Beruflich Dokumente

Kultur Dokumente

CNC Programming 06-11-2017

Hochgeladen von

Ajay Kumar Bathula0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

34 Ansichten69 Seitencnc programming

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldencnc programming

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

34 Ansichten69 SeitenCNC Programming 06-11-2017

Hochgeladen von

Ajay Kumar Bathulacnc programming

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 69

Computer Numerical

Control Programming

N. Vijaya Kumar

November 6, 2017 N. Vijaya Kumar

Points to be Covered

Axes designation

Part programming fundamentals

November 6, 2017 N. Vijaya Kumar

Part program writing

Word address format

Part programming manual (actual

machine tool and control)

November 6, 2017 N. Vijaya Kumar

Word address format

N035 G01 X120.5 Y55.0 Z-12.0 F150 M03;

N035 refers to the block number 35

G01 refers to a preparatory code 1 for linear

interpolation

X120.5 refers to X coordinate value 120.5 units

Y55.0 refers to Y coordinate value 55.0 units

Z-12.0 refers to Z coordinate value -12.0 units

F150 refers to a feed rate of 150 units/min

M03 refers to a miscellaneous code value of 3 that

starts the spindle in the clockwise direction

; refers to the end of block

November 6, 2017 N. Vijaya Kumar

Word address format

A Angular dimension around X axis

B Angular dimension around Y axis

C Angular dimension around Z axis

D Angular dimension around special axis or

third feed function

E Angular dimension around special axis or

second feed function

F Feed function

G Preparatory function

November 6, 2017 N. Vijaya Kumar

Word address format

H Unassigned

I Distance to arc centre or thread lead

parallel to X

J Distance to arc centre or thread lead

parallel to Y

K Distance to arc centre or thread lead

parallel to Z

November 6, 2017 N. Vijaya Kumar

Word address format

M Miscellaneous function

N Sequence number

O Reference rewind stop

P Third rapid traverse dimension or tertiary

motion dimension parallel to X

Q Second rapid traverse dimension or

tertiary motion dimension parallel to Y

R First rapid traverse dimension or tertiary

motion dimension parallel to Z

November 6, 2017 N. Vijaya Kumar

Word address format

S Spindle speed function

T Tool function

U Secondary motion dimension parallel to X

V Secondary motion dimension parallel to Y

W Secondary motion dimension parallel to Z

X Primary X motion dimension

Y Primary Y motion dimension

Z Primary Z motion dimension

November 6, 2017 N. Vijaya Kumar

Word address format

N5 G2 X53 Y53 Z53 U..V..W..I..J..

K..F5 S4 T4 M2 ;

November 6, 2017 N. Vijaya Kumar

Coordinate Function

The various word addresses used for

specifying coordinates are X, Y, Z, U, V, W, I,

J, K, A, B, C, etc.

They can be specified using a direct decimal

format.

N025 T01 M03 S1000 ;

N030 G01 X15.450 Y35.540 Z-2.0 F120 ;

N035 X-25.500 Y55.545 ;

N045 X15.450 Y35.540 ;

November 6, 2017 N. Vijaya Kumar

Feed Function

Generally the feed rate is specified with F

word address and specified in mm per

minute.

The value specified normally is the speed

with which the spindle moves along the

specified path.

For example, F120 in the above statement

means that the feed rate is specified as 120

mm per minute (assuming metric units are

used in the program).

November 6, 2017 N. Vijaya Kumar

Feed Function

It is also possible to specify feed using

the mm per revolution units, with a

special preparatory function.

The feed rate specified in any block

remains modal.

It is possible to change programmed

feed by the use of feed rate over switch

on the machine tool control panel.

November 6, 2017 N. Vijaya Kumar

Speed Function

The spindle speed can be set using the S

word address.

The number after the S is the speed of the

spindle specified directly in revolutions per

minute.

For example, S1000 in the above statement

means that the spindle speed is specified as

1000 revolutions per minute.

