Beruflich Dokumente

Kultur Dokumente

Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%

Hochgeladen von

RyanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%

Hochgeladen von

RyanCopyright:

Verfügbare Formate

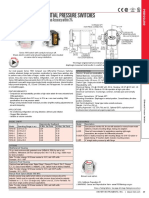

®

PRESSURE

SERIES 2000

MAGNEHELIC® DIFFERENTIAL PRESSURE GAGES

Indicate Positive, Negative or Differential, Accurate within 1% YEAR LIMITED

WARRANTY

RUBBER PRESSURE RELIEF PLUG

WILL UNSEAT ITSELF WHEN GAGE [3] 6-32 X 3/16 [4.76] DEEP

IS OVERPRESSURIZED HOLES EQUALLY SPACED ON

.025 [.64] SPACE CREATED BY 3 SPACER A Ø4-1/8 [104.78] BOLT CIRCLE

PADS WHEN SURFACE MOUNTED. FOR PANEL MOUNTING

DO NOT OBSTRUCT. PROVIDES PATH 17/32

FOR RELIEF OF OVERPRESSURE. [13.49] 1/8 FEMALE NPT

1/8 FEMALE HIGH PRESSURE

NPT HIGH CONNECTION

PRESSURE 1-3/4

1-1/4 [31.75] CONNECTION [44.45]

Ø4-1/2 1/8 FEMALE

[114.3] NPT LOW

PRESSURE 1/2

CONNECTION [12.70]

Ø4-3/4 15/32 [11.91]

[120.65] 1/8 FEMALE NPT LOW

1-11/16 [42.86] 7/16 [11.11] 11/16

[17.46] PRESSURE CONNECTION

Standard Magnehelic® Gage 17/32

[13.49] ø4-3/4 [120.65] 1/8 FEMALE NPT

1-1/4 PANEL CUTOUT HIGH PRESSURE

[31.75] CONNECTION

ø5

[127] 1-3/4

ø4-47/64 [44.45]

ø4-1/2 [120.27]

[114.3] 1/2

VIDEO ON

[12.70]

LI

NE

ø5-1/2 15/32 11/16 1/8 FEMALE

High Accuracy Magnehelic® Gage [139.70] [11.91] 2-17/32 3/16 [17.46] NPT LOW

MOUNTING RING [64.29] [4.76] PRESSURE

Note: Shown with optional -SS bezel CONNECTION

Select the Series 2000 Magnehelic® Differential Pressure Gages for a versatile low SPECIFICATIONS

differential pressure gage with a wide choice of 81 models and 27 options to choose Service: Air and non-combustible, Temperature Limits: 20 to 140°F*

from. Using Dwyer’s simple, frictionless Magnehelic® gage movement, it quickly compatible gases (natural gas option (-6.67 to 60°C). -20°F (-28°C) with low

indicates air or non-corrosive gas pressures--either positive, negative (vacuum) or available). Note: May be used with temperature option.

differential. The design resists shock, vibration, over-pressures and is weatherproof hydrogen. Order a Buna-N diaphragm. Size: 4˝ (101.6 mm) diameter dial face.

to IP67. Pressures must be less than 35 psi. Mounting Orientation: Diaphragm in

Select the –HA High Accuracy Magnehelic® gage option for an accuracy within 1% Wetted Materials: Consult factory. vertical position. Consult factory for other

Differential Pressure Gages

of full scale. Also included with the –HA option at no extra cost are a mirrored scale Housing: Die cast aluminum case and position orientations.

overlay and a 6 point calibration certificate. bezel, with acrylic cover. Exterior finish Process Connections: 1/8˝ female NPT

is coated gray to withstand 168 hour salt duplicate high and low pressure taps -

FEATURES/BENEFITS spray corrosion test. one pair side and one pair back.

• Easy to read gage through undistorted plastic face permits viewing from far away Accuracy: ±2% (-HA model ±1) of Weight: 1 lb 2 oz (510 g), MP & HP 2 lb

• Patented design provides quick response to pressure changes means no delay in FS (±3% (-HA ±1.5%) on -0, -100PA, 2 oz (963 g).

assessing critical situations -125PA, -10MM and ±4% (-HA ±2%) on Standard Accessories: Two 1/8˝ NPT

• Durable and rugged housing and high-quality components combine to provide long- -00, -60PA, -6MM ranges), throughout plugs for duplicate pressure taps, two

service life and minimized down-time range at 70°F (21.1°C). 1/8˝ pipe thread to rubber tubing adapter,

• High accuracy option is twice as accurate as the standard Magnehelic® gage Pressure Limits: -20 in Hg to 15 psig and three flush mounting adapters with

(-0.677 to 1.034 bar); MP option: 35 psig screws. (Mounting and snap ring retainer

APPLICATIONS (2.41 bar); HP option: 80 psig (5.52 bar). substituted for three adapters in MP &

• Filter monitoring Enclosure Rating: IP67. HP gage accessories.)

