Beruflich Dokumente

Kultur Dokumente

VFD Fault Detection

Hochgeladen von

Emmanuel S SombilonCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

VFD Fault Detection

Hochgeladen von

Emmanuel S SombilonCopyright:

Verfügbare Formate

Downloaded at Reliabilityweb.com on the web at http://www.reliabilityweb.

com

VFD FAULT DETECTION

USING MCEMAX

As motor drives become more important in industry, the need to analyze faults associated with them

increases. PdMA’s MCEMAX is a great tool for analyzing faults in Variable Frequency Drives (VFDs).

Although modern technology has seen great improvement in the reliability of drives, naturally occurring

events will cause faults in a drive, especially if they were originally installed in an inappropriate

application. The primary focus of this article is on Pulse Width Modulated (PWM) drives without fault

mode operating capabilities. Although these drives do not employ fault mode operation capability, in some

cases, they will keep running even with a fault. This article will show that through the use of the MCEMAX

technology, faults in these drives are detectable with a very high level of confidence.

FAULT DETECTION

As with other predictive maintenance technologies, trending is the best method of fault detection. Trending

methodology also applies to fault detection in VFDs. By trending data over a period of time, a technician is

better able to detect developing problems in motors or power systems. Occasionally, faults occur that did

not exhibit any trends before the occurrence, these types of failures are considered random in nature. This

article covers faults that have occurred, yet, the drive continues to operate in a mode that appears normal

externally.

Upstream (Line Side) Diagnosis

Upstream (Line Side) diagnosis of the VFD (not diagnosis of the motor) refers to testing on the incoming

power to the VFD as shown in Figure 1. By testing upstream of the VFD, open diodes and open phases can

be detected using the MCEMAX. Upstream diagnosis is only useful for diagnosing the VFD, do not

perform overall motor diagnostics upstream of the VFD.

Line Variable Frequency Drive (VFD) Load

Side Side

Power

System Motor

MCEMAX

Voltage Probes

MCEMAX

MCEMAX

Current Probes

Figure 1

VFD Fault Detection Using MCEMAX PdMA Corporation 1

Downloaded at Reliabilityweb.com on the web at http://www.reliabilityweb.com

Open diode

Using the MCEMAX technology, a technician is able to reliably detect an open diode fault (Figure 2) using

the results from a MCEMAX Power Test.

Open

Diode

Line Load

Side Side

Front End DC Back End

Rectifier BUS Output Section

Section

Figure 2

Table 1

Non-Faulted Faulted The phase current (Current RMS) of the

Current 1 (RMS) 0.54 0.74 phase with the open diode will decrease

Current 2 (RMS) 0.54 0.29 approximately 50% on the affected

Current 3 (RMS) 0.50 0.70 phase, and increase slightly on the other

two phases (Table 1).

Table 2

Non- Percent (%) Current Imbalance will

Faulted increase to approximately 50% on the

Faulted

% Current Imbalance 4.79 % 49.32 % affected phase (Table 2).

Table 3

Non- Current THD will decrease by

Faulted approximately 50% on the affected

Faulted

Current 1 (THD) 151.56 169.94 phase, and increase slightly on the other

Current 2 (THD) 148.84 79.19 two phases (Table 3).

Current 3 (THD) 154.02 168.61

Table 4

Non-Faulted Faulted kW will decrease by approximately 50%

Phase 1 kW 0.06 0.09 on the affected phase, and increase on

Phase 2 kW 0.06 0.03 the remaining phases (Table 4).

Phase 3 kW 0.06 0.08

VFD Fault Detection Using MCEMAX PdMA Corporation 2

Downloaded at Reliabilityweb.com on the web at http://www.reliabilityweb.com

Table 5

Non-Faulted Faulted kVAR will decrease by approximately

Phase 1 kVAR 0.11 0.16 20% on the affected phase, and increase

Phase 2 kVAR 0.11 0.09 by approximately 40% on the remaining

Phase 3 kVAR 0.11 0.15 phases (Table 5).

