Beruflich Dokumente

Kultur Dokumente

Limestone Impact Crusher / Started Apx 20 Sep 2017 On Till Date

Hochgeladen von

laxman JoshiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Limestone Impact Crusher / Started Apx 20 Sep 2017 On Till Date

Hochgeladen von

laxman JoshiCopyright:

Verfügbare Formate

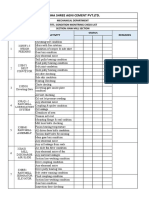

LIMESTONE IMPACT CRUSHER / STARTED APX 20TH SEP 2017 ON TILL DATE

1. Dump hopper protection plates new fabricated at two sides to avoid spillage under safety.

2. Apron feeder conveying lamella plates back side 25x250x10 mtr at 3 places provide

throughout conveyor to avoid material spillage.

3. Apron feeder both side skirt rubber fabricated & fixed in the location.

4. Apron feeder discharge end, feeding impact crusher entrance area chain curtain new

provided to avoid crushed stone, back feeding and uniform feeding purpose. This will give

excellent results.

5. As per RV consultant recommendation impact liner adjusted fully & full welded to adjusting

bolt. By this act, blow bar & impact liners broken. After inspection removed to welding

channels & maintained in required gap.

6. Blow bar 06 NOS new replaced at first time completed on 27-08-2018 / second time

balanced available 02 NOS also replaced.

7. 240 BC2 belt conveyor bend pulley shaft broken on 30-05-2018 new fabricated with shaft

machined to bearing size and fixed in the location, trail taken handed over for continues

operation.

8. Tripper belt conveyor, cable drum erection as per drawing.

9. 240 BC1 belt conveyor belt – 3 times partial belt replaced & cold vulcanization done.

10. 230 IM1 impact crusher impact liners set at middle 06 NOS new replaced on 30-07-2018 due

to broken.

11. 230 AF1 Apron feeder reducer backstop damage on 21-08-2018 after replaced new back

hold arrangement, replaced to it gearbox.

12. Crusher impact liners at bottom side liners new set replaced on 22-09-2018 due to broken.

13. Crusher drive, hydraulic coupling oil seal replaced, due to leaking.

14. Crusher impact wall liner at top side set new 06 NOS replaced on 21-05-2019 due to

broken.

15. Crusher blow bar welding buildup work doing every Tuesday to reduce gap, resulting to set

small sized lime stone after crushing.

16. 240 BC1 belt conveyor, new belt replaced with cold vulcanization.

17. Crusher chute new fabricated with liners and replaced in the location.

18. 260 BC2 hopper feeding belt conveyor bend pulley shaft broken at gravity station new

pulley fabricated with shaft, after machining pulley fixed in the location & handover for

operation.

19. Crusher discharge impact rollers 04 NOS new replaced.

20. 240BC2 belt conveyor tripper trolley shifting and de rail tripper trolley. Damage belt and

bend pulley shaft. Belt conveyor belt joint and new bend pulley fixing work.

Das könnte Ihnen auch gefallen

- Automated Alternative To Conventional Tunnelling: Tachus AgDokument7 SeitenAutomated Alternative To Conventional Tunnelling: Tachus AgHarold TaylorNoch keine Bewertungen

- Nagpur Metro Rail Project ExploredDokument29 SeitenNagpur Metro Rail Project ExploredSumit BhagatNoch keine Bewertungen

- Operating & Maintenance Manual Rotary Kiln Burner: Customer: XXXX Facility: XXXX UC Commission No.: XX/XXXXDokument18 SeitenOperating & Maintenance Manual Rotary Kiln Burner: Customer: XXXX Facility: XXXX UC Commission No.: XX/XXXXzain140Noch keine Bewertungen

- viewNitPdf 1454067Dokument8 SeitenviewNitPdf 1454067laxmiccNoch keine Bewertungen

- Finalised Mec-10001013-0-1Dokument6 SeitenFinalised Mec-10001013-0-1MUHAMMAD WARIS SQNoch keine Bewertungen

- Po SM InfraDokument5 SeitenPo SM InfraAvi DantkaleNoch keine Bewertungen

- Foundation For Roller PressDokument3 SeitenFoundation For Roller PressRollerJonny0% (1)

- Dailyprogress Report Nov 2016Dokument52 SeitenDailyprogress Report Nov 2016Vinod Kumar VermaNoch keine Bewertungen

