Beruflich Dokumente

Kultur Dokumente

JSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure Vessels

Hochgeladen von

MajdiSahnoun100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

1K Ansichten2 SeitenUltrasonic Thickness Measurement

Originaltitel

JSA-Visual Inspection and Ultrasonic Thickness Measurement on Pressure Vessels

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenUltrasonic Thickness Measurement

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

1K Ansichten2 SeitenJSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure Vessels

Hochgeladen von

MajdiSahnounUltrasonic Thickness Measurement

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

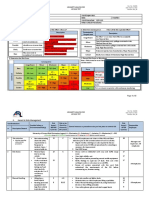

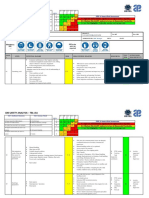

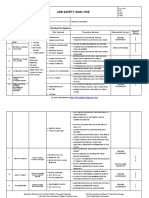

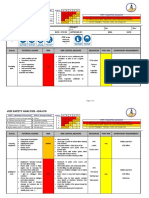

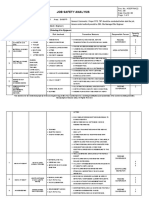

JOB SAFETY ANALYSIS

Ref: – JSA-…….

Facility / Site: CPF Location within Site: Chemical storage Permit No: 25459 Permit Type: COLD Date: 21.05.2019

area

Task Description: Visual inspection and ultrasonic thickness measurement on pressure vessels

REQUIRED REFERENCES JSA REVIEW

Have the relevant Procedures, Standards, Guidelines,

or Safe Work Practices been reviewed? Yes N/A

Pending confirmation by the Task Leader of site conditions, I agree that the attached JSA identifies the

significant Task Steps, Hazards, and Controls.

JSA REVIEWER (Supervisor or Designate):

RISK ASSESSMENT

Must existing Procedures or Work Practices be

Yes No Name / Signature: HBIB BOUSABBEH Company: MSBI

modified to perform this work?

After mitigation, are there any hazards that continue to WORK SITE VERIFICATION

present a potentially significant risk? (Scenario-Based Yes No

Risk Assessment required)

The Work Team has assessed the worksite conditions and confirms:

The JSA addresses the applicable hazards and necessary controls.

PPE REQUIRED DURING THIS TASK

The Team has the appropriate resources (people and equipment) to do the job safely.

HARD HAT SAFETY GLASSES

Others that could be affected by the work have been informed.

FACE SHIELD TASK LEADER:

SAFETY SHOES / BOOTS

GOGGLES

Name / Signature: Company:MSBI

FALL PROTECTION

FALL RESTRAINT

COMPLETE THE SECTION BELOW IF THIS JSA IS NOT PART OF A PERMIT PACK

GLOVES:

COTTON Work Team Declaration:

LEATHER I acknowledge that I have reviewed the attached JSA, I understand my roles

and responsibilities, and I will comply with the instructions for this task.

IMPACT PROTECTION

Name (print): Name (print):

Dust mask OTHER (specify):

Work clothes

OTHER PPE (specify):

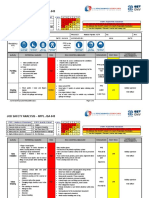

TASK STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT

(Number) (What could go wrong?) (How can harm be prevented?) MITIGATION STATES

PTW signed by authorised person.

Ensure correct PPE available for task

Procedure or task unclear Carry out toolbox talk

Miscommunication Clear access to work zone.

MSBI Emergency

1- Work permit in place Workers involved in the tasks are not All workers involved are competent and

Response plan

competent They understand the scope of the work and

Incorrect tools or PPE the hazards/risks associated with the

task.

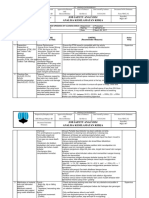

Clean and arrange the work area.