Table 6

Non-Faulted Faulted kVA will decrease by approximately

Phase 1 kVA 0.13 0.19 20% on the affected phase, and increase

Phase 2 kVA 0.13 0.10 by approx 40% on the remaining phases

Phase 3 kVA 0.12 0.17 (Table 6).

Of these methods, the best method of detection is the RMS current decrease of approximately 50% and the

% Current Imbalance increase to 50%, which is detectable for all frequencies from 15 Hz to 60 Hz and

loads from 0% Load (no-load) to 100% Load. The next best detection method is the current Total

Harmonic Distortion (THD) decrease of approximately 50%.

After detecting a possible fault in the drive, you should try to verify the fault is in the drive, and not a

measurement error. To do this, switch the test leads of the MCEMAX between two of the phases, and

perform the power test again. If you receive the same results, except on a different phase, the fault is most

likely in the drive.

Shorted diode

A shorted diode trips the drive on occurrence, therefore, there are no detection procedures for this type of

fault.

Open phase

An open phase occurs when a connection has come loose either at the component level or externally to the

drive (Figure 3).

Open

Phase

Line Load

Side Side

Front End DC Back End

Rectifier BUS Output Section

Section

Figure 3

VFD Fault Detection Using MCEMAX PdMA Corporation 3

Downloaded at Reliabilityweb.com on the web at http://www.reliabilityweb.com

A technician can detect an open phase by the following:

Table 7

Non-Faulted Faulted RMS current on the faulted phase will

Current 1 (RMS) 0.53 0.00 decrease to 0.00 Amps and increase on

Current 2 (RMS) 0.52 0.99 the other two phases by approximately

Current 3 (RMS) 0.50 0.98 90% (Table 7).

Table 8

Non- % Current Imbalance increases to

Faulted approximately 100% (Table 8).

Faulted

% Current Imbalance 3.57 % 99.62 %

Table 9

Non-Faulted Faulted Current Crest Factor (CF) on the faulted

Current 1 CF 3.51 15.41 phase increases to approximately 15%

Current 2 CF 3.37 4.31 and there is a slight increase on the other

Current 3 CF 3.66 4.31 phases (Table 9).

Table 10

Non-Faulted Faulted kW decreases to 0.00 on the faulted

Phase 1 kW 0.06 0.00 phase and increases by approximately

Phase 2 kW 0.06 0.09 50% on the other phases, but the total

Phase 3 kW 0.06 0.11 kW remains constant (Table 10).

Total kW 0.19 0.20

Table 11

Non-Faulted Faulted kVAR decreases to 0.00 on the faulted

Phase 1 kVAR 0.11 0.00 phase and increases by approximately

Phase 2 kVAR 0.11 0.26 100% on the other phases (Table 11).

Phase 3 kVAR 0.11 0.25

Total kVAR 0.32 0.51

Table 12

Non- kVA decreases to 0.00 on the faulted

Faulted phase and increases by approximately

Faulted

Phase 1 kVA 0.12 0.00 100% on the other phases (Table 12).

Phase 2 kVA 0.12 0.27

Phase 3 kVA 0.12 0.27

Total kVA 0.37 0.55

VFD Fault Detection Using MCEMAX PdMA Corporation 4

Downloaded at Reliabilityweb.com on the web at http://www.reliabilityweb.com

Downstream (Load Side) Diagnosis

Downstream fault diagnosis of the VFD refers to testing on the output side of the VFD, which is between

the VFD and the motor as shown in Figure 4. By testing downstream of the VFD, open diodes, and open

phases can be detected using the MCEMAX. Testing downstream of the VFD is not the preferred location

when performing VFD diagnostics (Line Side is the preferred location), but is the recommended test

location when performing overall motor diagnostics.

Line Variable Frequency Drive (VFD) Load

Side Side

Power

System Motor

MCEMAX

Voltage Probes MCEMAX

MCEMAX

Current Probes

Figure 4

Open diode

A technician is able to detect a faulted diode in the rectifier portion of the drive by using the MCEMAX

technology downstream of the drive. At 60 Hz, with the motor loaded to at least 50%, an open diode is

detectable by an increase in the Phase-Neutral Voltage Imbalance to approximately 15% (Table 13).