November 6, 2017 N. Vijaya Kumar

Speed Function

Though this is the normal usage, it is

also possible to specify the spindle

speed in cutting speed units as meters

per minute using a special preparatory

function.

November 6, 2017 N. Vijaya Kumar

Tool Function

The tool to be used for an operation is

to be identified by the T word address.

For example, T01 in the above

statement means that the tool number

1 is to be placed in the spindle.

The tool number is considered as the

tool magazine position in the case of

machines with automatic tool changers.

November 6, 2017 N. Vijaya Kumar

Tool Function

In some cases the tool number may

also have to be combined with the tool

offset register number, which is

described later.

November 6, 2017 N. Vijaya Kumar

Preparatory functions

The preparatory functions are denoted

by the word address 'G'.

This function principally controls the

geometric functions of the controller.

It generally has two digits, e.g. G01,

G42, and G90 as per ISO specifications.

Many of the current day controllers

have extended this to 3 or 4 digits.

November 6, 2017 N. Vijaya Kumar

Preparatory functions

Most of the G codes are modal in nature, so

that they need not be repeated in every

block.

Another point to be noted with these codes is

that the G codes are divided into various

groups depending upon their functionality.

It is expected that only one code from each

of the group should be given in any given

block.

November 6, 2017 N. Vijaya Kumar

Preparatory functions

It is generally possible to include more than

one G address in one block, provided these

functions are not mutually exclusive.

In GE-Fanuc controls upto 5 G codes can be

given in one block.

Some other controls have different limits, but

generally upto 3 codes in a single block will

be permissible.

November 6, 2017 N. Vijaya Kumar

Preparatory functions

It should also be noted that some of the G

codes remain in force when the control is

started or reset.

These are termed as default or turn on codes.

Though it is a prudent practice, to specify all

the necessary G codes while writing the

programs, some times it may be possible by

the experienced programmers to take

advantage of these default codes and reduce

the length of the program.

November 6, 2017 N. Vijaya Kumar

Preparatory functions (Motion

group )

*G00 Rapid Positioning

G01 Linear Interpolation

G02 Circular interpolation Clockwise

G03 Circular interpolation Counter

clockwise

* Generally specified as default code

November 6, 2017 N. Vijaya Kumar

Preparatory functions (Active

plane selection group )

*G17 XY Plane selection

G18 XZ Plane selection

G19 YZ Plane selection

* Generally specified as default code

November 6, 2017 N. Vijaya Kumar

Preparatory functions

Units group

*G70 Inch units

G71 Metric units

Co-ordinate system group

*G90 Absolute co-ordinate system

G91 Incremental co-ordinate system

* Generally specified as default code

November 6, 2017 N. Vijaya Kumar

Co-ordinate system group,

G90 and G91

The coordinate data can be input into the

program either in the absolute or in the

incremental system.

The absolute coordinate system is indicated

by the preparatory function G90.

In absolute system, the dimensions are given

with respect to a common datum established

by the programmer.

November 6, 2017 N. Vijaya Kumar

Co-ordinate system group,

G90 and G91

Fig from P N Rao – CAD/CAM Principles and

Applications, Tata McGrawHill

November 6, 2017 N. Vijaya Kumar

Absolute Programming

Suppose the route to be 0-A-B-C in absolute

programming system

N010 G90 G01 X15.0 Y15.0 F200; Point A

N015 X25.0; Point B. Notice no change in Y-axis

N020 X45.0 Y10.0; Point C

G90 code is modal and will remain in force till it is cancelled

by another code from the same group, i.e., G91 for

incremental programming.

November 6, 2017 N. Vijaya Kumar

Absolute Programming

Suppose the route to be 0-A-C-B then:

N010 G90 G01 X15.0 Y15.0 F200; Point A

N015 X45.0 Y10.0; Point C

N020 X25.0 Y15.0; Point B.

November 6, 2017 N. Vijaya Kumar

Incremental Programming

In the case of incremental

programming the G-code used is G91.

In incremental programming, the

actual distance moved by the tool from

the current position is programmed.

Unlike with G90, the programmed data

changes only if the route of the move

is altered.

