC Manual PDFDokument4 SeitenGLC Manual PDFHendra WibisonoNoch keine Bewertungen

- Technical Manual and Electronical Regulation Vvvf-4: Cabin DoorsDokument7 SeitenTechnical Manual and Electronical Regulation Vvvf-4: Cabin DoorsMaicol Rodolfo CaizaNoch keine Bewertungen

- 01 - Control BoxDokument2 Seiten01 - Control BoxMoises PerelloNoch keine Bewertungen

- 05 - Test-Run in High SpeedDokument8 Seiten05 - Test-Run in High SpeedAndiosoNoch keine Bewertungen

- Support-Doordrive ManualDokument8 SeitenSupport-Doordrive ManualhabibullaNoch keine Bewertungen

- NICE3000 电梯一体化控制器用户手册 (英文详版) - V1.0 PDFDokument232 SeitenNICE3000 电梯一体化控制器用户手册 (英文详版) - V1.0 PDFAsdrubal Fredy GutierrezNoch keine Bewertungen

- Đấu Nối - EC160 PDFDokument8 SeitenĐấu Nối - EC160 PDFHùng VĩNoch keine Bewertungen

- Planos Electricos Escaleras NW-BB BELLO MONTEDokument14 SeitenPlanos Electricos Escaleras NW-BB BELLO MONTEFranklin PalaciosNoch keine Bewertungen

- Appendix 2: System TroubleshootingDokument4 SeitenAppendix 2: System Troubleshootingعلاء صقرNoch keine Bewertungen

- 04 - Muse Ed - SR-02-0-PCB - 090327Dokument48 Seiten04 - Muse Ed - SR-02-0-PCB - 090327Moises PerelloNoch keine Bewertungen

- CL - Omkar ElectronicsDokument16 SeitenCL - Omkar ElectronicsSazzad Hossan RaselNoch keine Bewertungen

- Operation and Maintenance Manual For WYJ 250 Series Permanent-Magnet Synchronous Gearless Traction MachineDokument20 SeitenOperation and Maintenance Manual For WYJ 250 Series Permanent-Magnet Synchronous Gearless Traction MachineJULIONoch keine Bewertungen

- Toshiba Spacel IIIDokument11 SeitenToshiba Spacel IIITran Huy50% (2)

- Hitachi Lift UAG SN1Dokument20 SeitenHitachi Lift UAG SN1Taimoor Ahmed100% (1)

- Hamcb SwordDokument101 SeitenHamcb SwordNaseh Ya NasehNoch keine Bewertungen

- Field Industrial Gen2 Lux Engineering Page Otis Nec Gien Amt Booklet Field PDFDokument35 SeitenField Industrial Gen2 Lux Engineering Page Otis Nec Gien Amt Booklet Field PDFAnonymous 7Iyjn4T25zNoch keine Bewertungen

- Mitsubishi Escalator SpecificationsDokument3 SeitenMitsubishi Escalator SpecificationsFERNSNoch keine Bewertungen

- SPS2 ManualDokument16 SeitenSPS2 ManualElevator & Escalator EngineeringNoch keine Bewertungen

- 5elevator Installation Manual For Elevator With Machine Room V1.4 - 1Dokument113 Seiten5elevator Installation Manual For Elevator With Machine Room V1.4 - 1aneesh tNoch keine Bewertungen

- MAYR Elevator BrakesDokument8 SeitenMAYR Elevator Brakesgeorge_zouridisNoch keine Bewertungen

- Img 0020Dokument1 SeiteImg 0020Venkateshan VenuNoch keine Bewertungen

- Hidra CRONO - EN81-76 Configuration Guide - enDokument8 SeitenHidra CRONO - EN81-76 Configuration Guide - engianfrancoNoch keine Bewertungen

- Otis Offer PDFDokument12 SeitenOtis Offer PDFgoodsum01Noch keine Bewertungen

- Project Managers Program: Technical NoteDokument20 SeitenProject Managers Program: Technical NotealfreliaNoch keine Bewertungen

