Beruflich Dokumente

Kultur Dokumente

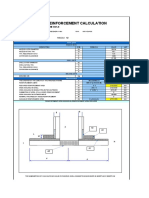

Hydrostatic Test Pressure Calculation: Pipe Data

Hochgeladen von

Akram AlhaddadOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hydrostatic Test Pressure Calculation: Pipe Data

Hochgeladen von

Akram AlhaddadCopyright:

Verfügbare Formate

Pipeline Engineering

Hydrostatic Test Pressure Calculation ver 0.0

https://pipeeng.com/hydrotest.html

Project ABC Project Developer PipeEng

Date 8/22/2019, 5:50:28 PM Approver

Revision 0 Reviewer

This tool was developed for test engineers and contractors to plan the pipeline hydrostatic test operation. The

elevation gradient, along with the location and volume of the water source, and the pipe design data should be

used to determine the length and number of test segments. The test gradient should be calculated to be sure

the test pressure falls within the specified pressure limits.

Pipe Data

Pipe Outer Diameter, OD inch 12.75

Line Pipe Wall Thickness, t inch 0.375

Line Pipe Grade, S psi 70000

Heavy Wall Pipe Wall Thickness, t' inch N/A

Heavy Wall Pipe Grade, S' psi N/A

Maximum Operating Pressure, MOP psig 1440

Pressure @ 1.10 * MOP psig 1584

Pressure @ 1.25 * MOP psig 1800

Pressure @ 1.40 * MOP psig 2016

Pressure @ 1.50 * MOP psig 2160

Pressure @ 80% SMYS psig 3294

Pressure @ 90% SMYS psig 3706

Pressure @ 100% SMYS psig 4118

Pressure @ 110% SMYS psig 4529

Pipe Profile

Test Segment Upstream Point Chainage, U/S ft 0

Test Segment Downstream Point Chainage, U/S ft 65,617

Test Segment Upstream Point Elevation, Eu ft 656.0

High Point Elevation, Eh ft 820.0

Low Point Elevation, El ft 623.0

Instrumentation Elevation, Ei ft 700.0

Test Segment Downstream Point Elevation, Ed ft 787.5

Test Segment Length, L ft 65,617

mile 51,535

Test Segment Volume, V ft³ 51,535

(Segment volume ignores heavy wall pipe volume reduction) gal 385,512

Calculated Water Volume for a Pressure Increase, ΔV ft³/psig 0.2

(Caclulated based on compressibility of water at 50°F) gal/psig 1.6

Estimated Squeeze Volume, Vs ft³ 974

(Caclulated based on pressure @ 110% SMYS) gal 7,284

0.2% Offset Volume For PV Plot, Vo ft³ 103

(When yield plotting is required) gal 771

Downloaded on 8/22/2019, 5:50:28 PM from pipeeng.com Page 1 of 2

Pipeline Engineering

Minimum Strength Test Pressure

Parameters psig % MOP % SMYS

High Point Pressure 1800 125.0 43.7

Test Segment Upstream Point Pressure 1871 129.9 45.4

Low Point Pressure (Line Pipe) 1885 130.9 45.8

Low Point Pressure (Heavy Wall Pipe) N/A N/A N/A

Instrumentation Pressure 1852 128.6 45.0

Test Segment Downstream Point Pressure 1814 126.0 44.1

Maximum Strength Test Pressure

Parameters psig % MOP % SMYS

Low Point Pressure (Line Pipe) 2757 191.5 67.0

Low Point Pressure (Heavy Wall Pipe) N/A N/A N/A

Test Segment Upstream Point Pressure 2743 190.5 66.6

High Point Pressure 2672 185.5 64.9

Instrumentation Pressure 2724 189.1 66.1

Test Segment Downstream Point Pressure 2686 186.5 65.2

Minimum Leak Test Pressure

Parameters psig % MOP % SMYS

High Point Pressure 1584 110.0 38.5

Test Segment Upstream Point Pressure 1655 114.9 40.2

Low Point Pressure (Line Pipe) 1669 115.9 40.5

Low Point Pressure (Heavy Wall Pipe) N/A N/A N/A