• Air velocity with Dwyer pitot tube Overpressure: Relief plug opens Agency Approvals: Meets the technical

• Blower vacuum monitoring at approximately 25 psig (1.72 bar), requirements of EU Directive 2011/65/EU

• Fan pressure indication standard gages only.u (RoHS II). Note: -SP models not RoHS

• Duct, room or building pressures approved.

• Clean room positive pressure indication Note: For applications with high cycle rate within gage total pressure rating, next

higher rating is recommended. See Medium and High pressure options.

*Low temperature models available as special options.

ACCESSORIES

Model Description

A-432 Portable kit; combine carrying case with any Magnehelic® gage of

standard range, except high pressure connection. Includes 9 ft (2.7

m) of 3/16˝ ID rubber tubing, standhang bracket and terminal tube

with holder

A-605 Air filter gage accessory kit; adapts any standard Magnehelic® gage

for use as an air filter gage. Includes aluminum surface mounting

bracket with screws, two 5 ft (1.5 m) lengths of 1/4˝ aluminum tubing,

two static pressure tips and two molded plastic vent valves, integral

compression fittings on both tips and valves A-432 A-605

A-605B Air filter gage accessory kit; air filter kit with two plastic open/close

valves, two 4˝ steel static tips, plastic tubing and mounting flange

A-605C Air filter gage accessory kit; air filter kit with two plastic open/close

valves, two plastic static tips, plastic tubing and mounting flange

uOver Protection Note: See page 21 (Series 2000)

20 DWYER INSTRUMENTS, INC. | dwyer-inst.com

®

PRESSURE

SERIES 2000

MAGNEHELIC® DIFFERENTIAL PRESSURE GAGES

Indicate Positive, Negative or Differential, Accurate within 1%

Bezel provides flange for flush mounting in panel. O-ring seal for cover assures pressure integrity of case.

Clear plastic face is highly resistant to breakage. Provides OVERPRESSURE PROTECTION

undistorted viewing of pointer and scale. Blowout plug is comprised of a rubber plug on the rear

which functions as a relief valve by unseating and venting

Precision litho-printed scale is accurate and easy to read. the gage interior when over pressure reaches approximately

25 psig (1.7 bar). To provide a free path for pressure relief,

Calibrated range spring is flat spring steel. Small there are four spacer pads which maintain 0.023˝ clearance

amplitude of motion assures consistency and long life. It when gage is surface mounted. Do not obstruct the gap

reacts to pressure on diaphragm. Live length adjustable for created by these pads.

calibration. The blowout plug is not used on models above 180˝ of

water pressure, medium or high pressure models, or on

Red tipped pointer of heat treated aluminum tubing is easy gages which require an elastomer other than silicone for the

to see. It is rigidly mounted on the helix shaft. diaphragm.

The blowout plug should not be used as a system

Pointer stops of molded rubber prevent pointer over-travel overpressure control. High supply pressures may still

without damage. cause the gage to fail due to over pressurization, resulting

in property damage or serious injury. Good engineering

“Wishbone” assembly provides mounting for helix, helix practices should be utilized to prevent your system from

bearings and pointer shaft. exceeding the ratings of any component.

Jeweled bearings are shock-resistant mounted; provide Die cast aluminum case is precision made and iridite-

virtually friction-free motion for helix. Motion damped with dipped to withstand 168 hour salt spray corrosion test.

high viscosity silicone fluid. Exterior finished in baked dark gray hammerloid. One case

size is used for all standard pressure options, and for both

Helix is precision made from an alloy of high magnetic surface and flush mounting.

permeability. Mounted in jeweled bearings, it turns freely,

following the magnetic field to move the pointer across Silicone rubber diaphragm with integrally molded O-ring

the scale. is supported by front and rear plates. It is locked and

sealed in position with a sealing plate and retaining ring.

Zero adjustment screw is conveniently located in the Diaphragm motion is restricted to prevent damage due to

plastic cover, and is accessible without removing cover. overpressures.

O-ring seal provides pressure tightness.

Samarium Cobalt magnet mounted at one end of range

spring rotates helix without mechanical linkages.

MODEL CHART

Range, Range, Range, MM Range, Dual Scale Air Velocity Units

Model Inches of Water Model PSI Model of Water Model kPa For use with pitot tube

2000-00N†•• .05-0-.2 2201 0-1 2000-6MM†•• 0-6 2000-0.5KPA 0-0.5

2000-00†•• 0-.25 2202 0-2 2000-10MM†• 0-10 2000-1KPA 0-1

2000-0†• 0-.50 2203 0-3 2000-15MM 0-15 2000-1.5KPA 0-1.5 Range, in w.c./

Differential Pressure Gages

2001 0-1.0 2204 0-4 2000-25MM 0-25 2000-2KPA 0-2 Model Velocity F.P.M.

