Beruflich Dokumente

Kultur Dokumente

Thapar Institute of Engg. & Tech., Patiala: Roll Number

Hochgeladen von

GaurangiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Thapar Institute of Engg. & Tech., Patiala: Roll Number

Hochgeladen von

GaurangiCopyright:

Verfügbare Formate

Roll Number:

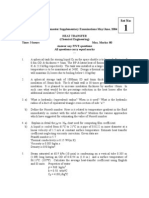

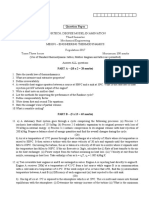

Thapar Institute of Engg. & Tech., Patiala

Department Chemical Engineering

BE-Chemical (Yr Semester) MST UCH605: Process Utility and

Industrial Safety

13m March, 2019

Time: 2 Hours; MM: 30 Name of Faculty:

Rakesh Kumar Gupta

Notes: Answer all the questions. Use of steam table and psychometric chart is allowed.

Assume suitable data or assumptions, if required. Draw neat diagrams as required.

Question description M.M.

Q. No.

1(a) What are different uses of steam generation? Classify boilers according to 4

relative position of hot gases and water, method of firing and nature of heat

source to be used.

1(b) A boiler generates steam at 98.1 kPa and 200°C from feed water at 37°C. The 4

coal used in furnace has a calorific value of 33681 kJ/kg and 10 kg steam is

generated per kg of coal burned. If 250 kg of coal is fired per hour, what will

be the boiler efficiency?

2(a) What is the use of jet ejectors in any process industry? Completely discuss 4

working of a steam jet ejector with help of suitable diagram.

2(b) Air at 290 K is compressed from 101.3 kPa to 2065 kPa in a two stage 6

p pt 25

compressor operating with a mechanical efficiency of 85%. The relationi

= constant applies during compression stages. The compression ratio in each of

stages is same. Calculate the work required for compression of per kg of air

compressed.

3(a) What do you understand by hardness in water? What different types of hardness 4

are present in water? How water hardness can be removed from water? Discuss.

3(b) Air at a temperature of 37.8°C, pressure of 101.3 kPa and relative humidity of 5

52% is passed into a cooling tower. Air exits tower at temperature of 48.9°C

and relative humidity of 84%. Calculate the rate of water evaporation from

cooling tower if dry air flow rate is 28.3 m3/s in the tower.

Write short notes on followings: 1.5

4

marks

a) Steam traps

each

b) Different uses of water in process industry

Page 1 of 1

Das könnte Ihnen auch gefallen

- 3565 - GUG-W-16-5398 - Year - B.E. (With Credits) - Regular-Semester 2012 - Mechanical Engineering Sem VI Subject - ME604 - Thermal EngineeringDokument2 Seiten3565 - GUG-W-16-5398 - Year - B.E. (With Credits) - Regular-Semester 2012 - Mechanical Engineering Sem VI Subject - ME604 - Thermal EngineeringYash BeleNoch keine Bewertungen

- rr310303 Thermal Engineering IIDokument8 Seitenrr310303 Thermal Engineering IISrinivasa Rao GNoch keine Bewertungen

- Final Exam Set A Cpd30303 July2020 081220 CompleteDokument10 SeitenFinal Exam Set A Cpd30303 July2020 081220 CompleteAzhan FikriNoch keine Bewertungen

- 62235-mt - Thermal Power PlantsDokument2 Seiten62235-mt - Thermal Power PlantsSRINIVASA RAO GANTANoch keine Bewertungen

- r05222103 ThermodynamicsDokument8 Seitenr05222103 ThermodynamicsSRINIVASA RAO GANTANoch keine Bewertungen

- r05322303 Heat Transfer in Bio ProcessorsDokument7 Seitenr05322303 Heat Transfer in Bio ProcessorsSRINIVASA RAO GANTANoch keine Bewertungen

- Thermal EngineeringDokument8 SeitenThermal Engineeringboppana sujwalNoch keine Bewertungen

- Assignment L01 (Thursday, 11.30 Am)Dokument9 SeitenAssignment L01 (Thursday, 11.30 Am)MawareNoch keine Bewertungen

- Code - No: 35089: Jawaharlal Nehru Technological University HyderabadDokument6 SeitenCode - No: 35089: Jawaharlal Nehru Technological University HyderabadSRINIVASA RAO GANTANoch keine Bewertungen

- Sample Question Paper Thermal EngineeringDokument5 SeitenSample Question Paper Thermal Engineeringरितेश हरोडेNoch keine Bewertungen