Instrumentation Pressure 1636 113.6 39.7

Test Segment Downstream Point Pressure 1598 111.0 38.8

Maximum Leak Test Pressure

Parameters psig % MOP % SMYS

Low Point Pressure (Line Pipe) 1844 128.1 44.8

Low Point Pressure (Heavy Wall Pipe) N/A N/A N/A

Test Segment Upstream Point Pressure 1830 127.1 44.4

High Point Pressure 1759 122.1 42.7

Instrumentation Pressure 1811 125.7 44.0

Test Segment Downstream Point Pressure 1773 123.1 43.1

Downloaded on 8/22/2019, 5:50:28 PM from pipeeng.com Page 2 of 2

Das könnte Ihnen auch gefallen

- Anchor Flange Calculation stresses verifiedDokument3 SeitenAnchor Flange Calculation stresses verifiedLizbeth Fiallos AvilaNoch keine Bewertungen

- TES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)Dokument19 SeitenTES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)BetoCostaNoch keine Bewertungen

- 4 2500 (F347H)Dokument2 Seiten4 2500 (F347H)siddhesh_guessNoch keine Bewertungen

- Heat Flow During GTA Welding of PipesDokument7 SeitenHeat Flow During GTA Welding of Pipesabraham silva hernandezNoch keine Bewertungen

- Petroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputDokument5 SeitenPetroleum Development Oman LLC: Appendix-2: Pipe Stress Analysis Checklist-Input/OutputAbhijeetNoch keine Bewertungen

- Welding Parameter Sheet - PQR - TemplateDokument1 SeiteWelding Parameter Sheet - PQR - TemplatevalararumugamsNoch keine Bewertungen

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDokument5 SeitenASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNoch keine Bewertungen

- DOT Pipeline SpecificationsDokument20 SeitenDOT Pipeline Specificationssect349Noch keine Bewertungen

- Test Report Long-Term Ring Bending Strain (SB)Dokument4 SeitenTest Report Long-Term Ring Bending Strain (SB)Diana QuinteroNoch keine Bewertungen

- Calc Hoop StressDokument11 SeitenCalc Hoop StressApril TrevinoNoch keine Bewertungen

- Dike Wall Height Calculation Sheet OptimizationDokument7 SeitenDike Wall Height Calculation Sheet OptimizationSaqib LaeeqNoch keine Bewertungen

- Easyflex Flexible Hose DatasheetDokument2 SeitenEasyflex Flexible Hose DatasheetzassssNoch keine Bewertungen

- Evaluation of Flanged Connections Due To Piping L.oaoDokument9 SeitenEvaluation of Flanged Connections Due To Piping L.oaoSJNoch keine Bewertungen

- Actuated Ball Valve 357 D - BDKDokument4 SeitenActuated Ball Valve 357 D - BDKfarhanakhtar ansariNoch keine Bewertungen

- PSV Reaction Force - Closed SystemDokument5 SeitenPSV Reaction Force - Closed SystemWayne MonneryNoch keine Bewertungen

- Hot Tapping Split Tee SpecificationDokument19 SeitenHot Tapping Split Tee SpecificationAli ClubistNoch keine Bewertungen

- Pipe Stress AnalysisDokument72 SeitenPipe Stress AnalysisarvapoNoch keine Bewertungen

- API 650 Baseplate DesignDokument3 SeitenAPI 650 Baseplate DesignmjlazoNoch keine Bewertungen

- (0209) 031801Dokument12 Seiten(0209) 031801Sixto Gerardo Oña AnaguanoNoch keine Bewertungen

- Fault Data Request Form: Customer / Requestor SectionDokument1 SeiteFault Data Request Form: Customer / Requestor SectionRaphael212219100% (1)

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetDokument1 SeitePY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540Noch keine Bewertungen