2002 0-2.0 2205 0-5 2000-30MM 0-30 2000-2.5KPA 0-2.5 2000-00AV†•• 0-.25/

2003 0-3.0 2210* 0-10 2000-50MM 0-50 2000-3KPA 0-3 300-2000

2004 0-4.0 2215* 0-15 2000-80MM 0-80 2000-4KPA 0-4 2000-0AV†• 0-.50/

2005 0-5.0 2220* 0-20 2000-100MM 0-100 2000-5KPA 0-5 500-2800

2006 0-6.0 2230** 0-30 2000-125MM 0-125 2000-8KPA 0-8 2001AV 0-1.0/

2008 0-8.0 2000-150MM 0-150 2000-10KPA 0-10 500-4000

2010 0-10 Range, CM 2000-200MM 0-200 2000-15KPA 0-15 2002AV 0-2.0/

2012 0-12 Model of Water 2000-250MM 0-250 2000-20KPA 0-20 1000-5600

2015 0-15 2000-300MM 0-300 2000-25KPA 0-25 2005AV 0-5.0/

2020 0-20 2000-15CM 0-15 Zero Center Ranges 2000-30KPA 0-30 2000-8800

2025 0-25 2000-20CM 0-20 2300-6MM†•• 3-0-3 2010AV 0-10/

2030 0-30 2000-25CM 0-25 Zero Center Ranges

2300-10MM†• 5-0-5 2300-1KPA .5-0-.5 2000-12500

2040 0-40 2000-50CM 0-50 2300-20MM†• 10-0-10

2050 0-50 2000-80CM 0-80 2300-2KPA 1-0-1

Model Range, Pa 2300-2.5KPA 1.25-0-1.25

2060 0-60 2000-100CM 0-100

2000-150CM 0-150 2000-60NPA†•• 10-0-50 2300-3KPA 1.5-0-1.5

2080 0-80

2000-200CM 0-200 2000-60PA†•• 0-60 Dual Scale English/Metric Models

2100 0-100

2000-250CM 0-250 2000-100PA†• 0-100 Range, Range,

2120 0-120

2000-300CM 0-300 2000-125PA†• 0-125 Model in w.c. Pa or kPa

2150 0-150

Zero Center Ranges 2000-250PA 0-250 2000-00D†•• 0-.25 0-62 Pa

2160 0-160 2000-300PA 0-300 2000-0D†• 0-0.5 0-125 Pa

2180* 0-180 2300-4CM 2-0-2 2000-500PA 0-500 2001D 0-1.0 0-250 Pa

2250* 0-250 2300-10CM 5-0-5 2000-750PA 0-750 2002D 0-2.0 0-500 Pa

Zero Center Ranges 2300-30CM 15-0-15 2000-1000PA 0-1000 2003D 0-3.0 0-750 Pa

2300-00†•• 0.125-0-0.125 Zero Center Ranges 2004D 0-4.0 0-1.0 kPa

2300-0†• .25-0-.25 Model Range, Pa 2005D 0-5.0 0-1.25 kPa

2301 .5-0-.5 2300-60PA†•• 30-0-30 2006D 0-6.0 0-1.5 kPa

2302 1-0-1 2300-100PA†• 50-0-50 2008D 0-8.0 0-2.0 kPa

2304 2-0-2 2300-120PA 60-0-60 2010D 0-10 0-2.5 kPa

2310 5-0-5 2300-200PA 100-0-100 2015D 0-15 0-3.7 kPa

2320 10-0-10 2300-250PA 125-0-125 2020D 0-20 0-5 kPa

2330 15-0-15 2300-300PA 150-0-150 2025D 0-25 0-6.2 kPa

2300-500PA 250-0-250 2050D 0-50 0-12.4 kPa

2300-1000PA 500-0-500 2060D 0-60 0-15 kPa

†These ranges calibrated for vertical scale position • Accuracy ±3% •• Accuracy ±4% *MP option standard **HP option standard

VELOCITY AND VOLUMETRIC FLOW UNITS ACCESSORIES

Scales are available on the Magnehelic ®

gage that read in velocity units (FPM, m/s) Model Description

or volumetric flow units (SCFM, m3/s, m3/h). A-321 Safety relief valve

Stocked velocity units with dual range scales A-448 3-piece magnet kit for mounting Magnehelic® gage directly to magnetic surface

in inches w.c. and feet per minute are shown A-135 Rubber gasket for panel mounting

above. For other ranges contact the factory. A-401 Plastic carry case

When ordering volumetric flow scales please A-310A 3-way vent valves. In applications where pressure is continuous and the

specify the maximum flow rate and its Magnehelic® gage is connected by metal or plastic tubing which cannot be easily

corresponding pressure. removed, we suggest using Dwyer A-310A vent valves to connect gage. Pressure

Example: 0.5 in w.c. = 16,000 CFM. can then be removed to check or re-zero the gage. A-310A

