Beruflich Dokumente

Kultur Dokumente

16-2819 Welders Interpretation

Hochgeladen von

mahmoud_allam3Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

16-2819 Welders Interpretation

Hochgeladen von

mahmoud_allam3Copyright:

Verfügbare Formate

March 28, 2017

Mahmoud Allam

Project Services Company. (S.A.E) – PSC

Desert Road, Amria, Kilo 37, Alexandria, Egypt

mahmoud.allam@psc-eg.com

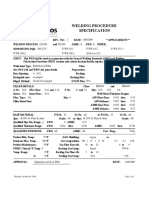

Subj: Section IX, (2013 Edition); QW-452 and QW-461.9 - Performance Qualification

Thickness Limits and Test Specimens

Item: 16-2819

Dear Sir,

Our understanding of the questions in your inquiry and our replies are as follows:

Background: A welder prepares a performance qualification test coupon using 20 mm thick plate

by depositing three layers of weld metal for a total deposited weld metal thickness of 10 mm in

the 2G position, then moves the test coupon to the 4G position and deposits three additional

layers of weld metal for an additional deposited weld metal thickness of 10 mm.

Question (1): Does the condition described above qualify the welder for unlimited deposited weld

metal thickness in the flat, horizontal, and overhead positions?

Reply (1): No. See Table QW-452.1(b).

Question (2): Does the condition described above qualify the welder for a maximum deposited

weld metal thickness of 20 mm in each of the flat, horizontal, and overhead positions?

Reply (2): Yes.

Respectfully submitted,

Steve Rossi

Secretary; BPV Committee on Welding, Brazing & Fusing (IX)

(212) 591-7522

rossisj@asme.org

ASME procedures provide for reconsideration of this interpretation when or if additional information is available which the inquirer

believes might affect the interpretation. Further, persons aggrieved by this interpretation may appeal to the cognizant ASME

committee or subcommittee. As stated in the foreword of the code document, ASME does not “approve”, “certify”, rate”, or

“endorse” any item, construction, proprietary device or activity.

Das könnte Ihnen auch gefallen

- Study of Ductile-Brittle Transition Temperature of 9Cr-1Mo SteelsDokument2 SeitenStudy of Ductile-Brittle Transition Temperature of 9Cr-1Mo Steelsmahmoud_allam3Noch keine Bewertungen

- Fracture Toughness of The Heat Affected Zone in Girth WeldsDokument7 SeitenFracture Toughness of The Heat Affected Zone in Girth Weldsmahmoud_allam3Noch keine Bewertungen

- Method For Mechanical Properties EvaluationDokument5 SeitenMethod For Mechanical Properties Evaluationmahmoud_allam3Noch keine Bewertungen

- Passivating Gel For Stainless SteelDokument2 SeitenPassivating Gel For Stainless Steelmahmoud_allam3Noch keine Bewertungen

- Furnaces and RefractoriesDokument36 SeitenFurnaces and Refractoriesengkassem100% (5)

- 1english Reg Final Nov 2010 PDFDokument367 Seiten1english Reg Final Nov 2010 PDFmahmoud_allam3Noch keine Bewertungen

- Steam Generators 2Dokument33 SeitenSteam Generators 2gbharathreddysNoch keine Bewertungen

- PICKLING Gel FOR STAILESS STEEL PdsDokument2 SeitenPICKLING Gel FOR STAILESS STEEL Pdsmahmoud_allam3Noch keine Bewertungen

- Code Case 2891 U-2 CerDokument1 SeiteCode Case 2891 U-2 Cermahmoud_allam3Noch keine Bewertungen

- Code Case 2891 U-2 CerDokument1 SeiteCode Case 2891 U-2 Cermahmoud_allam3Noch keine Bewertungen

- Projects Follow UpDokument1 SeiteProjects Follow Upmahmoud_allam3Noch keine Bewertungen

- Request For Code CaseDokument2 SeitenRequest For Code Casemahmoud_allam3Noch keine Bewertungen

- Engineering, Steel Fabrication and Process Equipment ManufacturerDokument4 SeitenEngineering, Steel Fabrication and Process Equipment Manufacturermahmoud_allam3Noch keine Bewertungen

- Nitrogen Purging For Stainless SteelDokument4 SeitenNitrogen Purging For Stainless Steelmahmoud_allam3Noch keine Bewertungen

- ASME New Code Case LetterDokument1 SeiteASME New Code Case Lettermahmoud_allam3Noch keine Bewertungen

- Color Metallurgy of Cast IronDokument13 SeitenColor Metallurgy of Cast Ironmahmoud_allam3Noch keine Bewertungen

- Welding of P91Dokument10 SeitenWelding of P91mahmoud_allam3Noch keine Bewertungen

- Aluminim WPSDokument5 SeitenAluminim WPSmahmoud_allam3Noch keine Bewertungen

- Presentation For WeldingDokument31 SeitenPresentation For Weldingmahmoud_allam3Noch keine Bewertungen

- Heat Treatment of 9 CRDokument12 SeitenHeat Treatment of 9 CRmahmoud_allam3Noch keine Bewertungen

- WPS for GTAW Welding of Aluminum Butt JointsDokument2 SeitenWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3Noch keine Bewertungen

- Assessment of Welding ConsumablesDokument17 SeitenAssessment of Welding Consumablesmahmoud_allam3Noch keine Bewertungen

- Welding CrMo Steels for Power and Petrochemical ApplicationsDokument11 SeitenWelding CrMo Steels for Power and Petrochemical Applicationsmahmoud_allam3100% (1)

- Color Metallurgy of Cast IronDokument13 SeitenColor Metallurgy of Cast Ironmahmoud_allam3Noch keine Bewertungen

- Journal Modified 9% CR Steels For AdvancedDokument6 SeitenJournal Modified 9% CR Steels For Advancedmahmoud_allam3Noch keine Bewertungen

- 10 1 1 161 3015Dokument7 Seiten10 1 1 161 3015rinshadNoch keine Bewertungen

- WPS for GTAW Welding of Aluminum Butt JointsDokument2 SeitenWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3Noch keine Bewertungen

- Aluminim WPSDokument5 SeitenAluminim WPSmahmoud_allam3Noch keine Bewertungen

- WPS for GTAW Welding of Aluminum Butt JointsDokument2 SeitenWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)