- Design and Analysis of Piping System With Supports Using CAESAR-IIDokument5 SeitenDesign and Analysis of Piping System With Supports Using CAESAR-IIincaurcoNoch keine Bewertungen

- Vortex Shedding Load On PipingDokument1 SeiteVortex Shedding Load On Pipingananyo_sengupta100% (1)

- 8 AS4041 ASME B31 3 Pipe Wall ThicknessDokument8 Seiten8 AS4041 ASME B31 3 Pipe Wall ThicknessĐinh Thiện SỹNoch keine Bewertungen

- Wall Thickness Calculation Followed B31.8 PDFDokument3 SeitenWall Thickness Calculation Followed B31.8 PDFBPCL HCULOBS100% (1)

- Estudo de Caso - Asme 2398Dokument6 SeitenEstudo de Caso - Asme 2398biancogallazziNoch keine Bewertungen

- Insulation Joint PDFDokument7 SeitenInsulation Joint PDFBabatunde OlalekanNoch keine Bewertungen

- Calculation of PipeReinforcement ASMEB31 1Dokument4 SeitenCalculation of PipeReinforcement ASMEB31 1threedlabsNoch keine Bewertungen

- FEA On ThermowellDokument4 SeitenFEA On Thermowellvaisakp777Noch keine Bewertungen

- Asme B31.8 Nozzles CalcDokument16 SeitenAsme B31.8 Nozzles CalcSAMER OSMANNoch keine Bewertungen

- Pipe Support Load Calculation SheetDokument3 SeitenPipe Support Load Calculation SheetHassan Muhammad TundeNoch keine Bewertungen

- Cross Country Piping Stress AnalysisDokument8 SeitenCross Country Piping Stress Analysisprabu2001Noch keine Bewertungen

- Application of Bellows Expansion Joints in Piping SystemDokument5 SeitenApplication of Bellows Expansion Joints in Piping Systemjlcheefei9258Noch keine Bewertungen

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDokument49 SeitenDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536Noch keine Bewertungen

- Inputs Required For FIV & AIV StudyDokument1 SeiteInputs Required For FIV & AIV StudyRonak MotaNoch keine Bewertungen

- Material and anchor load data for steel pipeDokument4 SeitenMaterial and anchor load data for steel pipeMichael RobinsonNoch keine Bewertungen

- Code Construction: ASME B16.49 (Induction Bend) Outside Diameter O.D. (MM) Angle Bending Ø Tangent Length at Each End Wall Thickness (MM)Dokument4 SeitenCode Construction: ASME B16.49 (Induction Bend) Outside Diameter O.D. (MM) Angle Bending Ø Tangent Length at Each End Wall Thickness (MM)Edwardhutauruk100% (1)

- SIF Calculation For Piping ConnectionsDokument6 SeitenSIF Calculation For Piping ConnectionsManuelNoch keine Bewertungen

- INTERNAL PRESSURE CALCULATIONS FOR PIPING & PIPELINESDokument89 SeitenINTERNAL PRESSURE CALCULATIONS FOR PIPING & PIPELINESCastro Quinteros WinstonNoch keine Bewertungen

- EPM-GL-PI-CLC-0004 - Rev 0 - Slug Flow Force CalculationDokument4 SeitenEPM-GL-PI-CLC-0004 - Rev 0 - Slug Flow Force CalculationHernán DazaNoch keine Bewertungen

- Ansi b31.3 Allowable StressDokument2 SeitenAnsi b31.3 Allowable StressTsouki Tsouki100% (2)

- Data Sheet For Barred Tee 010719 PDFDokument1 SeiteData Sheet For Barred Tee 010719 PDFkandraNoch keine Bewertungen

- LiquidDokument2 SeitenLiquidsiddhesh_guessNoch keine Bewertungen

- PSV Reaction Force CalculationDokument2 SeitenPSV Reaction Force CalculationSuthanNoch keine Bewertungen

- Flange Leakage 6Dokument2 SeitenFlange Leakage 6hamid sobirinNoch keine Bewertungen