- SpreadsheetDokument12 SeitenSpreadsheetBiji JacobNoch keine Bewertungen

- Limestone crusher, raw mill, and kiln equipment issuesDokument1 SeiteLimestone crusher, raw mill, and kiln equipment issuesSSAC PVT.LTD.Noch keine Bewertungen

- Project - Construction of Over Head ReservoirDokument9 SeitenProject - Construction of Over Head ReservoirAkash MallickNoch keine Bewertungen

- TG SPRING FOUNDATIONDokument9 SeitenTG SPRING FOUNDATIONkannanNoch keine Bewertungen

- Customer Complaints RegisterDokument7 SeitenCustomer Complaints RegisterdanielsasikumarNoch keine Bewertungen

- Box PushingDokument4 SeitenBox PushingNArendra REddy100% (3)

- Construction of Four Lane Fly OverDokument8 SeitenConstruction of Four Lane Fly Overvenkateswara rao Pothina100% (2)

- 35 (V) - Concrete PumpDokument9 Seiten35 (V) - Concrete PumpPrasanta ParidaNoch keine Bewertungen

- PDF 1Dokument5 SeitenPDF 1MR R C CLARKENoch keine Bewertungen

- British Graveyard ComplexDokument35 SeitenBritish Graveyard ComplexD.V.Srinivasa RaoNoch keine Bewertungen

- Wirtgen Recycling EquipmentsDokument12 SeitenWirtgen Recycling EquipmentsRaj Paulam GandhiNoch keine Bewertungen

- Overhauling of pumps, pipes and valves at Ranichak pumping stationDokument40 SeitenOverhauling of pumps, pipes and valves at Ranichak pumping stationTarunPatraNoch keine Bewertungen

- Bearing Spares (Capital Item) : JustificationDokument6 SeitenBearing Spares (Capital Item) : Justificationshani5573Noch keine Bewertungen

- Atlas Copco Hydraulic Feeds: BMH 2000 Series Technical DataDokument2 SeitenAtlas Copco Hydraulic Feeds: BMH 2000 Series Technical DataDuber Cáceres Malaver100% (2)

- 'Replacement of Corroded and Perforated Cross Girders of BR - NO.449 DNDokument11 Seiten'Replacement of Corroded and Perforated Cross Girders of BR - NO.449 DNgopi bhupathiNoch keine Bewertungen

- Cone CrusherDokument4 SeitenCone CrusherSam ShiddoNoch keine Bewertungen

- Ball Mill Liner ReplacementDokument26 SeitenBall Mill Liner ReplacementParmeshwar Nath Tripathi100% (1)

- JP For Bullet ErectionDokument7 SeitenJP For Bullet ErectionsshastrimechNoch keine Bewertungen

- Bhel Bearing ErectionDokument39 SeitenBhel Bearing ErectionASHUTOSH KUMAR100% (2)

- Plagiarism Scan Report: Plagiarised UniqueDokument3 SeitenPlagiarism Scan Report: Plagiarised UniqueAsr FlowerNoch keine Bewertungen

- About StetterDokument9 SeitenAbout Stettergsm.nkl6049Noch keine Bewertungen

- Ok Vertical Roller Mill V 3Dokument8 SeitenOk Vertical Roller Mill V 3Andra EneNoch keine Bewertungen

- Rotary Kiln - Refractory Lining InstallationDokument41 SeitenRotary Kiln - Refractory Lining InstallationNael94% (16)

- PSC Girder Bridge Construction - Construction of A Bridge-Bridge Construction MethodDokument16 SeitenPSC Girder Bridge Construction - Construction of A Bridge-Bridge Construction MethodVinay Raj100% (1)

- EV Hammer Impact Crusher Single Stage CrushingDokument7 SeitenEV Hammer Impact Crusher Single Stage CrushingMohamed ShehataNoch keine Bewertungen

- Shutdown Maintenance Raw Mill Section July 2017Dokument3 SeitenShutdown Maintenance Raw Mill Section July 2017vinodsnNoch keine Bewertungen

- Ahmed A'nasser Hitch ReportDokument3 SeitenAhmed A'nasser Hitch Reportmohamed hamedNoch keine Bewertungen

- AIXAM 500SL maintenance and service recordsDokument14 SeitenAIXAM 500SL maintenance and service recordsWarren GrayNoch keine Bewertungen

- PEX250í 1200 Instruction ManualDokument10 SeitenPEX250í 1200 Instruction ManualSebastian Aguila RaipanNoch keine Bewertungen