Be careful when used wire brush and

equipment

2- Preparation of pressure Wear adequate PPE’s

vessel surface, conduct Equipment pre-use check MSBI Emergency

Wire brush failure causing hand injuries

ultrasonic thickness Wash your hand after handling and response Plan

measurement on pressure Slip or fall before eating First Aid kit in place

vessels Do not expose to extreme heat

Make sure that all equipment are stored

in the correct place

MSBI Emergency

Slips trips and falls Keep work area tidy and clean response Plan

3- Housekeeping Unsafe access Regular Housekeeping and keep all First Aid kit in

Obstacles in work area area free from hazards place

Spill kit in place

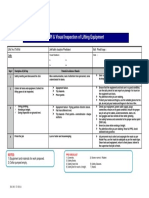

Name Position Date Signed

Prepared By Area Supervisor

Checked By Area HSSE Supervisor

Approved By PTW Coordinator

Das könnte Ihnen auch gefallen

- JSA For HDPE Liner Fusion Welding PDFDokument4 SeitenJSA For HDPE Liner Fusion Welding PDFHaleemUrRashidBangash67% (3)

- Job Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralDokument2 SeitenJob Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralNico Raharjo60% (5)

- JSA Erection of Gathering TentDokument12 SeitenJSA Erection of Gathering TentMuhammad Tariq100% (2)

- ISC-JSA Installation of Portable CabinDokument4 SeitenISC-JSA Installation of Portable CabinSameer Almahboub25% (4)

- شرح مصطلحات النيبوشDokument22 Seitenشرح مصطلحات النيبوشYasser Bouzeghaia100% (1)

- GP 43.0 PUWER-Equipment-Safety-ChecklistDokument4 SeitenGP 43.0 PUWER-Equipment-Safety-ChecklistLarbi BelazizNoch keine Bewertungen

- JSA-Use of Temporary Energization (Power Generator)Dokument4 SeitenJSA-Use of Temporary Energization (Power Generator)MajdiSahnoun100% (1)

- Jsa Non Destructive TestingDokument2 SeitenJsa Non Destructive Testingghulammohyuddin100% (1)

- Hira For Fabrication Work of Steel Structure - CMRLDokument21 SeitenHira For Fabrication Work of Steel Structure - CMRLmahesh naik0% (2)

- Lifting Plan GuidelinesDokument45 SeitenLifting Plan GuidelinesFerry H. Sitohang100% (5)

- R1937-JSA-004 Job Safety Analysis For Pipe PullDokument3 SeitenR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalNoch keine Bewertungen

- JSA-020-Safety Watch-Hot WorkDokument2 SeitenJSA-020-Safety Watch-Hot WorkNishad MuhammedNoch keine Bewertungen

- JSA006 - Vacuum Box TestingDokument5 SeitenJSA006 - Vacuum Box TestingLaohan LiuNoch keine Bewertungen

- HydroTest JHADokument14 SeitenHydroTest JHAorganicspolybond100% (2)

- JSA For Fabrication WorksDokument11 SeitenJSA For Fabrication Workssurendra behera100% (3)

- JSA For Holiday Testing PDFDokument4 SeitenJSA For Holiday Testing PDFMohammed Minhaj67% (3)

- Jsa. Cable Laying and TerminationDokument10 SeitenJsa. Cable Laying and TerminationMon Trang NguyễnNoch keine Bewertungen

- Manual Tig Welding (RRC) - Job ProcedureDokument3 SeitenManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- 001 - JHA Survey Setting Out - REV000Dokument5 Seiten001 - JHA Survey Setting Out - REV000Venkadesh Periathambi100% (2)

- 4-JSA - Unloading Under Inert - F9030 B NewDokument6 Seiten4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNoch keine Bewertungen

- JSA-049 Valves & Support Installation and DismantlingDokument4 SeitenJSA-049 Valves & Support Installation and DismantlingMoaatazz Nouisri75% (4)

- Jsa Radiographic Test RTDokument1 SeiteJsa Radiographic Test RTHussein Adnan Fneish100% (1)

- JSA Template 2017-05-31 Cable Tray InstallationDokument19 SeitenJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezNoch keine Bewertungen

- JSA-Loading-Offloading of Chemical Products With ForkliftDokument4 SeitenJSA-Loading-Offloading of Chemical Products With ForkliftMajdiSahnoun100% (2)

- JSA-Loading-Offloading of Chemical Products With ForkliftDokument4 SeitenJSA-Loading-Offloading of Chemical Products With ForkliftMajdiSahnoun100% (2)

- WR Drakalube PDFDokument9 SeitenWR Drakalube PDFCristian Orosco ValverdeNoch keine Bewertungen

- Ra 11058Dokument69 SeitenRa 11058Art Corbe0% (1)

- SIS Safety Requirements Specification Guideline PDFDokument19 SeitenSIS Safety Requirements Specification Guideline PDFrieza_fNoch keine Bewertungen

