Beruflich Dokumente

Kultur Dokumente

WPS Format For Asme Ix - Wps - Gtaw Saw

Hochgeladen von

The Welding Inspections CommunityOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

WPS Format For Asme Ix - Wps - Gtaw Saw

Hochgeladen von

The Welding Inspections CommunityCopyright:

Verfügbare Formate

The Welding Inspections Community

https://www.weldinginspections.net

contact@weldinginspections.net

Vung Tau City, SR. Viet Nam

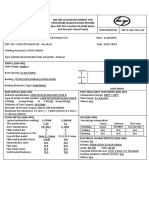

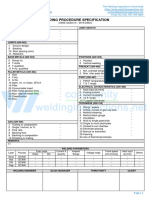

WELDING PROCEDURE SPECIFICATION

(ASME Section IX – 2019 Edition)

DESCRIPTION JOINT SKETCH

1 WPS no.

2 Date of issue

3 Applicable code

4 Welding process

JOINTS (QW-402) GTAW SAW

.1 Groove design - -

.4 Backing n/a -

.5 Backing - n/a

.10 Root spacing - -

.11 Retainers - -

BASE METALS (QW-403) POSITIONS (QW-405) GTAW SAW

.5 Group no. - - .1 Position - -

.6 T limits - .3 Vertical welding - n/a

.8 T qualified -

.9 Max. pass thick. <= 13 [mm] n/a - PREHEAT (QW-406)

.11 P-no. qualified - - .1 Min. preheat temperature - -

FILLER METALS (QW-404) .2 Preheat maint. n/a -

.3 Size [mm] - n/a .3 Max. inter-pass temperature - -

.4 F-No. - - PWHT (QW-407)

.5 A-No. - - .1 PWHT temperature - -

.6 Diameter [mm] n/a - .2 T & T range - -

.9 Flux-wire classification n/a -

.10 Alloy flux n/a - ELECTRICAL CHARACTERISTICS (QW-409)

.12 Spec. no. or Class. SFA/A - n/a .1 Heat input [kJ/mm] - -

.14 Filler - n/a .3 Pulsing current - n/a

.22 Consumable insert - n/a .4 Current & polarity - -

.23 Filler metal product form - n/a .8 I & E range - -

.24 Supplemental filler n/a - .12 Tungsten electrode - n/a

.27 Alloy elements n/a -

.29 Flux designation n/a -

.30 Max. deposit metal thick. - -

.33 Classification - - TECHNIQUE (QW-410)

.34 Flux type n/a - .1 String / weave - -

.35 Flux-wire classification n/a - .3 Orifice, nozzle or gas cup size - n/a

.36 Re-crushed slag n/a - .5 Method cleaning - -

.50 Flux - n/a .6 Method back gouge - -

.7 Oscillation - -

.8 Tube work distance n/a -

GAS (QW-408) .9 Multi to single pass/side - -

.1 Trailing or composition - n/a .10 Single to multi electrodes - -

.2 Single, mixture, or % - n/a .11 Closed to out chamber - n/a

.3 Flow rate - n/a .15 Electrode spacing - -

.5 Backing flow - n/a .25 Manual or automatic - -

.9 Backing or composition - n/a .26 Peening - -

.10 Shielding or trailing - n/a .64 Use of thermal processes - -

REMARKS

(*)

WELDING PARAMETERS

Filler metal Current & Ampere Travel speed Heat Input

Layer Process Voltage range Others

Class. Dia. polarity Range [mm/minute] [kJ/mm]

Root GTAW - - - - - - - -

Hot GTAW - - - - - - - -

Fill SAW - - - - - - - -

Cap SAW - - - - - - - -

WELDING ENGINEER QA/QC MANAGER THIRD PARTY CLIENT

Page | 1

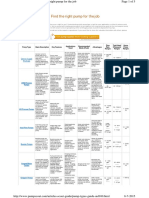

Das könnte Ihnen auch gefallen

- Define of WPS & PQRDokument16 SeitenDefine of WPS & PQRThanh Hua100% (1)

- 5FPipe to plate welding procedureDokument2 Seiten5FPipe to plate welding procedureTrudie0% (1)

- 03 WPS CS 1Dokument3 Seiten03 WPS CS 1mohammadNoch keine Bewertungen

- GMAWDokument12 SeitenGMAWsushant47Noch keine Bewertungen

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDokument9 Seiten2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanNoch keine Bewertungen

- Acceptable Grade of Plate Material (API 650)Dokument1 SeiteAcceptable Grade of Plate Material (API 650)juantamad02Noch keine Bewertungen

