Beruflich Dokumente

Kultur Dokumente

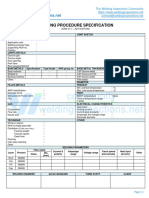

WPS Format For ISO 15614-1 WPS

Hochgeladen von

The Welding Inspections Community0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

215 Ansichten1 SeiteWelding procedure specification format

ASME IX, AWS D1.1, BS EN ISO 15614-1

Read more: http://bit.ly/31v9NSh

Originaltitel

WPS format for ISO 15614-1 WPS

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenWelding procedure specification format

ASME IX, AWS D1.1, BS EN ISO 15614-1

Read more: http://bit.ly/31v9NSh

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

215 Ansichten1 SeiteWPS Format For ISO 15614-1 WPS

Hochgeladen von

The Welding Inspections CommunityWelding procedure specification format

ASME IX, AWS D1.1, BS EN ISO 15614-1

Read more: http://bit.ly/31v9NSh

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

The Welding Inspection Community

https://www.weldinginspections.net

contact@weldinginspections.net

WELDING PROCEDURE SPECIFICATION

WPS number Qualified to

Date Company Name

Supporting WPQR (s)

References documents

MATERIAL / JOINTS QUALIFIED WELD/TEST CONDITIONS

Joint type

Parent metal(s)

Notes

TEST PIECE MATERIAL SPECIFICATION MATERIAL SIZE QUALIFIED Min. Max.

Type Material thickness fillet (mm) - -

Welded to Material thickness butt (mm) - -

Backing Outside diameter (mm) - -

Other Throat thickness (mm) - -

WELDING PROCESS

Welding process

Process 1 Process 2

Type

FILLER METALS

Manufacturer / trade name -

-

Designation type -

-

Designation -

-

Size (mm) -

-

Deposited thickness (mm) -

POSITION

Position of groove All

PREHEAT

Min. preheat temperature (ºC) -

Max. interpass temperature (ºC) -

GAS

Shielding gas / type - -

Flow rate (l/min.) - -

Composition - -

Backing gas / type - -

Flow rate (l/min.) - -

Composition - -

ELECTRICAL (root) (hot) (fill) (cap)

Filler size (mm)

Amperages

Voltages

Travel speed (mm/min.)

Heat input (kJ/mm)

Tungsten size /type (mm)

Current & polarity

DC pulsing current

TECHNIQUE

String or weave

Maximum width of run (mm)

Orifice / gas cup size (mm)

Multi or Single pass per side

Closed or out-of-chamber

Surface preparation

Initial or inter-pass cleaning

Back gouging method

WELDING ENGINEER QA/QC MANAGER THIRD PARTY CLIENT

1/1

Das könnte Ihnen auch gefallen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- WPS Format For ISO 15614-1 PQRDokument3 SeitenWPS Format For ISO 15614-1 PQRThe Welding Inspections Community100% (2)

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Dokument2 SeitenASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Welding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)Dokument2 SeitenWelding Procedure Specification (WPS) : (Applicable Code/Standard: ISO 15614-2 Edition 2005)saioman100% (7)

- WPS Format For ISO 9606-1 WelderDokument2 SeitenWPS Format For ISO 9606-1 WelderThe Welding Inspections Community100% (1)

- WPQR Welding Procedure Qualification RecordsDokument3 SeitenWPQR Welding Procedure Qualification Recordsramesh rajaNoch keine Bewertungen

- WPS Format For ISO 15614-1 PWPSDokument1 SeiteWPS Format For ISO 15614-1 PWPSThe Welding Inspections CommunityNoch keine Bewertungen

- WPS & PQR - 2021Dokument82 SeitenWPS & PQR - 2021Subramanian RNoch keine Bewertungen

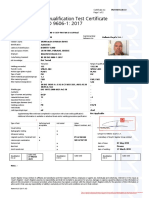

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDokument3 SeitenWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNoch keine Bewertungen

- WPQ Process As Per ISO-9606-1 2013Dokument4 SeitenWPQ Process As Per ISO-9606-1 2013Md Anamul Hoque0% (1)

- Gmaw Complete Aws d1.6Dokument1 SeiteGmaw Complete Aws d1.6Hamza Nouman100% (1)

- Weld Checklist PQRDokument2 SeitenWeld Checklist PQRScott Trainor100% (1)

