Beruflich Dokumente

Kultur Dokumente

TARCE Vol.6 No.2 July December 2017 Pp.1 6

Hochgeladen von

Ajit P. SinghCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TARCE Vol.6 No.2 July December 2017 Pp.1 6

Hochgeladen von

Ajit P. SinghCopyright:

Verfügbare Formate

The Asian Review of Civil Engineering

ISSN: 2249 - 6203 Vol.. 6 No.2, 2017, pp.1-6

© The Research Publication, www.trp.org.in

Study of Plastic Waste Mixed Bituminous Concrete Using Dry Process

for Road Construction

Anurag V. Tiwari1 and Y R M Rao2

1

Assistant Professor, Department of Civil Engineering, Sipna College of Engineering and Technology,

Amravati, Maharastra, India

2

Principal, Dr. Pauls Engineering College, Villupuram District, Tamil Nadu, India

Email: anuragearth@gmail.com, dryrmrao@rediffmail.com

Abstract - Waste plastic is accumulation all over the world from petroleum sources. The rutting, cracking, formation

causing serious environmental problems. This paper aims to of potholes and disintegration of surface layers of flexible

study the Plastic Waste Mixed Bituminous Concrete Using pavements roads due to temperature and seasonal

Dry Process for Road Construction. The study evaluates the variations, stresses due to heavy traffic loads usually

addition of shredded waste plastic in the bituminous concrete

occurs. Hence the utilization of waste plastic in the roads

which results in significant increase in the stability value and

Marshall Properties of mix. The study reveals that the use of can minimize the above effects and therefore it is more

waste plastic in bituminous concrete is safe and sustainable important to make the roads more durable and stronger.

for road construction. The present study investigates the use of plastic waste

Keyword: Plastic Waste, Waste reuse, Road construction using dry process in bituminous concrete for road

construction. The objectives of study are:

I. INTRODUCTION

1. To study the marshal properties of bituminous mix

Road network of any country is backbone of its economy. using plastic waste and fly ash as filler.

Construction of road involve huge amount of money. One 2. To find the utility of waste plastic material in

can achieve the desired durability and Considerable saving bitumen mixes for road construction.

may be done during the construction of roads if proper 3. To study and propose durable course by exploring

engineering design is done. The desired properties to be the utilization of plastic waste and fly ash which

considered during design of bituminous mix are sufficient are available abundantly.

stability, durability, Flexibility, Skid resistance, 4. To provide an eco friendly road way.

Workability, Air voids and Economy. Increase in

population, rapid urbanization, development activities and II. LITERATURE REVIEW

change in life style has resulted in increase of quantum of

plastic waste in India. This huge amount of generated Amol S. Bhale (2011) stated that in recent years,

plastic had become a serious problem for our environment. applications of plastic wastes have been considered in road

the disposal of plastic wastes is a great problem. These are construction with great interest in many developing

non-biodegradable product due to which these materials countries. It was concluded that on heating at 100-160°C,

pose environmental pollution and problems like breast plastics such as polyethylene, polypropylene and

cancer, reproductive problems in humans and animals, polystyrene, soften and exhibit good binding properties.

genital abnormalities and even in human sperm count and Blending of the softened plastic with bitumen results in a

quality[1]. One of the solutions to this problem is to mixed that is amenable for road laying. In future this will

convert the waste plastic into some useful product. Indian also result in having strong, durable and eco-friendly roads

government has already taken an initiative to implement which will relieve the earth from all type of plastic-

4R policy i.e reuse, reduce, recycle and recover in the form waste[1].

of “Swach Bharat Abhiyan”.