- Color Coding Welding Consumables to Prevent MisuseDokument3 SeitenColor Coding Welding Consumables to Prevent MisusefizanlaminNoch keine Bewertungen

- Itp GRPDokument4 SeitenItp GRPJo FrancescNoch keine Bewertungen

- WPS for FCAW Welding of SteelDokument2 SeitenWPS for FCAW Welding of SteelHamid MansouriNoch keine Bewertungen

- TDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsDokument3 SeitenTDC-10A Rev 3 Upgradation by Welding of C12A Steel CastingsGohilakrishnan ThiagarajanNoch keine Bewertungen

- Wps For Aluminium WeldingDokument8 SeitenWps For Aluminium WeldingMohammed MusaNoch keine Bewertungen

- Ferrite Content ReportDokument2 SeitenFerrite Content ReportJawad MunirNoch keine Bewertungen

- Wps Mma PipeDokument2 SeitenWps Mma PipeDimitris NikouNoch keine Bewertungen

- WPS (1) 1Dokument5 SeitenWPS (1) 1Pedro José PadillaNoch keine Bewertungen

- T.C.L. Co. - Test & Control LaboratoriesDokument2 SeitenT.C.L. Co. - Test & Control LaboratoriesA. ΒρατσισταNoch keine Bewertungen

- Welding Parameters Control PipelineDokument1 SeiteWelding Parameters Control PipelinemusheerNoch keine Bewertungen

- Report on Welding Procedure Specifications for Single V-Groove JointsDokument15 SeitenReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- Sample Wps Carbon Steel GTAW SMAW PDFDokument2 SeitenSample Wps Carbon Steel GTAW SMAW PDFirwanNoch keine Bewertungen

- WPS PQR 12 PDFDokument9 SeitenWPS PQR 12 PDFVinay YadavNoch keine Bewertungen

- WPS 316 L PDFDokument4 SeitenWPS 316 L PDFIrinaNoch keine Bewertungen

- Welding Procedure Qualification Record: Shipyard LogoDokument4 SeitenWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- Form UT, MT, PT, RTDokument5 SeitenForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDokument3 SeitenWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNoch keine Bewertungen

- Sample Forms WPS PQRDokument22 SeitenSample Forms WPS PQRGMNoch keine Bewertungen

- Course Module 4Dokument6 SeitenCourse Module 4Makise AghataNoch keine Bewertungen

- Welding Procedure Specification for Vertical Storage TanksDokument6 SeitenWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNoch keine Bewertungen

- Wps PQRDokument7 SeitenWps PQRsobariNoch keine Bewertungen

- Wps GT 9b Cvn90 Rev 1 PDFDokument6 SeitenWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNoch keine Bewertungen

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Dokument1 SeiteWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- Welding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateDokument2 SeitenWelding Procedure Specification: Wps No.: Bpscl/Shel/Wps - 05 DateAmjad PathanNoch keine Bewertungen

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Dokument4 SeitenProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabNoch keine Bewertungen

- PQR With-PwhtDokument2 SeitenPQR With-PwhtKarthikNoch keine Bewertungen

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Dokument1 SeiteQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Noch keine Bewertungen

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDokument3 SeitenWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNoch keine Bewertungen

- WPS GTAW-SMAW h1Dokument1 SeiteWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNoch keine Bewertungen

- Baosteel hot rolled steel plate quality certificateDokument3 SeitenBaosteel hot rolled steel plate quality certificateDang TranNoch keine Bewertungen

- Wps Sp14 Reva PDFDokument9 SeitenWps Sp14 Reva PDFravi00098Noch keine Bewertungen

- Sabari Engineering PQRDokument3 SeitenSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- WPS & PQR (E Co Cr-E)Dokument3 SeitenWPS & PQR (E Co Cr-E)HossamSAshourNoch keine Bewertungen

- SAIC-W-2006 Rev 8Dokument4 SeitenSAIC-W-2006 Rev 8saravananmenmathiNoch keine Bewertungen

- TDC-10B Heat Treatment For C12A Steel CastingsDokument2 SeitenTDC-10B Heat Treatment For C12A Steel CastingsGohilakrishnan ThiagarajanNoch keine Bewertungen

- Welding Checklist For Field WeldingDokument1 SeiteWelding Checklist For Field Weldingnapster386Noch keine Bewertungen

- Welding Report For Tank 1Dokument1 SeiteWelding Report For Tank 1Rifki HasyaNoch keine Bewertungen