- Igat6 D PL Me SPC 0007 01 Spec For Barred TeeDokument9 SeitenIgat6 D PL Me SPC 0007 01 Spec For Barred Teeamini_mohi100% (1)

- Sampling Cylinder Thickness Calculation As Per B31.8Dokument4 SeitenSampling Cylinder Thickness Calculation As Per B31.8SathiyaseelanNoch keine Bewertungen

- Hot TapDokument1 SeiteHot TapDavid Rios CruzNoch keine Bewertungen

- Modern Flange Design BulletinDokument45 SeitenModern Flange Design BulletinIgorToporsky100% (1)

- Hot Tap Construction StandardDokument12 SeitenHot Tap Construction StandardgfgfNoch keine Bewertungen

- TBE-Pressure Vessel Standard TemplateDokument4 SeitenTBE-Pressure Vessel Standard TemplateSiva baalanNoch keine Bewertungen

- JAG Neway Ball Valves PDFDokument32 SeitenJAG Neway Ball Valves PDFprsiva2420034066Noch keine Bewertungen

- Technical DataDokument48 SeitenTechnical Datashekhar2681Noch keine Bewertungen

- Pipeline CrossingDokument2 SeitenPipeline CrossingRobby TriNoch keine Bewertungen

- API RP 1102 Pipeline Crossing Calculations: Input DataDokument2 SeitenAPI RP 1102 Pipeline Crossing Calculations: Input DataCHANADAS50% (4)

- API RP 1102 Pipeline Crossing Calculations: Input DataDokument2 SeitenAPI RP 1102 Pipeline Crossing Calculations: Input Datapatrick6364Noch keine Bewertungen

- Emerson Automation Solutions 3950 Greenbriar Stafford TX, 77477 United States (281) 274-4400 Quote NumberDokument2 SeitenEmerson Automation Solutions 3950 Greenbriar Stafford TX, 77477 United States (281) 274-4400 Quote Numberdiego veyzagaNoch keine Bewertungen

- Ancor Flanges Asme ViiiDokument3 SeitenAncor Flanges Asme ViiiAnjani PrabhakarNoch keine Bewertungen

- You May Continue To Read On CSWIP 3.1: Question With Answer and Explanation - Part 2Dokument12 SeitenYou May Continue To Read On CSWIP 3.1: Question With Answer and Explanation - Part 2Akram AlhaddadNoch keine Bewertungen

- Welding Procedures and Welders WG01 7th November 2012Dokument18 SeitenWelding Procedures and Welders WG01 7th November 2012RamanujadaasanNoch keine Bewertungen

- AbstractDokument7 SeitenAbstractAkram AlhaddadNoch keine Bewertungen

- Portable Digital X-Ray Systems For Security Applica Ons - PDFDokument3 SeitenPortable Digital X-Ray Systems For Security Applica Ons - PDFAkram AlhaddadNoch keine Bewertungen

- Welding Procedures and Welders WG01 7th November 2012Dokument18 SeitenWelding Procedures and Welders WG01 7th November 2012RamanujadaasanNoch keine Bewertungen

- 39 - A and F Classification NumbersDokument1 Seite39 - A and F Classification NumbersAkram AlhaddadNoch keine Bewertungen

- Inspection and Welding Repairs of Pressure VesselsDokument9 SeitenInspection and Welding Repairs of Pressure VesselsClaudia Mms100% (1)

- Welding Procedures and Welders WG01 7th November 2012Dokument18 SeitenWelding Procedures and Welders WG01 7th November 2012RamanujadaasanNoch keine Bewertungen

- Welding Procedures and Welders WG01 7th November 2012Dokument18 SeitenWelding Procedures and Welders WG01 7th November 2012RamanujadaasanNoch keine Bewertungen

- Inspection and Welding Repairs of Pressure VesselsDokument9 SeitenInspection and Welding Repairs of Pressure VesselsClaudia Mms100% (1)