R.Sathishkumar et.al, (2013) investigated and revealed that

The generation of waste plastic has caused many effects on properties of bitumen can be improved with the

the environment, resulting in huge landfill mountainous incorporation of modifiers. The bitumen treated with these

structure which is harmful to the human health as well as modifiers is known as Modified Bitumen. In this study,

to all living organisms. Therefore, the recycling and bitumen of grade VG 30 is selected and improved its

reusing of plastic wastes is found to be more advantageous. properties by the addition of modifiers such as Low

The natural bitumen extraction has resulted in more usage Density Poly Ethylene (LDPE) waste and Pulverised Tyre

of non-renewable sources which are not sustainable in Waste (PTW). Results showed that Penetration value of

environment. The plastic usage in roads can replace some modified bitumen decreases by 6.8% for PTW and 13.6%

percentage of natural bitumen that is extracted or distilled for LDPE waste. Softening point value increases by 8.16%

1 TARCE Vol.6 No.2 July-December 2017

Anurag V. Tiwari and Y R M Rao

for PTW and 14.28% for LDPE waste. Ductility value has bitumen in many aspects. The aggregate is heated about

decreased by 39.6% for PTW and increased by 18.86% for temperature160oC. After the heating of aggregate, the hot

LDPE waste. In Marshall test, the stability value has aggregate is transfer into the mixing chamber. At the

increased by 30% for PTW and 28.46% for LDPE waste. mixing chamber, the shredded plastics waste is to be

Addition of the modifier reduced the flow value by 34.69% added. It gets coated uniformly over the aggregate within

for PTW and 39.59% for LDPE waste, which shows that 30 to 60 seconds, giving an oily look.

the flow property has increased. Thus results of this study

concluded that addition of PTW and LDPE waste has The bitumen is added in hot plastic coated aggregate at

improved the properties of penetration, ductility and 160oC. It is observed that Marshall Stability value

softening temperature of the modified bitumen. As the increases with polyethylene content up to 6% and

stiffness of the material is improved, it is capable of taking thereafter decreases and also the Marshall Flow value

high load and increase the resistance and durability of the decreases upon addition of polythene i.e the resistance to

pavements [2]. deformations under heavy wheel loads increases [4].

Afroz Sultana.SK et.al, (2012) studied Utilization of Waste Vatsal Patel et.al, (2014) highlighted the urgent need for

Plastic as a Strength Modifier in Surface Course of re-examining and formulating new guidelines and

Flexible and Rigid Pavements. The study investigates the specifications with regard to the design and construction of

potential use of waste plastic as a modifier for asphalt roads in India using plastic wastes.

concrete and cement concrete pavement.

Plastic waste, consisting of carry bags, cups etc can be The cost of road construction is also decreased and the

used as a coating over aggregate and this coated stone can maintenance cost is almost nil. The roads are found to be

be used for road construction. Different ratios of plastic stronger with increased Marshall Stability value, better

such as Polypropylene (PP), Low Density Polyethylene resistance towards rain water and water stagnation so no

(LDPE), and High Density Polyethylene (HDPE) by stripping and no potholes, increase binding and better

weight of asphalt were blended with 80/100 paving grade bonding of the mix thus reduction in pores in aggregate

asphalt. By using plastic as a coating over aggregates, the and hence less rutting raveling[5].

properties of aggregates are improved.

III. MATERIAL AND MIX DESIGN

Based on the stability values, the optimum percentage of

plastic is 8%, 6% for plastic coated aggregate samples and Various materials used in the construction of flexible

polymer modified bitumen samples respectively for PP pavements are bitumen, aggregate (fine and coarse), filler,

type of plastic, and 8% is optimum for LDPE type of and shredded plastic waste. The bitumen used for present

plastic for both plastic coated aggregate and polymer study is of 60/70 penetration grade and is obtained from

modified samples. This shows hat weak aggregates can be BPCL, Nagpur and PWD, Amravati.

used in construction by using plastic as a binder material.

By adding plastic to the unmodified bitumen, the Coarse aggregates, fine aggregates and flyash were

rheological properties have been improved. There is an collected from local crusher. The plastic waste was

increase in the softening point and decrease in penetration segregated from the municipal waste and shredded at the

and ductility values [3]. local plastic waste recycling plant at MIDC, Amravati.