Table 13

Non-Faulted Faulted

Voltage Imbalance Ph-N 0.42 % 15.14 %

Phase out

One phase that was completely out (open connection) was reliably detectable downstream of the drive

when the drive was operating at 60 Hz (at any load) by an increase in the Voltage Imbalance to

approximately 50%. At lower speeds, a phase out fault was not reliably detectable.

Table 14

Non-Faulted Faulted

Voltage Imbalance Ph-N 1.11 % 54.73 %

AFTER A FAULT IS DETECTED

Once any of these faults are detected, although the drive may still be running, it is recommended that you

repair or replace the drive, or contact the manufacturer of the drive for their recommendations. Failure to

remedy the situation may result in excessive heat in either the drive or the motor and cause far greater

losses.

VFD Fault Detection Using MCEMAX PdMA Corporation 5

Downloaded at Reliabilityweb.com on the web at http://www.reliabilityweb.com

CONCLUSIONS

From our research, we found certain faults in drives can be reliably detected using the MCEMAX

technology (Table 13). These faults include an open diode and an open phase. Open diodes were

detectable both up and downstream of the drive. An open phase was detectable upstream of the drive at all

frequencies and loads. Furthermore, an open phase was detectable downstream if the drive was running at

full speed (typically 60 Hz), but it was not reliably detectable downstream if the drive frequency was below

60Hz. Future research will include a line and load side analysis of the back-end of a drive with back-end

and power circuit related anomalies, and other possible detection methods using the MCEMAX technology.

Table 15

Fault Detection Capabilities of the MCEMAX Technology

Component Type of Fault Detectable Detectable

Upstream Downstream

Diode Open Yes Yes *

Short No (Drive Failure) No (Drive Failure)

Phase Open Yes Yes *

Short No (Drive Failure) No (Drive Failure)

* when the motor is run at full speed (typically 60 Hz).

VFD Fault Detection Using MCEMAX PdMA Corporation 6

Downloaded at Reliabilityweb.com on the web at http://www.reliabilityweb.com

Related Sources

Bezesky, David M., Kreitzer, Scott, “NEMA Application Guide for AC Adjustable Speed Drive Systems,”

IEEE/PCIC 2001 Conference 7, 9.

Braun, D., Pixler, D., LeMay, P., “IGBT Module Rupture Categorization and Testing,” IEEE Industry

Applications Society Annual Meeting, (October 1997).

Budek, Roman. “Troubleshooting IGBT Failures,” IXYS Application Note #11 Martan, Inc., (Last Revised

8/21/02).

Houdek, John A., “Reactors Maximize Drive System Reliability,” Power Quality Assurance, (February,

2000).

Mayfield, Eddie, “Troubleshooting Variable Speed AC Motor Drives,”

http://www.maintenanceresources.com/ReferenceLibrary/ACDrives/drive.htm (January 26, 2004).

Mendes, A. M. S., and Cardoso, A. J. Marques, “Performance Analysis of Three-Phase Induction Motor

Drives Under Inverter Fault Conditions,” SDEMPED 2003, (August 2003).

Welchko, Brian A., Lipo, Thomas A., Jahns, Thomas M., and Schulz, Steven E., “Fault Tolerant Three-

Phase AC Motor Drive Topologies; A Comparison of Features, Cost, and Limitations,” IEEE-

International Electrical Machines and Drives Conference, June 1-4, 2003. IEEE Catalog Number

03EX679C, ISBN 0-7803-7818-0.

WJ Application Note, “MTBF Analysis for WJ Communications GaAs Devices,” The Communications

Edge,”

[http://www.wj.com/pdf/appnotes/MTBF%20Analysis%20for%20WJ%20Components_July%202002.

pdf ], (July 2002).