- Service Bulletin: CopierDokument2 SeitenService Bulletin: CopierMubasher AliNoch keine Bewertungen

- BBM ROAD SURFACE CONSTRUCTIONDokument21 SeitenBBM ROAD SURFACE CONSTRUCTIONVitthal BhideNoch keine Bewertungen

- Precast Driven R.C.C PileDokument3 SeitenPrecast Driven R.C.C PilePriodeep ChowdhuryNoch keine Bewertungen

- Kiln Support Roller Bearing ReplacementDokument6 SeitenKiln Support Roller Bearing ReplacementhaziqNoch keine Bewertungen

- Shut Down Progress Report Raw Mill:: Patch Work On Holes of Classifier Casing Was Carried OutDokument7 SeitenShut Down Progress Report Raw Mill:: Patch Work On Holes of Classifier Casing Was Carried Outzain140Noch keine Bewertungen

- Site Weekly Observation ReportDokument20 SeitenSite Weekly Observation Reportbra9tee9tiniNoch keine Bewertungen

- Refractory Installation Techniques in Cement Rotary KilnsDokument86 SeitenRefractory Installation Techniques in Cement Rotary KilnsMKPashaPasha88% (8)

- Cement Concrete Road: Strong, Durable & Noiseless SurfaceDokument8 SeitenCement Concrete Road: Strong, Durable & Noiseless SurfaceBiswanath PanigrahiNoch keine Bewertungen

- Khandala - Pipe - Line - Work - Phase 1 PDFDokument23 SeitenKhandala - Pipe - Line - Work - Phase 1 PDFborkarsd007Noch keine Bewertungen

- Esquire Builders Hoist Opt & Maint ManualDokument15 SeitenEsquire Builders Hoist Opt & Maint Manualmailme_viju100% (1)

- 2700 Wearings Coat and AppurtenancesDokument5 Seiten2700 Wearings Coat and Appurtenancesdhamu_i4uNoch keine Bewertungen

- Grouts & AnchorsDokument6 SeitenGrouts & Anchorseng_osamahazaymehNoch keine Bewertungen

- Review No 157Dokument7 SeitenReview No 157M.IBRAHEEMNoch keine Bewertungen

- GERB Spring Loaded DECK InfDokument14 SeitenGERB Spring Loaded DECK Infmohan_krishna372100% (1)

- Tunnel and Shaft SolutionsDokument48 SeitenTunnel and Shaft SolutionsMohamed H. Jiffry100% (3)

- Ash Handling PlantDokument6 SeitenAsh Handling Plantapumoni123Noch keine Bewertungen

- 70000905clinker Crusher (Peyvand)Dokument32 Seiten70000905clinker Crusher (Peyvand)hamid hoorshadNoch keine Bewertungen

- MOSAIC LINE 1 PART REPLACEMENT AND REPAIR 2018Dokument1 SeiteMOSAIC LINE 1 PART REPLACEMENT AND REPAIR 2018goblin horehoreNoch keine Bewertungen

- Lake Windcrest-3a 2021 Updated 5 26 21Dokument5 SeitenLake Windcrest-3a 2021 Updated 5 26 21frank SchulerNoch keine Bewertungen

- Pump Repair Report Details Equipment IssuesDokument16 SeitenPump Repair Report Details Equipment Issuesproject acsdNoch keine Bewertungen

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsVon EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNoch keine Bewertungen

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsVon EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsBewertung: 4 von 5 Sternen4/5 (1)

- Book 1 WDDokument1 SeiteBook 1 WDlaxman JoshiNoch keine Bewertungen

- Book 1Dokument1 SeiteBook 1laxman JoshiNoch keine Bewertungen

- Yp DFDokument1 SeiteYp DFlaxman JoshiNoch keine Bewertungen

- GhgfhsDokument1 SeiteGhgfhslaxman JoshiNoch keine Bewertungen

- Book 1Dokument1 SeiteBook 1laxman JoshiNoch keine Bewertungen

- Daily maintenance checklist for LS crusherDokument6 SeitenDaily maintenance checklist for LS crusherlaxman JoshiNoch keine Bewertungen

- Brief document notes and timesDokument1 SeiteBrief document notes and timeslaxman JoshiNoch keine Bewertungen

- Condition monitoring of raw mill sectionDokument2 SeitenCondition monitoring of raw mill sectionlaxman JoshiNoch keine Bewertungen

- Struct Steel - STD WtsDokument3 SeitenStruct Steel - STD WtsnayabaaNoch keine Bewertungen