Akanksha Yadav (2016), has stated that the use of polymer

coated aggregate is better than the use of polymer modified

TABLE 1 PHYSICAL PROPERTIES OF COARSE AGGREGATES

Sl. No. of test Specification

Test Test Result Standards

No. Performed Requirement

1 Aggregate impact value 3 22.40% Max 30% IS : 2386 (Part IV) - 1963

2 Abrasion value 3 28.10% Max 40% IS : 2386 (Part IV) – 1963

3 Crushing value 3 24.30% Max 30% IS : 2386 (Part IV) – 1963

Combined Elongation index

4 3 17.20% Max 30% IS : 2386 (Part I) – 1963

and Flakiness index

20 mm: 2.830

5 Specific gravity 6 - IS : 2386 (Part IV) – 1963

10 mm: 2.792

6 Water Absorption 3 0.1% Max 2% IS: 2386 (Part III)-1963

TARCE Vol.6 No.2 July-December 2017 2

Study of Plastic Waste Mixed Bituminous Concrete Using Dry Process for Road Construction

TABLE 2 PHYSICAL PROPERTIES OF BITUMEN

Specification

Sl. No. Test Test Result Standards

Requirement

1 Penetration test 68 65-90 IS : 1203-1978

2 Softening point test 53 40-60 IS : 1205-1978

3 Specific Gravity 1.01 Min 0.99 IS: 1206 (Part I) -1978

4 Ductility test 87 Min 75 IS : 1208-1978

Marshall Mix Design was conducted to optimize the mix mixture is extremely important and closely related to

design and quantity of waste plastic. Dry process was used stability, durability and permeability. The following

to prepare Marshall Samples. equation represents the percentage of air voids in the

specimen.

In this process the aggregates were heated to 170°C. The

shredded plastic waste retaining on 2.36 mm sieve is added

in proportion by weight to the hot aggregate. The quantity

of waste plastic LDPE and HDPE was added varying from D. Voids in the Mineral Aggregate (VMA)

0% to 12%.

VMA is the volume of inter granular void space between

This plastic gets coated over the aggregate uniformly. the aggregate particles of a compacted paving mixture. It

Immediately the hot Bitumen at 160°C is added with the includes the air voids and the volume of the asphalt not

mixture and compacted with 75 blows on both face to get absorbed into the aggregate .

Marshall Samples.

VMA describes the portion of space in a compacted asphalt

The average values for Bulk specific Gravity, stability, pavement or specimen which is not occupied by the

flow, AV, VMA and VFB were calculated and graphs were aggregate. VMA is expressed as a percentage of the total

plotted. According to Das, A. and Chakroborty P. the volume of the mix Voids Filled with Binder (VFB).

following properties were calculated based on volumetric

analysis.[6]

A. Bulk Specific Gravity of sample (Gb) E. Voids Filled with Bitumen (VFB)

The bulk density of the sample is determined by weighing VFB is the voids in the mineral aggregate frame work filled

the sample in air and in water. The specific gravity of the with bitumen binder. This represents the volume of the

specimen is given by effective bitumen content.

It can also be described as the percent of the volume of the

VMA that is filled with bitumen. VFB is inversely related to

B. Theoretical specific gravity of the mix (Gt) air voids and hence as air voids decreases, the VFB

increases.

Theoretical specific gravity Gt is the specific gravity

without considering air voids, and is given by:

IV. RESULTS AND DISCUSSION

C. Air voids percent (AV) The optimum binder content for the mix was found to be

6% which was further used for the subsequent study. The

It is the total volume of the small pockets of air between the details of volumetric and mechanical properties are

coated aggregate particles throughout a compacted paving tabulated in the table below.

mixture, expressed as a percent of the bulk volume of the

compacted paving mixture. The amount of air voids in a

3 TARCE Vol.6 No.2 July-December 2017

Anurag V. Tiwari and Y R M Rao

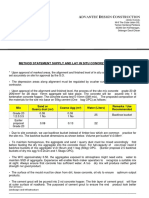

TABLE 3 VOLUMETRIC AND MECHANICAL PROPERTIES

Bulk Void Analysis Marshall Stability (KN)