- AbstractDokument7 SeitenAbstractAkram AlhaddadNoch keine Bewertungen

- AbstractDokument7 SeitenAbstractAkram AlhaddadNoch keine Bewertungen

- Check Liste de Verification WpsDokument2 SeitenCheck Liste de Verification WpsAkram AlhaddadNoch keine Bewertungen

- Xrs4 20v Specsheet FB June2018Dokument2 SeitenXrs4 20v Specsheet FB June2018Akram AlhaddadNoch keine Bewertungen

- 10 Questions To Ask When Choosing A Phased Array Probe 170203205027Dokument1 Seite10 Questions To Ask When Choosing A Phased Array Probe 170203205027Akram AlhaddadNoch keine Bewertungen

- {347CDC53-D5E5-42B1-9A3A-58E9CCD3C01D}Dokument9 Seiten{347CDC53-D5E5-42B1-9A3A-58E9CCD3C01D}Mayur PatelNoch keine Bewertungen

- Check Liste de Verification WpsDokument2 SeitenCheck Liste de Verification WpsAkram AlhaddadNoch keine Bewertungen

- Hydrotest FormulaDokument17 SeitenHydrotest FormulaEarnest007100% (2)

- Woc Hse Manual Standards: Woc LP EP DepartmentDokument12 SeitenWoc Hse Manual Standards: Woc LP EP DepartmentAkram AlhaddadNoch keine Bewertungen

- 2-Technical Data Sheet- Marathon IQ GF (500μm)Dokument8 Seiten2-Technical Data Sheet- Marathon IQ GF (500μm)Akram AlhaddadNoch keine Bewertungen

- Woc Hse Manual Standards: Woc LP EP DepartmentDokument12 SeitenWoc Hse Manual Standards: Woc LP EP DepartmentAkram AlhaddadNoch keine Bewertungen

- Technical Data Sheet Baltoflake EcolifeDokument5 SeitenTechnical Data Sheet Baltoflake EcolifeAkram AlhaddadNoch keine Bewertungen

- Post Weld Heat Treatment ProcedureDokument9 SeitenPost Weld Heat Treatment ProcedureAkram AlhaddadNoch keine Bewertungen

- 3-Jotun Thinner No. 17Dokument2 Seiten3-Jotun Thinner No. 17Akram AlhaddadNoch keine Bewertungen

- Woc Hse Manual Standards: Woc LP EP DepartmentDokument12 SeitenWoc Hse Manual Standards: Woc LP EP DepartmentAkram AlhaddadNoch keine Bewertungen

- Technical Data Sheet for Penguard HB Epoxy CoatingDokument5 SeitenTechnical Data Sheet for Penguard HB Epoxy Coatinghardik033Noch keine Bewertungen

- Test - Mmet 402, Exam 2, Ultrasonic Testing - QuizletDokument49 SeitenTest - Mmet 402, Exam 2, Ultrasonic Testing - QuizletAkram AlhaddadNoch keine Bewertungen

- Follow HereDokument18 SeitenFollow HereAkram Alhaddad100% (1)

- Test - API 1169 - QuizletDokument13 SeitenTest - API 1169 - QuizletAkram Alhaddad0% (1)

- Uji Coba Aplikasi Pemanenan Air Hujan Dan Sumur Resapan Di Wilayah Bogor, Depok Dan JakartaDokument11 SeitenUji Coba Aplikasi Pemanenan Air Hujan Dan Sumur Resapan Di Wilayah Bogor, Depok Dan JakartaJoko NugrohoNoch keine Bewertungen

- Water FilterDokument3 SeitenWater FilterMohamad Singer محمد سنجرNoch keine Bewertungen

- Pe-501003-009 STPDokument9 SeitenPe-501003-009 STPJeyakumar ArumugamNoch keine Bewertungen

- Salt Concentration: Fresh WaterDokument31 SeitenSalt Concentration: Fresh WaterAli Raza (Alee)Noch keine Bewertungen

- Perhitungan Data Efisiensy PolytropicDokument4 SeitenPerhitungan Data Efisiensy PolytropicPlant DrainNoch keine Bewertungen