DWYER INSTRUMENTS, INC. | dwyer-inst.com 21

®

PRESSURE

HIGH ACCURACY MAGNEHELIC® DIFFERENTIAL PRESSURE GAGE YEAR LIMITED

WARRANTY

Twice as accurate as the OPTIONS - HIGH ACCURACY MAGNEHELIC® GAGE

standard Magnehelic ® gage To order

add suffix: Description

Mirrored scale overlay -HA High Accuracy Magnehelic® Gage. Accuracy

eliminates parallax error within 1% and weatherproof. Also includes

mirrored scale overlay and a six point

calibration certificate

IP67 weatherproof housing -SS Corrosion resistant brushed 304 stainless

steel bezel

VIDEO ON

6-Point Calibration

LI

Certificate Included

NE

Optional brushed SS bezel

Accuracy Specifications: See page 20 (Series 2000)

ADDITIONAL GAGE OPTIONS OPTIONS - OTHER OPTIONAL BEZELS

To order add suffix: Description

-CB Chrome bezel option: A chrome plated aluminum bezel for an

aesthetically pleasing finish when mounting on metal surfaces

such as control panels.

-SB Stainless steel bezel option: 304 stainless steel electro polished

Ra 16 finished bezel.

-SS Corrosion resistant brushed 304 stainless steel bezel

OPTIONS - LED SETPOINT INDICATOR

To order add suffix: Description

-SP Bright red LED on right scale shows when setpoint is reached.

Field adjustable from gage face, unit operates on 12-24

VDC. Setpoint indicator option comes with medium pressure

Differential Pressure Gages

(MP) bezel.

Note: 4-13/16˝ hole for flush mounting.

OPTIONS - ADJUSTABLE SIGNAL FLAG

LED Setpoint Indicator Adjustable Signal Flag To order add suffix: Description

-ASF Integral with plastic gage cover. Available for most models

except those with medium or high pressure construction. Can be

ordered with gage or separate.

OPTIONS - TRANSPARENT OVERLAYS

To order add suffix: Description

-G Green (to highlight and emphasize critical pressures)

-R Red (to highlight and emphasize critical pressures)

-Y Yellow (to highlight and emphasize critical pressures)

Transparent Overlay Mirrored Scale Overlay OPTIONS - MIRRORED SCALE OVERLAY

To order add suffix: Description

-M A mirrored scale overlay is also available to assist in reducing

parallax error.

OPTIONS - INTEGRATED MOUNTING PLATE

To order add suffix: Description

-AHU1 Furnished with attached surface mounting plate

-AHU2 Furnished with attached surface mounting plate and including

A-481 installer kit (2 plastic static pressure tips and 7´of

PVC tubing)

Integrated Mounting Plate

OPTIONS - FOR HIGH STATE PRESSURE APPLICATIONS

To order add suffix: Description

-HP High pressure option: for pressures to 80 psig

-MP Medium pressure option: for pressures to 35 psig

OPTIONS

To order add suffix: Description

-FC Factory calibration certificate

-LT Low temperatures to -20°F (-28°C)

-NIST NIST traceable calibration certificate

22 DWYER INSTRUMENTS, INC. | dwyer-inst.com

®

PRESSURE

MAGNEHELIC® GAGE MOUNTING ACCESSORIES

Pressure

Reference

Port

A-610 A-369 A-464 A-299

A-286 A-300 A-368 A-371

A single case size is used for most models of Magnehelic® gages. They can be ACCESSORIES

flush or surface mounted with standard hardware supplied. Complete mounting and Model Description

connection fittings plus instructions are furnished with each instrument. A 4-9/16˝ hole A-610 Pipe mounting kit for installing on 1-1/4˝ to 2˝ horizontal or vertical pipe

is required for flush panel mounting. A-286 Magnehelic® gage panel mounting flange

Flush mounting is easily accomplished with the new A-300 Flush Mounting bracket. A-369 Stand-hang bracket, aluminum, for Magnehelic® gage

This bracket provides a solution to quickly and conveniently flush mount the A-300 Flush mounting bracket

Magnehelic® gage. The A-300 is ideal for mounting the Magnehelic® gage on control A-464 Flush mount kit for Magnehelic® gage

panel doors. A-368 Surface mounting plate, aluminum, for Magnehelic® gage

The A-368 is a simple bracket for quickly surface mounting the Magnehelic® gage. A-299 Mounting bracket, flush mount for Magnehelic® gage, bracket is then

After securing the Magnehelic® gage to the A-368 bracket, mount the bracket on any surface mounted, steel with gray hammerloid epoxy finish

flat surface. A-371 Surface mounting bracket, use with medium pressure (-MP) or high

The A-369 allows the Magnehelic® gage to be easily carried to locations where

Differential Pressure Gages

pressure (-HP) models only

pressure readings need to be taken. The A-369 can stand on its own or hang on a

nail or hook.