Theoretica

Specific

Bitumen l Specific

Gravity Flow (mm)

content % Gravity Gt AV VMA VFB Measured Corrected

Gb

(gm/cm3)

(gm/cm3)

5 2.195 2.389 8.131 23.046 64.818 10.52 9.40 2.32

5.5 2.204 2.361 6.673 23.146 71.334 12.14 10.69 2.54

6 2.205 2.334 5.527 23.508 76.605 13.89 11.95 2.64

6.5 2.200 2.307 4.639 24.076 80.897 12.11 10.70 3.22

7 2.198 2.281 3.638 24.552 85.285 11.56 10.05 3.72

Fig.1 Stability Vs Bitumen Content Fig. 3 Bitumen content Vs Air Void %

Fig. 2 Bitumen content Vs V.M.A%

Fig. 4 Bitumen content Vs V.F.B%

Fig. 5 Bitumen Content Vs Flow

The volumetric and mechanic properties of the mix were obtained after adding various types of plastic and the results were

tabulated in the table below.

TARCE Vol.6 No.2 July-December 2017 4

Study of Plastic Waste Mixed Bituminous Concrete Using Dry Process for Road Construction

TABLE 4 VOLUMETRIC AND MECHANIC PROPERTIES

Theoretical Marshall Stability (KN)

Type Plastic Bulk Specific Void Analysis

Specific

of Waste Gravity Gb Flow(mm)

Gravity Gt

Plastic % (gm/cm3) AV VMA VFB Measured Corrected

(gm/cm3)

0 2.205 2.334 5.53 23.51 76.61 13.89 11.95 2.64

LDPE 2 2.232 2.334 4.38 22.58 80.64 12.95 12.43 2.57

HDPE 2 2.236 2.334 4.20 22.44 81.49 13.17 12.81 2.71

LDPE 4 2.236 2.334 4.20 22.43 81.85 13.30 12.51 2.68

HDPE 4 2.240 2.334 4.04 22.31 82.15 13.77 12.89 2.71

LDPE 6 2.244 2.334 3.85 22.15 82.61 15.37 13.52 2.74

HDPE 6 2.253 2.334 3.48 21.85 84.08 15.25 13.57 2.87

LDPE 8 2.252 2.334 3.53 21.89 83.89 16.52 14.70 3.30

HDPE 8 2.259 2.334 3.19 21.62 85.34 16.92 15.51 3.51

LDPE 10 2.243 2.334 3.90 22.19 82.44 14.56 13.16 3.83

HDPE 10 2.247 2.334 3.72 22.04 83.15 15.01 13.90 3.92

LDPE 12 2.237 2.334 4.15 22.39 81.77 14.37 13.17 3.97

HDPE 12 2.248 2.334 3.70 22.03 83.39 15.34 14.06 4.22

The maximum stability was found to be 14.70 KN and 15.51 The excessive air void may result in the cracking due to

KN for the 8% of LDPE and HDPE plastic waste content insufficient bitumen binders, Where as low air void may

reapectively. The addition of waste plastic at 8% incresed produce more plastic flow and result in bitumen bleeding.

the stability value which results in the improvement of The air voids for the 8% of the LDPE and HDPE plastic

toughness of the mix. Subsequently the flow value of the waste content was found to be within the specified limit of

mix has increased which results in the increase in the minimum 3% to maximum 6%. Also the other properties

workability of the mix. like VMA and VFB were found to be well within the limits.