- WWW - Manaresults.Co - In: II B. Tech I Semester Regular/Supplementary Examinations, October/November - 2018 ThermodynamicsDokument8 SeitenWWW - Manaresults.Co - In: II B. Tech I Semester Regular/Supplementary Examinations, October/November - 2018 Thermodynamicsashoku24007Noch keine Bewertungen

- Department of Electrical and Electronic EngineeringDokument2 SeitenDepartment of Electrical and Electronic EngineeringSourav RoyNoch keine Bewertungen

- Sr059210304 ThermodynamicsDokument8 SeitenSr059210304 ThermodynamicsandhracollegesNoch keine Bewertungen

- Power Plant EngineeringDokument4 SeitenPower Plant EngineeringKishore KrishNoch keine Bewertungen

- Rajiv Gandhi University of Knowledge Technologies, Basar Mechanical EngineeringDokument7 SeitenRajiv Gandhi University of Knowledge Technologies, Basar Mechanical EngineeringPunith YadavNoch keine Bewertungen

- 15P403 May18Dokument3 Seiten15P403 May18Aakhil FizanNoch keine Bewertungen

- rr310303 Thermal Engineering IIDokument9 Seitenrr310303 Thermal Engineering IISRINIVASA RAO GANTANoch keine Bewertungen

- Jntu Kakinada - B.tech - Thermal Engineering II r13 Rt31035112017 FR 744Dokument8 SeitenJntu Kakinada - B.tech - Thermal Engineering II r13 Rt31035112017 FR 744NAGA PAVAN KUMAR ANoch keine Bewertungen

- rr221403 Thermal Engineering and Heat TransferDokument8 Seitenrr221403 Thermal Engineering and Heat TransferSRINIVASA RAO GANTANoch keine Bewertungen

- 07 r059210304 ThermodynamicsDokument8 Seiten07 r059210304 ThermodynamicsandhracollegesNoch keine Bewertungen

- Rr210304 ThermodynamicsDokument8 SeitenRr210304 ThermodynamicsSrinivasa Rao G100% (1)

- 23.end Sem Question Paper - BMEL-405 2016-17Dokument2 Seiten23.end Sem Question Paper - BMEL-405 2016-17Manish SharmaNoch keine Bewertungen

- Heat Transfer May2004 NR 310803Dokument8 SeitenHeat Transfer May2004 NR 310803Nizam Institute of Engineering and Technology LibraryNoch keine Bewertungen

- rr310804 Mass Transfer Operations IDokument8 Seitenrr310804 Mass Transfer Operations ISRINIVASA RAO GANTANoch keine Bewertungen

- THERMODYNAMICS Oct-Nov 2019Dokument8 SeitenTHERMODYNAMICS Oct-Nov 2019Karthik CruiseNoch keine Bewertungen

- Heat Transfer: B.Tech. (Chemical Engineering) Fifth Semester (C.B.S.)Dokument2 SeitenHeat Transfer: B.Tech. (Chemical Engineering) Fifth Semester (C.B.S.)Anurag TalwekarNoch keine Bewertungen

- Refrigeration & Air Conditioning: III B. Tech II Semester Regular Examinations, April/May-2019Dokument8 SeitenRefrigeration & Air Conditioning: III B. Tech II Semester Regular Examinations, April/May-2019srinivasNoch keine Bewertungen

- R07 Set No. 2Dokument8 SeitenR07 Set No. 2JanneNoch keine Bewertungen

- 1 - DMX9402 - Thermal Energy Utilities (TEU) - LMS Assignment 1 - 2022Dokument3 Seiten1 - DMX9402 - Thermal Energy Utilities (TEU) - LMS Assignment 1 - 2022abhishakeNoch keine Bewertungen

- 2016 August N6 Power MachinesDokument11 Seiten2016 August N6 Power MachinesPino PinoNoch keine Bewertungen

- Thermal EngineeringDokument1 SeiteThermal EngineeringSoumya BsoumyaNoch keine Bewertungen

- Assignment 1Dokument3 SeitenAssignment 1MaJasmineMayeNoch keine Bewertungen

- Heat Transfer Jan2003 NR 320305Dokument8 SeitenHeat Transfer Jan2003 NR 320305Nizam Institute of Engineering and Technology LibraryNoch keine Bewertungen

- Engineering ChemistryDokument5 SeitenEngineering Chemistryapi-26349602Noch keine Bewertungen

- Stucor Qp-Me8595Dokument9 SeitenStucor Qp-Me8595MS CreationsNoch keine Bewertungen

- NR-222001-Thermal Engineering and Heat TransferDokument8 SeitenNR-222001-Thermal Engineering and Heat TransferSrinivasa Rao GNoch keine Bewertungen