- 19010493-SC - A00 - 19010493 - ME320LNnew Series Elevator AC Drive - 20161121Dokument145 Seiten19010493-SC - A00 - 19010493 - ME320LNnew Series Elevator AC Drive - 20161121Ks BharathiyarNoch keine Bewertungen

- Steel W Orks Products (Thailand) : Elevator Controller SystemDokument4 SeitenSteel W Orks Products (Thailand) : Elevator Controller Systemtran xobonNoch keine Bewertungen

- Jarless Con Door DriveDokument1 SeiteJarless Con Door Drivewakeel ahmedNoch keine Bewertungen

- Di B'rite Elevator: Installation ManualDokument26 SeitenDi B'rite Elevator: Installation ManualIshtiaq HussainNoch keine Bewertungen

- Mel 03 - 08C2 - ElenessaDokument1 SeiteMel 03 - 08C2 - ElenessaUmer FarooqNoch keine Bewertungen

- Tool Velino FT853Dokument12 SeitenTool Velino FT853Polinho DonacimentoNoch keine Bewertungen

- Is-A300is-M300 Lift Control PanelDokument28 SeitenIs-A300is-M300 Lift Control PanelUnique Product100% (1)

- GSD SM Instruction Book PDFDokument15 SeitenGSD SM Instruction Book PDFMitro100% (1)

- Multi-Function Keypad "TP-G1-: Instruction ManualDokument64 SeitenMulti-Function Keypad "TP-G1-: Instruction Manualjacky100% (1)

- Orona LiftDokument4 SeitenOrona LiftMarius Ionita100% (1)

- 211Dokument14 Seiten211AdjieNoch keine Bewertungen

- MUSE ED Elevator: Installation ManualDokument29 SeitenMUSE ED Elevator: Installation ManualMoises PerelloNoch keine Bewertungen

- Muse Ed /: Trouble ShootingDokument10 SeitenMuse Ed /: Trouble ShootingMoises PerelloNoch keine Bewertungen

- Monarch Mctcpece1Dokument48 SeitenMonarch Mctcpece1Sazzad Hossan RaselNoch keine Bewertungen

- Regen Drive UK PDFDokument2 SeitenRegen Drive UK PDFAliRouyouNoch keine Bewertungen

- Fujitec Vietnam 1806Dokument8 SeitenFujitec Vietnam 1806Nguyen Hung0% (1)

- 25 TM Installation ManualDokument18 Seiten25 TM Installation ManualReynold Suarez83% (6)

- 0 - Start Up Routine ManualDokument2 Seiten0 - Start Up Routine ManualMoises PerelloNoch keine Bewertungen

- Fujitec BrakesDokument10 SeitenFujitec Brakesjeferson_camiloNoch keine Bewertungen

- KLEEMANN Lifts UK Limited Unit 8, Arena, 14 Charbridge Lane, Bicester, OxfordshireDokument5 SeitenKLEEMANN Lifts UK Limited Unit 8, Arena, 14 Charbridge Lane, Bicester, OxfordshireEsfan GaripNoch keine Bewertungen

- GSD-SM Instruction BookDokument15 SeitenGSD-SM Instruction BookKen LeeNoch keine Bewertungen

- Asanoor Compact IranDokument51 SeitenAsanoor Compact IranSatheesh RamaNoch keine Bewertungen

- PRECISION - EscalatorParts 800 233 0838 SCHINDLER EscalatorPartsDokument16 SeitenPRECISION - EscalatorParts 800 233 0838 SCHINDLER EscalatorPartsChristian Córdoba GamboaNoch keine Bewertungen

- THX07 MulticardDokument3 SeitenTHX07 MulticardKrishan singhNoch keine Bewertungen

- I Ma 3010.71 1320 622 Huy 067 - A - ComDokument140 SeitenI Ma 3010.71 1320 622 Huy 067 - A - ComValério de Oliveira Santos100% (1)