Fig.6 Bitumen Content Vs Stability Fig.8 Bitumen Content Vs V.M.A%

Fig.7 Bitumen Content Vs Flow Fig.9 Bitumen Content Vs V.F.B %

5 TARCE Vol.6 No.2 July-December 2017

Anurag V. Tiwari and Y R M Rao

Fig.10 Bitumen Content Vs Air Void %

REFERENCES

V.CONCLUSION

[1] Amol S. Bale, ‘Potential Reuse of Plastic Waste in Road

Construction: A Review’, International Journal of Advanced

Addition of 8% of the LDPE and HDPE plastic waste

Engineering Technology E-ISSN 0976-3945,Vol.II, Issue III,

improves the stability value of the mix which results is the PG. NO. 233-236, July-September, 2011.

increase in the toughness of the mix. Due to addition of [2] R.Sathishkumar and Dr.S.P.Jeyapriya, ‘Comparison of Strength

plastic waste the flow value increases resulting the Properties of Bitumen Mixed With Waste Materials As

Modifier’, International Journal of Civil Engineering and

improvement in the workability. Addition of plastic waste

Technology (IJCIET), Vol. 4, Issue 4, PG. NO. 219-224, July-

results in decrease in the air voids which reduces the August 2013.

bleeding of bitumen. The volumetric and marshall [3] Afroz Sultana.SK, K.S.B. Prasad, ‘Utilization of Waste Plastic

properties of the mix show the acceptable trends and could as a Strength Modifier in Surface Course of Flexible and Rigid

Pavements’ International Journal of Engineering Research and

satisfy the specified limits. The use of waste plastic in

Applications (IJERA) ISSN: 2248-9622 Vol. 2, Issue 4, pg. no.

bituminous concrete is safe and sustainable for road 1185-1191, July-August 2012.

construction. [4] Akanksha Yadav, ‘Use of Waste Plastic in Flexible Pavement

Construction - A Case Study’, Imperial Journal of

Interdisciplinary Research (IJIR) Vol-2, Issue-9, ISSN: 2454-

1362, 2016.

[5] Vatsal Patel, Snehal Popli and Drashti Bhatt, ‘Utilization of

Plastic Waste in Construction of Roads’, International Journal

of Scientific Research, Vol. 3, Issue: 4, ISSN No 2277 – 8179,

Pg. No. 161-163, April 2014.

[6] Das, A. and Chakroborty P. (2010), “Principles of

Transportation Engineering.”, Prentice Hall of India, New

Delhi, pp 294-299.

TARCE Vol.6 No.2 July-December 2017 6

Das könnte Ihnen auch gefallen

- Disclosure To Promote The Right To InformationDokument9 SeitenDisclosure To Promote The Right To InformationAjit P. SinghNoch keine Bewertungen

- IS12269 53-Grade Ordinary Portland Cement-Specification 2000 PDFDokument20 SeitenIS12269 53-Grade Ordinary Portland Cement-Specification 2000 PDFAjit P. SinghNoch keine Bewertungen

- Specification FOR 53gradeordinaryportlandcement: Indian StandardDokument20 SeitenSpecification FOR 53gradeordinaryportlandcement: Indian StandardAjit P. SinghNoch keine Bewertungen

- Pile Load Test PDFDokument11 SeitenPile Load Test PDFAjit P. SinghNoch keine Bewertungen

- A Viscosity Primer: Viscosity Definitions ViscosityDokument3 SeitenA Viscosity Primer: Viscosity Definitions ViscosityAjit P. SinghNoch keine Bewertungen

- IS-6461 Part-1 1972Dokument25 SeitenIS-6461 Part-1 1972sourav1302Noch keine Bewertungen

- Is 1489 (Part-2) Portland-Pozzolana Cement Specification (CADokument15 SeitenIs 1489 (Part-2) Portland-Pozzolana Cement Specification (CARamarraju KalidindiNoch keine Bewertungen

- Cad ShortcutsDokument8 SeitenCad ShortcutsPrabhat KumarNoch keine Bewertungen

- @Ltwrwi?Rqs'Ptt-Fm TFZ: Indian StandardDokument6 Seiten@Ltwrwi?Rqs'Ptt-Fm TFZ: Indian StandardDevela AvinashNoch keine Bewertungen

- AutoCAD Commands 1 PDFDokument6 SeitenAutoCAD Commands 1 PDFAlvin YanglayNoch keine Bewertungen

- Quick HealDokument1 SeiteQuick Healsamarth_bajpai2322Noch keine Bewertungen

- Greek Alphabet and Its Pronunciation PDFDokument1 SeiteGreek Alphabet and Its Pronunciation PDFAjit P. SinghNoch keine Bewertungen