VFD Fault Detection Using MCEMAX PdMA Corporation 7

Das könnte Ihnen auch gefallen

- Variable Speed DrivesDokument546 SeitenVariable Speed DrivescysautsNoch keine Bewertungen

- 4DX Pro System Manual - EngDokument26 Seiten4DX Pro System Manual - EngAlejandro Cabrera67% (6)

- Fluke 8062a Service ManualDokument124 SeitenFluke 8062a Service Manualmuszeresz100% (1)

- Fire Triangle:: Fire Is The Combination of HEAT, FUEL & OXYGEN. Fire Is The Chemical Reaction of Heat, Fuel & OxygenDokument3 SeitenFire Triangle:: Fire Is The Combination of HEAT, FUEL & OXYGEN. Fire Is The Chemical Reaction of Heat, Fuel & OxygenMohammad Jahid AlamNoch keine Bewertungen

- 02 PDFDokument17 Seiten02 PDFSerban LucianNoch keine Bewertungen

- BA BT300 DLT1201 13 aEN 009Dokument188 SeitenBA BT300 DLT1201 13 aEN 009Teddy HariyantoNoch keine Bewertungen

- Research To Study Variable Frequency Drive and Its Energy SavingsDokument4 SeitenResearch To Study Variable Frequency Drive and Its Energy SavingsIjsrnet EditorialNoch keine Bewertungen

- Techrite Siemens Siemens Lme Series Burner Controls 013060320901Dokument28 SeitenTechrite Siemens Siemens Lme Series Burner Controls 013060320901Kang KamalNoch keine Bewertungen

- PID Tuning TutorDokument4 SeitenPID Tuning TutorKiran KulkarniNoch keine Bewertungen

- Performance Analysis of Stand-Alone PV System Using Single Voltage Sensor Based MPPT MethodDokument7 SeitenPerformance Analysis of Stand-Alone PV System Using Single Voltage Sensor Based MPPT MethodIJRASETPublicationsNoch keine Bewertungen

- MEM 341 - Chapter 13 Pneumati CircuitDokument14 SeitenMEM 341 - Chapter 13 Pneumati CircuitMuhammad AbdullahNoch keine Bewertungen

- FL Sim p4-6Dokument369 SeitenFL Sim p4-6pauloghunterNoch keine Bewertungen

- Boiler Level PID ControlDokument6 SeitenBoiler Level PID ControlRio EstikaNoch keine Bewertungen

- Design of Solar Water Pumping System With FCMA Soft StarterDokument4 SeitenDesign of Solar Water Pumping System With FCMA Soft StarterRiad TifaNoch keine Bewertungen

- 1 s2.0 S0038092X17303377 MainDokument15 Seiten1 s2.0 S0038092X17303377 MainCaroline TedescoNoch keine Bewertungen

- EE6511-Control and Instrumentation Laboratory - 2013 - RegulationDokument98 SeitenEE6511-Control and Instrumentation Laboratory - 2013 - Regulationmokshagna saitejaNoch keine Bewertungen

- Quemadores Modulares Ficha Tecnica RS - M - TS0015UK02Dokument36 SeitenQuemadores Modulares Ficha Tecnica RS - M - TS0015UK02maikolNoch keine Bewertungen

- OP AMP NotesDokument31 SeitenOP AMP NotesEbonguko ClintonNoch keine Bewertungen

- Project Report of Laser Security Alarm SystemDokument25 SeitenProject Report of Laser Security Alarm SystemB LIKHITH KUMARNoch keine Bewertungen

- Ness D8xD16x Installer ManualDokument88 SeitenNess D8xD16x Installer ManualMarkAshNoch keine Bewertungen

- 96 - 31 Combustion BenchmarkDokument42 Seiten96 - 31 Combustion BenchmarkKECS_kckNoch keine Bewertungen

- Assignment Report1Dokument20 SeitenAssignment Report1Keshav GopaulNoch keine Bewertungen

- Photovoltaic System 1Dokument62 SeitenPhotovoltaic System 1Ankit SinghNoch keine Bewertungen

- Cbus Training Manual V2-3-0Dokument149 SeitenCbus Training Manual V2-3-0Darwin BernardoNoch keine Bewertungen

- MiniatureCircuitBreakers Primer EN 201601250852395217 PDFDokument60 SeitenMiniatureCircuitBreakers Primer EN 201601250852395217 PDF3238NDNoch keine Bewertungen

- Riello Rs 44 Technical ManualDokument60 SeitenRiello Rs 44 Technical Manualferagur11Noch keine Bewertungen