November 6, 2017 N. Vijaya Kumar

Incremental Programming

The program for route 0-A-B-C would be:

N010 G91 G01 X15.0 Y15.0 F200; Point A

N015 X10.0; Point B. Notice no change in Y-axis

N020 X20.0 Y-5.0; Point C

November 6, 2017 N. Vijaya Kumar

Incremental Programming

When route is changed to 0-A-C-B, then the

program will be:

N010 G91 G01 X15.0 Y15.0 F200; Point A

N015 X30.0 Y-5.0; Point C

N020 X-20.0 Y5.0; Point B.

November 6, 2017 N. Vijaya Kumar

Absolute and Incremental

Programming

While writing NC program in incremental

mode, care has to be taken to designate

the actual movement of the tool in the

positive or negative axis direction.

This is true even when the movement of

the tool is in the first quadrant, still some of

the movements have been identified as

negative because the tool is moving in the

negative axis direction.

November 6, 2017 N. Vijaya Kumar

Absolute and Incremental Programming

It is generally suggested that a fresh

programmer may stick to programming in

absolute system in the beginning.

This will help in reducing the possible

mistakes in specifying the coordinates.

Any error in coordinates in absolute

programming will result in only an error in

that part, while in the case of incremental

programming the error will continue further

down in all subsequent blocks.

November 6, 2017 N. Vijaya Kumar

Units group, G70, G71

The CNC part programs can use either inch

units or metric units.

The choice will have to be specified in the

beginning of the program.

The codes used are G70 for inch

programming and G71 for mm

programming.

The program units cannot be changed in

between.

November 6, 2017 N. Vijaya Kumar

Units group, G70, G71

In GE-Fanuc controls normally G20 and

G21 are used for the units in place of

G70 and G71.

This can be changed optionally to G70

and G71 using the programmable

functions of the control system.

November 6, 2017 N. Vijaya Kumar

Active plane selection group,

G17, G18, G19

Some of the functions in NC control can

only work in a plane rather than in all

the 3 possible co-ordinate axes.

This therefore requires the selection of

active plane.

This can be done by using these codes

G17, G18, G19 .

November 6, 2017 N. Vijaya Kumar

XY plane selection for vertical axis milling

machines

November 6, 2017 N. Vijaya Kumar

XY plane selection for Horizontal axis

milling machines

November 6, 2017 N. Vijaya Kumar

XZ plane selection for vertical axis milling

machines

November 6, 2017 N. Vijaya Kumar

YZ plane selection for vertical axis milling

machines

November 6, 2017 N. Vijaya Kumar

Absolute Preset, G92

As described earlier, each of the machine tool

has a separate machine reference point.

However, this point is not very convenient to

use as a co-ordinate datum for the part.

Most of the NC machine tools allow for a

'Floating Datum' to be fixed anywhere in the

machining envelope of the machine tool.

November 6, 2017 N. Vijaya Kumar

November 6, 2017 N. Vijaya Kumar

Absolute Preset, G92

As a result, the programmer can choose

a convenient position on the part as

datum, which may be referred to as

'Program Zero Point'.

The same will have to be communicated

to the NC controller as datum.

N015 G92 X2.0 Y1.0 Z1.0 ;

November 6, 2017 N. Vijaya Kumar

Work piece datums

G53 to G56 are the other codes used for

setting the programmable datum positions.

These would allow for a fixing a number of

positions on the machine table whose co-

ordinates can be entered into the controller

as a permanent memory.

When required their positions can be simply

called by giving the particular G code in the

program.

November 6, 2017 N. Vijaya Kumar

November 6, 2017 N. Vijaya Kumar

Work piece datums

This would also be useful for machining

a batch of components all of which are

located on the machine table each at

the positions indicated by G53, G54,

etc.

November 6, 2017 N. Vijaya Kumar

Motion group, G00, G01, G02,

G03

This is the most important group of

codes used in part programming.

Most of the common motions are

specified using this set of codes.

G00 is normally the turn on code from

this list.