- JSA For Kerb Stone in Process AreaDokument3 SeitenJSA For Kerb Stone in Process AreaMohammed Minhaj100% (1)

- Emergency Isolation of Process Plant in Chemical IndustryDokument3 SeitenEmergency Isolation of Process Plant in Chemical IndustryStefano Squadrani100% (1)

- Electrical InstallationDokument3 SeitenElectrical InstallationWalid KhelfaNoch keine Bewertungen

- JSA - Repair-Coating and Finition WorkDokument3 SeitenJSA - Repair-Coating and Finition WorkAMIN100% (1)

- JSA of MPI InspectionDokument1 SeiteJSA of MPI Inspectionengmuhmud100% (1)

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDokument5 SeitenJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz NouisriNoch keine Bewertungen

- JSA For Hydrotesting PDFDokument6 SeitenJSA For Hydrotesting PDFMohammed Minhaj100% (1)

- Jha New - PWHTDokument6 SeitenJha New - PWHTSalam AlkataluniNoch keine Bewertungen

- Jsa Loading and Unloading of Pile PipesDokument4 SeitenJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- Jsa For Cutting, Grinding and Welding For GulfconDokument3 SeitenJsa For Cutting, Grinding and Welding For GulfconOgunwa Emmanuel100% (1)

- JSA-For Lifting Activity by CraneDokument3 SeitenJSA-For Lifting Activity by CraneEman MantoNoch keine Bewertungen

- Jsa Welding Cutting and Grinding at Closing AreaDokument7 SeitenJsa Welding Cutting and Grinding at Closing AreaDedy Kurniawan100% (2)

- Fabrication Work Risk AssessmentDokument11 SeitenFabrication Work Risk Assessmentstansilous100% (1)

- 008 JSA - Manual BoringDokument3 Seiten008 JSA - Manual BoringMohammed MinhajNoch keine Bewertungen

- Jsa For Radiography WorkDokument2 SeitenJsa For Radiography WorkVipul ShankarNoch keine Bewertungen

- Jsa For Intallation of Sub Pipe RackDokument7 SeitenJsa For Intallation of Sub Pipe RackMohammed Minhaj100% (2)

- Petrochina International Jabung LTD.: Job Safety AnalysisDokument4 SeitenPetrochina International Jabung LTD.: Job Safety AnalysisYosua SitumorangNoch keine Bewertungen

- Job Safety Analysis: (Risk Assessment)Dokument8 SeitenJob Safety Analysis: (Risk Assessment)Ped KapedNoch keine Bewertungen

- JSA Formet New Structural Steel ErectionDokument11 SeitenJSA Formet New Structural Steel Erectionsakthi venkatNoch keine Bewertungen

- Hazard Identification & Risk Assessment Sheet ForDokument6 SeitenHazard Identification & Risk Assessment Sheet Forasathish.eee100% (1)

- Jsa For Blowing of Air in Underground PipesDokument4 SeitenJsa For Blowing of Air in Underground PipesMohammed MinhajNoch keine Bewertungen

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Dokument6 SeitenJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganNoch keine Bewertungen

- JSA-018 Lifting With Mobile CraneDokument5 SeitenJSA-018 Lifting With Mobile CraneOmar Dhieb100% (1)

- 1installation of Steel Structures JHA 1 (06!06!2015)Dokument33 Seiten1installation of Steel Structures JHA 1 (06!06!2015)Karthik babu100% (2)

- JSA For DPTDokument3 SeitenJSA For DPTMohammed Minhaj100% (1)

- JSA For Flare Pit Area Including Night WorksDokument4 SeitenJSA For Flare Pit Area Including Night WorksMohammed MinhajNoch keine Bewertungen

- R1937-JSA-005 Job Safety Analysis For Riser InstallationDokument3 SeitenR1937-JSA-005 Job Safety Analysis For Riser InstallationVineet AgrawalNoch keine Bewertungen

- Jha Piping Insulation Installation and Dismantle Work p28Dokument12 SeitenJha Piping Insulation Installation and Dismantle Work p28AmirHakimRusli100% (1)

- JSA - Bolt TensioningDokument5 SeitenJSA - Bolt TensioningRaju KhalifaNoch keine Bewertungen