- Fluid Mechanics: Presentation By:-Mohammad Hammad JoufarDokument14 SeitenFluid Mechanics: Presentation By:-Mohammad Hammad JoufarHammad JoufarNoch keine Bewertungen

- Water GasDokument3 SeitenWater GaschristopheNoch keine Bewertungen

- Centrifugal Compressor ReportDokument92 SeitenCentrifugal Compressor Reportبلال محمودNoch keine Bewertungen

- Solutions For Heat Transfer Quiz-II: D. Height of The CylinderDokument2 SeitenSolutions For Heat Transfer Quiz-II: D. Height of The CylindermkvemulaNoch keine Bewertungen

- Slimline PDFDokument40 SeitenSlimline PDFmmmitchNoch keine Bewertungen

- Conversion of Wet Flow Rate To Dry Flow Rate Bruce Burton, Research and Development Manager 10-15-1999Dokument3 SeitenConversion of Wet Flow Rate To Dry Flow Rate Bruce Burton, Research and Development Manager 10-15-1999Victor VazquezNoch keine Bewertungen

- Reservoir Drive MechanismsDokument36 SeitenReservoir Drive MechanismsUsman HasanNoch keine Bewertungen

- Regulador EQA-722Dokument4 SeitenRegulador EQA-722Ronan CristhiamNoch keine Bewertungen

- Practical-Characteristics of Waste WaterDokument19 SeitenPractical-Characteristics of Waste WatersarfaNoch keine Bewertungen

- AutoCAD PID 2011 Features and BenefitsDokument5 SeitenAutoCAD PID 2011 Features and BenefitsIfeanyi Ezemonye-AgwuegboNoch keine Bewertungen

- Part 6 Skin Factor and Its ComponentsDokument34 SeitenPart 6 Skin Factor and Its ComponentsChai Cws100% (2)

- Compressible Flow Through Convergent and Laval NozzlesDokument10 SeitenCompressible Flow Through Convergent and Laval NozzlesIshwar SinghNoch keine Bewertungen

- Solucionario Química Capitulo 12 - Whitten - 10 EdiciónDokument21 SeitenSolucionario Química Capitulo 12 - Whitten - 10 EdiciónDanielNoch keine Bewertungen

- Pressure Measurement DevicesDokument27 SeitenPressure Measurement Devices翁绍棠Noch keine Bewertungen

- Tutorial Problems StatementDokument21 SeitenTutorial Problems StatementAbni AbhiNoch keine Bewertungen

- USA Heat Transfer EtcDokument9 SeitenUSA Heat Transfer EtcFernan Macusi0% (1)

- Situ Ciharus Potential for Water Supply and MicrohydroDokument12 SeitenSitu Ciharus Potential for Water Supply and MicrohydrodonichimaruNoch keine Bewertungen

- Fluid Pressure Measurement PDFDokument51 SeitenFluid Pressure Measurement PDFNateNoch keine Bewertungen

- Water and Living OrganismsDokument4 SeitenWater and Living OrganismsVeiliLookNoch keine Bewertungen

- ENV ENG - " Design of Sewer System "Dokument10 SeitenENV ENG - " Design of Sewer System "anon_702179917Noch keine Bewertungen

- Pumps - 1Dokument9 SeitenPumps - 1PrashantNoch keine Bewertungen

- Biogas For Print Model 2Dokument1 SeiteBiogas For Print Model 2Berns DulamNoch keine Bewertungen

- Gas Condensate Reservoir Properties and CalculationsDokument14 SeitenGas Condensate Reservoir Properties and CalculationsAnonymous nztG1AGvNoch keine Bewertungen

- The Difference Between Solid, Liquid, and Gaseous StatesDokument9 SeitenThe Difference Between Solid, Liquid, and Gaseous StatesFikriZalsyaNoch keine Bewertungen

- Upgrading Plant List 2014Dokument29 SeitenUpgrading Plant List 2014olliehortonNoch keine Bewertungen