SERIES A-320

INSTRUMENT ENCLOSURES

Protects Various Instruments

A-320-A A-320-A With Gage Installed A-320-B A-320-B With Gage Installed

Series A-320 Instrument Enclosures protect instruments in all applications. The SPECIFICATIONS

A-320-A fits standard Magnehelic® size instruments (4-9/16˝ diameter) and the Housing: ABS.

A-320-B fits standard 3000MR Photohelic® switch/gage size instruments (4-13/16˝ Process Connections: Anodized aluminum.

diameter). Both models include silicone tubing, gage barbs and mounting hardware. Enclosure Rating: NEMA 1 (IP10). Note: Check instruments rating.

Weight: Model A-320-A: 11.29 oz (320 g); A-320-B: 16.23 oz (420 g).

MODEL CHART Gage Size Opening: A-320-A: 4-9/16 in (115.89 mm); A-320-B: 4-13/16 in (122.24

Model Compatible Instruments mm).

A-320-A 2000 Magnehelic® Gage, DM-1000 Digital Differential Pressure Gage,

DM-2000 Differential Pressure Transmitter

A-320-B 3000MR Photohelic® Switch/Gage, Series 605 Magnehelic®

Differential Pressure Transmitter, DH3 Digihelic® Pressure Controller,

2000 Magnehelic® Gage with medium and high pressure options

DWYER INSTRUMENTS, INC. | dwyer-inst.com 23

Das könnte Ihnen auch gefallen

- TE32+MANUAL (FZ Transm) (041-060)Dokument20 SeitenTE32+MANUAL (FZ Transm) (041-060)Marco Guachun100% (1)

- 2018 ThermogravimetricAnalysisofPolymersBookChapter PDFDokument30 Seiten2018 ThermogravimetricAnalysisofPolymersBookChapter PDFA1234 AJEFNoch keine Bewertungen

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Dokument4 SeitenMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 1%Johan VBNoch keine Bewertungen

- Dwyer 2000Dokument4 SeitenDwyer 2000Saravana KumarNoch keine Bewertungen

- Magnehelic Differential Pressure Gages: SolutionsDokument2 SeitenMagnehelic Differential Pressure Gages: Solutionsdaniel GasperinNoch keine Bewertungen

- Series 2000 - Magnahelic Differential Pressure GaugeDokument2 SeitenSeries 2000 - Magnahelic Differential Pressure GaugeKoteswara RaoNoch keine Bewertungen

- 004 005 D PDFDokument2 Seiten004 005 D PDFRangga Prasetya BaitullahNoch keine Bewertungen

- MAGNEHELICDokument2 SeitenMAGNEHELICCésar Arturo TorresNoch keine Bewertungen

- Serie 2000Dokument2 SeitenSerie 2000Fredy MurilloNoch keine Bewertungen

- Dwyer 2300 250pa Pressure Gauge DatasheetDokument2 SeitenDwyer 2300 250pa Pressure Gauge DatasheetGorch Marroko100% (1)

- Purafil Side Access BulletinDokument5 SeitenPurafil Side Access BulletinPablo TorresNoch keine Bewertungen

- Magnehelic-Gage Series 2000Dokument2 SeitenMagnehelic-Gage Series 2000Jonathan GanNoch keine Bewertungen

- Fr. No.: +-+ - All Angles All Decimal Dimensions Standard Tolerances Unless Noted: 1 .005Dokument1 SeiteFr. No.: +-+ - All Angles All Decimal Dimensions Standard Tolerances Unless Noted: 1 .005César Arturo TorresNoch keine Bewertungen

- Digihelic 3 Differential Pressure Controllers: Digihelic Controller in Photohelic Gage, Square Root Output For FlowDokument1 SeiteDigihelic 3 Differential Pressure Controllers: Digihelic Controller in Photohelic Gage, Square Root Output For FlowAdriana Zarahi Velez HernandezNoch keine Bewertungen

- Magnehelic Series 2000 - CatDokument2 SeitenMagnehelic Series 2000 - CatFerdian AriestaNoch keine Bewertungen

- Magnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 2%Dokument2 SeitenMagnehelic Differential Pressure Gages: Indicate Positive, Negative or Differential, Accurate Within 2%SlametKhoerudinNoch keine Bewertungen

- Explosion-Proof Differential Pressure SwitchDokument1 SeiteExplosion-Proof Differential Pressure SwitchTadau EnergyNoch keine Bewertungen

- 1910 00 ManualDokument4 Seiten1910 00 ManualRusty AllenNoch keine Bewertungen

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDokument4 SeitenSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsKrissthian EspitiaNoch keine Bewertungen

- Series 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsDokument4 SeitenSeries 605 Magnehelic Differential Pressure Indicating Transmitter Specifications - Installation and Operating InstructionsAlberto Angel Mora ZavalaNoch keine Bewertungen