November 6, 2017 N. Vijaya Kumar

Rapid Positioning, G00

This is used for moving the tool at a rapid

rate (normally the maximum available feed

rate such as 8,000 or 40,000 mm/min) along

the axes involved for achieving the position

programmed.

It is not important for this code, the path

taken by the tool to reach the programmed

point.

November 6, 2017 N. Vijaya Kumar

Rapid Positioning, G00

This is a modal (stays active till

cancelled by any other function of its

family, i.e., G01, G02, G03) function.

It is also the 'turn on mode' (available

as soon as the system is switched on or

when a new program starts).

Referring to Fig. 13-13, from position A,

it is required to achieve position B.

November 6, 2017 N. Vijaya Kumar

Rapid Positioning, G00

November 6, 2017 N. Vijaya Kumar

Linear or Straight line

Interpolation, G01

This code is generally used when the

material is to be cut using a feed rate.

When the motion is desired along a

straight line at a given feed rate, this

function is used.

It is modal.

November 6, 2017 N. Vijaya Kumar

November 6, 2017 N. Vijaya Kumar

Circular Interpolation, G02 /

G03

When an arc is to be traversed in a

plane, the function G02 or G03 is used

if the direction of the motion is

clockwise or anti-clockwise respectively,

looking in the negative direction of the

axis perpendicular to the plane.

November 6, 2017 N. Vijaya Kumar

November 6, 2017 N. Vijaya Kumar

November 6, 2017 N. Vijaya Kumar

Dwell, G04

This is to give a delay in the program.

When the G04 code is encountered, the

controller stops at that particular point for a

specified time mentioned in the block.

After that time the controller continues to

execute the next block in the program.

The delay time is normally mentioned in

seconds using the X word address.

In some controls, other than X may also be

used.

November 6, 2017 N. Vijaya Kumar

Dwell, G04

N045 G04 X3.0; This calls for a

stoppage of the control for a period of 3

seconds.

N045 G04 P3000; This calls for a

stoppage of the control for a period of 3

seconds.

November 6, 2017 N. Vijaya Kumar

Miscellaneous Functions, M

These functions actually operate some

controls on the machine tool and thus affect

the running of the machine.

Generally only one-M code is supposed to be

given in a single block.

However, some controllers allow for two or

more M codes to be given in a block,

provided these are not mutually exclusive,

e.g., coolant ON (M07) and OFF (M09)

cannot be given in one block.

November 6, 2017 N. Vijaya Kumar

Miscellaneous functions

Less number of M codes have been

standardized by ISO compared to G

codes in view of the direct control

exercised by these on the machine tool.

November 6, 2017 N. Vijaya Kumar

Miscellaneous functions

M00 Program Stop

This would terminate the auto operation of

the machine after completing the instructions

in the block in which it has been

programmed.

This is called 'Program stop' and if it is

required to continue with the rest of the

program, the 'start' button on the console is

to be pressed.

November 6, 2017 N. Vijaya Kumar

Miscellaneous functions

M00 Program Stop

This is useful for changing the clamp position

or to carry out inspection of a particular

dimension after a machining cut is taken.

This being a pause function, and calls for the

attention of the operator, delays the

completion of the program and therefore

should be avoided as far as possible.

November 6, 2017 N. Vijaya Kumar

Miscellaneous functions

M01 Optional stop

This is 'Optional stop' and stops the

machine, as in the case of M00, only if

the "Optional stop" switch on the

controller console is 'ON'.

This is useful when inspection is to be

carried out on some components and

not all in a given batch.

November 6, 2017 N. Vijaya Kumar

Miscellaneous functions

M02 End of program

This is 'End of program' and it causes

the stopping of the machine and

clearing of all the control registers.

Another code M30 also does the same

function.

November 6, 2017 N. Vijaya Kumar

Miscellaneous functions

M03 Spindle start – clockwise direction

This miscellaneous function for machine

spindle control for clockwise rotation.

This starts the spindle to move in the

clockwise direction at the speed set earlier

using the S word address.