- Microcontrollers Notes For IV Sem ECE StudentsDokument19 SeitenMicrocontrollers Notes For IV Sem ECE StudentsVigneshwar DhamodharanNoch keine Bewertungen

- Building Technologies: HVAC ProductsDokument28 SeitenBuilding Technologies: HVAC ProductsDavid'Sh VeraNoch keine Bewertungen

- Design of Solar Panel As Wind Turbine BladesDokument12 SeitenDesign of Solar Panel As Wind Turbine BladesIJRASETPublicationsNoch keine Bewertungen

- Sun Tracking System For Productivity Enhancement o PDFDokument9 SeitenSun Tracking System For Productivity Enhancement o PDFRameswaran BalasubramaniamNoch keine Bewertungen

- Sem2 Mechatronics LabsheetDokument18 SeitenSem2 Mechatronics LabsheetengrodeNoch keine Bewertungen

- PID ControlDokument32 SeitenPID Controlanurag_pai_1Noch keine Bewertungen

- Boiler-Tuning Basics, Part II PDFDokument12 SeitenBoiler-Tuning Basics, Part II PDFIain NeillNoch keine Bewertungen

- Single-Phase Power Transformers - Course Sample - 579439-591956 PDFDokument43 SeitenSingle-Phase Power Transformers - Course Sample - 579439-591956 PDFjhonxd05Noch keine Bewertungen

- Principles of CombustionDokument14 SeitenPrinciples of CombustionJesus Garcia100% (1)

- CorrigéDokument7 SeitenCorrigéIbrahima GueyeNoch keine Bewertungen

- 06 Programmable Logic Controller PracticalDokument3 Seiten06 Programmable Logic Controller PracticalAnkitNoch keine Bewertungen

- MQ135 (Ver1.4) - ManualDokument7 SeitenMQ135 (Ver1.4) - ManualPavankumar VijapurNoch keine Bewertungen

- Boiler Service ManualDokument60 SeitenBoiler Service ManualBrian JonesNoch keine Bewertungen

- Flame Detector Working Principle of The Flame DetectorDokument3 SeitenFlame Detector Working Principle of The Flame DetectorCJ Caño-JardinNoch keine Bewertungen

- University of Mauritius: (10 Mins Reading Time)Dokument3 SeitenUniversity of Mauritius: (10 Mins Reading Time)Keshav GopaulNoch keine Bewertungen

- Basic Programmable Logic Control - PLCDokument6 SeitenBasic Programmable Logic Control - PLCIzan SiroonNoch keine Bewertungen

- Variable Speed Chillers With PicvDokument1 SeiteVariable Speed Chillers With PicvPradeep SukumaranNoch keine Bewertungen

- Introduction To Operational Amplifiers: 0 in OutDokument3 SeitenIntroduction To Operational Amplifiers: 0 in Outjaya1816Noch keine Bewertungen

- Smart Metering For Low Voltage Using Arduino Due PDFDokument6 SeitenSmart Metering For Low Voltage Using Arduino Due PDFUmeshNoch keine Bewertungen

- Final Project MITMagnetic LevitationDokument5 SeitenFinal Project MITMagnetic LevitationfandinoNoch keine Bewertungen

- Intelligent Device Management Tutorial: CalibrationDokument16 SeitenIntelligent Device Management Tutorial: Calibrationtrozn2812100% (1)

- TroubleshootingDokument24 SeitenTroubleshootingAamer Khawaja100% (1)

- Bending The RulesDokument2 SeitenBending The RuleskikiuNoch keine Bewertungen

- Hollias Macs V6 Training: Hardware Introduction - KM SeriesDokument71 SeitenHollias Macs V6 Training: Hardware Introduction - KM Seriesmessam110Noch keine Bewertungen

- PLC Troubleshooting: Troubleshooting Inputs and OutputsDokument5 SeitenPLC Troubleshooting: Troubleshooting Inputs and OutputsMd Omar FaruqueNoch keine Bewertungen

- Adressable Intelligent Fire Alarm Panel ManualDokument31 SeitenAdressable Intelligent Fire Alarm Panel ManualAlai5119Noch keine Bewertungen