- Continuous Level Transmitter: Customize To Fit Application, 316 SS or Buna-N FloatsDokument1 SeiteContinuous Level Transmitter: Customize To Fit Application, 316 SS or Buna-N FloatsMohamed HammamNoch keine Bewertungen

- Dwyer B - 30Dokument20 SeitenDwyer B - 30Alex MeadowsNoch keine Bewertungen

- DA-DS CatDokument2 SeitenDA-DS Catsorin sorinNoch keine Bewertungen

- Dweyer Pressure SwitchDokument1 SeiteDweyer Pressure SwitchMuhamad PriyatnaNoch keine Bewertungen

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDokument2 SeitenSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJuan Carlos Chara VelazcoNoch keine Bewertungen

- Dwyer - 1630-Presostato SwitchDokument2 SeitenDwyer - 1630-Presostato Switchomorales.cyvsaNoch keine Bewertungen

- 616kd 11 DatasheetDokument1 Seite616kd 11 Datasheetramalho12andyNoch keine Bewertungen

- Differential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageDokument1 SeiteDifferential Pressure Transmitter: Same Size As Standard Magnehelic Differential Pressure GageJose Antonio Yupa MedinaNoch keine Bewertungen

- CO Component Description: Discharge DelaysDokument1 SeiteCO Component Description: Discharge DelayskiuNoch keine Bewertungen

- Photohelic Pressure Switch/Gages: 3-In-One Indicating Gage, Lo-Limit and Hi-Limit ControlDokument2 SeitenPhotohelic Pressure Switch/Gages: 3-In-One Indicating Gage, Lo-Limit and Hi-Limit ControlAnonymous u0wETydFNoch keine Bewertungen

- Anemometro Dwyer VT-200Dokument1 SeiteAnemometro Dwyer VT-200Israel Hernandez GomezNoch keine Bewertungen

- As Sea20007e Ew 121 128 B As Ew 129Dokument1 SeiteAs Sea20007e Ew 121 128 B As Ew 129Juan RuizNoch keine Bewertungen

- Compact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%Dokument1 SeiteCompact Low Differential Pressure Switches: Set Points From 0.07 To 20 in W.C. Repetitive Accuracy Within 3%ANGEL FLORESNoch keine Bewertungen

- Dwyer 4000 SeriesDokument1 SeiteDwyer 4000 SeriesMuh RenandaNoch keine Bewertungen

- Series DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDokument2 SeitenSeries DM-2000 Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsJorge Renato Chirinos QuiñonezNoch keine Bewertungen

- Series 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating InstructionsDokument2 SeitenSeries 647 Wet/Wet Differential Pressure Transmitter: Specifications - Installation and Operating Instructionsindra_onevisionNoch keine Bewertungen

- Interruptor de FlujoDokument1 SeiteInterruptor de FlujoCarlos RojasNoch keine Bewertungen

- Ficha Tecnica Mod 2-5002Dokument2 SeitenFicha Tecnica Mod 2-5002Nestor Augusto Duran SanchezNoch keine Bewertungen

- Dwyer-1910-1-Product OverviewDokument1 SeiteDwyer-1910-1-Product OverviewRusty AllenNoch keine Bewertungen

- Differential Pressure Transmitter: NEMA 4X Enclosure, 0.25% FS AccuracyDokument1 SeiteDifferential Pressure Transmitter: NEMA 4X Enclosure, 0.25% FS AccuracyDanielle YepezNoch keine Bewertungen

- Manometro Presion Diferencial PDFDokument1 SeiteManometro Presion Diferencial PDFCharlie MartinezNoch keine Bewertungen

- Diaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive ApplicationsDokument1 SeiteDiaphragm Seal For DA Series Pressure Switch: PVC and FEP Construction For Corrosive Applicationsluat1983Noch keine Bewertungen

- Photo Helic Ps PDFDokument4 SeitenPhoto Helic Ps PDFSoumen PaulNoch keine Bewertungen

- PL5 PMC365 CVR 20-25Dokument6 SeitenPL5 PMC365 CVR 20-25Dwiki RamadhaniNoch keine Bewertungen

- Astral: 3/4" MANUAL Air Vent 16" Ø ManwayDokument1 SeiteAstral: 3/4" MANUAL Air Vent 16" Ø Manwayalquiler pisosNoch keine Bewertungen

- Duct Insertion Temperature Sensor - BTT-D-04 1 - DwyerDokument1 SeiteDuct Insertion Temperature Sensor - BTT-D-04 1 - DwyerSigit KuncoroNoch keine Bewertungen

- JETTA 96 Tierras A BateríaDokument7 SeitenJETTA 96 Tierras A BateríajcarlosahuatltNoch keine Bewertungen

- Esp Calculation Exhaust Air-TaDokument4 SeitenEsp Calculation Exhaust Air-TaAshiq NishmaNoch keine Bewertungen