When it is given in a block would be the first

code to be executed before all the other

codes in a block are acted upon.

November 6, 2017 N. Vijaya Kumar

Miscellaneous functions

M04 Spindle start – Counter clockwise

direction

This miscellaneous function for machine

spindle control for counter clockwise rotation.

This starts the spindle to move in the counter

clockwise direction at the speed set earlier

using the S word address.

When it is given in a block would be the first

code to be executed before all the other

codes in a block are acted upon.

November 6, 2017 N. Vijaya Kumar

Miscellaneous functions

M05 Stop the machine spindle

It is the miscellaneous function for

stopping the machine spindle.

When it is given in a block would be the

last code to be executed after all the

other codes in a block are acted upon.

November 6, 2017 N. Vijaya Kumar

Miscellaneous functions

M06 is for tool change.

M07 is for 'Coolant 1 On'

M08 is for 'Coolant 2 On'

M09 is for 'Coolant Off'

November 6, 2017 N. Vijaya Kumar

Miscellaneous functions

M13

the miscellaneous function for machine

spindle control for clockwise rotation and the

starting of the coolant simultaneously.

This starts the spindle to move in the

clockwise direction at the speed set earlier

using the S word address.

When it is given in a block would be the first

code to be executed before all the other

codes in a block are acted upon.

November 6, 2017 N. Vijaya Kumar

Miscellaneous functions

M30 is similar to M02.

It indicates 'End of tape' and 'tape rewind'.

If a paper tape is used, the tape is rewind till

the % sign is encountered.

For machines working with RAM, the active

program comes to the beginning. Many a

times M02 and M30 are synonymous in

operation in modern day controllers.

November 6, 2017 N. Vijaya Kumar

Program Number

Program number is specified by O

word address, generally.

It is not essential, but useful for

storage purposes.

November 6, 2017 N. Vijaya Kumar

Das könnte Ihnen auch gefallen

- LAB 5 - Coding LectureDokument16 SeitenLAB 5 - Coding LectureHusnain AliNoch keine Bewertungen

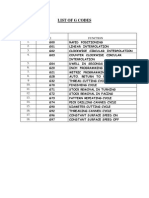

- List of G Codes: SR - NO. Code Function 1. 2. 3. 4Dokument28 SeitenList of G Codes: SR - NO. Code Function 1. 2. 3. 4pmagrawal100% (1)

- Basic Information of CNC ProgramDokument16 SeitenBasic Information of CNC Programjawad khalidNoch keine Bewertungen

- Mach4 G and M Code Reference ManualDokument81 SeitenMach4 G and M Code Reference ManualMegi Setiawan SNoch keine Bewertungen

- CNC Programming GuideDokument12 SeitenCNC Programming GuideAman RizviNoch keine Bewertungen

- Govt. Tool Room Training Center CNC ProgrammingDokument15 SeitenGovt. Tool Room Training Center CNC ProgrammingShivananda Chavannavar33% (3)

- CNC Programming3Dokument109 SeitenCNC Programming3Akash SriNoch keine Bewertungen

- Turning: Chapter ObjectivesDokument78 SeitenTurning: Chapter ObjectivesDany EscobarNoch keine Bewertungen

- CNC Programming Word AddressingDokument9 SeitenCNC Programming Word Addressingmustafa1011Noch keine Bewertungen

- Mach4 Mill GCode ManualDokument60 SeitenMach4 Mill GCode Manualsahiljain_146Noch keine Bewertungen

- New Microsoft Word DocumentDokument19 SeitenNew Microsoft Word DocumentŤhåýğųŢjNoch keine Bewertungen

- Mach4 G and M Code Reference ManualDokument60 SeitenMach4 G and M Code Reference ManualRAKESH PRAJAPATI100% (1)

- CNC ProgDokument38 SeitenCNC ProgPoornima JoshiNoch keine Bewertungen

- Lecture 5 CNC Part IIDokument36 SeitenLecture 5 CNC Part IIsneha barmanNoch keine Bewertungen