- Rfid Based Security System: A Project ReportDokument22 SeitenRfid Based Security System: A Project ReportHeartin HariNoch keine Bewertungen

- Industrial BoilersDokument26 SeitenIndustrial BoilersAnkit bohra0% (1)

- Colorado School of Mines CHEN403: 1 Where MinDokument12 SeitenColorado School of Mines CHEN403: 1 Where MinpoopoophoNoch keine Bewertungen

- Solve Electrical Problems With Thermal ImagingDokument4 SeitenSolve Electrical Problems With Thermal ImagingUdit AgrawalNoch keine Bewertungen

- 2009B (D09) C1 Question PaperDokument17 Seiten2009B (D09) C1 Question PaperLila LilakNoch keine Bewertungen

- VFD Fault DetectionDokument7 SeitenVFD Fault Detectionamk2009Noch keine Bewertungen

- Module IvDokument14 SeitenModule Ivbobby4u143Noch keine Bewertungen

- Power Quality and Dynamic Voltage Restorer (DVR)Dokument51 SeitenPower Quality and Dynamic Voltage Restorer (DVR)damarNoch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Measurement of FLUKE Insulation Resistance MeggerDokument22 SeitenMeasurement of FLUKE Insulation Resistance MeggerEmmanuel S SombilonNoch keine Bewertungen

- Philips MasterLED2011Dokument7 SeitenPhilips MasterLED2011Emmanuel S SombilonNoch keine Bewertungen

- VFD Installation Checklist Danfoss IndustriesDokument4 SeitenVFD Installation Checklist Danfoss IndustriesEmmanuel S SombilonNoch keine Bewertungen

- Electrical PackageDokument260 SeitenElectrical Packageazmat_86Noch keine Bewertungen

- Facts Worth Knowing About Frequency ConvertersDokument167 SeitenFacts Worth Knowing About Frequency ConvertersEduardo SuarezNoch keine Bewertungen

- Traffic Lights PLC ControlDokument9 SeitenTraffic Lights PLC ControlEmmanuel S SombilonNoch keine Bewertungen

- Digital Air - Conditioner Controller KR - 454Dokument42 SeitenDigital Air - Conditioner Controller KR - 454Emmanuel S Sombilon100% (1)

- Pcea: ": Electrical Preventive Maintenance - Spend A Little - Save A Lot"Dokument30 SeitenPcea: ": Electrical Preventive Maintenance - Spend A Little - Save A Lot"Arnulfo LavaresNoch keine Bewertungen

- DigiSpeed GX User030Dokument22 SeitenDigiSpeed GX User030Emmanuel S SombilonNoch keine Bewertungen

- Electro-Pneu Circ DiagDokument10 SeitenElectro-Pneu Circ DiagEmmanuel S SombilonNoch keine Bewertungen

- 3 Way and 4 Way SwitchesDokument2 Seiten3 Way and 4 Way SwitchesEmmanuel S SombilonNoch keine Bewertungen

- Autocad Shortcut Keys 2008Dokument4 SeitenAutocad Shortcut Keys 2008Emmanuel S SombilonNoch keine Bewertungen

- Legrand Catalogue 2012 Industrial Plugs SocketsDokument14 SeitenLegrand Catalogue 2012 Industrial Plugs SocketsLelli KurniaNoch keine Bewertungen

- Protecting Transmission Lines Terminated Into Transformers: Elmo Price and Roger Hedding, ABB IncDokument12 SeitenProtecting Transmission Lines Terminated Into Transformers: Elmo Price and Roger Hedding, ABB IncproteccionesNoch keine Bewertungen

- s200 Typical 3 Line-Sch r2 20kv SWGR Cb200a Coupler Jabar 17-2Dokument12 Seitens200 Typical 3 Line-Sch r2 20kv SWGR Cb200a Coupler Jabar 17-2Agam HutapeaNoch keine Bewertungen

- General Radio 1650-BDokument60 SeitenGeneral Radio 1650-BkrendelaNoch keine Bewertungen

- Disconnect Switches and Operating MechanismDokument28 SeitenDisconnect Switches and Operating MechanismReginald D. De GuzmanNoch keine Bewertungen