- WX Approval DrawingDokument18 SeitenWX Approval DrawingcadamaoNoch keine Bewertungen

- 18.20 (59'-9") Client Drawing Title: Car Parking-1Dokument1 Seite18.20 (59'-9") Client Drawing Title: Car Parking-1KeerthivasanNoch keine Bewertungen

- Engine Controls MAXIMA 2003Dokument5 SeitenEngine Controls MAXIMA 2003Rogelio ArenasNoch keine Bewertungen

- Certified: 3/23/2021 Garrett BinnsDokument1 SeiteCertified: 3/23/2021 Garrett Binnsjose luis rios guerraNoch keine Bewertungen

- Accord 2000 (Ecm)Dokument3 SeitenAccord 2000 (Ecm)jamespituco3Noch keine Bewertungen

- Dwyer MagnehelicmanualDokument2 SeitenDwyer MagnehelicmanualAndres GonzalesNoch keine Bewertungen

- Wet/Wet Differential Pressure Transmitter: Series 629CDokument2 SeitenWet/Wet Differential Pressure Transmitter: Series 629CElmer Ramón Murillo MejiaNoch keine Bewertungen

- Hydraulic Drawing For Cam 3xDokument19 SeitenHydraulic Drawing For Cam 3xSuresh NataniNoch keine Bewertungen

- Ametek Nautilair 150560 150561 150562 150563 150564 150565 Tech SheetDokument2 SeitenAmetek Nautilair 150560 150561 150562 150563 150564 150565 Tech SheetAlejandroNoch keine Bewertungen

- Magnehelic Differential Pressure Gage: Bulletin A-27Dokument2 SeitenMagnehelic Differential Pressure Gage: Bulletin A-27Marco Antonio Rivera DoteroNoch keine Bewertungen

- 23 Ridge-Hip (Floating) DetailDokument1 Seite23 Ridge-Hip (Floating) DetailAhmed Saber NassarNoch keine Bewertungen

- MEUCFSGENDokument8 SeitenMEUCFSGENRyanNoch keine Bewertungen

- Megalam Fabsafe MD, MX, MG: Clean Process Filters: E10 To U17 - HEPA/ULPA PanelsDokument1 SeiteMegalam Fabsafe MD, MX, MG: Clean Process Filters: E10 To U17 - HEPA/ULPA PanelsRyanNoch keine Bewertungen

- Iec60076 11 I1 (Ed2.0) enDokument2 SeitenIec60076 11 I1 (Ed2.0) enRyanNoch keine Bewertungen

- How To Size and Specify Hvac/R Ultraviolet-C TechnologyDokument6 SeitenHow To Size and Specify Hvac/R Ultraviolet-C TechnologyRyanNoch keine Bewertungen

- Explosion Proof ModelDokument1 SeiteExplosion Proof ModelRyanNoch keine Bewertungen

- Laws of Malaysia: Temporary Measures For Reducing The Impact of Coronavirus Disease 2019 (COVID-19)Dokument32 SeitenLaws of Malaysia: Temporary Measures For Reducing The Impact of Coronavirus Disease 2019 (COVID-19)RyanNoch keine Bewertungen

- An Introduction To PressurisationDokument63 SeitenAn Introduction To PressurisationRyanNoch keine Bewertungen

- SMC PU TubingDokument6 SeitenSMC PU TubingRyanNoch keine Bewertungen

- Case Study BS7346-8 For Web2Dokument2 SeitenCase Study BS7346-8 For Web2RyanNoch keine Bewertungen

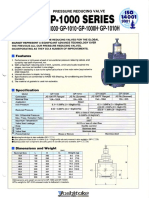

- Yoshitake CI Steam PRV 10K FE GP-1000 - 1Dokument1 SeiteYoshitake CI Steam PRV 10K FE GP-1000 - 1RyanNoch keine Bewertungen

- Solar Takes Off at India's Airports: March - April 2015Dokument41 SeitenSolar Takes Off at India's Airports: March - April 2015RyanNoch keine Bewertungen

- Return To IndexDokument16 SeitenReturn To IndexRyanNoch keine Bewertungen

- CCBP 2017 10october LR PDFDokument36 SeitenCCBP 2017 10october LR PDFRyanNoch keine Bewertungen

- CCBP 2017 10october LR PDFDokument36 SeitenCCBP 2017 10october LR PDFRyanNoch keine Bewertungen

- Ref Guide Surface Prep Req-EnDokument4 SeitenRef Guide Surface Prep Req-EnRyanNoch keine Bewertungen

- Genie Scissor Lift MaintenanceDokument97 SeitenGenie Scissor Lift MaintenanceRyanNoch keine Bewertungen

- Cabp 2017 10october LRDokument52 SeitenCabp 2017 10october LRRyanNoch keine Bewertungen