- CNC Part ProgrammingDokument9 SeitenCNC Part ProgrammingC.K. VishwakarmaNoch keine Bewertungen

- CAD/CAM/CAE IntroductionDokument149 SeitenCAD/CAM/CAE IntroductionalexiskandarNoch keine Bewertungen

- G M Codes For Turning and MillingDokument10 SeitenG M Codes For Turning and MillingParanthaman RamanNoch keine Bewertungen

- Chapter 6Dokument56 SeitenChapter 6gashawletaNoch keine Bewertungen

- 5 - G-CodeDokument55 Seiten5 - G-CodefamilyumaNoch keine Bewertungen

- CNC Programming and PolymerDokument21 SeitenCNC Programming and PolymerAnilNoch keine Bewertungen

- CNC Milling: Programming for Milling OperationsDokument90 SeitenCNC Milling: Programming for Milling OperationsJanric AltuveNoch keine Bewertungen

- CNC Programming FundamentalsDokument26 SeitenCNC Programming Fundamentalsmohamed alsalhyNoch keine Bewertungen

- CNC TechDokument20 SeitenCNC TechBharath KumarNoch keine Bewertungen

- CNC CodesDokument8 SeitenCNC CodesKevin DebryuneNoch keine Bewertungen

- UNIT 7 - CNC - Lecture 3 - ProgrammingDokument33 SeitenUNIT 7 - CNC - Lecture 3 - ProgrammingRakshithNoch keine Bewertungen

- CNC Part ProgrammingDokument61 SeitenCNC Part ProgrammingrajaNoch keine Bewertungen

- 2.5 Programming Functions: (Mm/min or Inch/min) (Mm/rev or Inch/rev)Dokument59 Seiten2.5 Programming Functions: (Mm/min or Inch/min) (Mm/rev or Inch/rev)Srinivas YadavNoch keine Bewertungen

- ME8691 CNC Programming FundamentalsDokument62 SeitenME8691 CNC Programming FundamentalssamnztNoch keine Bewertungen

- Manual ProgrammingDokument11 SeitenManual ProgrammingSumugan SwaroopNoch keine Bewertungen

- MSC Lecture 6Dokument28 SeitenMSC Lecture 6Chán Chênh VênhNoch keine Bewertungen

- Mill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram ExampleDokument73 SeitenMill Fanuc: Fanuc G68 Coordinate Rotation - Subprogram Exampleسليمان مصريNoch keine Bewertungen

- CNC Programming Guide for Mechanical EngineersDokument21 SeitenCNC Programming Guide for Mechanical EngineersVarshaNoch keine Bewertungen

- Specific Codes: Letter AddressesDokument16 SeitenSpecific Codes: Letter AddressesVijay KumarNoch keine Bewertungen

- Part Programming: Unit II 2nd EvaluationDokument14 SeitenPart Programming: Unit II 2nd EvaluationEduardo ResendizNoch keine Bewertungen

- Numerical Control ProgrammingDokument81 SeitenNumerical Control Programmingmsaqibraza93Noch keine Bewertungen

- 9.2 Part Programming For NC SystemsDokument6 Seiten9.2 Part Programming For NC SystemsWeween IbrahimNoch keine Bewertungen

- CNC PROGRAMMING TITLEDokument104 SeitenCNC PROGRAMMING TITLEAnvit TiwariNoch keine Bewertungen

- Buku Panduan Pemrograman MTU 200MDokument73 SeitenBuku Panduan Pemrograman MTU 200MMãüç Ãfîf50% (2)

- Cam RecordDokument39 SeitenCam Recordryan saraNoch keine Bewertungen

- A New PetrolDokument9 SeitenA New PetrolMariano Escobar AvilaNoch keine Bewertungen

- Manual Part ProgrammingDokument38 SeitenManual Part ProgrammingHot Shot100% (1)

- How To Use Charly 4U Milling Mchine Using The GcodeDokument18 SeitenHow To Use Charly 4U Milling Mchine Using The GcodeAnish KumarNoch keine Bewertungen