- API Welding Procedure Specification PDFDokument3 SeitenAPI Welding Procedure Specification PDFBob LeeNoch keine Bewertungen

- WPQ Form English US1Dokument2 SeitenWPQ Form English US1Maria Louis ArputharajNoch keine Bewertungen

- Agoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Dokument3 SeitenAgoco Welding Procedure Specification: Gtaw/Smaw Manual JOINTS (QW-402)Anonymous 7vljJzH100% (1)

- 1662 15Dokument117 Seiten1662 15RajamanikkamNoch keine Bewertungen

- Procedure for Flame Straightening Structural SteelDokument3 SeitenProcedure for Flame Straightening Structural SteelAvishek Gupta100% (1)

- WPQDokument10 SeitenWPQayoki100% (3)

- ASTM A453 Grade 660 Stud - Bolt.nut - WasherDokument1 SeiteASTM A453 Grade 660 Stud - Bolt.nut - WasherTdk DallasNoch keine Bewertungen

- QAP CondenserDokument3 SeitenQAP CondenserisaacNoch keine Bewertungen

- GTAW Welding Process ParametersDokument12 SeitenGTAW Welding Process Parametersmiteshpatel191Noch keine Bewertungen

- 385 2 Internal Gtaw+SmawDokument2 Seiten385 2 Internal Gtaw+Smawsubash1688Noch keine Bewertungen

- W-55 PLATE ID CARDDokument6 SeitenW-55 PLATE ID CARDKrishnan TnNoch keine Bewertungen

- Optimized Title for Welspun MPQT ReportDokument84 SeitenOptimized Title for Welspun MPQT ReportAlam MD SazidNoch keine Bewertungen

- PT Kuwera Karya Me: PanduDokument2 SeitenPT Kuwera Karya Me: PanduGalang Pratama PutraNoch keine Bewertungen

- Highlights On ASME Essential VariablesDokument8 SeitenHighlights On ASME Essential VariableschowhkNoch keine Bewertungen

- WPQ-1083 3G PDFDokument2 SeitenWPQ-1083 3G PDFduendex360100% (1)

- ASME IX Sample WPS GTAW SMAWDokument1 SeiteASME IX Sample WPS GTAW SMAWDeepak ShrivastavNoch keine Bewertungen

- WPS Format For ASME IX - WPS - SAWDokument1 SeiteWPS Format For ASME IX - WPS - SAWThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For ISO 15614-1 WPSDokument1 SeiteWPS Format For ISO 15614-1 WPSThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For ISO 15614-1 PQRDokument3 SeitenWPS Format For ISO 15614-1 PQRThe Welding Inspections Community100% (2)

- WPS Format For ISO 15614-1 PWPSDokument1 SeiteWPS Format For ISO 15614-1 PWPSThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For AWS D1.1 - WPS - SAWDokument1 SeiteWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For AWS D1.1 - WPS - SMAWDokument1 SeiteWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For ISO 9606-1 WelderDokument2 SeitenWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- WPS Format For AWS D1.1 - WPS - FCAWDokument1 SeiteWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For AWS D1.1 - PQR - SMAWDokument3 SeitenWPS Format For AWS D1.1 - PQR - SMAWThe Welding Inspections Community100% (3)

- WPS Format For ASME IX - WPS - SAWDokument1 SeiteWPS Format For ASME IX - WPS - SAWThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For ASME IX - WQTDokument1 SeiteWPS Format For ASME IX - WQTThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For AWS D1.1 - WelderDokument1 SeiteWPS Format For AWS D1.1 - WelderThe Welding Inspections Community100% (1)

- WPS Format For Asme Ix - Wps - Gtaw SmawDokument1 SeiteWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- WPS Format For Asme Ix - Wps - SmawDokument1 SeiteWPS Format For Asme Ix - Wps - SmawThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For Asme Ix - Wps - GtawDokument1 SeiteWPS Format For Asme Ix - Wps - GtawThe Welding Inspections Community50% (2)

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDokument1 SeiteWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For ASME IX - PQR-AllDokument3 SeitenWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDokument1 SeiteWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- WPS Format For Asme Ix - Wps - Fcaw GmawDokument1 SeiteWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNoch keine Bewertungen

- Repair Instructions - Off Vehicle: A/Trans Case AssemblyDokument94 SeitenRepair Instructions - Off Vehicle: A/Trans Case AssemblyHidromaticos RNoch keine Bewertungen

- NO. Nama Alat Keterangan Gambar Alat: 1. Actuator PneumaticDokument28 SeitenNO. Nama Alat Keterangan Gambar Alat: 1. Actuator PneumaticVeronica Nina Miyora SitumorangNoch keine Bewertungen