- Concrete Joints ACPADokument12 SeitenConcrete Joints ACPAgarystlmo100% (2)

- ASTM D 445-06-Viscosity PDFDokument10 SeitenASTM D 445-06-Viscosity PDFIndra AditamaNoch keine Bewertungen

- ASTM D 445-06-Viscosity PDFDokument10 SeitenASTM D 445-06-Viscosity PDFIndra AditamaNoch keine Bewertungen

- Use of Plastic Waste in Bituminous Mixes of Flexible Pavements by Wet and Dry Methods: A Comparative StudyDokument10 SeitenUse of Plastic Waste in Bituminous Mixes of Flexible Pavements by Wet and Dry Methods: A Comparative StudyAjit P. SinghNoch keine Bewertungen

- A Detailed Study of CBR Method For Flexible Pavement Design: Er. Devendra Kumar Choudhary, Dr. Y. P JoshiDokument15 SeitenA Detailed Study of CBR Method For Flexible Pavement Design: Er. Devendra Kumar Choudhary, Dr. Y. P JoshipradeepNoch keine Bewertungen

- Use of Plastic Waste in Bituminous Mixes of Flexible Pavements by Wet and Dry Methods: A Comparative StudyDokument10 SeitenUse of Plastic Waste in Bituminous Mixes of Flexible Pavements by Wet and Dry Methods: A Comparative StudyAjit P. SinghNoch keine Bewertungen

- Bridge Components and Seismic DesignDokument67 SeitenBridge Components and Seismic DesignRojan MathewNoch keine Bewertungen

- A Viscosity Primer: Viscosity Definitions ViscosityDokument3 SeitenA Viscosity Primer: Viscosity Definitions ViscosityAjit P. SinghNoch keine Bewertungen

- CBR Saturado y No SaturadoDokument4 SeitenCBR Saturado y No SaturadoebherlinNoch keine Bewertungen

- VinothDokument21 SeitenVinothHnd Inst HydraulicsNoch keine Bewertungen

- 1498 Soil ClasificationDokument28 Seiten1498 Soil ClasificationRamesh100% (4)

- Flexible Pavement Design PDFDokument38 SeitenFlexible Pavement Design PDFBhoopesh KayapakNoch keine Bewertungen

- Bridge Components and Seismic DesignDokument67 SeitenBridge Components and Seismic DesignRojan MathewNoch keine Bewertungen

- Four Laning of Hospet-Chitradurg Section NH-13 Concrete Mix DesignDokument35 SeitenFour Laning of Hospet-Chitradurg Section NH-13 Concrete Mix DesignAjit P. SinghNoch keine Bewertungen

- California Bearing Ratio Test: 1. ObjectiveDokument3 SeitenCalifornia Bearing Ratio Test: 1. ObjectivePanchadcharam PushparubanNoch keine Bewertungen

- VinothDokument21 SeitenVinothHnd Inst HydraulicsNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Transportation 1: Modes and EngineeringDokument36 SeitenTransportation 1: Modes and EngineeringEtienneMmeliSibindiNoch keine Bewertungen

- Theoretical Driving Exam Sample ReviewerDokument29 SeitenTheoretical Driving Exam Sample ReviewerJoanneley Bartolome100% (1)

- ASTM D6433-09 Pagina 16Dokument224 SeitenASTM D6433-09 Pagina 16Angel Ananias Balbin Saenz100% (1)

- Lecture 5 Speed and Delay Study 1 PDFDokument28 SeitenLecture 5 Speed and Delay Study 1 PDFgdfgNoch keine Bewertungen

- CSRA Guidelines for Erosion ProtectionDokument121 SeitenCSRA Guidelines for Erosion ProtectionSwain Niranjan100% (1)

- 1.2 - Mr. A.P. Jayathissa Resident Engineer (Anuradhapura) PDFDokument34 Seiten1.2 - Mr. A.P. Jayathissa Resident Engineer (Anuradhapura) PDFmpchanakaNoch keine Bewertungen