- Struct Steel - STD WtsDokument3 SeitenStruct Steel - STD WtsnayabaaNoch keine Bewertungen

- Philippine Army BDU BidDokument2 SeitenPhilippine Army BDU BidMaria TeresaNoch keine Bewertungen

- Chapter 19 - 20 Continuous Change - Transorganizational ChangeDokument12 SeitenChapter 19 - 20 Continuous Change - Transorganizational ChangeGreen AvatarNoch keine Bewertungen

- Rubric 5th GradeDokument2 SeitenRubric 5th GradeAlbert SantosNoch keine Bewertungen

- GP Rating GSK Exit ExamDokument108 SeitenGP Rating GSK Exit ExamMicle VM100% (4)

- Speed Reducer GearboxDokument14 SeitenSpeed Reducer Gearboxعبد للهNoch keine Bewertungen

- Methods to estimate stakeholder views of sustainabilityDokument7 SeitenMethods to estimate stakeholder views of sustainabilityAlireza FatemiNoch keine Bewertungen

- Statistical Decision AnalysisDokument3 SeitenStatistical Decision AnalysisTewfic SeidNoch keine Bewertungen

- Draft SemestralWorK Aircraft2Dokument7 SeitenDraft SemestralWorK Aircraft2Filip SkultetyNoch keine Bewertungen

- SiloDokument7 SeitenSiloMayr - GeroldingerNoch keine Bewertungen

- CBT For BDDDokument13 SeitenCBT For BDDGregg Williams100% (5)

- Case Study IndieDokument6 SeitenCase Study IndieDaniel YohannesNoch keine Bewertungen

- Real Estate Broker ReviewerREBLEXDokument124 SeitenReal Estate Broker ReviewerREBLEXMar100% (4)

- MA1201 Calculus and Basic Linear Algebra II Solution of Problem Set 4Dokument10 SeitenMA1201 Calculus and Basic Linear Algebra II Solution of Problem Set 4Sit LucasNoch keine Bewertungen

- Exercise-01: JEE-PhysicsDokument52 SeitenExercise-01: JEE-Physicsjk rNoch keine Bewertungen

- Paper SizeDokument22 SeitenPaper SizeAlfred Jimmy UchaNoch keine Bewertungen

- Allan S. Cu v. Small Business Guarantee and FinanceDokument2 SeitenAllan S. Cu v. Small Business Guarantee and FinanceFrancis Coronel Jr.Noch keine Bewertungen

- Todo Matic PDFDokument12 SeitenTodo Matic PDFSharrife JNoch keine Bewertungen

- IELTS Speaking Q&ADokument17 SeitenIELTS Speaking Q&ABDApp Star100% (1)

- Gabinete STS Activity1Dokument2 SeitenGabinete STS Activity1Anthony GabineteNoch keine Bewertungen

- Anti Jamming of CdmaDokument10 SeitenAnti Jamming of CdmaVishnupriya_Ma_4804Noch keine Bewertungen

- WWW - Commonsensemedia - OrgDokument3 SeitenWWW - Commonsensemedia - Orgkbeik001Noch keine Bewertungen

- CTR Ball JointDokument19 SeitenCTR Ball JointTan JaiNoch keine Bewertungen

- Training Customer CareDokument6 SeitenTraining Customer Careyahya sabilNoch keine Bewertungen

- Indian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewDokument8 SeitenIndian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewPRINCIPAL BHILWARANoch keine Bewertungen

- Strategies For StartupDokument16 SeitenStrategies For StartupRoshankumar BalasubramanianNoch keine Bewertungen

- Big Joe Pds30-40Dokument198 SeitenBig Joe Pds30-40mauro garciaNoch keine Bewertungen

- Special Power of Attorney: Benedict Joseph M. CruzDokument1 SeiteSpecial Power of Attorney: Benedict Joseph M. CruzJson GalvezNoch keine Bewertungen

- Consensus Building e Progettazione Partecipata - Marianella SclaviDokument7 SeitenConsensus Building e Progettazione Partecipata - Marianella SclaviWilma MassuccoNoch keine Bewertungen

- Audi Q5: First Generation (Typ 8R 2008-2017)Dokument19 SeitenAudi Q5: First Generation (Typ 8R 2008-2017)roberto100% (1)

- Bula Defense M14 Operator's ManualDokument32 SeitenBula Defense M14 Operator's ManualmeNoch keine Bewertungen