Beruflich Dokumente

Kultur Dokumente

LSCM - Group Assign

Hochgeladen von

navneet. pgdm17cOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

LSCM - Group Assign

Hochgeladen von

navneet. pgdm17cCopyright:

Verfügbare Formate

Analysis:

The case is about the speculation and wrong forecasting of products by the Sport Obermeyer which

is a high end fashion skiwear designer and merchandising company. It describes about the issues

faced by the company such as long lead times, intuition and sheer speculation, improper feedback

and communication with retailers and inaccurate forecasts of retailer demand. Due to inability to

predict correctly the company was facing excess merchandising and losses. It describes about the

products, suppliers, and supply chain method used by the company.

Solution for Problem 1

In order to determine what items should be produced where, a risk assessment was conducted for

all lines per the average forecast for each line. The standard deviation was determined in order to

analyze the risk associated with each line. A benchmark of twice of standard deviation was used to

determine the associated risk. Any item with a standard deviation below 2 is considered a low risk

item while any item with a standard deviation higher than 2 is considered a high risk item.

It is assumed that first order placed must be at least 600 units per item in Hong Kong and 1,200 units

per item in China. The remainder of the average forecast will be made up in the second order. Here

in the process we have used the formula

Sum(Average Forecast – K* Standard deviation) to find the total maximum quantity of products. Here

the production commitment is 1000

so Sum (Avg forecast – K * Std) = 10000. By using trial and error method we got k=2 Following given

in exhibit 10.

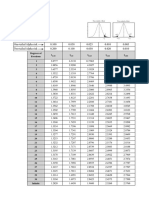

Style Average Forecast Standard deviation 2 x Standard Deviation

Gail 1,017 194 388

Isis 1,042 323 646

Entice 1,358 248 496

Assault 2,525 340 680

Teri 1,100 381 762

Electra 2,150 404 807

Stephanie 1,113 524 1,048

Seduced 4,017 556 1,113

Anita 3,296 1,047 2,094

Daphne 2,383 697 1,349

Here we will subtract 2 Standard deviation from average of each line because the average forecast is

used to determine the final solution.

Average Forecast Standard deviation Average- 2*SD Hong kong

1,017 194 629 629

1,042 323 396 600

1,358 248 862 862

2,525 340 1845 1845

1,100 381 338 600

2,150 404 1342 1342

1,113 524 65 600

4,017 556 2905 2905

3,296 1,047 1202 1202

2,383 697 989 989

Here the total average forecast is 20000 but our first commitment is 10000 so K=2 we got above

forecasted quantities to be produced by Hong Kong and China.

At the Hong Kong plant, there is a minimum of 600 units required per line produced. For this reason,

the initial quantity for the Daphne, Isis, Teri, and Stephanie lines would need to be increased to meet

this requirement for the first order.

Changes

Reducing number of styles handled and to predict customer demand for individual style.

To create promotion strategy to persuade retailers to order.

PRODUCTION SYSTEM

• Increasing production Quality of China to be closed to Hong Kong.

To reduce lead time of production especially the preparation of raw materials

• Increase bargaining power with suppliers by ordering via big supplier that can commit on

timeline

• Collect stock raw materials which is base on Ski cloth production

Das könnte Ihnen auch gefallen

- Repeat Your Methodology and Assume How That All 10 Styles Are Made in ChinaDokument3 SeitenRepeat Your Methodology and Assume How That All 10 Styles Are Made in ChinaTampan BadaiNoch keine Bewertungen

- Permanent Strand Anchor System: Main StandardsDokument7 SeitenPermanent Strand Anchor System: Main StandardsGopu RNoch keine Bewertungen

- Water production and consumption 1982-2017 in millions of gallonsDokument3 SeitenWater production and consumption 1982-2017 in millions of gallonsJinxNoch keine Bewertungen

- Water Production and Consumption 1982 To 2017Dokument3 SeitenWater Production and Consumption 1982 To 2017JinxNoch keine Bewertungen

- Operation Management Sports Obermeyer, LTDDokument3 SeitenOperation Management Sports Obermeyer, LTDSachin BalahediNoch keine Bewertungen

- Polycab LT Cables Pricelist 2017Dokument2 SeitenPolycab LT Cables Pricelist 2017Rajaa The greatNoch keine Bewertungen

- Tabla T StudenteDokument2 SeitenTabla T Studenteasesoria contableNoch keine Bewertungen

- LSCM - Sec B02 - Group 2 - Sport Obermeyer CaseDokument5 SeitenLSCM - Sec B02 - Group 2 - Sport Obermeyer CaseVikrant YadavNoch keine Bewertungen