- Ata 52Dokument70 SeitenAta 52Geovanni Riquelme LooNoch keine Bewertungen

- Ge Frame 3 Gas Turbine Compressor Drive Application Control PackageDokument3 SeitenGe Frame 3 Gas Turbine Compressor Drive Application Control PackagehasnaNoch keine Bewertungen

- Chaoda SSBV-05102018Dokument7 SeitenChaoda SSBV-05102018Dam VoNoch keine Bewertungen

- Thermo Heat PumpDokument15 SeitenThermo Heat PumpAkshay BhadangeNoch keine Bewertungen

- 2018 COE Troubleshooting 1 - ENG PDFDokument886 Seiten2018 COE Troubleshooting 1 - ENG PDFThanh Hoang67% (3)

- API LIcenseDokument9 SeitenAPI LIcenseNadeem AnsariNoch keine Bewertungen

- Pump Types Guide - Find The Right Pump FoDokument5 SeitenPump Types Guide - Find The Right Pump FoROHIT CHOUDHURYNoch keine Bewertungen

- Experiment: Major Loss in Pipe: ObjectiveDokument14 SeitenExperiment: Major Loss in Pipe: Objectivetesfa negaNoch keine Bewertungen

- JT Assembly English A4Dokument2 SeitenJT Assembly English A4kutikuppalaNoch keine Bewertungen

- A General Review of The Causes and Acceptance of Shape ImperfectionsDokument7 SeitenA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekNoch keine Bewertungen

- 6 Rolled BeamsDokument3 Seiten6 Rolled BeamsBCXC LLAMNoch keine Bewertungen

- Engg MechanicsDokument284 SeitenEngg Mechanicsmukesh_mlbNoch keine Bewertungen

- Department of Fluid Mechanics: Delhi Technological UniversityDokument10 SeitenDepartment of Fluid Mechanics: Delhi Technological University2K20-ME-161 Mridul AnandNoch keine Bewertungen

- Process Engineering Manual 005 IIDokument29 SeitenProcess Engineering Manual 005 IIzoeNoch keine Bewertungen

- Winmena - TRRDokument6 SeitenWinmena - TRRFAIYAZ AHMEDNoch keine Bewertungen

- Robotics With: ROS WorkshopDokument30 SeitenRobotics With: ROS WorkshopViba R UdupaNoch keine Bewertungen

- 10speed EatonDokument2 Seiten10speed EatonChristopherNoch keine Bewertungen

- Annexure - A Process Flow Diagram (ECOTEX)Dokument2 SeitenAnnexure - A Process Flow Diagram (ECOTEX)Dipjyoti SenNoch keine Bewertungen

- Pegasus EX 3200-5200 Parts ListDokument120 SeitenPegasus EX 3200-5200 Parts ListJanos KornfeldNoch keine Bewertungen

- Operating Instructions: Gas Engine 12 V 4000 Lx2 XX 16 V 4000 Lx2 XXDokument183 SeitenOperating Instructions: Gas Engine 12 V 4000 Lx2 XX 16 V 4000 Lx2 XXforuzzNoch keine Bewertungen

- Turbocharging and Supercharging ExplainedDokument51 SeitenTurbocharging and Supercharging ExplainedYoseph MershaNoch keine Bewertungen

- A Report On Structural Analysis and Design On Residental BuildingDokument82 SeitenA Report On Structural Analysis and Design On Residental BuildingCharchitNoch keine Bewertungen

- Sumitomo HSMDokument68 SeitenSumitomo HSMEdisson Yanqui VivancoNoch keine Bewertungen

- Kershaw 12-12BridgeCraneDokument3 SeitenKershaw 12-12BridgeCranecamelia_pirjan5776Noch keine Bewertungen

- Cosfb - Composite Slim-Floor Beam: Experimental Test Campaign and EvaluationDokument15 SeitenCosfb - Composite Slim-Floor Beam: Experimental Test Campaign and EvaluationDima OvsiiNoch keine Bewertungen

- Swimming Pool Calculation: To Calculate Pipe SizingDokument2 SeitenSwimming Pool Calculation: To Calculate Pipe SizingBenjamin YusuphNoch keine Bewertungen

- Vibratoin Severity - ISO 2372Dokument1 SeiteVibratoin Severity - ISO 2372HARSHANoch keine Bewertungen

- Vertical Mills V2 0Dokument56 SeitenVertical Mills V2 0recai100% (1)