- Lathe Miscellaneous FunctionDokument7 SeitenLathe Miscellaneous FunctionsuryavenkatramanNoch keine Bewertungen

- FANUCMDokument24 SeitenFANUCMpramodgowdruNoch keine Bewertungen

- 01 CNC Lab Manual NIT APDokument4 Seiten01 CNC Lab Manual NIT APDevesh RehanNoch keine Bewertungen

- Programming 1Dokument44 SeitenProgramming 1shubhanshu kumarNoch keine Bewertungen

- Trumatic 200R Programing ManualDokument42 SeitenTrumatic 200R Programing ManualPPNoch keine Bewertungen

- CIM LAB ManualDokument58 SeitenCIM LAB ManualBruce ColonNoch keine Bewertungen

- CNC Programming Guide: Coordinate Systems, Plane Selection, and Interpolation FunctionsDokument90 SeitenCNC Programming Guide: Coordinate Systems, Plane Selection, and Interpolation FunctionsDerik NelsonNoch keine Bewertungen

- Axis positions, feedrates, tool offsets and more for CNC machiningDokument13 SeitenAxis positions, feedrates, tool offsets and more for CNC machiningzokiplusNoch keine Bewertungen

- Custom Macro B (Fanuc)Dokument42 SeitenCustom Macro B (Fanuc)JohnPaulSmith1100% (1)

- Lathe GCode ProgrammingDokument89 SeitenLathe GCode ProgrammingluisNoch keine Bewertungen

- Typical CNC Machining Centre: Horizontal Axis Milling Vertical Axis MillingDokument82 SeitenTypical CNC Machining Centre: Horizontal Axis Milling Vertical Axis MillingAbdul RehmanNoch keine Bewertungen

- Basic Machine Codes For CNC MillingDokument46 SeitenBasic Machine Codes For CNC MillingMohd Zaieri100% (5)

- Unit 4CADMDokument62 SeitenUnit 4CADMSurulivelrajantNoch keine Bewertungen

- CNC Turning Machines: Coordinate System and Programming CyclesDokument34 SeitenCNC Turning Machines: Coordinate System and Programming CyclesAmaterasu Susanoo TsukuyomiNoch keine Bewertungen

- 11 Cad Cam CNC Programming MVVDokument37 Seiten11 Cad Cam CNC Programming MVVbassem smatiNoch keine Bewertungen

- Chapter 3.CNC Part ProgrammingDokument61 SeitenChapter 3.CNC Part ProgrammingDr. Vivek SrivastavaNoch keine Bewertungen

- Guidelines for the Economic Analysis of ProjectsVon EverandGuidelines for the Economic Analysis of ProjectsNoch keine Bewertungen

- Litpack ManuelDokument66 SeitenLitpack ManuelMoussaab BerkaniNoch keine Bewertungen

- RDD Stata 1Dokument23 SeitenRDD Stata 1Denis Lima E AlvesNoch keine Bewertungen

- LA-950V2 - Software Instruction Manual PDFDokument119 SeitenLA-950V2 - Software Instruction Manual PDFdavid arturo oriz rdzNoch keine Bewertungen

- Table of Contents and Basic Hydraulic PrinciplesDokument6 SeitenTable of Contents and Basic Hydraulic Principleskawser zamanNoch keine Bewertungen

- Chapter 1Dokument10 SeitenChapter 1Misganaw YeshiwasNoch keine Bewertungen

- MSIP Period Maps Tool 200901Dokument8 SeitenMSIP Period Maps Tool 200901Kenny CasillaNoch keine Bewertungen

- Motion & Geometry based methods in Frequency Domain Computer VisionDokument31 SeitenMotion & Geometry based methods in Frequency Domain Computer VisionBasudha PalNoch keine Bewertungen

- YLAC-1808 应力分析报告(Stress Analysis-1808)Dokument19 SeitenYLAC-1808 应力分析报告(Stress Analysis-1808)arisandiyusufNoch keine Bewertungen