- JSA Hot WorkDokument3 SeitenJSA Hot WorkNasir Mehmood Aryani100% (1)

- JSA GC-5 Mobile ScaffoldingDokument6 SeitenJSA GC-5 Mobile Scaffoldinggrande100% (2)

- JSA For Hydro Test Activites (Generic)Dokument4 SeitenJSA For Hydro Test Activites (Generic)Khaled Ismail88% (25)

- JSA-for Lifting Activity by Crane. (11-01-2016)Dokument3 SeitenJSA-for Lifting Activity by Crane. (11-01-2016)Mohammed Minhaj100% (2)

- Risk Assessment Rib Erection & FabricationDokument2 SeitenRisk Assessment Rib Erection & FabricationAkash SharmaNoch keine Bewertungen

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Dokument1 SeiteJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDokument2 SeitenJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNoch keine Bewertungen

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDokument15 SeitenSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda BukshNoch keine Bewertungen

- JSA For DuctDokument13 SeitenJSA For DuctRakeshkasarlaNoch keine Bewertungen

- Job Safety Analysis: Required References Jsa ReviewDokument3 SeitenJob Safety Analysis: Required References Jsa ReviewMajdiSahnounNoch keine Bewertungen

- HVAC Fans Initial Energisation Battery RoomDokument3 SeitenHVAC Fans Initial Energisation Battery RoomMajdiSahnounNoch keine Bewertungen

- Battery FillingDokument3 SeitenBattery FillingMajdiSahnounNoch keine Bewertungen

- Process Safety - Recommended Practice On Key Performance IndicatorsDokument36 SeitenProcess Safety - Recommended Practice On Key Performance IndicatorsmarianalourenNoch keine Bewertungen

- CPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0Dokument5 SeitenCPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0MajdiSahnounNoch keine Bewertungen

- CPF-JSA-010 Scaffolding Erection ZONE CLASS0Dokument5 SeitenCPF-JSA-010 Scaffolding Erection ZONE CLASS0MajdiSahnounNoch keine Bewertungen

- Safety in Drilling ManualDokument151 SeitenSafety in Drilling Manualstoianz100% (1)

- Andamios PDFDokument69 SeitenAndamios PDFleonciomavarezNoch keine Bewertungen

- 904studyguide O&G Well InspectionDokument88 Seiten904studyguide O&G Well InspectionMajdiSahnounNoch keine Bewertungen

- Ladder Inspection ChecklistDokument1 SeiteLadder Inspection ChecklistMajdiSahnounNoch keine Bewertungen

- 1 - Workplace Safety Inspections TextDokument36 Seiten1 - Workplace Safety Inspections TextDodi DodoNoch keine Bewertungen

- EulaDokument3 SeitenEulaBrandon YorkNoch keine Bewertungen

- HSNO Er Ug 05Dokument190 SeitenHSNO Er Ug 05MajdiSahnounNoch keine Bewertungen

- Seat Belt AccDokument6 SeitenSeat Belt AccMajdiSahnounNoch keine Bewertungen

- 5 Behavior and DrivingDokument11 Seiten5 Behavior and DrivingMajdiSahnounNoch keine Bewertungen

- Driving Accident TruckDokument8 SeitenDriving Accident TruckMajdiSahnounNoch keine Bewertungen

- 4 652225233830281222 PDFDokument89 Seiten4 652225233830281222 PDFMajdiSahnounNoch keine Bewertungen

- Case HistoriesDokument4 SeitenCase HistoriesMajdiSahnounNoch keine Bewertungen

- 300 English WordsDokument11 Seiten300 English WordsjojaiNoch keine Bewertungen

- Jsa-046 Highway Crossing and Steel CasingDokument11 SeitenJsa-046 Highway Crossing and Steel CasingMajdiSahnounNoch keine Bewertungen

- NA-OTP-PMT-0805-HS-SPE-0006 - Security Standards For Temporary Construction Facilities For CPF Scope PDFDokument15 SeitenNA-OTP-PMT-0805-HS-SPE-0006 - Security Standards For Temporary Construction Facilities For CPF Scope PDFMajdiSahnounNoch keine Bewertungen

- JSA-054 Crossing WorksDokument6 SeitenJSA-054 Crossing WorksMajdiSahnounNoch keine Bewertungen

- 4 968738115655041029Dokument16 Seiten4 968738115655041029MajdiSahnounNoch keine Bewertungen