- Coät 1: Haøng 1: Noäi Dung BaûngDokument1 SeiteCoät 1: Haøng 1: Noäi Dung BaûngMinh BáchNoch keine Bewertungen

- ResEng2 Exam-2018Dokument4 SeitenResEng2 Exam-2018Nijat AhmadovNoch keine Bewertungen

- T Test F Test TableDokument337 SeitenT Test F Test TableHải NhưNoch keine Bewertungen

- Phân Tích EFADokument5 SeitenPhân Tích EFAAn PhúcNoch keine Bewertungen

- The Division Gear Attribute SheetDokument24 SeitenThe Division Gear Attribute SheetbrunoNoch keine Bewertungen

- ME 370: Adams Lab.: 2021: Session 5Dokument5 SeitenME 370: Adams Lab.: 2021: Session 5Aadhya SinghNoch keine Bewertungen

- 1/C CU 15KV 220 NL-EPR 133% TS SIM Pull PVC MV-105Dokument2 Seiten1/C CU 15KV 220 NL-EPR 133% TS SIM Pull PVC MV-105RodNoch keine Bewertungen

- Beta Price List - PE - Pipe 15-03-21Dokument1 SeiteBeta Price List - PE - Pipe 15-03-21Jugno ShahNoch keine Bewertungen

- Formula Sheet and Stat Tables For Final Exam 2023-24Dokument3 SeitenFormula Sheet and Stat Tables For Final Exam 2023-24Xinman KongNoch keine Bewertungen

- HW2 Ans RevDokument14 SeitenHW2 Ans RevanonymoussionNoch keine Bewertungen

- DADM AssignmentDokument97 SeitenDADM AssignmentSai KiranNoch keine Bewertungen

- 551850943-Bang-Tra-cac-chuanDokument5 Seiten551850943-Bang-Tra-cac-chuanTuấn Anh TrầnNoch keine Bewertungen

- Standard Normal and Student's T Distribution TableDokument5 SeitenStandard Normal and Student's T Distribution TablePhương DungNoch keine Bewertungen

- Final Psikometri Analisis FaktorDokument4 SeitenFinal Psikometri Analisis FaktorirsyadNoch keine Bewertungen

- Table of Areas Under The Normal Curve (Updated 2023)Dokument2 SeitenTable of Areas Under The Normal Curve (Updated 2023)Anathea Gabrielle OrnopiaNoch keine Bewertungen

- 2010 Census of Population and Housing in Apayao Province, PhilippinesDokument3 Seiten2010 Census of Population and Housing in Apayao Province, PhilippinesdunscotusNoch keine Bewertungen

- T2 - T DistributionDokument1 SeiteT2 - T Distributionvirendra navadiyaNoch keine Bewertungen

- Tugas - Data Preparation and AnalysisDokument4 SeitenTugas - Data Preparation and AnalysisAndersonkevin GwenhureNoch keine Bewertungen

- Sports Obermeyer Case SolutionDokument2 SeitenSports Obermeyer Case SolutionNotThatRobinRatreNoch keine Bewertungen

- Standard Normal Distribution and Student's T-Distribution TablesDokument5 SeitenStandard Normal Distribution and Student's T-Distribution TablesNgọc NguyễnNoch keine Bewertungen

- BgtraDokument5 SeitenBgtraLộc Phạm PhướcNoch keine Bewertungen

- (RDMP) BQ Piping Smp3 170601 Iti Rev0Dokument365 Seiten(RDMP) BQ Piping Smp3 170601 Iti Rev0Fahmy FlipNoch keine Bewertungen

- Statistial TablesDokument8 SeitenStatistial TablesOshi Ahmed100% (1)

- Table T: Critical Values For The Student's T Distributions: DF DFDokument1 SeiteTable T: Critical Values For The Student's T Distributions: DF DFChristine SentillasNoch keine Bewertungen

- UntitledDokument381 SeitenUntitledDhvani PanchalNoch keine Bewertungen

- Bang Tra Xử Lý Số LiệuDokument8 SeitenBang Tra Xử Lý Số Liệuánh ngọc lê trầnNoch keine Bewertungen

- Bảng tra phân phối chuẩn hóa (Standard Normal Distribution)Dokument8 SeitenBảng tra phân phối chuẩn hóa (Standard Normal Distribution)Nguyễn TrangNoch keine Bewertungen

- Data SheetDokument2 SeitenData SheetArielNoch keine Bewertungen

- EFA analysis reveals factors of Vietnamese documentDokument4 SeitenEFA analysis reveals factors of Vietnamese documentTrân Phạm Ngọc HuyềnNoch keine Bewertungen