- En Caisson VI-D4Dokument6 SeitenEn Caisson VI-D4RyanNoch keine Bewertungen

- TOTAL PEMAKAIAN ROL-aprilDokument6 SeitenTOTAL PEMAKAIAN ROL-aprilHarisanto AsNoch keine Bewertungen

- Grinding and Surface Finishing ProcessesDokument65 SeitenGrinding and Surface Finishing ProcessesDr.V.K.Bupesh RajaNoch keine Bewertungen

- Performance-Based Seismic Design of Reinforced Concrete Beam-Column Joints, Zhongguo GuanDokument6 SeitenPerformance-Based Seismic Design of Reinforced Concrete Beam-Column Joints, Zhongguo GuanQurrain MirNoch keine Bewertungen

- Nanostructures and NanomaterialsDokument2 SeitenNanostructures and NanomaterialsSantosh MysoreNoch keine Bewertungen

- 4860 Molenaar IIIDokument165 Seiten4860 Molenaar IIIJhinson BriceñoNoch keine Bewertungen

- Janchik R Lost Circulation Solutions For Lime Stones and Induced FracturesDokument23 SeitenJanchik R Lost Circulation Solutions For Lime Stones and Induced FracturesVarun DodhiaNoch keine Bewertungen

- GB 8163-2008Dokument14 SeitenGB 8163-2008hungNoch keine Bewertungen

- Relief Vent Sizing For A Grignard Reaction: Ming-Huei Yue, John J. Sharkey and Joseph C. Leung?Dokument6 SeitenRelief Vent Sizing For A Grignard Reaction: Ming-Huei Yue, John J. Sharkey and Joseph C. Leung?anon_463510259Noch keine Bewertungen

- Weld Metal CertificateDokument1 SeiteWeld Metal CertificatePhương Do QuangNoch keine Bewertungen

- BSR 2014 PDFDokument134 SeitenBSR 2014 PDFRavindu RansaraNoch keine Bewertungen

- Ajilima 395 ReportDokument8 SeitenAjilima 395 ReportLionel ZaysonNoch keine Bewertungen

- DIFC Commissioning Schedule - 18.10.2023Dokument15 SeitenDIFC Commissioning Schedule - 18.10.2023Mohamed AshrafNoch keine Bewertungen

- Two Bedroom Apartment 2Dokument1 SeiteTwo Bedroom Apartment 2RUTH ELIZABETH NAMUTEBINoch keine Bewertungen

- Handbook - Calculations 5 PDFDokument1 SeiteHandbook - Calculations 5 PDFSmith SivaNoch keine Bewertungen

- Metamorphic Rocks PracticalDokument27 SeitenMetamorphic Rocks PracticalMr Gk meenaNoch keine Bewertungen

- Noble Metalfree Hydrogen Evolution Catalysts For Water Splitting2015chemical Society ReviewsDokument34 SeitenNoble Metalfree Hydrogen Evolution Catalysts For Water Splitting2015chemical Society ReviewsDaniel Camilo CanoNoch keine Bewertungen

- TOC - Table of Compliance Arsitek SimDokument40 SeitenTOC - Table of Compliance Arsitek SimImran nasution0% (1)

- Manufacturing Technology II - Notes PDFDokument17 SeitenManufacturing Technology II - Notes PDFSenthil Kumar Subramanian100% (1)

- 0111 - Stainless Steel - Solenoid Fluid Control Valve - UKDokument72 Seiten0111 - Stainless Steel - Solenoid Fluid Control Valve - UKGuilherme KieckowNoch keine Bewertungen

- Surfactant PDFDokument11 SeitenSurfactant PDFqwertyNoch keine Bewertungen

- Handbook of Building Materials For Fire Protection - Engineering ReferenceDokument5 SeitenHandbook of Building Materials For Fire Protection - Engineering ReferenceDorinNoch keine Bewertungen

- 01 Footing With MomentDokument4 Seiten01 Footing With MomentVinay Joshi100% (2)

- Review On Metallization Approaches For High-Efficiency Silicon Heterojunction Solar CellsDokument16 SeitenReview On Metallization Approaches For High-Efficiency Silicon Heterojunction Solar Cells蕭佩杰Noch keine Bewertungen

- Add AcidDokument4 SeitenAdd AcidKathir KiranNoch keine Bewertungen

- Gear CalculationDokument58 SeitenGear CalculationSachin KubasadNoch keine Bewertungen

- Safety Data Sheet Chemical Aquatrol - 275-1Dokument4 SeitenSafety Data Sheet Chemical Aquatrol - 275-1nikoNoch keine Bewertungen

- 1 PDFDokument8 Seiten1 PDFAke BenNoch keine Bewertungen

- UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161Dokument4 SeitenUCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex UCAR™ Latex D 161sriatul2006Noch keine Bewertungen

- Project ThesisDokument56 SeitenProject ThesisHiren ThesiyaNoch keine Bewertungen