- Thapar University, Patiala Department of Chemical Engineering B.E. - CHE (IV - Semester) MSEDokument2 SeitenThapar University, Patiala Department of Chemical Engineering B.E. - CHE (IV - Semester) MSEazsdxNoch keine Bewertungen

- IES 1988 - CONV - EditedDokument7 SeitenIES 1988 - CONV - EditedAyush NarayanNoch keine Bewertungen

- R16 Aug 2021Dokument2 SeitenR16 Aug 2021Md. SunmunNoch keine Bewertungen

- Gujarat Technological UniversityDokument3 SeitenGujarat Technological Universityfeyayel988Noch keine Bewertungen

- December 2011 (See Also March 2011)Dokument3 SeitenDecember 2011 (See Also March 2011)Prosit ChakrabortyNoch keine Bewertungen

- r05220304 Thermal Engineering IDokument8 Seitenr05220304 Thermal Engineering ISrinivasa Rao G100% (2)

- 136EB052019Dokument3 Seiten136EB052019Naveen niratkarNoch keine Bewertungen

- 8.assignment Tutorial QPDokument13 Seiten8.assignment Tutorial QPvsureshkannanmsecNoch keine Bewertungen

- Icam (Lille) - Heat Exchanger Course Icam 2 - Autumn 2003 Heat Exchanger Examples - Sheet 2Dokument3 SeitenIcam (Lille) - Heat Exchanger Course Icam 2 - Autumn 2003 Heat Exchanger Examples - Sheet 2FahmiRamdanNoch keine Bewertungen

- r05312002 Power Plant and Turbo MachineryDokument8 Seitenr05312002 Power Plant and Turbo MachineryRafael ContrerasNoch keine Bewertungen

- WWW - Manaresults.co - In: II B. Tech I Semester Supplementary Examinations, May - 2019 ThermodynamicsDokument1 SeiteWWW - Manaresults.co - In: II B. Tech I Semester Supplementary Examinations, May - 2019 Thermodynamicsashoku24007Noch keine Bewertungen

- ME8595 Thermal Engineering IIDokument4 SeitenME8595 Thermal Engineering IIHarry HarryNoch keine Bewertungen

- Me8391 - EtdDokument3 SeitenMe8391 - Etdsyed1188Noch keine Bewertungen

- Continuous Assessment Test - IDokument8 SeitenContinuous Assessment Test - IAkash SharmaNoch keine Bewertungen

- 4 Thermodynamics Nov2004 NR 21030Dokument8 Seiten4 Thermodynamics Nov2004 NR 21030Nizam Institute of Engineering and Technology LibraryNoch keine Bewertungen

- NR-410305 - Refrigeration and Air ConditioningDokument8 SeitenNR-410305 - Refrigeration and Air ConditioningSrinivasa Rao GNoch keine Bewertungen

- B) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed SuitablyDokument2 SeitenB) All Sub-Parts of A Question Must Be Answered at One Place Only, Otherwise It Will Not Be Valued. C) Missing Data Can Be Assumed Suitablymilan mottaNoch keine Bewertungen

- 07 r05310306 Thermal Engineering IIDokument8 Seiten07 r05310306 Thermal Engineering IIandhracollegesNoch keine Bewertungen

- Heat Transfer in Polymer Composite Materials: Forming ProcessesVon EverandHeat Transfer in Polymer Composite Materials: Forming ProcessesNicolas BoyardNoch keine Bewertungen

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentVon EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNoch keine Bewertungen

- Membrane Processes: Pervaporation, Vapor Permeation and Membrane Distillation for Industrial Scale SeparationsVon EverandMembrane Processes: Pervaporation, Vapor Permeation and Membrane Distillation for Industrial Scale SeparationsNoch keine Bewertungen

- Process Intensification for Sustainable Energy ConversionVon EverandProcess Intensification for Sustainable Energy ConversionNoch keine Bewertungen

- Auxiliary Examination (Feb. 2020 PDFDokument2 SeitenAuxiliary Examination (Feb. 2020 PDFGaurangiNoch keine Bewertungen

- Leeds AnalystsDokument3 SeitenLeeds AnalystsGaurangiNoch keine Bewertungen

- Thapar Institute of Engg. & Tech., Patiala: Roll NumberDokument1 SeiteThapar Institute of Engg. & Tech., Patiala: Roll NumberGaurangiNoch keine Bewertungen

- WorkSheet 6Dokument2 SeitenWorkSheet 6GaurangiNoch keine Bewertungen

- Thapar Institute of Engg. & Tech., Patiala: Roll NumberDokument1 SeiteThapar Institute of Engg. & Tech., Patiala: Roll NumberGaurangiNoch keine Bewertungen