- Iso 15614-13Dokument24 SeitenIso 15614-13Marija IvanovskaNoch keine Bewertungen

- Fcaw 16 THKDokument5 SeitenFcaw 16 THKparesh2387Noch keine Bewertungen

- Welding procedure specification guideDokument3 SeitenWelding procedure specification guideAnilNoch keine Bewertungen

- Sfa 5.22 PDFDokument36 SeitenSfa 5.22 PDFLuis Evangelista Moura PachecoNoch keine Bewertungen

- Welding Procedure Qualification Certificate EN ISO 15614-1: 2017Dokument3 SeitenWelding Procedure Qualification Certificate EN ISO 15614-1: 2017dcsamaraweera100% (1)

- MIG Welding PWPSDokument1 SeiteMIG Welding PWPSelectronicmail2ughf6525Noch keine Bewertungen

- Hardness Test Report: Test Details Machine DetailsDokument1 SeiteHardness Test Report: Test Details Machine DetailsESHWAR CHARYNoch keine Bewertungen

- Welder Visual Inspection ReportsDokument24 SeitenWelder Visual Inspection ReportsKyNoch keine Bewertungen

- Aws d1.1 WPS, PQR & WQTDokument4 SeitenAws d1.1 WPS, PQR & WQTWeld Bro SandeepNoch keine Bewertungen

- WPS Creation Sample ISODokument1 SeiteWPS Creation Sample ISOmusheerNoch keine Bewertungen

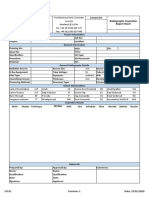

- Radiographic Inspection Report SheetDokument1 SeiteRadiographic Inspection Report SheetMike BoyesNoch keine Bewertungen

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDokument6 SeitenWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNoch keine Bewertungen

- Wps PQR Aws d11 FormDokument2 SeitenWps PQR Aws d11 Formflakosisas100% (1)

- WPS 136 FWDokument1 SeiteWPS 136 FWsocaugusto100% (1)

- Sample - Welding ManualDokument42 SeitenSample - Welding ManualAmit shah100% (3)

- Reports - QAQC - R0Dokument10 SeitenReports - QAQC - R0talupurumNoch keine Bewertungen

- Welder Qualification CertificateDokument2 SeitenWelder Qualification CertificatevitharvanNoch keine Bewertungen

- BPV IX-16-3 QW-283 - ButteringDokument1 SeiteBPV IX-16-3 QW-283 - ButteringyutweldingNoch keine Bewertungen

- Ilcs-Smaw-D1.3-Deck (G) WPSDokument3 SeitenIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Dokument3 SeitenWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNoch keine Bewertungen

- Welder Qualification Certificate SEODokument2 SeitenWelder Qualification Certificate SEORahulNoch keine Bewertungen

- PQR & WPQ Standard Testing Parameter WorksheetDokument4 SeitenPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNoch keine Bewertungen

- P-WPS 135 - MAG (GR 316)Dokument9 SeitenP-WPS 135 - MAG (GR 316)Tarun PatelNoch keine Bewertungen

- Tecnical Review ChecklistDokument6 SeitenTecnical Review ChecklistShaun Holder100% (1)

- A Comparison of ISO 15614 Part 1 and ASME IXDokument3 SeitenA Comparison of ISO 15614 Part 1 and ASME IXsusanwebNoch keine Bewertungen

- P1 To P8Dokument9 SeitenP1 To P8Pat AuffretNoch keine Bewertungen

- WPQR - Form As Per EN PDFDokument3 SeitenWPQR - Form As Per EN PDFAnilNoch keine Bewertungen

- P91 Profile WpsDokument6 SeitenP91 Profile WpsManzar KhanNoch keine Bewertungen

- ASME IX QW (Welding General Requirements)Dokument12 SeitenASME IX QW (Welding General Requirements)Ariq Fauzan100% (1)

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDokument3 SeitenWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENoch keine Bewertungen

- DIN en 462-1 Image Quality of Radiographs (Wire Type)Dokument10 SeitenDIN en 462-1 Image Quality of Radiographs (Wire Type)QA QC100% (2)

- Brazing Procedure Specification (BPS) : (Automatic, Manual, Machine, or Semi-Automatic)Dokument3 SeitenBrazing Procedure Specification (BPS) : (Automatic, Manual, Machine, or Semi-Automatic)Joyce GordonioNoch keine Bewertungen