- Valores de La T-Student A Niveles de Confianza (A Dos Colas)Dokument1 SeiteValores de La T-Student A Niveles de Confianza (A Dos Colas)Rolando Torres PachecoNoch keine Bewertungen

- Bảng tra phân phối chuẩn hóa (Standard Normal Distribution)Dokument8 SeitenBảng tra phân phối chuẩn hóa (Standard Normal Distribution)Hiếu ÂnNoch keine Bewertungen

- Bảng tra phân phối chuẩn hóa (Standard Normal Distribution)Dokument8 SeitenBảng tra phân phối chuẩn hóa (Standard Normal Distribution)Hiếu ÂnNoch keine Bewertungen

- Bảng tra phân phối chuẩn hóa (Standard Normal Distribution)Dokument8 SeitenBảng tra phân phối chuẩn hóa (Standard Normal Distribution)Hiếu ÂnNoch keine Bewertungen

- Bảng tra phân phối chuẩn hóa (Standard Normal Distribution)Dokument8 SeitenBảng tra phân phối chuẩn hóa (Standard Normal Distribution)Hiếu ÂnNoch keine Bewertungen

- Bảng tra phân phối chuẩn hóa (Standard Normal Distribution)Dokument8 SeitenBảng tra phân phối chuẩn hóa (Standard Normal Distribution)Hiếu ÂnNoch keine Bewertungen

- Bảng tra phân phối chuẩn hóa (Standard Normal Distribution)Dokument8 SeitenBảng tra phân phối chuẩn hóa (Standard Normal Distribution)Hiếu ÂnNoch keine Bewertungen

- Bảng tra phân phối chuẩn hóa (Standard Normal Distribution)Dokument8 SeitenBảng tra phân phối chuẩn hóa (Standard Normal Distribution)Hiếu ÂnNoch keine Bewertungen

- Bảng tra phân phối chuẩn hóa (Standard Normal Distribution)Dokument8 SeitenBảng tra phân phối chuẩn hóa (Standard Normal Distribution)Hiếu ÂnNoch keine Bewertungen

- Bảng tra phân phối chuẩn hóa (Standard Normal Distribution)Dokument8 SeitenBảng tra phân phối chuẩn hóa (Standard Normal Distribution)Hiếu ÂnNoch keine Bewertungen

- BUSI 740 Strategic Supply Chain Management Case 1Dokument7 SeitenBUSI 740 Strategic Supply Chain Management Case 1Vlad BelyaevNoch keine Bewertungen

- BudgetaryDokument22 SeitenBudgetaryAlexander TiopanNoch keine Bewertungen

- Bangtra Phanphoi Laplace, Student, FisherDokument6 SeitenBangtra Phanphoi Laplace, Student, Fisherkhoa nguyenNoch keine Bewertungen

- Philippines Promotional Export Rates: For International Priority ShipmentsDokument2 SeitenPhilippines Promotional Export Rates: For International Priority Shipmentsjsus22Noch keine Bewertungen

- Critical Values of The Student T DistributionDokument1 SeiteCritical Values of The Student T DistributionSyifaNoch keine Bewertungen

- Oblique Shock PropertiesDokument29 SeitenOblique Shock PropertiesJeremy GorospeNoch keine Bewertungen

- Z Purlin Spec SheetDokument2 SeitenZ Purlin Spec SheetMeeNoch keine Bewertungen

- Final KemoDokument1 SeiteFinal KemoAnnisa PutriNoch keine Bewertungen

- Landingnippleprofilechart PDFDokument1 SeiteLandingnippleprofilechart PDFabbas1368Noch keine Bewertungen

- Structural Steel Plate Dimensions and Weights ChartDokument6 SeitenStructural Steel Plate Dimensions and Weights ChartBang OchimNoch keine Bewertungen

- Listed Are Critical of For Specified Degrees (Left Column) (Column For Two-Tailed and SignificantDokument1 SeiteListed Are Critical of For Specified Degrees (Left Column) (Column For Two-Tailed and SignificantzwslpoNoch keine Bewertungen

- Case Report Group2Dokument4 SeitenCase Report Group2navneet. pgdm17cNoch keine Bewertungen

- Project ProposalDokument1 SeiteProject Proposalnavneet. pgdm17cNoch keine Bewertungen

- Durability. It's Even Voicing, Duration of Its Tone and Sweetness of Tone Throughout TheDokument4 SeitenDurability. It's Even Voicing, Duration of Its Tone and Sweetness of Tone Throughout Thenavneet. pgdm17cNoch keine Bewertungen