- DatasheetDokument466 SeitenDatasheetJonas Hamilton100% (1)

- Kit de Tierra Mod 200ecs-G3Dokument2 SeitenKit de Tierra Mod 200ecs-G3Carlos.MurilloNoch keine Bewertungen

- PLC AnsDokument21 SeitenPLC Ansali158hNoch keine Bewertungen

- Tram 2 PreampDokument30 SeitenTram 2 Preampdecky999100% (1)

- EFEN ChangeoverDokument2 SeitenEFEN ChangeoverSalmanNoch keine Bewertungen

- Weidmuller DRAC Series AC Receptacles Flyer LIT0915 072016v1 PDFDokument2 SeitenWeidmuller DRAC Series AC Receptacles Flyer LIT0915 072016v1 PDFeuqehtb100% (1)

- Lect 9,10 - MOSFET DC AnalysisDokument17 SeitenLect 9,10 - MOSFET DC Analysisshashikala kotiNoch keine Bewertungen

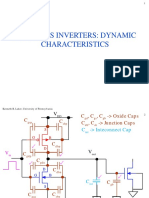

- Ee 560 Mos Inverters: Dynamic CharacteristicsDokument41 SeitenEe 560 Mos Inverters: Dynamic CharacteristicssallyNoch keine Bewertungen

- Design & Construction of A 220V Voltage StabilizerDokument48 SeitenDesign & Construction of A 220V Voltage StabilizerSboNoch keine Bewertungen

- COMMNG-ELEC-053 PMCC Charging ProcedureDokument3 SeitenCOMMNG-ELEC-053 PMCC Charging ProceduresantoshkumarNoch keine Bewertungen

- UCM224D - Technical Data SheetDokument8 SeitenUCM224D - Technical Data Sheet3efooNoch keine Bewertungen

- Easy Servo Motors: Stepper Motors With Encoders, 0.9 NM To 20 0 NMDokument13 SeitenEasy Servo Motors: Stepper Motors With Encoders, 0.9 NM To 20 0 NMKarthick MNoch keine Bewertungen

- Trouble Shooting For DT410 - UK-samlet04082017SDokument27 SeitenTrouble Shooting For DT410 - UK-samlet04082017Swirawat patthumNoch keine Bewertungen

- User's Guide: Continuity Tester Pro Model CT20Dokument1 SeiteUser's Guide: Continuity Tester Pro Model CT20Adam SonenshineNoch keine Bewertungen

- 1SBL367001R1300 Af52 30 00 13Dokument6 Seiten1SBL367001R1300 Af52 30 00 13NISHANNoch keine Bewertungen

- F24 60 en (A4) V1.2Dokument2 SeitenF24 60 en (A4) V1.2dozer_kamilNoch keine Bewertungen

- IM in ELEN-30083-ELECTRICAL MACHINES-PALUSTRE #RPPDokument62 SeitenIM in ELEN-30083-ELECTRICAL MACHINES-PALUSTRE #RPPAHSTERINoch keine Bewertungen

- How To Prepare Schedule of LoadsDokument6 SeitenHow To Prepare Schedule of LoadsFlorencio Jolongbayan0% (1)

- Item Description Required by Supplier: Data Sheets: MV / LV TransformersDokument1 SeiteItem Description Required by Supplier: Data Sheets: MV / LV TransformersessamNoch keine Bewertungen

- 3842406Dokument43 Seiten3842406veeru_virenderNoch keine Bewertungen

- Ee101 BJT 1Dokument95 SeitenEe101 BJT 1Shubham MittalNoch keine Bewertungen

- Group AssignmentDokument1 SeiteGroup AssignmentMulugetaNoch keine Bewertungen

- QBankDokument4 SeitenQBankdanang4166Noch keine Bewertungen

- ECE 765 - Module 2A - FinalDokument20 SeitenECE 765 - Module 2A - FinalNamiraNoch keine Bewertungen

- CH7 - IC Design تصميم الدارات المتكاملةDokument76 SeitenCH7 - IC Design تصميم الدارات المتكاملةOmran ShahrourNoch keine Bewertungen