- Ami-003 WPSDokument2 SeitenAmi-003 WPSBenjamin BrownNoch keine Bewertungen

- Fit Up ReportDokument5 SeitenFit Up ReportAkash Singh Tomar100% (1)

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Dokument2 SeitenWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- Welder Qualification Test Certificate BS EN ISO 9606-1: 2017Dokument2 SeitenWelder Qualification Test Certificate BS EN ISO 9606-1: 2017idthdrayahbdnhauniNoch keine Bewertungen

- Application DIN 2303Dokument8 SeitenApplication DIN 2303Marcelle Poll100% (1)

- Welder Qualification CertificateDokument2 SeitenWelder Qualification CertificateLuttpi100% (1)

- List of Qualified WeldersDokument3 SeitenList of Qualified WeldersdavNoch keine Bewertungen

- Survey Welding-Standards 03-11-2011Dokument0 SeitenSurvey Welding-Standards 03-11-2011Florin SoicuNoch keine Bewertungen

- MEI - Aluminium MIG WeldDokument56 SeitenMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- Long Seam Inspection ProcedureDokument4 SeitenLong Seam Inspection ProcedureDeepak100% (1)

- ALuminium MIG Welding of All Series With Filler MetalsDokument37 SeitenALuminium MIG Welding of All Series With Filler MetalsSuresh G KumarNoch keine Bewertungen

- Fermi Lab Orbital Welding ProcedureDokument2 SeitenFermi Lab Orbital Welding ProcedurePramod Athiyarathu100% (1)

- Astm A 384Dokument2 SeitenAstm A 384Shandy HaykalzNoch keine Bewertungen

- Awsd1 191019041556 PDFDokument1 SeiteAwsd1 191019041556 PDFBiswasNoch keine Bewertungen

- WPS Format For AWS D1.1 - WPS - SMAWDokument1 SeiteWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNoch keine Bewertungen

- Coal Handling Abcdpdf PDF To ExcelDokument4 SeitenCoal Handling Abcdpdf PDF To ExcelSHANTANU PATHAKNoch keine Bewertungen

- WPS Format For ISO 15614-1 PWPSDokument1 SeiteWPS Format For ISO 15614-1 PWPSThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For AWS D1.1 - WPS - FCAWDokument1 SeiteWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For AWS D1.1 - PQR - SMAWDokument3 SeitenWPS Format For AWS D1.1 - PQR - SMAWThe Welding Inspections Community100% (3)

- WPS Format For AWS D1.1 - WPS - SMAWDokument1 SeiteWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For ASME IX - WQTDokument1 SeiteWPS Format For ASME IX - WQTThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For AWS D1.1 - WPS - SAWDokument1 SeiteWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For AWS D1.1 - WelderDokument1 SeiteWPS Format For AWS D1.1 - WelderThe Welding Inspections Community100% (1)

- WPS Format For Asme Ix - Wps - SmawDokument1 SeiteWPS Format For Asme Ix - Wps - SmawThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For Asme Ix - Wps - GtawDokument1 SeiteWPS Format For Asme Ix - Wps - GtawThe Welding Inspections Community50% (2)

- WPS Format For ASME IX - WPS - SAWDokument1 SeiteWPS Format For ASME IX - WPS - SAWThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For Asme Ix - Wps - Gtaw SmawDokument1 SeiteWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- WPS Format For Asme Ix - Wps - Gtaw SawDokument1 SeiteWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDokument1 SeiteWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- WPS Format For Asme Ix - Wps - Gtaw Fcaw GmawDokument1 SeiteWPS Format For Asme Ix - Wps - Gtaw Fcaw GmawThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For Asme Ix - Wps - Fcaw GmawDokument1 SeiteWPS Format For Asme Ix - Wps - Fcaw GmawThe Welding Inspections CommunityNoch keine Bewertungen

- WPS Format For ASME IX - PQR-AllDokument3 SeitenWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Antimony Deposit Types & Origins: The Composite Gold-Antimony Vein Deposit at Kharma (Bolivia)Dokument2 SeitenAntimony Deposit Types & Origins: The Composite Gold-Antimony Vein Deposit at Kharma (Bolivia)Milton ObandoNoch keine Bewertungen

- SafetyDataSheet (SDS) 31 Liquid en 03122020Dokument14 SeitenSafetyDataSheet (SDS) 31 Liquid en 03122020Harry VandermeerNoch keine Bewertungen