- MMR Elevator - SI: FOD Test & Commissioning For SI210 ControllerDokument20 SeitenMMR Elevator - SI: FOD Test & Commissioning For SI210 ControllerBrahim Chergui100% (1)

- Elevator Mechanic: Passbooks Study GuideVon EverandElevator Mechanic: Passbooks Study GuideNoch keine Bewertungen

- Elevator Apprentice: Passbooks Study GuideVon EverandElevator Apprentice: Passbooks Study GuideNoch keine Bewertungen

- Elevator Inspector: Passbooks Study GuideVon EverandElevator Inspector: Passbooks Study GuideNoch keine Bewertungen

- Elevator Mechanic's Helper: Passbooks Study GuideVon EverandElevator Mechanic's Helper: Passbooks Study GuideNoch keine Bewertungen

- Testing-and-Commissioning NICE PARAMETERDokument2 SeitenTesting-and-Commissioning NICE PARAMETERGutmonarchNoch keine Bewertungen

- Export Market Dairy Tariffs Guide 15 May 2020Dokument184 SeitenExport Market Dairy Tariffs Guide 15 May 2020GutmonarchNoch keine Bewertungen

- ARES Maintenance Manual: IndexDokument10 SeitenARES Maintenance Manual: IndexGutmonarchNoch keine Bewertungen

- Escalator C PDFDokument1 SeiteEscalator C PDFGutmonarchNoch keine Bewertungen

- ARES Maintenance Manual: IndexDokument7 SeitenARES Maintenance Manual: IndexGutmonarchNoch keine Bewertungen

- KRUGER FDA - Series Centrifugal FanDokument51 SeitenKRUGER FDA - Series Centrifugal FanSusan LamNoch keine Bewertungen

- ARES Maintenance Manual: IndexDokument10 SeitenARES Maintenance Manual: IndexGutmonarchNoch keine Bewertungen

- ARES Maintenance Manual: IndexDokument10 SeitenARES Maintenance Manual: IndexGutmonarchNoch keine Bewertungen

- SIGMA ARES Escalator 11Dokument4 SeitenSIGMA ARES Escalator 11Gutmonarch100% (1)

- SIGMA ARES Escalator 11Dokument4 SeitenSIGMA ARES Escalator 11Gutmonarch100% (1)

- Mitsubishi VFGL Mon Set SettingsDokument8 SeitenMitsubishi VFGL Mon Set SettingsGutmonarch71% (14)

- OTIS EscalatorDokument7 SeitenOTIS EscalatorGutmonarch0% (1)

- Mitsubishi Elenessa Encoder CalibrationDokument6 SeitenMitsubishi Elenessa Encoder CalibrationGutmonarchNoch keine Bewertungen

- All About SharksDokument3 SeitenAll About SharksGutmonarchNoch keine Bewertungen

- Wire Rope Lubricant PDFDokument1 SeiteWire Rope Lubricant PDFGutmonarchNoch keine Bewertungen

- ASIO4ALL v2 Instruction ManualDokument11 SeitenASIO4ALL v2 Instruction ManualDanny_Grafix_1728Noch keine Bewertungen

- New 5396 Brown and Haley Compressed Air - Project Assessment Report Rev ADokument17 SeitenNew 5396 Brown and Haley Compressed Air - Project Assessment Report Rev AGutmonarchNoch keine Bewertungen

- Acd2-Mrl Sur en PDFDokument100 SeitenAcd2-Mrl Sur en PDFGutmonarch88% (16)

- E1102m PDFDokument283 SeitenE1102m PDFBhawani Singh RajawatNoch keine Bewertungen

- Imagerunner Advance 8205Dokument264 SeitenImagerunner Advance 8205Gerardo SaucedaNoch keine Bewertungen

- Skema MB Manual Ga-78lmt-S2p - v.4.0 - eDokument44 SeitenSkema MB Manual Ga-78lmt-S2p - v.4.0 - eneno supartiniNoch keine Bewertungen