- PlanDokument132 SeitenPlanpvpallasigui3126Noch keine Bewertungen

- Design of Flexible PavementsDokument165 SeitenDesign of Flexible Pavementskyugu67% (3)

- TMC 421 PDFDokument82 SeitenTMC 421 PDFJamie MooreNoch keine Bewertungen

- Roadside Service StationDokument34 SeitenRoadside Service StationGedeBudiSuprayogaNoch keine Bewertungen

- MSI BL PIEZO AXLE SENSORDokument2 SeitenMSI BL PIEZO AXLE SENSORErikoNoch keine Bewertungen

- Archived CAITM Part B May 2010Dokument232 SeitenArchived CAITM Part B May 2010binsuniNoch keine Bewertungen

- EFFECTIVE TRAFFIC MANAGEMENT THROUGH OPTIMAL USE OF ROAD LANESDokument1 SeiteEFFECTIVE TRAFFIC MANAGEMENT THROUGH OPTIMAL USE OF ROAD LANESArif ZulNoch keine Bewertungen

- CBSE Class X Social Science Sample Paper SolvedDokument17 SeitenCBSE Class X Social Science Sample Paper SolvedAnanay ChaudhryNoch keine Bewertungen

- Operating A Moped or ScooterDokument75 SeitenOperating A Moped or ScooterJohnNoch keine Bewertungen

- Daily Inspection Report: Division of ConstructionDokument7 SeitenDaily Inspection Report: Division of ConstructionOkan KalendarNoch keine Bewertungen

- TRANSLINK - Company Profile PDFDokument39 SeitenTRANSLINK - Company Profile PDFKaran DaveNoch keine Bewertungen

- Irc 37 2001Dokument1 SeiteIrc 37 2001Gampa Vamshi KrishnaNoch keine Bewertungen

- Construction Method DrainageDokument15 SeitenConstruction Method Drainageipmawan100% (1)

- 2 Animesh Kashyap PPT On Plastic RoadDokument23 Seiten2 Animesh Kashyap PPT On Plastic RoadANIMESH KASHYAPNoch keine Bewertungen

- Seminar ZeeshanMUR2001218Dokument23 SeitenSeminar ZeeshanMUR2001218Abdul QadirNoch keine Bewertungen

- HILL ROAD by Prof. Ujjval J SolankiDokument43 SeitenHILL ROAD by Prof. Ujjval J SolankiUjjval SolankiNoch keine Bewertungen

- MOTOR TRAFFIC (AMENDMENT) Act Sri LankaDokument111 SeitenMOTOR TRAFFIC (AMENDMENT) Act Sri LankaramaaramaaNoch keine Bewertungen

- Mineral Economics Discipline PresentationDokument27 SeitenMineral Economics Discipline Presentationmujib uddin siddiquiNoch keine Bewertungen

- 1 Name of Work:-Improvement of Epum Road (Northern Side) Connecting With Imphal-Saikul Road I/c Pucca DrainDokument1 Seite1 Name of Work:-Improvement of Epum Road (Northern Side) Connecting With Imphal-Saikul Road I/c Pucca DrainHemam PrasantaNoch keine Bewertungen

- Civil BoQ Document for 50MW Solar Power PlantDokument35 SeitenCivil BoQ Document for 50MW Solar Power PlantRaviraj ThoratNoch keine Bewertungen

- Method Statement Kerb Cast in Situ (Site Mix) - For MergeDokument5 SeitenMethod Statement Kerb Cast in Situ (Site Mix) - For Mergekesavan1990Noch keine Bewertungen

- Part 4 - 4.13 Asphalt Joint and Crack SealantDokument4 SeitenPart 4 - 4.13 Asphalt Joint and Crack SealantAbdul Wahab JamilNoch keine Bewertungen

- Human Settlement: Case StudyDokument17 SeitenHuman Settlement: Case StudyaparnaNoch keine Bewertungen