- How Cloud Computing Impacts SMEDokument10 SeitenHow Cloud Computing Impacts SMEnavneet. pgdm17cNoch keine Bewertungen

- Orange Book 2nd Edition 2011 AddendumDokument4 SeitenOrange Book 2nd Edition 2011 AddendumAlex JeavonsNoch keine Bewertungen

- BBA Course SyllabusDokument37 SeitenBBA Course SyllabusK18376 67381KNoch keine Bewertungen

- VWB Case StudyDokument4 SeitenVWB Case StudySamarth GargNoch keine Bewertungen

- SBR Open TuitionDokument162 SeitenSBR Open TuitionpatrikosNoch keine Bewertungen

- Etr Template ExampleDokument56 SeitenEtr Template ExampleNur Fadhlin SakinaNoch keine Bewertungen

- 264354822072023INDEL4SB22220720231808Dokument9 Seiten264354822072023INDEL4SB22220720231808tsmlaserdelhiNoch keine Bewertungen

- Organigrama Ypfb 20180208Dokument1 SeiteOrganigrama Ypfb 20180208Ana PGNoch keine Bewertungen

- Dedicated Freight Corridor in India - India Freight CorridorDokument9 SeitenDedicated Freight Corridor in India - India Freight CorridorThe United IndianNoch keine Bewertungen

- Manajemen Fungsional Pertemuan 1Dokument64 SeitenManajemen Fungsional Pertemuan 1ingridNoch keine Bewertungen

- Brand Management Assignment (Project)Dokument9 SeitenBrand Management Assignment (Project)Haider AliNoch keine Bewertungen

- Assignment On Banking & InsuranceDokument11 SeitenAssignment On Banking & InsuranceRyhanul IslamNoch keine Bewertungen

- Role-Play EditedDokument3 SeitenRole-Play EditedNingning RomarateNoch keine Bewertungen

- IGI Insurance CompanyDokument26 SeitenIGI Insurance Companymach!50% (2)

- Inedic Manual en - Innovation and Ecodesign in The Ceramic IndustryDokument163 SeitenInedic Manual en - Innovation and Ecodesign in The Ceramic Industryfrancisco33Noch keine Bewertungen

- Account Statement 12-10-2023T22 26 37Dokument1 SeiteAccount Statement 12-10-2023T22 26 37muawiyakhanaNoch keine Bewertungen

- Customer Journey MappingDokument10 SeitenCustomer Journey MappingpradieptaNoch keine Bewertungen

- Guidelines Rice Allowance 2022Dokument10 SeitenGuidelines Rice Allowance 2022Daisy JedhNoch keine Bewertungen

- Managing Human Resources, 4th Edition Chapters 1 - 17Dokument49 SeitenManaging Human Resources, 4th Edition Chapters 1 - 17Aamir Akber Ali67% (3)

- Adjudication Order in Respect of Brooks Laboratories Ltd. and Others in The Matter of IPO of Brooks Laboratories LTDDokument40 SeitenAdjudication Order in Respect of Brooks Laboratories Ltd. and Others in The Matter of IPO of Brooks Laboratories LTDShyam SunderNoch keine Bewertungen

- NETELLER UserGuide EnglishDokument94 SeitenNETELLER UserGuide EnglishAnindita AndriatiNoch keine Bewertungen

- Unit 3 Assignment: A Simple BudgetDokument5 SeitenUnit 3 Assignment: A Simple BudgetNguyên KhánhNoch keine Bewertungen

- Squash StickDokument56 SeitenSquash StickDanah Jane GarciaNoch keine Bewertungen

- Acct Statement - XX4279 - 19082023Dokument27 SeitenAcct Statement - XX4279 - 19082023mohitNoch keine Bewertungen

- Flexible Budgets, Direct-Cost Variances, and Management ControlDokument21 SeitenFlexible Budgets, Direct-Cost Variances, and Management Control2mrbunbunsNoch keine Bewertungen

- DHL TaiwanDokument25 SeitenDHL TaiwanPhương VõNoch keine Bewertungen

- My India in 2047Dokument3 SeitenMy India in 2047Karttikeya Mangalam NemaniNoch keine Bewertungen

- Proposal Change Management AmendmentDokument21 SeitenProposal Change Management Amendmentyesuf abdulhakimNoch keine Bewertungen

- CH 4Dokument31 SeitenCH 4ferasbarakat100% (2)

- Inmon vs Kimball Data Warehouse ApproachesDokument3 SeitenInmon vs Kimball Data Warehouse ApproachesDeepanshu KatariaNoch keine Bewertungen