- Vortex Flow Meters Pros and ConsDokument1 SeiteVortex Flow Meters Pros and ConsMuh_HesanNoch keine Bewertungen

- LF CL Brochure 2019Dokument4 SeitenLF CL Brochure 2019indra putraNoch keine Bewertungen

- Repair ListDokument36 SeitenRepair ListRizky SkrillexNoch keine Bewertungen

- Topic 1 ACMVDokument21 SeitenTopic 1 ACMVEmi ArisNoch keine Bewertungen

- Piping Pressure TestingDokument22 SeitenPiping Pressure TestingHadisupriadi100% (4)

- Water Pump QuotationDokument2 SeitenWater Pump QuotationWAN CHANDNoch keine Bewertungen

- 3AS 38320 App. Water Steam Diagram SFBW2728226SATFGDokument1 Seite3AS 38320 App. Water Steam Diagram SFBW2728226SATFGRabindranath Hendy TagoreNoch keine Bewertungen

- Valves & Fittings Question - 02Dokument3 SeitenValves & Fittings Question - 02mohamed elmasry100% (1)

- Method Statement FF Piping System Pipes - DotxDokument9 SeitenMethod Statement FF Piping System Pipes - DotxBader ShrbajiNoch keine Bewertungen

- TP 400levelDokument14 SeitenTP 400levelEmmanuelNoch keine Bewertungen

- IWCF WI Completion-Geo B&WDokument92 SeitenIWCF WI Completion-Geo B&WTuesou MachereNoch keine Bewertungen

- PDMF Filter Blower - TrainingDokument33 SeitenPDMF Filter Blower - TrainingCristian VegaNoch keine Bewertungen

- 60004d14608b8 Casappa Product Catalogue PDFDokument38 Seiten60004d14608b8 Casappa Product Catalogue PDFRafaelNoch keine Bewertungen

- 2021 Multi Split Catalogue Final MayDokument24 Seiten2021 Multi Split Catalogue Final MayMinh Phát Điều HoàNoch keine Bewertungen

- IHP Assignment On Unit 2Dokument1 SeiteIHP Assignment On Unit 2Tejas HambirNoch keine Bewertungen

- Hvac PDFDokument1 SeiteHvac PDFKoteswara RaoNoch keine Bewertungen

- 355GF Data Sheet US - MetricDokument2 Seiten355GF Data Sheet US - Metricminov minovitchNoch keine Bewertungen

- Airlift Geyser PumpDokument4 SeitenAirlift Geyser PumpAchmad RidhonyNoch keine Bewertungen

- Linseal Pump Instructions - EnglishDokument1 SeiteLinseal Pump Instructions - Englishms375Noch keine Bewertungen

- Sample Cylinders and Accessories enDokument13 SeitenSample Cylinders and Accessories enmoh_ichwanuddinNoch keine Bewertungen

- Pressure Reliefe DevicesDokument12 SeitenPressure Reliefe DevicesMuhammad GhufranNoch keine Bewertungen

- Advanced Production Engineering Chapter # 2 Choke PerformanceDokument50 SeitenAdvanced Production Engineering Chapter # 2 Choke PerformanceRaghadaNoch keine Bewertungen

- Hydraulic Control ROLCOX of The Rolls: Left RightDokument20 SeitenHydraulic Control ROLCOX of The Rolls: Left Rightiamprashantsingh0% (1)

- Gas LawsDokument35 SeitenGas LawsJoshua Manalac100% (3)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dokument15 SeitenInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768jesuz_mtz26Noch keine Bewertungen

- API Gate Valve - WKM Maintenance ManualDokument8 SeitenAPI Gate Valve - WKM Maintenance ManualsambhajiNoch keine Bewertungen

- Aerospace: Typical UsesDokument2 SeitenAerospace: Typical UsessrashmiiiscNoch keine Bewertungen

- Development of 1D Turbomachinery Meanline Solver With Physics-Based Detailed Loss ModelsDokument5 SeitenDevelopment of 1D Turbomachinery Meanline Solver With Physics-Based Detailed Loss ModelsBrahimABDNoch keine Bewertungen

- Поиск и Устранение Неисправностей CLIVET MDE-3 PDFDokument1 SeiteПоиск и Устранение Неисправностей CLIVET MDE-3 PDFelshan_asgarovNoch keine Bewertungen

- Pressure Drop Calculations (Shell Tube HX)Dokument6 SeitenPressure Drop Calculations (Shell Tube HX)Abhinav ChaudharyNoch keine Bewertungen