- DeLonghi Instruction Manual ECP3220 - 3420 - 3630Dokument7 SeitenDeLonghi Instruction Manual ECP3220 - 3420 - 3630ureehwsenqNoch keine Bewertungen

- ASME B31.3 Process Piping Code GuideDokument7 SeitenASME B31.3 Process Piping Code Guideshreyash bhadirkeNoch keine Bewertungen

- Tds 071 Rev 05 Residhere Am 140 SDokument1 SeiteTds 071 Rev 05 Residhere Am 140 Sاحمد عدنانNoch keine Bewertungen

- How Do Water Softeners WorkDokument3 SeitenHow Do Water Softeners Worknermeen ahmedNoch keine Bewertungen

- Gems Psi Paper 2004Dokument14 SeitenGems Psi Paper 2004biophr34kNoch keine Bewertungen

- Week 2 - Preparing Raw Materials For Salting and CuringDokument36 SeitenWeek 2 - Preparing Raw Materials For Salting and CuringLovely JavierNoch keine Bewertungen

- 13 - Chapter 3Dokument32 Seiten13 - Chapter 3Wahab Al-QaisiNoch keine Bewertungen

- Bosch GST 75 E ProfessionalDokument167 SeitenBosch GST 75 E ProfessionalAdriana AlvesNoch keine Bewertungen

- Storage ProteinDokument3 SeitenStorage ProteinprincessicyjulietNoch keine Bewertungen

- 6+7fertilisation Low Cost DripDokument21 Seiten6+7fertilisation Low Cost DripArnab MondalNoch keine Bewertungen

- Iffco ProjectDokument113 SeitenIffco ProjectShefali ShuklaNoch keine Bewertungen

- Gen Chem 2 DAILY LESSON LOGDokument8 SeitenGen Chem 2 DAILY LESSON LOGMaricriz Bioco100% (1)

- BIOTERGEPAS8SDokument2 SeitenBIOTERGEPAS8SJefferson Ravello RiverosNoch keine Bewertungen

- Pressure Gauges With Syphon PDFDokument2 SeitenPressure Gauges With Syphon PDFhussamengNoch keine Bewertungen

- Msds FFFP 3% UlDokument4 SeitenMsds FFFP 3% UlOtto JamesNoch keine Bewertungen

- Soundsafe Safety Data Sheet EnglishDokument5 SeitenSoundsafe Safety Data Sheet Englishard127Noch keine Bewertungen

- The Concrete Producer Article PDF - Comparing The Options For Cooling ConcreteDokument4 SeitenThe Concrete Producer Article PDF - Comparing The Options For Cooling Concretearangar1100% (1)

- Guida Step-By-Step SR Nexco Gingiva SolutionDokument38 SeitenGuida Step-By-Step SR Nexco Gingiva SolutionCostin SilviuNoch keine Bewertungen

- Essential Guide to Compressed Air SystemsDokument35 SeitenEssential Guide to Compressed Air SystemsvmramakrishnanNoch keine Bewertungen

- PLANS SCOUTCHEL: 100 Euros: Available PartsDokument2 SeitenPLANS SCOUTCHEL: 100 Euros: Available PartsIdris IbrahimNoch keine Bewertungen

- Flash Point StandardsDokument177 SeitenFlash Point Standardsgreat_triskelionNoch keine Bewertungen

- Equations of StateDokument33 SeitenEquations of StateDevika BharathanNoch keine Bewertungen

- What Is WeldingDokument4 SeitenWhat Is WeldingAnonymous hBBam1nNoch keine Bewertungen

- Ladder Inspection Form: Company Name: Ladder Reference Number: Inspector Dept. DateDokument2 SeitenLadder Inspection Form: Company Name: Ladder Reference Number: Inspector Dept. DatesantoshjayantiNoch keine Bewertungen

- MiniProject Stage 3 - Process Dynamic & ControlDokument8 SeitenMiniProject Stage 3 - Process Dynamic & ControlFarihah Eyfa100% (2)

- MSDS ScaleChem SI-7022Dokument5 SeitenMSDS ScaleChem SI-7022Muaz Haziq MusaNoch keine Bewertungen

- 72 Had DadDokument6 Seiten72 Had DadthestupiddogNoch keine Bewertungen

- Astm A681 PDFDokument14 SeitenAstm A681 PDFraulNoch keine Bewertungen