- Aerospace Engineering Sample Report PDFDokument4 SeitenAerospace Engineering Sample Report PDFDuncan LeeNoch keine Bewertungen

- Edexcel GCE Core 1 Mathematics C1 Jun 2005 6663 Mark SchemeDokument10 SeitenEdexcel GCE Core 1 Mathematics C1 Jun 2005 6663 Mark Schemerainman875Noch keine Bewertungen

- Stat 11 Q4 Week 2-SSLMDokument4 SeitenStat 11 Q4 Week 2-SSLMwiggleypuff100% (1)

- Snap Fit CalculationsDokument6 SeitenSnap Fit CalculationsSathish Kumar ChelladuraiNoch keine Bewertungen

- ISI Exam Sample PaperDokument5 SeitenISI Exam Sample PaperQarliddh0% (1)

- FIR FilterDokument32 SeitenFIR FilterWan TingNoch keine Bewertungen

- Basic Math PresentationDokument6 SeitenBasic Math PresentationGrayPrinceleyChuaNoch keine Bewertungen

- Mathematics AnswersDokument62 SeitenMathematics AnswersMohammad Reza RahimiNoch keine Bewertungen

- Hypothesis TestingDokument6 SeitenHypothesis TestingDynamic ClothesNoch keine Bewertungen

- Statistics - Lying Without Sinning?: - "Lies, Damned Lies, and Statistics"Dokument48 SeitenStatistics - Lying Without Sinning?: - "Lies, Damned Lies, and Statistics"αγαπημένη του ΧριστούNoch keine Bewertungen

- Python Practical Program-XiDokument10 SeitenPython Practical Program-XiTapaswiniNoch keine Bewertungen

- Toan-Ky-Thuat - Le-Minh-Cuong - ch5 - Applications-The-Laplace-Transform-To-Differential-Equations - (Cuuduongthancong - Com)Dokument7 SeitenToan-Ky-Thuat - Le-Minh-Cuong - ch5 - Applications-The-Laplace-Transform-To-Differential-Equations - (Cuuduongthancong - Com)Giang TônNoch keine Bewertungen

- Database Management System - DBMS (COMPUTER SCIENCE) Video Lecture For GATE Preparation (CS IT MCA)Dokument3 SeitenDatabase Management System - DBMS (COMPUTER SCIENCE) Video Lecture For GATE Preparation (CS IT MCA)Vishal SharmaNoch keine Bewertungen

- CEGP013091: 49.248.216.238 01/02/2023 13:36:42 Static-238Dokument5 SeitenCEGP013091: 49.248.216.238 01/02/2023 13:36:42 Static-238forfives2Noch keine Bewertungen

- Piefort 01Dokument154 SeitenPiefort 01Sumanth KolliparaNoch keine Bewertungen

- Java Important Questions SetDokument64 SeitenJava Important Questions SetChairil Aditya NurfadlilahNoch keine Bewertungen

- Calculate Discount and Percentage DiscountDokument12 SeitenCalculate Discount and Percentage DiscountMaria KimNoch keine Bewertungen

- P5 Maths 2019 SA2 Raffles Girls' Exam PaperDokument35 SeitenP5 Maths 2019 SA2 Raffles Girls' Exam PaperAqil SubendiNoch keine Bewertungen

- C++ OOP Course with Classes, Inheritance, TemplatesDokument3 SeitenC++ OOP Course with Classes, Inheritance, TemplatesCharmi GogriNoch keine Bewertungen

- Lecture 1 - Complex Numbers 1 The Field of Complex Numbers: 1.1 Arithmetic OperationsDokument6 SeitenLecture 1 - Complex Numbers 1 The Field of Complex Numbers: 1.1 Arithmetic OperationsManeeshNoch keine Bewertungen

- MIT AVL User Primer guideDokument43 SeitenMIT AVL User Primer guideTinashe ErwinNoch keine Bewertungen

- Wolfe - Cellular ThermodynamicsDokument13 SeitenWolfe - Cellular Thermodynamicsandres_old_condeNoch keine Bewertungen