- ItemDokument2 SeitenItemMajdiSahnounNoch keine Bewertungen

- Annex 17 - Induction Nawara ProjDokument18 SeitenAnnex 17 - Induction Nawara ProjMajdiSahnounNoch keine Bewertungen

- Safety Slogan CollectionDokument42 SeitenSafety Slogan CollectionSreedhar Patnaik.MNoch keine Bewertungen

- Job Safety Analysis: Required References Jsa ReviewDokument3 SeitenJob Safety Analysis: Required References Jsa ReviewMajdiSahnounNoch keine Bewertungen

- Battery FillingDokument3 SeitenBattery FillingMajdiSahnounNoch keine Bewertungen

- COP Cash in TransitDokument30 SeitenCOP Cash in TransitFrancisco SaraivaNoch keine Bewertungen

- Safe Work Method Statement (SWMS) Infection Prevention & ControlDokument1 SeiteSafe Work Method Statement (SWMS) Infection Prevention & ControlAnoirNoch keine Bewertungen

- PTW Training LV2 DraftDokument21 SeitenPTW Training LV2 DraftRaulNoch keine Bewertungen

- Excavation Risk AssessmentDokument11 SeitenExcavation Risk AssessmentMarwan NazzalNoch keine Bewertungen

- 102-71-6 Triethanolamine (2013)Dokument3 Seiten102-71-6 Triethanolamine (2013)Junhuey ShanNoch keine Bewertungen

- Sto Domingo DRRMDokument36 SeitenSto Domingo DRRMBrad-m CdrrmoNoch keine Bewertungen

- Safety Data Sheet: AluminumDokument8 SeitenSafety Data Sheet: AluminumClaudio BiaginiNoch keine Bewertungen

- Housekeeping NC Iii TraningDokument37 SeitenHousekeeping NC Iii TraningRuth Zamora Calanday DomingoNoch keine Bewertungen

- CRC 05110 MAF Cleaner Safety Data SheetDokument12 SeitenCRC 05110 MAF Cleaner Safety Data SheetBenjamin DoverNoch keine Bewertungen

- JHA Overhead Cleaning MP16Dokument4 SeitenJHA Overhead Cleaning MP16Jay JocoNoch keine Bewertungen

- IMPLAN To OPLAN SAKLOLODokument19 SeitenIMPLAN To OPLAN SAKLOLOTerrence33% (3)

- System Safety HandbookDokument161 SeitenSystem Safety HandbookenglandbroNoch keine Bewertungen

- 2016 W-2 Gross Wages CityDokument16 Seiten2016 W-2 Gross Wages CityportsmouthheraldNoch keine Bewertungen

- Trees Cutting: R4 / BBR111, Bandar Bukit Raja 2, Klang, Selangor. 35. Trees CuttingDokument2 SeitenTrees Cutting: R4 / BBR111, Bandar Bukit Raja 2, Klang, Selangor. 35. Trees CuttingRafee Pie100% (1)

- Jsa For Roof Air LiftDokument2 SeitenJsa For Roof Air LiftKoshy Thankachen100% (1)

- Jurnal k3Dokument24 SeitenJurnal k3FahmiNoch keine Bewertungen

- NEBOSH International Certificate in Fire Safety and Risk ManagementDokument2 SeitenNEBOSH International Certificate in Fire Safety and Risk Managementchaikal alghifariNoch keine Bewertungen

- Field Trip Risk AssessmentDokument4 SeitenField Trip Risk Assessmentapi-287142055100% (1)

- Fire Detection and Warning SystemsDokument1 SeiteFire Detection and Warning SystemsDinesh dhakarNoch keine Bewertungen

- Construction Safety: Working at HeightsDokument6 SeitenConstruction Safety: Working at Heightsakb2853Noch keine Bewertungen

- Manual Lifting & Handling Guidelines: PurposeDokument2 SeitenManual Lifting & Handling Guidelines: PurposeNagendra Kumar SinghNoch keine Bewertungen

- MSDS - Candelilla ButterDokument3 SeitenMSDS - Candelilla ButterVictor LopezNoch keine Bewertungen

- MS For Installation of Drainage PipesDokument20 SeitenMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- JSA HEMP Well Services Pg01-05Dokument5 SeitenJSA HEMP Well Services Pg01-05Ashok SureshNoch keine Bewertungen