- Catalog SanzDokument55 SeitenCatalog SanzGotlem BordNoch keine Bewertungen

- MPC6502 MPC8002 MS v01 PDFDokument3.628 SeitenMPC6502 MPC8002 MS v01 PDFthienanNoch keine Bewertungen

- Manual de Usuario Ups Surta 1500XLDokument18 SeitenManual de Usuario Ups Surta 1500XLGustavo HernandezNoch keine Bewertungen

- GoFood UATDokument3 SeitenGoFood UATArsyadani LuthfiNoch keine Bewertungen

- 3.4.3.5 Lab - Address Resolution Protocol (ARP)Dokument13 Seiten3.4.3.5 Lab - Address Resolution Protocol (ARP)Muhammad Musyawir0% (2)

- Hammer MillDokument2 SeitenHammer MillIfa FafaNoch keine Bewertungen

- EMIS Toolbox UserAdmin Guide PresentationDokument53 SeitenEMIS Toolbox UserAdmin Guide PresentationJonas Reduta CabacunganNoch keine Bewertungen

- Report Bonafide JeevaDokument5 SeitenReport Bonafide JeevaRamyaNoch keine Bewertungen

- General SpecificationDokument241 SeitenGeneral Specificationcyong7788Noch keine Bewertungen

- Plano Electrico Cargador 938KDokument34 SeitenPlano Electrico Cargador 938KANDRES FUENTES FANDIÑONoch keine Bewertungen

- Samsung Galaxy J2 Pro (2018) ManualDokument127 SeitenSamsung Galaxy J2 Pro (2018) ManualBruno CoutoNoch keine Bewertungen

- 1.2.3.6 Packet Tracer - Troubleshooting Connectivty IssuesDokument3 Seiten1.2.3.6 Packet Tracer - Troubleshooting Connectivty IssuesDaniel CatalinNoch keine Bewertungen

- Certification Flasharray Architect Professional Study GuideDokument21 SeitenCertification Flasharray Architect Professional Study Guidemukive100% (1)

- Vss Cheat SheetDokument1 SeiteVss Cheat SheetPiyush BhateeNoch keine Bewertungen

- Epsilon 140z DatasheetDokument2 SeitenEpsilon 140z DatasheetRiga RingsNoch keine Bewertungen

- Module 8Dokument2 SeitenModule 8RatulKumarMajumdarNoch keine Bewertungen

- Spirion Thales - Integration Guide FINAL 20220517Dokument20 SeitenSpirion Thales - Integration Guide FINAL 20220517tekena.alaminaNoch keine Bewertungen

- Redit ResumeDokument3 SeitenRedit ResumeIvanknezNoch keine Bewertungen

- 2099 Datum CDokument2 Seiten2099 Datum CNistha ChakrabortyNoch keine Bewertungen

- Brewery Automation: BREE 495 Ian Burelle 260 472 128Dokument41 SeitenBrewery Automation: BREE 495 Ian Burelle 260 472 128Fotonika ITSNoch keine Bewertungen

- Instructor Materials Chapter 8: Becoming A Cybersecurity SpecialistDokument24 SeitenInstructor Materials Chapter 8: Becoming A Cybersecurity SpecialistDewi Ayu LestariNoch keine Bewertungen

- Puff PlantDokument9 SeitenPuff Planttauseef52Noch keine Bewertungen

- Catalog Diode Supresoare PDFDokument52 SeitenCatalog Diode Supresoare PDFvalidaeNoch keine Bewertungen

- Wireless and Mobile Communication - SyllabusDokument1 SeiteWireless and Mobile Communication - SyllabusvinothNoch keine Bewertungen

- DWDM I Mid Objective QBDokument7 SeitenDWDM I Mid Objective QBkishore5783100% (1)

- Multithreading Sorting AssignmentDokument2 SeitenMultithreading Sorting AssignmentTan BunChhayNoch keine Bewertungen

- Test UM Product CatalogDokument28 SeitenTest UM Product Catalogdonhacbang100% (1)

- WG Next Generation FirewallsDokument16 SeitenWG Next Generation FirewallsVinod GuptaNoch keine Bewertungen